Certification Process of Storage Tank PDF

Diunggah oleh

dndudc0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

83 tayangan32 halamanTURK LOYDU is an independent, impartial classification, tifi ti d certification, and conformity assesment organization. With its Marine and Industry Divisions provides wide range of services; classification and statutory surveys of new building and existing ships.

Deskripsi Asli:

Judul Asli

Certification process of storage tank.pdf

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniTURK LOYDU is an independent, impartial classification, tifi ti d certification, and conformity assesment organization. With its Marine and Industry Divisions provides wide range of services; classification and statutory surveys of new building and existing ships.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

83 tayangan32 halamanCertification Process of Storage Tank PDF

Diunggah oleh

dndudcTURK LOYDU is an independent, impartial classification, tifi ti d certification, and conformity assesment organization. With its Marine and Industry Divisions provides wide range of services; classification and statutory surveys of new building and existing ships.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 32

CERTIFICATION PROCESS OF AN ATMOSPHERIC STORAGE TANK CERTIFICATIONPROCESSOFANATMOSPHERICSTORAGETANK

Presented b Eser Temi PresentedbyEserTemiz

TRK LOYDU TRKLOYDU

IndustryandCertificationDivision

1

WHOWEARE

TRKLOYDUisanindependent,

impartial

classification,

tifi ti d certification,and

conformityassesmentorganization.

WithitsMarineandIndustryDivisionsprovideswiderangeofservices;

Classificationandstatutorysurveysofnewbuildingandexistingships,andcertificationof

marinematerialsandproducts.

Thirdpartyinspections,CEmarkinginpressurevessels,systemcertifications,type

approvalsaresomeofthebusinessesamongsttheothers.

2

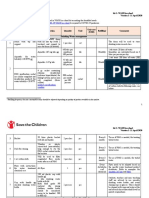

PHASESTOCERTIFICATION;

APPROVALOF

PROJECTSAND

CALCULATIONS

INSPECTION

OFFABRICATION

AND

CONSTRUCTION

FINALTESTS

QUALIFYINGOF

WELDING

PROCEDURESAND

WELDERS

CALCULATIONS

CONSTRUCTION WELDERS

3

APPROVALOFPROJECTSANDCALCULATIONSAREEXECUTEDACCORDINGTOAPI

650,653

WealsouseCOADEsoftwaretoverifythecalculationsanddesign,

To analyse the structure we use ANSYS program ToanalysethestructureweuseANSYSprogram.

4

BEFORECONSTRUCTIONOFATANKINTHEWORKSHOPANDINTHEPLANT

EXAMINATIONOF

QUALITYPLAN(ITP)

ISANESSENTIALSTEPNOTTOBEOVERLOOKED.

5

QUALIFICATIONOFWELDINGPROCEDURES

WeldingprocedurequalificationrecordsmustmeettherequirementsofSectionIXof

theASMECode.

Either AWSD1.1 or AWSD1.6 arealsoacceptableforladderand platformassemblies,

handrails,stairways,andothermiscellaneous assemblies,butnottheirattachmentsto

the tank. thetank.

6

QUALIFICATIONOFWELDERS

Theweldersandweldingoperatorsmust bequalified inaccordancewithSectionIXof

theASMECode.

7

INSPECTIONOFMATERIALS;

STEELPLATES

PIPES PIPES

PROFILES

FLANGESetc.

8

MARKING

Toenablethevariousfabricatedcomponentstobeassembledtogether

correctlyonsite,eachparthastobemarkedwithauniquenumbering

system.

Hardstampingmaybeusedaswell,butexceptfortheplateslessthan6

mmthick.

Markingalsoprovidestraceabilityofeachpieceofmaterial.

9

AFTERFORMINGOFSHELLPLATES

RADIUSOFEACHPLATEMUSTBECHECKED

NOTTOSPENDMUCHTIMEDURINGTHISSTEP,APREFORMEDPATTERNMODEL

MADEOFTHINMETALSHEETCANBEUSED.

PRIMERSHOULDBEAPPLIEDBEFORETRANSPORTINGTHESHEETSTOPLANT,AND

INCASEOFNOTTOAFFECTTHEQUALITYOFWELDS,ALLWELDFACESSHOULDBE

COVERED BY PAPER TAPE PREVIOUSLY TO KEEP CLEAN FROM PAINT RESIDUE COVEREDBYPAPERTAPEPREVIOUSLYTOKEEPCLEANFROMPAINTRESIDUE.

INCASEANYDEFORMATIONMAYOCCURDURINGTRANSPORTANDSTACKING,

PREFORMED SHELL PLATES SHOULD BE SETTLED ON A PACKSADDLE. PREFORMEDSHELLPLATESSHOULDBESETTLEDONAPACKSADDLE.

10

CONCRETERINGWALL,ANDBOTTOMSURFACEAREMEASUREDBYMEANSOF

TOTALSTATIONDEVICE.

APPROPRIATENESS OF DRAIN PIPES APPROPRIATENESSOFDRAINPIPES

ANCHORSARECHECKED

DIMENSIONS DIMENSIONS,

MATERIALTYPE

LOCATION

Tensiletestisrequiredforeach

partyofsteelrodsusedinthe

concrete

11

BOTTOMPLATESARESETTLEDACCORDINGTOPLATEORIENTATIONSCHEMEINTHE

APPROVEDPROJECT.

BOTTOMPLATESAREWELDEDAFTERCONSTRUCTINGOFCOARSES

LAPWELDEDBOTTOM

PLATESUNDERTANK

SHELL

12

TWOTYPESOFTANKFLOORINGARE;

BOTTOMDOWN:Generally,bottomdownisdesignforconerooftanks.Centre y g

oftheflooringisinstalledwithdrainpit.Waterinthetankis accumulatedinthepit

(lowestpointofthebottomplate/floor).

BOTTOMUP:Generally,thistypeofdesignisusedforfloatingrooftanks, 3to4

collectorpitsareinstalled,closetotheshellplate. Eachofthepitisprovidedwitha

waterdrawoffline.

Aslopeof1:120issuitable p

13

DRAWOFF SUMP DRAWOFFSUMP

Theerectionprocedureshallincludethefollowingsteps:

(a)aholeshallbecutinthebottomplateorasumpshall

beplacedinthe foundationbeforebottomplacement;

(b)aneatexcavationshallbemadetoconformtothe

shapeofthedrawoffsump,thesumpshallbeput inplace,

andthefoundationshallbecompactedaroundthesump

after placement; and afterplacement;and

(c)thesumpshallbeweldedtothebottom.

14

ADJUSTMENTOFFIRSTCOURSE

UPRIGHTNESS,ROUNDNESSANDDIAMETEROFTHECOURSEISMEASUREDMIN.

AT8POINTS.

ITISCONSIDEREDTHATTHEWELDSEAMSOFBOTTOMPLATESANDVERTICAL

SEAMSOFTHECOARSEARENOTTOBEINTERSECTEACHOTHER

15

ADJUSTMENTOFSECONDCOURSE

UPRIGHTNESS,ANDROUNDNESSOFTHESHELLISMEASUREDMIN.AT8POINTS.

THENVERTICALWELDSAREEXECUTEDOFTHEFIRSTCOURSE.

16

ADJUSTMENT OF THIRD COURSE ADJUSTMENTOFTHIRDCOURSE

UPRIGHTNESS AND ROUNDNESS OF THE SHELL IS MEASURED MIN AT 8 POINTS UPRIGHTNESS,ANDROUNDNESSOFTHESHELLISMEASUREDMIN.AT8POINTS.

THEN,VERTICALANDCIRCUMFERENTIALWELDSOFTHESECONDCOURSEARE

EXECUTED. EXECUTED.

SUCHPRINCIPLEISFOLLOWEDFORTHEOTHERCOURSES.

17

FOURTH

THIRD

FIRST

SECOND

COURSE

18

TYPICALANCHORAGE

19

TYPICALANCHORAGE

20

AFTER COMPLETING ALL WELDS OF THE COURSES BOTTOM PLATES ARE WELDED AFTERCOMPLETINGALLWELDSOFTHECOURSES,BOTTOMPLATESAREWELDED.

THENVACUUMTESTISPERFORMED.

Vacuumtestingisperformedusingatesting box

approximately150mm(6in.)wideby750mm

(30in.)long withaclearwindowinthetop,

whichprovidespropervisibility toviewthearea

underinspection.

Duringtesting,illumination shallbeadequate g g, q

forproperevaluationand interpretationofthe

test.

Theopenbottomshallbesealed againstthe

tank surface by a suitable gasket Connections tanksurfacebyasuitablegasket.Connections,

valves,lightingandgauges,shallbeprovidedas

required.

A soapfilmsolutionor commercial,leak

detectionsolution, applicabletotheconditions,

shallbeused.

21

CONSTRUCTION OF ROOF CONSTRUCTIONOFROOF

22

TYPICAL WELD JOINTS AT ROOF TYPICALWELDJOINTSATROOF

23

NON DESTRUCTIVE EXAMINATION OF A TANK NONDESTRUCTIVEEXAMINATIONOFATANK

Complete penetration and complete fusion are required for welds joining shell Completepenetrationandcompletefusionarerequiredfor weldsjoiningshell

platestoshellplates.

Inspection for the quality of the welds shall be made using either the radiographic Inspectionforthe qualityoftheweldsshallbemadeusingeithertheradiographic

method, oralternatively,byagreement betweenthepurchaserandthe

manufacturer,usingtheultrasonic method.Inadditiontotheradiographic or

ultrasonicexamination,theseweldsarealsovisuallyexamined. , y

Ingeneral,radiographicinspectionisrequiredforshellbuttwelds,annularplate

buttwelds,andflushtypeconnectionswithbuttwelds.

24

TESTINGOFTHESHELL

Aftertheentiretankandroofstructureiscompleted,the shellis testedbyoneofthe

following methods:

1 Ifwaterisavailablefortestingtheshell,thetankshallbe filledwithwateras follows:

itothemaximumdesignliquid level;

iiforatankwithatightroof,to50mmabovetheweldconnectingtheroofplateor

compressionbar tothetopangleorshell

2 Ifsufficientwatertofillthetankisnotavailable,thetank maybetestedby painting

ll f th j i t th i id ith hi hl t ti il allofthejointsontheinside withahighlypenetratingoil

25

FIREPROTECTION

FireprotectionsystemshallbeestablishedaccordingtotheNFPAstandards.

Thissystemisinspectedduringmanufacturingoftheinstallationandafterthat y p g g

functions,andperformanceareexamined.

Systemshallinclude;

Foambasedextinguishing,

Watercooling

Monitors

Dikeprotection

26

FIREPROTECTION

Forthecoolingwaterratesthestandardsdonotprovidecogruentvalues.

Theyonlyprescribeminimumwaterflowrates

API2030 :4.1litersperminutepersquaremeter

NFPA15 :10.5liters/min.m

2

IP19 :2liters/min.m

2

TobeonthesafesideforexposureprotectionwerecommendandapplyNFPA

rate. rate.

27

CATHODICPROTECTION

Bothsacrificialanodesystemorimpressedcurrentsystemareacceptable.

ThemainstandardforthisstepisAPI651. p

28

EARTHING

Tominimizetheaccumulationofelectrostaticchargeandprevent sparks,all

metalpartsofthestorageinstallationmust bebondedtogetherandearthed.

Maximumresistancetoearthof10ohmsisrecommended.

29

Aftercompletingallstructureofthetank,forthesurfacesoftheweldseams

and sides of the seams affected by heat; andsidesoftheseamsaffectedbyheat;

First,shotblastingthen

primerpaintshouldbeappliedbeforewholetankispainted.

30

AFTER PAINTING TANK IS READY TO BE CERTIFIED AFTERPAINTING,TANKISREADYTOBECERTIFIED.

31

Thanks you for your attention Thanksyouforyourattention

32

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Rigging Safety in Cranes PDFDokumen170 halamanRigging Safety in Cranes PDFLuis AcuaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Anchor Handling Tug Pre-Mob InspectionDokumen8 halamanAnchor Handling Tug Pre-Mob Inspectiondndudc100% (1)

- Cathodic Protection 2007Dokumen141 halamanCathodic Protection 2007arsssyBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Critical Path Method (CPM) in Project ManagementDokumen11 halamanCritical Path Method (CPM) in Project ManagementdndudcBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Offshore Book 2010Dokumen117 halamanOffshore Book 2010Mos Woraphon100% (1)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Check List - Air Compressor InspectionDokumen1 halamanCheck List - Air Compressor Inspectiondndudc100% (4)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- P6 - Manual Basic PDFDokumen230 halamanP6 - Manual Basic PDFdndudcBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- 101 6.0 Student GoldDokumen332 halaman101 6.0 Student Goldjmurzin100% (6)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Offshore Pipelaying Dynamic PDFDokumen150 halamanOffshore Pipelaying Dynamic PDFdndudcBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Primavera P6 Exercise WorksheetDokumen35 halamanPrimavera P6 Exercise Worksheetdyeyson3095% (19)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Primavera P6 Reports Tab SamplesDokumen27 halamanPrimavera P6 Reports Tab Samplestensix100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- General Description of Quay Wall Type PDFDokumen6 halamanGeneral Description of Quay Wall Type PDFdndudcBelum ada peringkat

- Plant Commissioning Start Up ProcedureDokumen100 halamanPlant Commissioning Start Up Proceduremsaad292% (124)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Primavera (P6)Dokumen316 halamanPrimavera (P6)Abde Ali83% (6)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- H - Quay Walls Restoriation Method StatementDokumen34 halamanH - Quay Walls Restoriation Method StatementVimalan Kannan100% (1)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Wireline Log Quality Control Reference ManualDokumen280 halamanWireline Log Quality Control Reference ManualMohamed Abd El-ma'boud83% (6)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- P6 Reference ManualDokumen550 halamanP6 Reference Manualsaluthomas100% (22)

- Wharf Design and AnalysisDokumen8 halamanWharf Design and AnalysisklynchelleBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- 5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepDokumen21 halaman5 - Technical Specifications For Sand & Murrum Filling Works - Pile Foundation For Tanks - ParadeepArup NathBelum ada peringkat

- Quay Construction With Concrete Caisson PDFDokumen5 halamanQuay Construction With Concrete Caisson PDFdndudcBelum ada peringkat

- Construction of A Breakwater and A Quay Wall Made of Box CaissonsDokumen2 halamanConstruction of A Breakwater and A Quay Wall Made of Box CaissonsAhmad Balah100% (1)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Quay Walls Design Guide Lines PDFDokumen151 halamanQuay Walls Design Guide Lines PDFkaleswara_tellakula100% (2)

- Construction Presentation - Container Terminal PDFDokumen60 halamanConstruction Presentation - Container Terminal PDFdndudc100% (1)

- Construction Quality ManualDokumen42 halamanConstruction Quality ManualBob Madlener100% (7)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Study of Breakwaters Constructed With One Layer of Armor Stone PDFDokumen58 halamanStudy of Breakwaters Constructed With One Layer of Armor Stone PDFdndudcBelum ada peringkat

- Quay Wall Construction PDFDokumen8 halamanQuay Wall Construction PDFdndudcBelum ada peringkat

- Metode Konstruksi Reklamasi PantaiDokumen55 halamanMetode Konstruksi Reklamasi PantaiHosea Luahambowo100% (1)

- Cape Charles Town Harbor PDFDokumen15 halamanCape Charles Town Harbor PDFdndudcBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- Sand Mound ManualDokumen60 halamanSand Mound ManualFlavio Jose MuhaleBelum ada peringkat

- EMI-EMC - SHORT Q and ADokumen5 halamanEMI-EMC - SHORT Q and AVENKAT PATILBelum ada peringkat

- Prepositions Below by in On To of Above at Between From/toDokumen2 halamanPrepositions Below by in On To of Above at Between From/toVille VianBelum ada peringkat

- S SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesDokumen3 halamanS SSB29 - Alternator Cables PM: WARNING: This Equipment Contains Hazardous VoltagesMohan PreethBelum ada peringkat

- MNO Manuale Centrifughe IngleseDokumen52 halamanMNO Manuale Centrifughe IngleseChrist Rodney MAKANABelum ada peringkat

- SPIE Oil & Gas Services: Pressure VesselsDokumen56 halamanSPIE Oil & Gas Services: Pressure VesselsSadashiw PatilBelum ada peringkat

- Community-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDokumen28 halamanCommunity-Based Monitoring System (CBMS) : An Overview: Celia M. ReyesDiane Rose LacenaBelum ada peringkat

- A Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentDokumen7 halamanA Perspective Study On Fly Ash-Lime-Gypsum Bricks and Hollow Blocks For Low Cost Housing DevelopmentNadiah AUlia SalihiBelum ada peringkat

- Brother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDokumen123 halamanBrother Fax 100, 570, 615, 625, 635, 675, 575m, 715m, 725m, 590dt, 590mc, 825mc, 875mc Service ManualDuplessisBelum ada peringkat

- DFUN Battery Monitoring Solution Project Reference 2022 V5.0Dokumen50 halamanDFUN Battery Monitoring Solution Project Reference 2022 V5.0A Leon RBelum ada peringkat

- NYLJtuesday BDokumen28 halamanNYLJtuesday BPhilip Scofield50% (2)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- 254 AssignmentDokumen3 halaman254 AssignmentSavera Mizan ShuptiBelum ada peringkat

- Contemp World Module 2 Topics 1 4Dokumen95 halamanContemp World Module 2 Topics 1 4Miguel EderBelum ada peringkat

- Technical Engineering PEEDokumen3 halamanTechnical Engineering PEEMariano Acosta Landicho Jr.Belum ada peringkat

- 19-2 Clericis LaicosDokumen3 halaman19-2 Clericis LaicosC C Bờm BờmBelum ada peringkat

- Moparm Action - December 2014 USADokumen100 halamanMoparm Action - December 2014 USAenricoioBelum ada peringkat

- R 18 Model B Installation of TC Auxiliary Lights and WingletsDokumen29 halamanR 18 Model B Installation of TC Auxiliary Lights and WingletsAlejandro RodríguezBelum ada peringkat

- Sena BrochureDokumen5 halamanSena BrochureNICOLAS GUERRERO ARANGOBelum ada peringkat

- Reverse Osmosis ProcessDokumen10 halamanReverse Osmosis ProcessHeshamBelum ada peringkat

- Database Management System and SQL CommandsDokumen3 halamanDatabase Management System and SQL Commandsdev guptaBelum ada peringkat

- ILRF Soccer Ball ReportDokumen40 halamanILRF Soccer Ball ReportgabalauiBelum ada peringkat

- Tekla Structures ToturialsDokumen35 halamanTekla Structures ToturialsvfmgBelum ada peringkat

- On Applied EthicsDokumen34 halamanOn Applied Ethicsamanpatel78667% (3)

- Brush Seal Application As Replacement of Labyrinth SealsDokumen15 halamanBrush Seal Application As Replacement of Labyrinth SealsGeorge J AlukkalBelum ada peringkat

- 1.2 The Main Components of Computer SystemsDokumen11 halaman1.2 The Main Components of Computer SystemsAdithya ShettyBelum ada peringkat

- LR Format 1.2Dokumen1 halamanLR Format 1.2Ch.Suresh SuryaBelum ada peringkat

- Occupational Therapy in Mental HealthDokumen16 halamanOccupational Therapy in Mental HealthjethasBelum ada peringkat

- Kit 2: Essential COVID-19 WASH in SchoolDokumen8 halamanKit 2: Essential COVID-19 WASH in SchooltamanimoBelum ada peringkat

- The Voice of The Villages - December 2014Dokumen48 halamanThe Voice of The Villages - December 2014The Gayton Group of ParishesBelum ada peringkat

- Fact Pack Financial Services KenyaDokumen12 halamanFact Pack Financial Services KenyaCatherineBelum ada peringkat

- Is 778 - Copper Alloy ValvesDokumen27 halamanIs 778 - Copper Alloy ValvesMuthu KumaranBelum ada peringkat