BS EN 12350 Slump Test

Diunggah oleh

Lloyd R. Ponce0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

610 tayangan2 halamantest

Judul Asli

SOP Slump Test

Hak Cipta

© © All Rights Reserved

Format Tersedia

XLS, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen Initest

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai XLS, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

610 tayangan2 halamanBS EN 12350 Slump Test

Diunggah oleh

Lloyd R. Poncetest

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai XLS, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 2

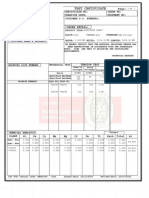

Testing Fresh Concrete

BS EN 12350-Part-2: Slump Test

Testing Fresh Concrete

This European standard specifies a method for determining the consistency of fresh concrete.

1- Apparatus Required

1- Base Plate 3- Compacting Rod 2- Slump Cone

This test in not suitable when the maximum size of aggregate in concrete is greater than 40 mm.

Before taking a sample of freshly mixed concrete, dampen

the sampling container (wheelbarrow) toughly by clean

water. Take a sample of freshly mixed concrete by using

every precaution that assist in obtaining sample that are truly

representative of the nature and condition of concrete. Take

enough sample to perform the Slump test and if there is any

test specimen required to take for testing.

1. Sampling

Test specimen made of metal not readily attacked

by cement paste, smooth free from dent, not thinner

than 1.5 mm, with diameter of base (2002)mm,

diameter of top (1002)mm, height of (3002)mm,

having open base and top parallel to each other at

right angles.

4- Scoop 5- Wheelbarrow

Capable of accurately measuring the

temperature through [0 to 50C] . With

immersion of 3 in. [75 mm]

2- Procedure

This test is sensitive to changes in the consistency of concrete which correspond to slumps between 10mm and 200mm.Beyond these extremes the measurement of slump

can be unsuitable.

Graduated form 0 mm to 300 mm, at

intervals not exceeding 5 mm.The zero

mark begin at the extreme end of the

ruler.

Made of hard non-absorbent material to

ensure proper mixing of concrete.

Made of a non-absorbent solid material , Rigid, flat

plate.

Made of steel or other non-absorbent hard material.

Straight having diameter of (16 1) mm and length

of (600 5) mm with rounded ends.

6- Thermometer 7- Measuring Ruler

A container made from non-absorbent

material not attacked by cement paste,

with appropriate dimensions such that

the concrete can be toughly re-mixed.

Dampen & Sampling

Note:

Test Report Shall include following :

a).Temperature of concrete b). Identification of the test Sample.

c) Date of test. d) Any indication of Shear slump.

e) No. of samples taken f) Location of performing of test

4. Measuring the Slump

Immediately after removal of the mould measure the slump

by determining the difference between the height of the

mould and that of the highest point of the slumped test

specimen.

The test in only valid if the slumped specimen remain

substantially intact and symmetrical.

If the Slumped specimen shears, another sample shall be

taken and repeat the procedure.

if two consecutive tests show a portion of the concrete

shearing off, so the concrete lacks the necessary plasticity and

not suitable for the slum test.

2. Testing Temperature

After taking a representative sample of freshly mixed

concrete, insert the thermometer sensor at least 75 mm inside

the concrete, make sure the concrete should cover the sensor

in all directions around it.Gently press the concrete around

the temperature measuring device at the surface of the

concrete so that ambient air temperature does not affect the

reading.

Leave the temperature measuring device in the freshly mixed

concrete for a minimum period of 2 min or until the

temperature reading stabilizes, then read and record the

temperature.

8.Strike of the concrete level with the upper edge of the

mould with the rod and remove spilled concrete from the

base plate.

9.Carefully raise the mould vertically by the handles, in

period of 5 s to 10 s in a steady upward lift.

1. Place the base plate on a flat and horizontal surface free

from external vibration or shock.

2. Clean the plate and dampen immediately prior to testing.

But keep free from superfluous moisture.

Report the true slump to the nearest 10 mm.

Testing Fresh Concrete

BS EN 12350-Part-2: Slump Test

3. Slump Test.

After testing the temperature, start test the Slump test

immediately. Perform the test in following steps.

5. Reporting

7.Add more concrete if necessary to the top layer to maintain

an excess concrete above the top of the mould.

3.Clean and dampen the Slump mould,than place it centrally

on the plate and hold in position by standing on two foot

pieces.

4. Mix the concrete toughly by scoop and fill the mould with

the concrete in three equal layers.(By volume)

10.Carry out the entire operation from start filling to removal

of the mould with in 150sec.

5. Compact each layers with 25 strokes of the tamping rod.

Uniformly distribute the strokes over the cross-section of

each layer.

6. Compact the Second and top layer each throughout its

depth. So that the strokes just penetrate into the immediately

underlying layer.

Testing Temperature

Positioning & Filling

Raising & Measuring

Rodding & Leveling

Reporting

Anda mungkin juga menyukai

- Conrete Mix Design & Making and Curing of Test SpecimenDokumen15 halamanConrete Mix Design & Making and Curing of Test SpecimenBlesBelum ada peringkat

- Cube Compressive Strenght TestDokumen6 halamanCube Compressive Strenght TestMM tarasBelum ada peringkat

- CONCRETING METHOD STATEMENTDokumen1 halamanCONCRETING METHOD STATEMENTEncik BadrulBelum ada peringkat

- Blinding & Concrete Method StatementDokumen5 halamanBlinding & Concrete Method Statementشاز إياسBelum ada peringkat

- Plastering Techniques and MethodsDokumen6 halamanPlastering Techniques and MethodsYazhisai SelviBelum ada peringkat

- Flexural TestDokumen13 halamanFlexural TestAliaBelum ada peringkat

- Bricks & Plastering Method StatementDokumen1 halamanBricks & Plastering Method StatementJan Umali100% (1)

- Method Statement For EarthworksDokumen3 halamanMethod Statement For EarthworksNorendro KangjamBelum ada peringkat

- Method of StatementDokumen8 halamanMethod of StatementHisham BerrasaliBelum ada peringkat

- Compressive Strength of ConcreteDokumen9 halamanCompressive Strength of ConcreteAmos kiprutoBelum ada peringkat

- Method Statement For HoneycombDokumen2 halamanMethod Statement For HoneycombCHAR JIN CHEEBelum ada peringkat

- Waterproofing Codes and MethodsDokumen5 halamanWaterproofing Codes and MethodsVenkatesha HebbarBelum ada peringkat

- Work Methodology For ConcreteDokumen3 halamanWork Methodology For ConcreteIsaac Addis0% (1)

- Method StatementDokumen4 halamanMethod StatementSagar ParabBelum ada peringkat

- Method Statement For Concrete WallDokumen7 halamanMethod Statement For Concrete WallDeo100% (2)

- Method Statement - Plastering, Dated. Jan. 03. 2007Dokumen5 halamanMethod Statement - Plastering, Dated. Jan. 03. 2007mohamed4879Belum ada peringkat

- Paving Method StatementDokumen7 halamanPaving Method StatementOfentse LedwabaBelum ada peringkat

- Standard Specs - Masonry WorkDokumen7 halamanStandard Specs - Masonry Worknirmal sutharBelum ada peringkat

- Wms - Concrete Repairing Works (Pedestals)Dokumen4 halamanWms - Concrete Repairing Works (Pedestals)krmchari100% (1)

- Turfing ChecklistDokumen1 halamanTurfing ChecklistshukriBelum ada peringkat

- Repairing of Plaster WallsDokumen4 halamanRepairing of Plaster WallsSayan GharBelum ada peringkat

- Compressive Strength of Mortar CubeDokumen5 halamanCompressive Strength of Mortar CubeNadia Aman100% (1)

- Sikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarDokumen3 halamanSikagrout - 214: High Performance, Non Shrink, Expanding Cementitious Grouting MortarSulaim Al KautsarBelum ada peringkat

- Sample CHB InstallationDokumen11 halamanSample CHB InstallationCatherine CatacutanBelum ada peringkat

- METHOD OF BLINDING CONCRETE WORKSDokumen6 halamanMETHOD OF BLINDING CONCRETE WORKSMohd Muksin100% (1)

- Method Statement For Construction of EmbankmentDokumen6 halamanMethod Statement For Construction of EmbankmentRabnawaz Imam100% (1)

- Method Statement for Concrete WorksDokumen7 halamanMethod Statement for Concrete WorksJeffrey WeyBelum ada peringkat

- Method Statement For Shotcreting WorksDokumen4 halamanMethod Statement For Shotcreting Worksnagesh1234Belum ada peringkat

- Slump Test ReportDokumen4 halamanSlump Test ReportAzman ScxBelum ada peringkat

- Method Statement For Construction of Mastic Asphalt (As Per Clause 515 of MORTH Specification)Dokumen4 halamanMethod Statement For Construction of Mastic Asphalt (As Per Clause 515 of MORTH Specification)DeepakBelum ada peringkat

- AIPL WMS Granite Flooring MethodDokumen3 halamanAIPL WMS Granite Flooring MethodDeepak PatilBelum ada peringkat

- Methodolgy of Rigid Pavement: Friday, 13 July 2012Dokumen19 halamanMethodolgy of Rigid Pavement: Friday, 13 July 2012Mac Lester MartinBelum ada peringkat

- Method Statement For Cmu Block WorkDokumen8 halamanMethod Statement For Cmu Block WorkAnwar MohiuddinBelum ada peringkat

- Checklist For Batching PlantDokumen1 halamanChecklist For Batching Plantravi raghav100% (3)

- CHECKLIST FOR CONCRETING PROJECTSDokumen13 halamanCHECKLIST FOR CONCRETING PROJECTSMin Khant AungBelum ada peringkat

- Sobha Developers Pvt. Ltd. Blockwork ActivityDokumen5 halamanSobha Developers Pvt. Ltd. Blockwork ActivityVikram DhabaleBelum ada peringkat

- Method Statement of HACKING WORKS ON CONCRETE WALL FOR LIFTDokumen3 halamanMethod Statement of HACKING WORKS ON CONCRETE WALL FOR LIFTfaizbukhari100% (2)

- MOS of Installation Rise FloorDokumen13 halamanMOS of Installation Rise FloorHussam WaleedBelum ada peringkat

- Cube Test ReportDokumen9 halamanCube Test ReportAnabarat Prem67% (6)

- Sand Replacement Method.Dokumen3 halamanSand Replacement Method.stormchaser01Belum ada peringkat

- Method of Statement (Concrete Repair)Dokumen3 halamanMethod of Statement (Concrete Repair)Sa3id HassanBelum ada peringkat

- DEMOLITION OF WALLS FOR DOOR/WINDOW OPENINGSDokumen2 halamanDEMOLITION OF WALLS FOR DOOR/WINDOW OPENINGSDarlyn SagreBelum ada peringkat

- Method Statement For Application of Waterproofing MembraneDokumen5 halamanMethod Statement For Application of Waterproofing MembraneAnjo MolinaBelum ada peringkat

- Method StatementDokumen8 halamanMethod StatementardsilvaBelum ada peringkat

- 09 Method Statement of RR MASONRYDokumen6 halaman09 Method Statement of RR MASONRYvsshayan_237420762Belum ada peringkat

- Method Statement of Jack-In Pile PDFDokumen3 halamanMethod Statement of Jack-In Pile PDFAMIR ASYRAF ZAINUDIN100% (1)

- Method Statement For Shrinkage CracksDokumen2 halamanMethod Statement For Shrinkage Cracksluvvie87Belum ada peringkat

- Ms For ShotcreteDokumen12 halamanMs For ShotcreteAnonymous ExWAN2xjFJ100% (1)

- 1Dokumen3 halaman1Muhammad AsyrafBelum ada peringkat

- Method Statement-External Wall PlasteringDokumen3 halamanMethod Statement-External Wall PlasteringkrishBelum ada peringkat

- Concrete Slump Test ExplainedDokumen4 halamanConcrete Slump Test Explainedsmh khanBelum ada peringkat

- Test ProcedureDokumen27 halamanTest ProcedureAjayBelum ada peringkat

- 6.gypsum WorkDokumen7 halaman6.gypsum WorkShenbagaraja PandianBelum ada peringkat

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Dokumen10 halamanWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainBelum ada peringkat

- Reinforcement-Method StatementDokumen4 halamanReinforcement-Method StatementTATATAHERBelum ada peringkat

- Methodology For Groove Filling in VDFDokumen2 halamanMethodology For Groove Filling in VDFDeepak Patil100% (1)

- Concrete Placement (Spec)Dokumen18 halamanConcrete Placement (Spec)Vetrivel MuruganBelum ada peringkat

- SOP-03-27-compressive Strength of ConcreteDokumen2 halamanSOP-03-27-compressive Strength of Concretemukesh100% (1)

- CE 222 Lab Exercise 9Dokumen3 halamanCE 222 Lab Exercise 9Reyy ArbolerasBelum ada peringkat

- BS 1881-Part 102-83Dokumen10 halamanBS 1881-Part 102-83karuna346Belum ada peringkat

- Planning Process 12 Step CLUPDokumen10 halamanPlanning Process 12 Step CLUPLloyd R. Ponce100% (1)

- Galvalume Rolling ShuttersDokumen40 halamanGalvalume Rolling ShuttersLloyd R. PonceBelum ada peringkat

- Winds Peed To Pressure ConversionDokumen1 halamanWinds Peed To Pressure ConversionLloyd R. PonceBelum ada peringkat

- TN 76Dokumen6 halamanTN 76Lloyd R. Ponce100% (3)

- TSSC 65 - 410Dokumen1 halamanTSSC 65 - 410Lloyd R. PonceBelum ada peringkat

- Calculating Fiber Loss and DistanceDokumen4 halamanCalculating Fiber Loss and DistanceroomforsquaresBelum ada peringkat

- British Standard document reviewDokumen23 halamanBritish Standard document reviewLloyd R. PonceBelum ada peringkat

- TN 76Dokumen6 halamanTN 76Lloyd R. Ponce100% (3)

- What plumbing designers need to know about valve materials and ratingsDokumen4 halamanWhat plumbing designers need to know about valve materials and ratingsLloyd R. PonceBelum ada peringkat

- Braided Hose Expansion JointDokumen1 halamanBraided Hose Expansion JointLloyd R. PonceBelum ada peringkat

- DIN 17007-4-1963, Material Type NumberDokumen9 halamanDIN 17007-4-1963, Material Type NumberLloyd R. PonceBelum ada peringkat

- CLASS NOTES Chap 10 1 Bond & AnchorageDokumen13 halamanCLASS NOTES Chap 10 1 Bond & Anchoragekohatian27796105Belum ada peringkat

- BS 957-1-1941, Specification For Feeler Gauges PDFDokumen14 halamanBS 957-1-1941, Specification For Feeler Gauges PDFLloyd R. PonceBelum ada peringkat

- DIN 17155-1983, Creep Resistant Steel Plate and StripDokumen16 halamanDIN 17155-1983, Creep Resistant Steel Plate and StripLloyd R. Ponce100% (1)

- FanEffectPPT2 PDFDokumen41 halamanFanEffectPPT2 PDFJoel AlcantaraBelum ada peringkat

- Concrete Expansion JointsDokumen80 halamanConcrete Expansion JointsDiana Sekar Sari100% (1)

- Planning Mandates of Local GovernmentsDokumen20 halamanPlanning Mandates of Local GovernmentsLloyd R. PonceBelum ada peringkat

- Directive 2006-42-CE - Machinery PDFDokumen63 halamanDirective 2006-42-CE - Machinery PDFeng13Belum ada peringkat

- Filled Composite ColumnDokumen1 halamanFilled Composite ColumnLloyd R. PonceBelum ada peringkat

- A R A T I o N A L I Z e D L o C A L P L A N N I N G S y S T e M I N T H e P H I L I P P I N e SDokumen25 halamanA R A T I o N A L I Z e D L o C A L P L A N N I N G S y S T e M I N T H e P H I L I P P I N e SLloyd R. PonceBelum ada peringkat

- CrackDokumen83 halamanCrackSeba Roskopf100% (1)

- Fulltext01 Early Age ConcreteDokumen18 halamanFulltext01 Early Age ConcreteLloyd R. PonceBelum ada peringkat

- CrackDokumen83 halamanCrackSeba Roskopf100% (1)

- M-Bloc Type C SubmittalDokumen2 halamanM-Bloc Type C SubmittalLloyd R. PonceBelum ada peringkat

- Dow Corning 993 Product InfoDokumen4 halamanDow Corning 993 Product InfoLloyd R. PonceBelum ada peringkat

- Jet FansDokumen15 halamanJet FansLloyd R. PonceBelum ada peringkat

- FanEffectPPT2 PDFDokumen41 halamanFanEffectPPT2 PDFJoel AlcantaraBelum ada peringkat

- Finishing MaterialsDokumen13 halamanFinishing MaterialsLloyd R. PonceBelum ada peringkat

- EnP Ultimate Reviewer No. 2ADokumen22 halamanEnP Ultimate Reviewer No. 2ALloyd R. Ponce0% (1)

- MTC AluminumDokumen1 halamanMTC AluminumLloyd R. PonceBelum ada peringkat

- Reul Randolph Geotechnique2003Dokumen15 halamanReul Randolph Geotechnique2003YuryPasichnyBelum ada peringkat

- ASHRAE - STD 90.1 - 2007 Energy Standar For BuildingsDokumen80 halamanASHRAE - STD 90.1 - 2007 Energy Standar For BuildingsJohn Henry Ramos SantosBelum ada peringkat

- Problem 2Dokumen2 halamanProblem 2Nestor ReyesBelum ada peringkat

- Head loss calculation for Souq Waqif car parking projectDokumen1 halamanHead loss calculation for Souq Waqif car parking projectKarthy GanesanBelum ada peringkat

- ITW Product Catalog39 PDFDokumen1 halamanITW Product Catalog39 PDFjohnBelum ada peringkat

- HND in Civil Engineering Code Title Assessor / Examiner CE 403Dokumen27 halamanHND in Civil Engineering Code Title Assessor / Examiner CE 403Madav Balgobin100% (1)

- Rebar: Rebar Is The Common Name For Cylindrical Shaped Steel Bars With Uniformly Spaced ProtrusionsDokumen21 halamanRebar: Rebar Is The Common Name For Cylindrical Shaped Steel Bars With Uniformly Spaced ProtrusionsTimberly100% (1)

- DBR PDFDokumen7 halamanDBR PDFrajeev shahBelum ada peringkat

- Republic of the Philippines site and building plansDokumen5 halamanRepublic of the Philippines site and building plansDean DumaguingBelum ada peringkat

- Heat and Mass Transfer of Single Droplet Particle DryingDokumen9 halamanHeat and Mass Transfer of Single Droplet Particle DryingLiliam Teresita Manrique DelgadoBelum ada peringkat

- 8 - Comparative Study of Piled Raft Foundation PDFDokumen5 halaman8 - Comparative Study of Piled Raft Foundation PDFHaleem Ullah KhanBelum ada peringkat

- Bolts Torque CalculatorDokumen4 halamanBolts Torque Calculatorcaod1712Belum ada peringkat

- Bosch Washing Machine WAS32461GB 90004608573Dokumen6 halamanBosch Washing Machine WAS32461GB 90004608573David GoldBelum ada peringkat

- Al-Si Alloys - Microstructure and Mechanical PropertiesDokumen18 halamanAl-Si Alloys - Microstructure and Mechanical PropertiesSravan Kumar50Belum ada peringkat

- Build Community With an Ice RinkDokumen39 halamanBuild Community With an Ice RinkQOBITBelum ada peringkat

- JEE Physics AalneDokumen1 halamanJEE Physics AalneJUBIBelum ada peringkat

- APP002 - Mar 2017Dokumen10 halamanAPP002 - Mar 2017Morris KwokBelum ada peringkat

- Aerospace: Hi-Shear CorporationDokumen1 halamanAerospace: Hi-Shear CorporationJose Miguel Atehortua ArenasBelum ada peringkat

- A554-15 Standard Specification For Welded Stainless Steel Mechanical TubingDokumen8 halamanA554-15 Standard Specification For Welded Stainless Steel Mechanical TubingChuthaBelum ada peringkat

- Reinforced concrete beam and floor slab detailsDokumen1 halamanReinforced concrete beam and floor slab detailsRbcabajes ButalonBelum ada peringkat

- Hygrobar B WaterstopDokumen2 halamanHygrobar B WaterstopMahesh SavandappaBelum ada peringkat

- Nominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODDokumen6 halamanNominal Pipe Size NPS, Nominal Bore NB, Outside Diameter ODjigneshdalwadiBelum ada peringkat

- Hydro Test ProceduresDokumen6 halamanHydro Test ProcedureswillBelum ada peringkat

- Aluminium CastingDokumen35 halamanAluminium CastingAnkur Aggarwal100% (1)

- CDKB Case StudyDokumen3 halamanCDKB Case StudyFederico De MartiniBelum ada peringkat

- Weld-Defects A - TWI PDFDokumen97 halamanWeld-Defects A - TWI PDFMKPashaPasha100% (2)

- Mech1442851738363 PDFDokumen57 halamanMech1442851738363 PDFMonevBelum ada peringkat

- Suva R-507Dokumen2 halamanSuva R-507Eliott Noe Rumiche ChungaBelum ada peringkat

- Solutions For Agricultural FilmsDokumen12 halamanSolutions For Agricultural FilmsAlfredo Ch. LinoBelum ada peringkat

- 400 - PWF Manual 2001 - LRDokumen52 halaman400 - PWF Manual 2001 - LRMichelle JonesBelum ada peringkat