Module2 New PartA

Diunggah oleh

Aswathy Cj0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

21 tayangan6 halamandrives

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Inidrives

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

21 tayangan6 halamanModule2 New PartA

Diunggah oleh

Aswathy Cjdrives

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 6

1

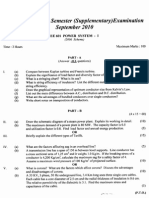

CONVERTERS IN ELECTRIC DRIVE SYSTEMS (Part A)

CONTROLLED RECTIFIER

The controlled rectifier converts AC voltage to a DC voltage in a controlled manner. In this section, we will discuss

on the control and modeling of a controlled rectifier applied in DC drive systems. The modeling of this converter is

an important step in the designing of a controller for the closed loop control system typically found in electrical

drives. We will limit our model to a continuous current mode for a single-phase rectifier (The continuous current

mode means that the output current of the converter will always be larger than zero). The modeling and control

discussed for the single-phase rectifier can be readily applied to a three-phase controlled rectifier.

In controlled rectifier, the output DC voltage is controlled by controlling the delay angles (or firing angles) of the

SCRs used in the converter. We have seen in our previous course (undergraduate course) that a relationship

between the average voltage V

a

, and the delay angle (or firing angle) of a single-phase controlled rectifier, !, is

given by:

(1)

where ! is the delay angle, V

m

is the peak input voltage and V

a

is the average output voltage. Note that this

equation is only valid for continuous current mode. It describes the average behavior of the rectifier over a period

of the output voltage. For a given delay angle, the instantaneous output voltage will contain ripple at the multiples of

the input voltage frequency (100Hz and 300Hz for a single and three phase rectifier with 50Hz supply frequency). If

the load inductance is low, this low frequency ripple will be reflected in the output current and hence the torque of

the DC motor. Low inductance can also results in a discontinuous armature current; hence it is customary to add

external inductance to the armature circuit.

In the equation (1), the relation between the delay angle and V

a

is nonlinear as depicted in Figure 1.

Figure 1 Transfer characteristic of a single phase converter with continuous current

Control technique

As part of the feedback control system in electrical drives, it is desirable that the relationship between the control

signal and the average output voltage to be linear especially when a linear controller (such as a PI controller) is

employed. As an example, Figure 2 shows a closed loop current control system for a DC motor drive employing a

single phase controlled rectifier. In DC drives (or in other type of electrical drives), it is normally necessary to control

the motor current since it is, in most of the cases, proportional to the developed motor torque. This is especially true

for a separately DC motor or a permanent magnet DC motor. The reference current (or reference torque) is

compared with actual current and the error is fed to the current controller (e.g. PI controller) to generate the control

signal, v

c

. The firing circuit is responsible in generating the pulses used to trigger the SCRs so that the desired

average voltage is produced at the output of the converter. As we have seen before, the relation between ! and the

average voltage V

a

is non-linear due to the cosine term present in the expression. If the relationship between v

c

and

! is linear, obviously the relationship between v

c

and V

a

will be non-linear. While it is true that we can linearize (1)

for the purpose of designing the controller, this however only valid for a small perturbation around an operating point

!

"

= cos

V 2

V

m

a

!

m

V 2

!

"

m

V 2

2

!

!

+

vin

"

+

va

"

Va

!

Ia

2

of the delay angle. The controller will not be optimized at a different operating point or delay angle. On the other

hand, if we can establish an inverse cosine relation between v

c

and !, then the relation between v

c

and V

a

will

become linear.

Figure 2 Current control loop employing controlled rectifier

There are several possible techniques that can be used to construct the firing circuit. One can use analog circuits,

digital circuits or microprocessors. The scheme that results in an inverse cosine relation between v

c

and ! is known

as the cosine-crossing scheme. An example of a firing circuit implementation that uses analog circuit is shown in

Figure 3 (this is extracted from P.C. Sen, Thyristor DC Drives). As discussed in the lecture, it can be shown that the

relationship between v

c

and ! is given by:

!

!

"

#

$

$

%

&

= '

(

s

c 1

V

v

cos

(2)

where V

s

is the maximum value of control signal v

c

. If (2) is substitute into (1), the relation between v

c

and V

a

is

given as:

s

c m

a

v

v V 2

V

!

= (3)

The same scheme can be applied to generate the firing signals for a three-phase controlled rectifier.

Control Model

It should be noted that using the cosine-crossing scheme as discussed above only gives a linear relationship

between the average output voltage and the control signal. The average output voltage is available for every

sampling interval, determined by the type of converters used. For instance, a 3phase fully controlled rectifier will

have an average output voltage that is averaged over 3.33ms ( = 10 x 10

3

6) and 10ms ( = 20 x 10

3

2) for a 1

phase converter. This can be considered as a sampled data system with sampling period of 3.33ms or 10ms

respectively. At the instance the control signal changes (e.g. a step change), there may be some time elapse

(delays) before the changes in output voltage takes place. This delay can have a maximum value equal to the

sampling period as illustrated in Figure 4 for a single-phase converter. A normal practice is to take the average

delay as half of the maximum delay. That is 1.67ms and 5ms for the single-phase and three-phase respectively.

firing

circuit

current

controller

controlled

rectifier

!

+

Va

vc

iref

3

Figure 3 Cosine crossing scheme (a) circuit,(b) timing diagram (extracted from Thysritor DC Drives, PC Sen)

(a)

(b)

4

Figure 4 Delay in singlephase controlled rectifier

In developing the model of the converter to be used in the control system design, the sampling effect and delay

characteristics have to be taken into considerations. With the time delay included, the converter can be modeled as

shown in Figure 5 ( for singlephase controlled rectifier):

Where

Figure 5 Controlled Rectifier model

We can, however, neglect the sampling effect of the output voltage by designing the closedloop bandwidth (for

example a current loop bandwidth) much smaller than the sampling frequency, typically (1/10)th of the sampling

frequency. By doing so, we will ensure that the control signal does not change faster than the capability of the

converter to produce a change in the average output voltage. To further simplifed the design, the delay can also be

removed provided that the closed-loop bandwidth is small enough. The control system based on this simplified

model however does take into account on the inter-sampling behavior, which can be critical and cause instability.

Simulation example Closed loop current control system

A closed loop current control system (Figure 2) was developed using Matlab/SIMULINK blocks and is shown in

Figure 6(a). The model is constructed using the blocks from the SimPowerSystem toolbox. The simulation uses the

single phase bridge configuration and the firing pulses are obtained from the 6 pulse generator (since no 4-pulse

generator is available). The PI controller is designed using the small signal model as discussed above, however the

closed loop bandwidth is selected to be a decade lower than the sampling frequency (i.e. 1/10 of 628.3 rad/s = 62.8

rad/s). The load is selected such that the current is continuous: R = 10#, L = 300mH. The reference current is

always positive since the converter can operate in the first and fourth quadrants. Simulation results in Figure 6(b)

shows that the output current is able to follow the reference although with a high low frequency ripple and poor

dynamics.

s

2

T

Ke ) s ( G

!

=

vc(s) Va(s)

G(s)

s

m

V

V 2

K

!

=

, T = 5 ms

5

(a)

(b)

Figure 6 Simulation of controlled rectifier (a) SIMULINK blocks, (b) Reference and output currents, output voltage

Quadrant of Operation

A controlled rectifier can only be operated in 2 quadrants. The output current I

a

(see Figure 1) can only flow in one

direction due to the unidirectional current property of the SCRs, however, based on equation (1), for ! > 90, the

average output voltage V

a

of a controlled rectifier can be reversed. Thus the two quadrants that the controlled

rectifier operates are (1) when the voltage and current are positive (V

a

> 0 and I

a

> 0), and (2) when the current is

positive but the voltage reversed, i.e. when ! > 90

o

(V

a

< 0, I

a

>0). When used in a separately excited DC motor

drive, the converter can only provide operations in forward motoring and reverse braking quadrants, thus is not

suitable for applications requiring forward braking mode. Modifications to the circuit and control have to be

introduced so that the controlled rectifier can be used for 4-quadrant operations:

Continuous

powergui

v

+

-

Voltage Measurement4

v

+

-

Voltage Measurement3

v

+

-

Voltage Measurement2

g

A

B

+

-

Universal Bridge

Step

Si gnal

Generator1

Series RLC Branch

Scope2

Scope

Saturati on

PID

PID Control l er1

Mux

In2

In5

Out1

Fi ri ng ci rcui t

cosi ne

i

+

-

Current Measurement1

i

+

-

Current Measurement

s

-

+

Controlled Voltage Source

10

Constant

AC Voltage Source

1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2

0

5

10

15

1 1.1 1.2 1.3 1.4 1.5 1.6 1.7 1.8 1.9 2

-400

-200

0

200

400

iref

iout

6

(a) Dual converters

Two controlled rectifiers connected back- to back is used as shown in Figure 7. Converter 1 provides operations in

Q1 and Q4, whereas converter 2 operates in Q2 and Q3. There are two control schemes that can be used for this

configuration:

(i) Operating each converter one at a time (non-simultaneous operation).

When operation from Q1 to Q2 is required (i.e. from forward motoring to forward braking), the

operation of the converter has to be switched from converter 1 to converter 2. Before the switching can

be made, the armature current has to be forced to zero by increasing the delay angle of converter 1 to

the highest possible value. When the current goes to zero, a certain deadtime is needed before

converter 2 is operated to ensure that the SCRs for converter 1 recover the reverse blocking capability.

After this deadtime, rectifier 2 is activated. The initial delay angle of converter 2 is set to the highest

value and gradually reduced (advance firing scheme) so that armature current builds up. The current

is regulated to the allowable maximum value through current control loop. The motor decelerates and

accelerates in reverse direction with converter 2 in operation.

(ii) Operating both converters simultaneously (simulataneous operation).

Both converters are operated simultaneously such as they produced the same average voltage. For

instance, if converter 1 operates with !1, then the delay angle of converter 2 should be (180

o

- !1).

This control scheme produces circulating current since the instantaneous voltages of the two

converters are not the same. To reduce the circulating current an interphase reactor is needed which

will inevitably introduce losses, cost and weight. As both converters are always in operation, there is

no deadtime delay (as discussed in (i)) involved.

Figure 7 Four-quadrant operation with dual converter

(b) Single converter with reversing switch

Using this technique, only one fully controlled rectifier is needed, however reversing switches (contactors) are

needed in order to provide the reverse current flow (see Figure 8). When F1 and F2 are closed (R1 and R2 opened),

the converter operates in Q1 and Q4, and when R1 and R2 close, the converter operates in Q2 and Q3. Similar to

non-simultaneous operation of dual converter, before the contactors can be opened (and closed), the current has to

be forced to zero by advancing the delay angle. The delay angle is then gradually reduced and controlled such that

the safe limit is not exceeded using current control loop.

Figure 8 Four-quadrant operation with single converter

Converter

1 (Q1)

$

T

Converter

1 (Q4)

Converter

2 (Q2)

Converter

2 (Q3)

F1

F2

R1

R2

+ Va -

3phase

supply

3-phase

supply

3-phase

supply

Converter 1 Converter 2

+

Va

"

$

T

F1 and F2 are

closed (Q1)

R1 and R2 are

closed (Q3)

R1 and R2 are

closed (Q2)

F1 and F2 are

closed (Q4)

Anda mungkin juga menyukai

- Detailed Analysis of DC-Link Virtual Impedance-Based Suppression Method For Harmonics Interaction in High-Power PWM Current-Source Motor DrivesDokumen13 halamanDetailed Analysis of DC-Link Virtual Impedance-Based Suppression Method For Harmonics Interaction in High-Power PWM Current-Source Motor DrivesAswathy CjBelum ada peringkat

- ODokumen8 halamanOAswathy CjBelum ada peringkat

- EcapDokumen35 halamanEcapAswathy CjBelum ada peringkat

- ODokumen8 halamanOAswathy CjBelum ada peringkat

- Gateee QuestionsDokumen15 halamanGateee QuestionsAswathy CjBelum ada peringkat

- PvimDokumen6 halamanPvimAswathy CjBelum ada peringkat

- Survey of Bio Inspired Optimization AlgorithmsDokumen15 halamanSurvey of Bio Inspired Optimization AlgorithmsAswathy Cj0% (1)

- Power Systems I Sept 2010 (2006 Ad)Dokumen2 halamanPower Systems I Sept 2010 (2006 Ad)Aswathy CjBelum ada peringkat

- ODokumen8 halamanOAswathy CjBelum ada peringkat

- Engineering Mathematics - Sample Questions - Set-3Dokumen3 halamanEngineering Mathematics - Sample Questions - Set-3Aswathy CjBelum ada peringkat

- Ee Gate'13Dokumen16 halamanEe Gate'13menilanjan89nLBelum ada peringkat

- Cusat DSP Question PaperDokumen14 halamanCusat DSP Question PaperSabith PockerBelum ada peringkat

- Math 450 Applied Probability ModelsDokumen34 halamanMath 450 Applied Probability ModelsAswathy CjBelum ada peringkat

- Python FundamentalsDokumen61 halamanPython FundamentalsAswathy CjBelum ada peringkat

- Python GraphsDokumen22 halamanPython GraphsAswathy CjBelum ada peringkat

- ECE 514 Nonlinear Adaptive Control Lecture NotesDokumen4 halamanECE 514 Nonlinear Adaptive Control Lecture NotesAswathy CjBelum ada peringkat

- Py4Inf 06 StringsDokumen31 halamanPy4Inf 06 StringsAswathy CjBelum ada peringkat

- Meetings in English - Unit 3 PDFDokumen4 halamanMeetings in English - Unit 3 PDFAswathy CjBelum ada peringkat

- Introduction To Python: Chen LinDokumen51 halamanIntroduction To Python: Chen LinGiridhar SripathiBelum ada peringkat

- Currents in A Single-Phase FWaveDokumen8 halamanCurrents in A Single-Phase FWaveAswathy CjBelum ada peringkat

- Micro Hydro SummaryDokumen9 halamanMicro Hydro SummaryAswathy CjBelum ada peringkat

- Electrical Machines III 2010 Sept (2006 Ad)Dokumen2 halamanElectrical Machines III 2010 Sept (2006 Ad)Aswathy CjBelum ada peringkat

- SensorsDokumen46 halamanSensorsAswathy CjBelum ada peringkat

- Meetings in English - Unit 3 PDFDokumen4 halamanMeetings in English - Unit 3 PDFAswathy CjBelum ada peringkat

- Meetings in English - Unit 3 PDFDokumen4 halamanMeetings in English - Unit 3 PDFAswathy CjBelum ada peringkat

- Meetings in English - Unit 3 PDFDokumen4 halamanMeetings in English - Unit 3 PDFAswathy CjBelum ada peringkat

- Automatic Street Light ControllerDokumen1 halamanAutomatic Street Light ControllerAswathy CjBelum ada peringkat

- GlobalisationDokumen2 halamanGlobalisationAswathy CjBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- A4D450AO1809Dokumen6 halamanA4D450AO1809adeBelum ada peringkat

- S3100 Manual PDFDokumen112 halamanS3100 Manual PDFMazen AlhouseenBelum ada peringkat

- Aj5512e HZ3CDokumen3 halamanAj5512e HZ3CHendra KosasihBelum ada peringkat

- B.tech. Open Elective III & IV List 4th Year VIII Semester 2021-22Dokumen26 halamanB.tech. Open Elective III & IV List 4th Year VIII Semester 2021-22mahendranavionicsBelum ada peringkat

- N 1 Electrical Experi 07 GernDokumen100 halamanN 1 Electrical Experi 07 GernBrood BelegBelum ada peringkat

- Asy18eba WDokumen33 halamanAsy18eba WFrancisco Jose Domenech SalaBelum ada peringkat

- Annexure III Curriculum & Detailed Syllabus - Electric Motor Rewinding - 0Dokumen9 halamanAnnexure III Curriculum & Detailed Syllabus - Electric Motor Rewinding - 0Reynaldo PesqueraBelum ada peringkat

- Instruction Manual: Sizes 02 - 95, (2X - 8X)Dokumen28 halamanInstruction Manual: Sizes 02 - 95, (2X - 8X)Alejandro DallosBelum ada peringkat

- (Catalogue) Eaton - Hydraulics - Guide To Mobile Industrial HydraulicsDokumen16 halaman(Catalogue) Eaton - Hydraulics - Guide To Mobile Industrial HydraulicsTrần LêBelum ada peringkat

- Electric Motor Maintenance and Troubleshooting GuideDokumen7 halamanElectric Motor Maintenance and Troubleshooting GuidealexfrizBelum ada peringkat

- Design of An Outer-Rotor Brushless DC Motor For Control Moment Gyroscope ApplicationsDokumen72 halamanDesign of An Outer-Rotor Brushless DC Motor For Control Moment Gyroscope ApplicationsNecati CAGANBelum ada peringkat

- Review of Comparative Analysis of Speed Control Techniques of BLDC & PMSM MotorDokumen9 halamanReview of Comparative Analysis of Speed Control Techniques of BLDC & PMSM MotorIJRASETPublicationsBelum ada peringkat

- S100 - User Manual (Simple) - EN - V3.0 - 211020Dokumen270 halamanS100 - User Manual (Simple) - EN - V3.0 - 211020dul theoBelum ada peringkat

- PLC and SCADA PowerpointDokumen172 halamanPLC and SCADA PowerpointRay WongBelum ada peringkat

- Flying Scale Models Issue 270 May 2022Dokumen70 halamanFlying Scale Models Issue 270 May 2022zveicohenBelum ada peringkat

- Time Mark 471 Multi Stage AlternatorDokumen2 halamanTime Mark 471 Multi Stage AlternatorAladino SanchezBelum ada peringkat

- Gearboxes Instruction and Spare Parts Manual: Società Italiana Trasmissioni IndustrialiDokumen36 halamanGearboxes Instruction and Spare Parts Manual: Società Italiana Trasmissioni IndustrialiDlamini Innocent ThulaniBelum ada peringkat

- GEK - 91741A Dynamic Retarding AssemblyDokumen12 halamanGEK - 91741A Dynamic Retarding AssemblyKJDNKJZEFBelum ada peringkat

- N. Tesla.: 46 7, 2-, 4-4 (He/ea& 9a (AuDokumen5 halamanN. Tesla.: 46 7, 2-, 4-4 (He/ea& 9a (Auhix256Belum ada peringkat

- Hopkinsos TestDokumen3 halamanHopkinsos TestGANESH KUMAR B eee2018Belum ada peringkat

- BEML Bull Dozer Parts Inventory ListingDokumen354 halamanBEML Bull Dozer Parts Inventory ListingXiangzhendongBelum ada peringkat

- LS800 eDokumen124 halamanLS800 eNguyễn Bá ThịnhBelum ada peringkat

- Elevator Controller As360Dokumen81 halamanElevator Controller As360Carlos NotarioBelum ada peringkat

- Industrial Motor Control: Control Devices Control Diagram Starting MethodDokumen51 halamanIndustrial Motor Control: Control Devices Control Diagram Starting MethodMuhd Izwan Ikhmal Rosli100% (1)

- Randomation Vehicle Physics ManualDokumen36 halamanRandomation Vehicle Physics ManualbrokenBelum ada peringkat

- BYD C9U Diagnostic Circuit Diagram-EB-LU - SAL.P01-A0-20190308.ENDokumen61 halamanBYD C9U Diagnostic Circuit Diagram-EB-LU - SAL.P01-A0-20190308.ENAxelBelum ada peringkat

- Andhra Pradesh, IndiaDokumen2 halamanAndhra Pradesh, IndiaHarimadhavareddy YenireddyBelum ada peringkat

- Electrical 8 Years Bits PDFDokumen65 halamanElectrical 8 Years Bits PDFSasi Kanth Kola100% (1)

- DC Motor Control: Jacob FainguelerntDokumen30 halamanDC Motor Control: Jacob Fainguelerntcontrol 4uonlyBelum ada peringkat