Grease Traps and Interceptors - Bio-Systems SA

Diunggah oleh

Lh KooJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Grease Traps and Interceptors - Bio-Systems SA

Diunggah oleh

Lh KooHak Cipta:

Format Tersedia

10/1/2014 Grease traps and interceptors Bio-Systems SA

http://www.biosystemssa.co.za/Industrial/grease-traps-and-interceptors 1/3

Grease traps and interceptors

What are they?

Grease traps are used primarily in mechanical workshops and food industry kitchens. Their function

is always the same: to remove solids and fats, oils and greases (FOG) from liquid effluent streams.

A typical grease trap has three parts:

1. A solid particle interceptor also known as a sludge catcher;

2. A grease/fat interceptor called the stilling tank where FOG in dirty water is prevented

from rising to the surface; and

3. A small sampling chamber where the improved quality of the cleaned effluent can be

observed.

Grease traps are rated on their flow performance. For example:

Small users such as households and sandwich bars will use traps rated at 1.5lt per second;

Medium-sized restaurants and food production lines often use traps rated at 4.5lt per second;

and

Food courts, dairies, cheese factories, etc. will use a trap rated at 11lt per second.

How grease traps work

The aim of a grease trap is to improve the discharge quality of the effluent prior to it entering the

municipal sewer, and to allow an operator to remove solids and grease from the effluent stream with

ease.

Well designed grease traps usually have three chambers. The first chamber is equipped with

perforated solids retention baskets into which the inflowing effluent arrives. The second chamber,

between two baffles, slows the liquid permitting the oils to float to the surface (since oil floats on

water) where microorganisms - both latent and added - degrade the floating scum from the

underside, improving the quality of the effluent. When there is excessive fat in the effluent a scum

will form and is liable to steadily thicken with the increased daily volumes. This fat scum should be

removed carefully to avoid dripping and discarded in an approved fashion (BIO-SYSTEMS can

provide an established protocol for this task). The third chamber is narrow and allows for visual

inspection and sampling.

In many cases grease traps receive effluent from both floor drains and sinks. Dirty water flows

through the particle interceptor (perforated sieve baskets) where small solids such as metal swarf,

scraps of meat and vegetable solids are caught in the chamber baskets these should be emptied

into disposal bags twice a day before the rubbish putrefies and becomes unpleasant to handle. The

grease interceptor trap should be situated sufficiently far away (down-line) from the under sink

particle interceptor to allow the temperature of the dirty water to drop to below 40

o

C, preventing the

biomass of bacteria in the stilling tank from being damaged.

Common grease trap problems

Oil overload is a frequent problem plaguing industrial grease traps. Modern fuels, lubricants and

catering oils are highly complex compounds and pose even more of a problem because they are

difficult to degrade and take a long time to break down. The result? Congested, slimy drain pipes and

sulphurous, foul odours. This is also true of effluent in the food and catering industry where modern

trans fats often accumulate and cause blockages unless dealt with correctly and timeously.

The BIO-SYSTEMS solution

10/1/2014 Grease traps and interceptors Bio-Systems SA

http://www.biosystemssa.co.za/Industrial/grease-traps-and-interceptors 2/3

Our microbial blends ensure that the biodegradation of floating FOG and sludge in grease traps is

efficiently and effectively controlled. The quality of effluent migrating to the third chamber will not

only be improved thus lessening the load on municipal conveyance and treatment plants the

grease trap will be cleaner, healthier and free from unpleasant odours.

Mechanical areas

1. BIO-SYSTEMS B350

2. BIO-SYSTEMS L1800

3. Hard Surface Degreaser (HSDG)

4. Spill-Sorb

TM

Absorbents

Food industry

1. DrainFlow 60 (DF60)

2. Dop-a-Day

3. BIO-SYSTEMS B220 and B220R. B220 is the parent of FogFree and is supplied for

improving the quality of large industrial effluent systems where high grease loadings are

experienced.

These include most meat and fish processing plants, as well as manufacturers of soups,

confectionary, synthetic bread spreads, etc. B220R is a specialist pack designed for easy

application into grease sumps and effluent pump station wet-wells. Read more about BIO-

SYSTEMS B220R.

4. BIO-SYSTEMS L2120

5. FogFree (FF). FogFree is a DIY product compiled and marketed for use in food industry

kitchen grease traps in medium-sized factories, hotels and restaurants. Safe and easy to use,

it is compounded from a complex mixture of natural microbial powders that have been

blended to degrade FOG in kitchen drain interceptors and grease traps.

FF is particularly suited for use in the stilling tanks of traps where it has time to proliferate to

a viable biomass that will feed on the FOG, breaking it down to natural gasses and water.

There is no residue other than inherent, inorganic molecular radicals. For most catering

effluent, FogFree is the answer.

Just one 25g soluble pouch per week will maintain the average busy restaurant or

supermarket trap in good working order. The dosage must be increased proportionately

under heavy (peak season) loads.

6. AirMix Aerators/DAF Units

7. BIO-SYSTEMS B250

Grease trap before treatment

10/1/2014 Grease traps and interceptors Bio-Systems SA

http://www.biosystemssa.co.za/Industrial/grease-traps-and-interceptors 3/3

Grease trap three weeks after initial treatment

Factories

1. BIO-SYSTEMS B560 - cannery and winery waste

B560 is a dry micronutrient powder blend specially selected for organic processing wastes. It

provides a complete formulation for maximum biological activity and reacts with fruit,

vegetable and wine waste to produce biological enhancers. B560s aerobic and facultative

anaerobic microorganisms help to establish a biomass that provides greater resistance to the

effects of organic inhibitors present in the effluent. As a result, it is able to perform more

effectively than the naturally-occurring biomass. B560 is packaged in unique water soluble

pouches to make dosing hassle and mess free.

2. BIO-SYSTEMS B570 - pulp and paper (timber) mills

B570 is a microbial powder blend that degrades paper and pulp waste. It is used in paper and

card, and timber mills. The range of microorganisms selected for the B570 products are

chosen for their cellulose degradation abilities under both aerobic and anaerobic conditions.

To ensure optimal performance of these organisms under the toughest conditions, they are

blended together with high potency nutrients and stimulants. The production of enzymes

including a complex of cellulases, hemicellulases, amylases and lipases provide the capacity

to degrade extra cellular polymers (which cause foaming) and suppress the growth of the

filamentous organisms by affecting the structure of the filaments.

3. BIO-SYSTEMS B570 and BIO-SYSTEMS B560 products are both also excellent at degrading

sugar mill effluent.

Click on the BIO-SYSTEMS Product table for a complete list of products. Also see our Grease

trap case history.

Related content

Industrial effluent disposal at a glance

Treating effluent streams

Oil spills

Odour prevention

Confined spaces

Drain dos and don'ts

Industrial catering effluent

Anda mungkin juga menyukai

- YBPPGA (1) Aug 2011 PDFDokumen6 halamanYBPPGA (1) Aug 2011 PDFLh KooBelum ada peringkat

- Dow Completes Merger With Rohm and HaasDokumen2 halamanDow Completes Merger With Rohm and HaasLh KooBelum ada peringkat

- Biomass Energy Generation by PTMDokumen24 halamanBiomass Energy Generation by PTMLh KooBelum ada peringkat

- Peristaltic Pump With Speed Adjustable Flow: Product Specifications Pump View (MM)Dokumen1 halamanPeristaltic Pump With Speed Adjustable Flow: Product Specifications Pump View (MM)Lh KooBelum ada peringkat

- Taking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Dokumen2 halamanTaking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Lh KooBelum ada peringkat

- Taking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Dokumen2 halamanTaking A Zero Tolerance Approach To Bacteria Control, Delivers Piece of Mind 'Lh KooBelum ada peringkat

- D NanoTronDokumen2 halamanD NanoTronLh KooBelum ada peringkat

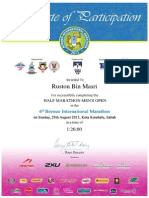

- BIM Half Marathon Men Open 15Dokumen1 halamanBIM Half Marathon Men Open 15Lh KooBelum ada peringkat

- D MicroTronDokumen2 halamanD MicroTronLh KooBelum ada peringkat

- BIM Half Marathon Men Open 16Dokumen1 halamanBIM Half Marathon Men Open 16Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 14Dokumen1 halamanBIM Half Marathon Men Open 14Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 18Dokumen1 halamanBIM Half Marathon Men Open 18Lh KooBelum ada peringkat

- TDS Cond Conversion ChartDokumen2 halamanTDS Cond Conversion ChartLh KooBelum ada peringkat

- BIM Half Marathon Men Open 19Dokumen1 halamanBIM Half Marathon Men Open 19Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 9Dokumen1 halamanBIM Half Marathon Men Open 9Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 11Dokumen1 halamanBIM Half Marathon Men Open 11Lh KooBelum ada peringkat

- Ozone Treatment of Cooling Tower WaterDokumen26 halamanOzone Treatment of Cooling Tower WaterLh KooBelum ada peringkat

- BIM Half Marathon Men Open 13Dokumen1 halamanBIM Half Marathon Men Open 13Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 7Dokumen1 halamanBIM Half Marathon Men Open 7Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 12Dokumen1 halamanBIM Half Marathon Men Open 12Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 2Dokumen1 halamanBIM Half Marathon Men Open 2Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 6Dokumen1 halamanBIM Half Marathon Men Open 6Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 1Dokumen1 halamanBIM Half Marathon Men Open 1Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 5Dokumen1 halamanBIM Half Marathon Men Open 5Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 4Dokumen1 halamanBIM Half Marathon Men Open 4Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 3Dokumen1 halamanBIM Half Marathon Men Open 3Lh KooBelum ada peringkat

- BIM Half Marathon Men Open 8Dokumen1 halamanBIM Half Marathon Men Open 8Lh KooBelum ada peringkat

- Cleaning, Sanitizing, and Pest Control in Food Processing, Storage, and Service AreasDokumen16 halamanCleaning, Sanitizing, and Pest Control in Food Processing, Storage, and Service AreasLh KooBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Industrial Training ReportDokumen26 halamanIndustrial Training ReportAnonymous frPDaoTDIBelum ada peringkat

- Water Balls: An Exciting New Product From A Company Called Skipping Rocks LabDokumen3 halamanWater Balls: An Exciting New Product From A Company Called Skipping Rocks LabEmanAbdel-HaqBelum ada peringkat

- ScrubberDokumen17 halamanScrubberMapa JoyceBelum ada peringkat

- US Masters Guide 2020 Rev 0 PDFDokumen14 halamanUS Masters Guide 2020 Rev 0 PDFYE CAPT100% (1)

- SAlient Features of CAADokumen12 halamanSAlient Features of CAAJaypee EvangelistaBelum ada peringkat

- Directed Writing Clean EnvironmentDokumen2 halamanDirected Writing Clean Environmentyudrea88Belum ada peringkat

- Essay On Environmental PollutionDokumen6 halamanEssay On Environmental PollutionLeonaldo RondonBelum ada peringkat

- Merina-CHAPTER I For Proposal of NaGdAhA......Dokumen7 halamanMerina-CHAPTER I For Proposal of NaGdAhA......Anonymous lVbhvJfBelum ada peringkat

- Introduction To Environmental EngineeringDokumen41 halamanIntroduction To Environmental Engineeringveeveegarcia_Belum ada peringkat

- Contah Soal Bahasa InggrisDokumen26 halamanContah Soal Bahasa InggrisRee AstawanBelum ada peringkat

- ENG LineUp 2021 Final LRDokumen28 halamanENG LineUp 2021 Final LRNazar KhanBelum ada peringkat

- Marine Environments and Administration Assignment 2Dokumen3 halamanMarine Environments and Administration Assignment 2Hasan IqbalBelum ada peringkat

- Biomass Fuelled Power PlantDokumen7 halamanBiomass Fuelled Power PlantpradeepdeceBelum ada peringkat

- Importance of TreesDokumen3 halamanImportance of TreesNirmala SugurBelum ada peringkat

- Plainfield Township Zoning Officer Review Letter - 6.12.2017 of Synagro Biosolids Plant ApplicationDokumen35 halamanPlainfield Township Zoning Officer Review Letter - 6.12.2017 of Synagro Biosolids Plant ApplicationDickBelum ada peringkat

- Pure Air FiltrationDokumen6 halamanPure Air FiltrationkambiadoBelum ada peringkat

- Air Pollution in DelhiDokumen3 halamanAir Pollution in DelhisharafinBelum ada peringkat

- Group 1 Pollution PresentationDokumen11 halamanGroup 1 Pollution PresentationAngel SuplicoBelum ada peringkat

- Nuclear Waste: Introduction To Its ManagementDokumen5 halamanNuclear Waste: Introduction To Its ManagementIJIRAE100% (1)

- TsaDokumen3 halamanTsaMehman NasibovBelum ada peringkat

- Nairobi Metro PlanningDokumen12 halamanNairobi Metro PlanningJeff KariukiBelum ada peringkat

- Markets in Action Essay QsDokumen12 halamanMarkets in Action Essay Qsmkc306Belum ada peringkat

- Etp ManualDokumen35 halamanEtp ManualAtul Sharma100% (3)

- Las Piñas Science High SchoolDokumen2 halamanLas Piñas Science High Schooldeviehex0% (1)

- Candesartan Cilexetil (Cas 145040-37-5) MSDSDokumen5 halamanCandesartan Cilexetil (Cas 145040-37-5) MSDSfdt895thBelum ada peringkat

- AACE Cost EstimateDokumen14 halamanAACE Cost Estimatesue1001Belum ada peringkat

- RPB Radex Airline Filter Product BrochureDokumen4 halamanRPB Radex Airline Filter Product BrochureALEXBelum ada peringkat

- Q.1. Connection To Down East: HenryDokumen6 halamanQ.1. Connection To Down East: HenryAhmad NofriyantoBelum ada peringkat

- Standard Contact AdhesiveDokumen4 halamanStandard Contact AdhesiveMd AmirulBelum ada peringkat

- 222 Essay 1Dokumen5 halaman222 Essay 1Yianni ContoravdisBelum ada peringkat