Air Conditioning

Diunggah oleh

MarijaŽaperHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Air Conditioning

Diunggah oleh

MarijaŽaperHak Cipta:

Format Tersedia

Split, July, 2014

Version 01

MARITIME TRAINING CENTRE

SPLIT CROATIA

114 Brigade br.12

21000 Split

Croatia

Tel: 385 (0) 21 558 581

385 (0) 21 558 507

Fax. 385 (0) 21 558 555

e-mail : maritime.training.centre@optinet.hr

AIR-CONDITIONING AND REFRIGERATION

CHILLERS

Prepared by: Approved by:

C/E Ivica Kui, ing. Dr.Sc. Ratko Boi, dipl.ing

1

a) Course Content

AIR-CONDITIONING AND REFRIGERATION

CHILLERS

Subject area Hours

Lectures

(L)

Exercises

(E)

1. The basic principles of physics 2,00 0,00

2. The enthalpy chart 1,00 0,00

3. R134a characteristics 2,00 1,00

4. Compression refrigeration cycles 2,00 0,00

5. Refrigeration compressors 3,00 0,00

6. A discussion on centrifugal compressor 2,00 0,00

7. Centrifugal compressor: surge limit 1,00 2,00

8. Operating and maintenance manual

9. Centrifugal compressor : YK R134a

10. Compressor mechanical instructions

11. Condensers

12. Evaporators

13. Vacuum drying and testing procedure

14. Software Enhancements

3,00

2,00

2,00

3,00

3,00

2,00

2,00

0,00

1,00

0,00

1,00

1,00

4,00

0,00

LECTURES

(L)

EXERCISES

(E)

30,00 30,00

TOTAL 40,00

2

b) Course Framework

Learning objectives References

Teaching

aids

1. The basic principles of physics

1.1. Measurement unit systems

1.2. Energy

1.3. Power

1.4. Thermodynamic principles

1.5. Temperature

1.6. Pressure

1.7. Phase changes

1.8. Temperature/pressure conversion factors

2. The enthalpy chart

2.1. Introduction

2.2. Scales used

2.3. Main transformations

3. R134a characteristics

4. Compression refrigeration cycles

4.1. Introduction

4.2. Single-stage compression cycle flow diagrams

4.3. Two- stage compression cycle flow diagrams

4.4. Comparison between single and two-stage

compression

5. Refrigeration compressors

5.1. General information

5.2. Piston compressors

5.3. Scroll compressors

5.4. Screw compressors

5.5. Centrifugal compressors

6. A discussion on centrifugal compressor

6.1. Overview

6.2. Design and operation

7. Centrifugal compressor: surge limit

7.1. Components

7.2. Compressor map

7.3. Surge limits

8. Operating and maintenance manual

8.1. Description of system and fundamentals of operation

8.2. System operating procedures

8.3. System components description

8.4. Operational maintenance

3

8.5. Troubleshooting

8.6. Maintenance

8.7. Preventive maintenance

9. Centrifugal compressor : YK R134a

9.1. Oil circuit

9.2. Proximity sensor

9.3. Level control

9.4. Refrigerant charge check

9.5. Barber-Colman actuator

10. Compressor mechanical instructions

10.1. General

10.2. Compressor service

10.3. Oil pump service

11. Condensers

11.1. Function

11.2. Water-cooled condensers

11.3. Water-cooled condensers and cooling tower

11.4. Evaporative condensers

11.5. Air-cooled condensers

11.6. Trouble-shooting and maintenance

12. Evaporators

12.1. Function

12.2. Liquid-chiller evaporators

12.3. Flooded evaporators

12.4. Plate-type evaporators

12.5. Secondary refrigerants

12.6. Air-conditioner evaporators

12.7. Defrosting

12.8. Special evaporators

13. Vacuum drying and testing procedure

12.1. Vacuum pull-down and measurement

12.2. Equipment and system to be evacuated

4

12.3. Using a vacuum to dry equipment

12.4. Procedure

12.5. Connecting pumps

12.6. Using vacuum pumps

12.7. Vacuum measurement

12.8. Interpretation of measurement

12.9. Corrective measures

12.10. Safety

12.11. Recordings

14. Software Enhancements

5

Anda mungkin juga menyukai

- Specification For Breathing Apparatus: 1. RequirementDokumen6 halamanSpecification For Breathing Apparatus: 1. RequirementMarijaŽaper100% (1)

- S G Ii: Piro UideDokumen32 halamanS G Ii: Piro UideMarijaŽaperBelum ada peringkat

- Breathing Apparatus Training CourseDokumen21 halamanBreathing Apparatus Training CourseMarijaŽaper100% (1)

- Intro To LNG Operations (Membrane)Dokumen190 halamanIntro To LNG Operations (Membrane)MarijaŽaper100% (1)

- Unipack II ManualDokumen30 halamanUnipack II ManualMarijaŽaper67% (3)

- Personal Sea Survival TechniquesDokumen28 halamanPersonal Sea Survival TechniquesNicoel90% (31)

- Medical Handbook For SeafarersDokumen213 halamanMedical Handbook For SeafarersmuscalualinaBelum ada peringkat

- GMDSS Handbook 2013Dokumen0 halamanGMDSS Handbook 2013AMSAsocialmedia100% (1)

- E005 Manual PDFDokumen139 halamanE005 Manual PDFMarijaŽaper100% (4)

- Vol 2+3 K98ME PDFDokumen865 halamanVol 2+3 K98ME PDFMarijaŽaper100% (1)

- IMO Guidelines PDFDokumen88 halamanIMO Guidelines PDFMarijaŽaperBelum ada peringkat

- RT Flex 11 PDFDokumen4 halamanRT Flex 11 PDFMarijaŽaperBelum ada peringkat

- IMO Guidelines PDFDokumen88 halamanIMO Guidelines PDFMarijaŽaperBelum ada peringkat

- Marine Radar PDFDokumen60 halamanMarine Radar PDFMarijaŽaperBelum ada peringkat

- Sea Navigation RadarDokumen24 halamanSea Navigation RadarLazelyn Lim100% (2)

- Rawdata Basic PDFDokumen2 halamanRawdata Basic PDFMarijaŽaper100% (1)

- Introduction To Ice Navigation PDFDokumen24 halamanIntroduction To Ice Navigation PDFMarijaŽaper100% (2)

- Determining Ship's Position PDFDokumen53 halamanDetermining Ship's Position PDFMarijaŽaper80% (5)

- Navigation PDFDokumen80 halamanNavigation PDFMarijaŽaperBelum ada peringkat

- Radar Safety Guidelines PDFDokumen2 halamanRadar Safety Guidelines PDFMarijaŽaperBelum ada peringkat

- 09 Magneticgyro CompassDokumen36 halaman09 Magneticgyro CompassMarijaŽaperBelum ada peringkat

- Offshore Cranes, Additional Requirements To NS-EN 13852-1: Statoil Governing DocumentDokumen35 halamanOffshore Cranes, Additional Requirements To NS-EN 13852-1: Statoil Governing DocumentMarijaŽaperBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Advanced Ceramic Components - Materials, Fabrication, and Applications PDFDokumen32 halamanAdvanced Ceramic Components - Materials, Fabrication, and Applications PDFDaxel Val100% (1)

- Evaluation of The Installation and Initial Condition of Overlays On Bridge Decks RosphaltDokumen55 halamanEvaluation of The Installation and Initial Condition of Overlays On Bridge Decks RosphaltRoy HobbsBelum ada peringkat

- Structural Masangkay 4 AnskeyDokumen6 halamanStructural Masangkay 4 AnskeyJeypee De GeeBelum ada peringkat

- ME2109 Fluid May2011Dokumen6 halamanME2109 Fluid May2011Hafsa Khan0% (1)

- IWM - Construction Material Recycling GuidebookDokumen40 halamanIWM - Construction Material Recycling GuidebookAllan HakBelum ada peringkat

- MoRTH Specifi Road Bridge 5th Rev 2013Dokumen898 halamanMoRTH Specifi Road Bridge 5th Rev 2013jegancivil82% (22)

- Q-RAY LED Street Lantern Datasheet - Eco-Lighting Technologies Pte LTDDokumen4 halamanQ-RAY LED Street Lantern Datasheet - Eco-Lighting Technologies Pte LTDazimzubirBelum ada peringkat

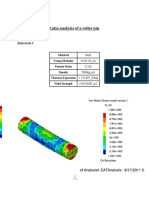

- Catia Analysis of A Roller PinDokumen15 halamanCatia Analysis of A Roller Pinanteneh tesfayeBelum ada peringkat

- Tutorial 6 DR RofdziDokumen8 halamanTutorial 6 DR RofdziSuaidah ShimaBelum ada peringkat

- Unit I Electrical and Electronic Systems: Electrical Wiring Systems 10Dokumen2 halamanUnit I Electrical and Electronic Systems: Electrical Wiring Systems 10Cebo DharuBelum ada peringkat

- Manual 162 PDFDokumen47 halamanManual 162 PDFDeimer Jose Figueroa ManriqueBelum ada peringkat

- 1811 Series: Pressure Relief ValvesDokumen24 halaman1811 Series: Pressure Relief ValvesIldefonso FloresBelum ada peringkat

- General Notes:: Typical Section of R.C.C. Storm Water DrainDokumen2 halamanGeneral Notes:: Typical Section of R.C.C. Storm Water Drainbijnor officeBelum ada peringkat

- Dieless Wire Drawing-An Experimental and Numerical Analysis: P. Tiernan, M.T. HilleryDokumen6 halamanDieless Wire Drawing-An Experimental and Numerical Analysis: P. Tiernan, M.T. HillerycostytzuBelum ada peringkat

- LamellaDokumen3 halamanLamellaRomeo Padilla IIIBelum ada peringkat

- ASTM B152 COBRE 7Cen-USDokumen6 halamanASTM B152 COBRE 7Cen-USLuis GuidekBelum ada peringkat

- Materials Science and Engineering by Callister Chapter 1 ReviewerDokumen3 halamanMaterials Science and Engineering by Callister Chapter 1 ReviewerTy ztickBelum ada peringkat

- Important Design of Vacuum ValveDokumen23 halamanImportant Design of Vacuum ValveNarendraBelum ada peringkat

- Table of Contents: Section 2.01 Section 2.02 Section 2.03Dokumen162 halamanTable of Contents: Section 2.01 Section 2.02 Section 2.03aaaayyyynnnnBelum ada peringkat

- KHG Brochure May2023 12 CompressedDokumen2 halamanKHG Brochure May2023 12 CompressedEbraheem GawadBelum ada peringkat

- ASTM C-780 Mortar PDFDokumen17 halamanASTM C-780 Mortar PDFLuis Suazo100% (2)

- Damage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanDokumen10 halamanDamage of Refractory Bricks Lined in Cement Rotary Kiln: Technical Research Laboratory, Mino Yogyo Co. LTD., JapanPham tony1604Belum ada peringkat

- LT Gate Globe Check Valves Api 602Dokumen12 halamanLT Gate Globe Check Valves Api 602Krunal MahidadiaBelum ada peringkat

- Electrical Design PrinciplesDokumen12 halamanElectrical Design PrinciplesLJ IDANE ARANASBelum ada peringkat

- PEC Design RulesDokumen31 halamanPEC Design RulesReymart Manablug100% (1)

- In-Place Methods To Estimate Concrete Strength: Reported by ACI Committee 228Dokumen41 halamanIn-Place Methods To Estimate Concrete Strength: Reported by ACI Committee 228yusak santosoBelum ada peringkat

- Luminarias Glamox para Areas DeportivasDokumen2 halamanLuminarias Glamox para Areas DeportivasAlberto PopushoyBelum ada peringkat

- Types of Fibre Reinforced PolymersDokumen5 halamanTypes of Fibre Reinforced PolymersNeerajBelum ada peringkat

- FM 1492BF En2 31026 PDFDokumen2 halamanFM 1492BF En2 31026 PDFchkzaBelum ada peringkat