BS en 12390-6 2000 (En)

Diunggah oleh

msohaibazizJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

BS en 12390-6 2000 (En)

Diunggah oleh

msohaibazizHak Cipta:

Format Tersedia

BRITISH STANDARD

BS EN

12390-6:2000

Incorporating

Corrigendum No. 1

Testing hardened

concrete

Part 6: Tensile splitting strength of

test specimens

The European Standard EN 12390-6:2000 has the status of a

British Standard

ICS 91.100.30

12 &23<,1* :,7+287 %6, 3(50,66,21 (;&(37 $6 3(50,77(' %< &23<5,*+7 /$:

BS EN 12390-6:2000

This British Standard, having

been prepared under the

direction of the Sector

Committee for Building and

Civil Engineering, was

published under the authority

of the Standards Policy and

Strategy Committee on

15 December 2000

BSI 17 November 2004

ISBN 0 580 36606 5

National foreword

This British Standard is the official English language version of

EN 12390-6:2000, including Corrigendum September 2004. It will supersede

BS 1881-117:1983, which will be withdrawn in 2003 when the full package of

concrete standards is available.

The UK participation in its preparation was entrusted to Technical Committee

B/517, Concrete, to Subcommittee B/517/1, Concrete production and testing,

which has the responsibility to:

A list of organizations represented on this subcommittee can be obtained on

request to its secretary.

Cross-references

The British Standards which implement international or European

publications referred to in this document may be found in the BSI Catalogue

under the section entitled International Standards Correspondence Index, or

by using the Search facility of the BSI Electronic Catalogue or of British

Standards Online.

This publication does not purport to include all the necessary provisions of a

contract. Users are responsible for its correct application.

Compliance with a British Standard does not of itself confer immunity

from legal obligations.

aid enquirers to understand the text;

present to the responsible international/European committee any

enquiries on the interpretation, or proposals for change, and keep the

UK interests informed;

monitor related international and European developments and

promulgate them in the UK.

Summary of pages

This document comprises a front cover, an inside front cover, the EN title page,

pages 2 to 10, an inside back cover and a back cover.

The BSI copyright notice displayed in this document indicates when the

document was last issued.

Amendments issued since publication

Amd. No. Date Comments

15439

Incorporating Corrigendum No. 1

17 November 2004 Amended foreword and

changes to subclause 6.3

EUROPEAN STANDARD

NORME EUROPENNE

EUROPISCHE NORM

EN 12390-6

October 2000

ICS 91.100.30 Incorporating corrigendum September 2004

English version

Testing hardened concrete - Part 6: Tensile splitting strength of

test specimens

Essai pour bton durci - Partie 6: Rsistance en traction par

fendage d'prouvettes

Prfung von Festbeton - Teil 6: Spaltzugfestigkeit von

Probekrpern

This European Standard was approved by CEN on 18 February 2000.

CEN members are bound to comply with the CEN/CENELEC Internal Regulations which stipulate the conditions for giving this European

Standard the status of a national standard without any alteration. Up-to-date lists and bibliographical references concerning such national

standards may be obtained on application to the Management Centre or to any CEN member.

This European Standard exists in three official versions (English, French, German). A version in any other language made by translation

under the responsibility of a CEN member into its own language and notified to the Management Centre has the same status as the official

versions.

CEN members are the national standards bodies of Austria, Belgium, Czech Republic, Denmark, Finland, France, Germany, Greece,

Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden, Switzerland and United Kingdom.

EUROPEAN COMMITTEE FOR STANDARDIZATION

COMI T EUROPEN DE NORMALI SATI ON

EUROPI SCHES KOMI TEE FR NORMUNG

Management Centre: rue de Stassart, 36 B-1050 Brussels

2000 CEN All rights of exploitation in any form and by any means reserved

worldwide for CEN national Members.

Ref. No. EN 12390-6:2000 E

Page 2

EN 12390-6:2000

Contents

Page

Foreword........................................................................................................................................................................... 3

1 Scope ........................................................................................................................................................................... 4

2 Normative references................................................................................................................................................. 4

3 Principle....................................................................................................................................................................... 4

4 Apparatus.................................................................................................................................................................... 4

5 Test specimens........................................................................................................................................................... 5

6 Procedures.................................................................................................................................................................. 6

7 Expression of results................................................................................................................................................. 7

8 Test Report.................................................................................................................................................................. 8

9 Precision...................................................................................................................................................................... 8

Annex A (normative) Determination of tensile splitting strength using cubic or prismatic specimens............ 9

Figure 1 - Jig for testing cylindrical specimens........................................................................................................... 5

Figure 2 - Curved loading piece..................................................................................................................................... 7

Page 3

EN 12390-6:2000

Foreword

This European Standard has been prepared by Technical Committee CEN/TC 104, Concrete (performance,

production, placing and compliance criteria), the Secretariat of which is held by DIN.

This European Standard shall be given the status of a national standard, either by publication of an identical text or

by endorsement, at the latest by April 2001, and conflicting national standards shall be withdrawn at the latest by

December 2003.

According to the CEN/CENELEC Internal Regulations, the national standards organizations of the following

countries are bound to implement this European Standard: Austria, Belgium, Czech Republic, Denmark, Finland,

France, Germany, Greece, Iceland, Ireland, Italy, Luxembourg, Netherlands, Norway, Portugal, Spain, Sweden,

Switzerland and the United Kingdom.

This standard is one of a series concerned with testing concrete.

It is based on the International Standard ISO 4108 Concrete Determination of tensile splitting strength of test

specimens.

It is recognized good practice to include measurement of density prior to the determination of tensile splitting

strength, as a check on compaction.

This test method was one of a number examined in a Laboratory inter-comparison part-funded by the EC under

Measurement and Testing programme, contract MAT1-CT94-0043. The programme and other references showed

the following:

a) Tensile splitting strengths measured between the normal plane platens of testing machines, gave the same results

as those using the special curved platens, originally described in ISO 4018. Although, therefore these curved platens

have been optionally retained in this standard, they are not necessary for the measurement.

b) The material used for the packing strips affects the apparent tensile strength measured. This has led to the

decision to standardize on hardboard strips, since they provided the lowest standard deviations.

c) The apparent tensile strength measured depends upon the shape and size of the test specimen used:

cubes gave higher measured tensile strengths than cylinders, by approximately 10 %;

150 mm cubes gave lower measured tensile strengths than 100 mm cubes;

the effect of cylinder size on measured tensile strength was not found to be significant, possibly due to the

variability of the data.

As a result of these conclusions from the laboratory programme, this standard restricts the measurement of tensile

splitting strength to cylindrical specimens used with hardboard packing strips, which is the reference method.

However, as some countries still test cubical or prismatic specimens, their use has been retained in a normative

annex. In cases of dispute, the reference method is the use of cylinders of 150 mm diameter and 300 mm length.

A draft for this standard was published in 1996 for CEN enquiry as prEN 12362. It was one of a series of

individually numbered test methods for fresh or hardened concrete. For convenience it has now been decided to

combine these separate draft standards into three new standards with separate parts for each method, as follows:

- Testing fresh concrete (EN 12350)

- Testing hardened concrete (EN 12390)

- Testing concrete in structures (EN 12504)

Page 4

EN 12390-6:2000

The series EN 12390 includes the following parts where the brackets give the numbers under which particular test

methods were published for CEN enquiry:

EN 12390 Testing hardened concrete -

Part 1: Shape, dimensions and other requirements of specimens and moulds (former prEN 12356:1996)

Part 2: Making and curing specimens for strength tests (former prEN 12379:1996)

Part 3: Compressive strength of test specimens (former prEN 12394:1996)

Part 4: Compressive strength - Specification for testing machines (former prEN 12390:1996)

Part 5: Flexural strength of test specimens (former prEN 12359:1996)

Part 6: Tensile splitting strength of test specimens (former prEN 12362:1996)

Part 7: Density of hardened concrete (former prEN 12363:1996)

Part 8: Depth of penetration of water under pressure (former prEN 12364:1996)

1 Scope

This standard specifies a method for the determination of the tensile splitting strength of cylindrical test specimens of

hardened concrete. A method using cubic or prismatic specimens is included in annex A (normative).

2 Normative references

This European Standard incorporates by dated or undated reference, provisions from other publications. These

normative references are cited at the appropriate places in the text and the publications are listed hereafter. For

dated references, subsequent amendments to or revisions of any of these publications apply to this European

Standard only when incorporated in it by amendment or revision. For undated references the latest edition of the

publication referred to applies (including amendments).

EN 12350-1, Testing fresh concrete Part 1: Sampling.

EN 12390-1, Testing hardened concrete Part 1: Shape, dimensions and other requirements of specimens and

moulds.

EN 12390-2, Testing hardened concrete Part 2: Making and curing specimens for strength tests.

EN 12390-4, Testing hardened concrete Part 4: Compressive strength Specification for testing machines.

EN 316, Wood fibreboards - Definition, classification and symbols.

3 Principle

A cylindrical specimen is subjected to a compressive force applied to a narrow region along its length. The resulting

orthogonal tensile force causes the specimen to fail in tension.

4 Apparatus

4.1 Testing machine, of EN 12390-4.

Curved steel loading pieces may be used in place of conventional plane platens, when tests are carried out on cubic

or prismatic specimen.

4.2 Jig (optional), for positioning the specimen and the packing strips. The jig shall not restrict the deformation of

the specimen during the test.

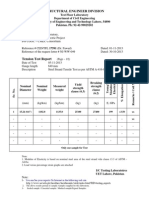

NOTE A suitable jig for cylindrical specimens is shown in figure 1.

Page 5

EN 12390-6:2000

4.3 Packing strips, conforming to EN 316, made of hardboard, of density > 900 kg/m and dimensions, width

(a) = (10 1) mm; thickness (t) = (4 1) mm and a length greater than the length of the line of contact of the test

specimen. Hardboard packing strips shall be used only once.

Dimensions in millimetres

Key

1 Steel loading piece

2 Hardboard packing strips

Figure 1 - Jig for testing cylindrical specimens

5 Test specimens

5.1 General

The test specimens shall be cylindrical, conforming to EN 12390-1, but a length/diameter ratio as low as 1 shall be

acceptable for cores. Specimens cast in moulds shall conform to EN 12350-1 and EN 12390-2.

The specimens shall be examined and any abnormalities observed shall be reported.

5.2 Adjustment of test specimens

Where the dimensions or shapes of test specimens do not conform to EN 12390-1, because they exceed the

respective tolerances, they shall be rejected or adjusted as follows:

uneven surfaces shall be levelled by grinding;

the deviation of angles shall be corrected by cutting and/or grinding.

5.3 Marking

Unless a centring jig is used, two lines shall be marked along which to apply the load. These lines shall be opposite

each other in an axial plane and the extremities of the two lines shall be connected over each end of the specimen, to

define clearly the plane of loading.

Page 6

EN 12390-6:2000

6 Procedures

6.1 Specimen preparation

For specimens stored in water, wipe any excess moisture from the surface of the specimen before placing in the

testing machine.

Wipe the bearing surfaces of the jig, packing strips, loading pieces and platens. Clean and remove any loose grit or

other extraneous material from the surface of the specimen that will be in contact with the packing strips.

6.2 Specimen positioning

Place the test specimen centrally in the testing machine, optionally using a jig. Carefully position packing strips and,

if required, loading pieces,along the top and bottom of the plane of loading of the specimen.

Ensure that the upper platen is parallel with the lower platen, during loading.

6.3 Loading

Ensure that the specimen remains centred when the load is first applied, either by means of a jig or by temporary

supports.

Select a constant rate of loading within the range 0,04 MPa/s (N/mm x s) to 0,06 MPa/s (N/mm x s). Apply the load

without shock and increase continuously, at the selected constant rate 10 %, until no greater load can be sustained.

NOTE The required loading rate on the testing machine is given by the formula:

2

x x x

R

d L s

=

where:

R is the rate of increase of load, in newtons per second;

L is the length of the specimen, in millimetres (see Figure 2);

d is the designated dimension of the specimen, in millimetres;

s is the increase in rate of stress, in megapascals per second, or newtons per square millimetre per second.

When using manually controlled testing machines, correct any tendency for the selected rate of loading to decrease,

as specimen failure is approached, by appropriate adjustment of the controls.

When using automatically controlled testing machines, check the rate of loading periodically, to ensure that the rate is

constant.

Record the maximum load indicated.

Page 7

EN 12390-6:2000

6.4 Examination of specimen

Examine the fractured specimen and the appearance of the concrete and record, if unusual.

Dimensions in millimetres

Key

1 Steel loading piece

2 Hardboard packing strips

3 Segment may be trimmed

Figure 2 - Curved loading piece

7 Expression of results

The tensile splitting strength is given by the formula:

d L

F

=

ct

x x

x 2

f

where

f

ct

is the tensile splitting strength, in megapascals or newtons per square millimetre;

F is the maximum load, in newtons;

L is the length of the line of contact of the specimen, in millimetres;

d is the designated cross-sectional dimension, in millimetres.

NOTE For deviations from the standard method in respect of the dimensions of the specimen, the strength

calculation may be based on the actual dimensions of the test specimen.

Express the tensile splitting strength to the nearest 0,05 MPa (N/mm).

Page 8

EN 12390-6:2000

8 Test report

The test report shall include:

a) identification of the test specimen;

b) details of adjustment (if appropriate);

c) surface moisture condition at time of test;

d) date of test;

e) appearance of concrete and type of fracture (if unusual);

f) tensile splitting strength of specimen (to nearest 0,05 MPa or 0,05 N/mm);

g) deviations from the standard method of testing;

h) a declaration from the person technically responsible for the test that the testing was carried out in accordance with

this standard except as detailed in item g).

9 Precision

There is currently no precision data for this test.

Page 9

EN 12390-6:2000

Annex A

(normative)

Determination of tensile splitting strength using cubic or prismatic specimens

A.1 Scope

This annex specifies a method for the determination of the tensile splitting strength of cubic and prismatic test

specimens of hardened concrete.

A.2 Normative references

See clause 2

A.3 Principle

A prismatic specimen is subjected to a compressive force applied to a narrow region. The resulting orthogonal tensile

force causes the specimen to fail in tension.

A.4 Apparatus

A.4.1 Testing Machine EN 12390-4.

Curved steel loading pieces may be used in place of or in addition to conventional plane platens (see figure 2).

A.4.2 Jig (optional)

A jig may be used for positioning the specimen and the packing strips. The jig shall not restrict the deformation of the

specimen during the test.

A.4.3 Packing strips

See 4.3

A.5 Test specimens

A.5.1 Requirements

The test specimens shall be cubic or prismatic, conforming to EN 12350-1, EN 12390-1 and EN 12390-2.

The specimens shall be examined and any abnormalities observed shall be reported.

A.5.2 Adjustment of test specimens

See 5.2

A.5.3 Marking

See 5.3

Page 10

EN 12390-6:2000

A.6 Procedures

The requirements of 6.1 apply.

The plane of loading shall be perpendicular to the trowelled surface.

A.7 Expression of results

See clause 7

NOTE The result obtained from testing a prismatic specimen of concrete is likely to be some 10 % higher than

that obtained from testing a cylindrical specimen of the same concrete.

A.8 Test report

The test report shall include the items listed in clause 8 and in addition it shall be stated that the specimen was cubic

or prismatic and the dimensions of the specimen shall be reported.

A.9 Precision

There is currently no precision data for this test.

blank

BS EN

12390-6:2000

BSI

389 Chiswick High Road

London

W4 4AL

BSI British Standards Institution

BSI is the independent national body responsible for preparing

British Standards. It presents the UK view on standards in Europe and at the

international level. It is incorporated by Royal Charter.

Revisions

British Standards are updated by amendment or revision. Users of

British Standards should make sure that they possess the latest amendments or

editions.

It is the constant aim of BSI to improve the quality of our products and services.

We would be grateful if anyone finding an inaccuracy or ambiguity while using

this British Standard would inform the Secretary of the technical committee

responsible, the identity of which can be found on the inside front cover.

Tel: +44 (0)20 8996 9000. Fax: +44 (0)20 8996 7400.

BSI offers members an individual updating service called PLUS which ensures

that subscribers automatically receive the latest editions of standards.

Buying standards

Orders for all BSI, international and foreign standards publications should be

addressed to Customer Services. Tel: +44 (0)20 8996 9001.

Fax: +44 (0)20 8996 7001. Email: orders@bsi-global.com. Standards are also

available from the BSI website at http://www.bsi-global.com.

In response to orders for international standards, it is BSI policy to supply the

BSI implementation of those that have been published as British Standards,

unless otherwise requested.

Information on standards

BSI provides a wide range of information on national, European and

international standards through its Library and its Technical Help to Exporters

Service. Various BSI electronic information services are also available which give

details on all its products and services. Contact the Information Centre.

Tel: +44 (0)20 8996 7111. Fax: +44 (0)20 8996 7048. Email: info@bsi-global.com.

Subscribing members of BSI are kept up to date with standards developments

and receive substantial discounts on the purchase price of standards. For details

of these and other benefits contact Membership Administration.

Tel: +44 (0)20 8996 7002. Fax: +44 (0)20 8996 7001.

Email: membership@bsi-global.com.

Information regarding online access to British Standards via British Standards

Online can be found at http://www.bsi-global.com/bsonline.

Further information about BSI is available on the BSI website at

http://www.bsi-global.com.

Copyright

Copyright subsists in all BSI publications. BSI also holds the copyright, in the

UK, of the publications of the international standardization bodies. Except as

permitted under the Copyright, Designs and Patents Act 1988 no extract may be

reproduced, stored in a retrieval system or transmitted in any form or by any

means electronic, photocopying, recording or otherwise without prior written

permission from BSI.

This does not preclude the free use, in the course of implementing the standard,

of necessary details such as symbols, and size, type or grade designations. If these

details are to be used for any other purpose than implementation then the prior

written permission of BSI must be obtained.

Details and advice can be obtained from the Copyright & Licensing Manager.

Tel: +44 (0)20 8996 7070. Fax: +44 (0)20 8996 7553.

Email: copyright@bsi-global.com.

Anda mungkin juga menyukai

- BS EN 12350-3-2009 Vebe Test PDFDokumen12 halamanBS EN 12350-3-2009 Vebe Test PDFMichelle Lee Sze Yee100% (2)

- BS en 12390-5-2009 Part 5 Flexural Strength of Test SpecimensDokumen14 halamanBS en 12390-5-2009 Part 5 Flexural Strength of Test SpecimensOmar Salama100% (2)

- BS en 12390-6-2009Dokumen14 halamanBS en 12390-6-2009Abu Alhassan A.100% (1)

- BS en 12390-2Dokumen10 halamanBS en 12390-2Vaqif Ahmedov100% (1)

- Bs en 12350 6 2009 1pdfDokumen14 halamanBs en 12350 6 2009 1pdfTIM100% (3)

- BS EN 12350-2 (2009) Slump TestDokumen12 halamanBS EN 12350-2 (2009) Slump TestAbderrahmaneTemhachet100% (5)

- Part 6 Aggregates For Unbound and Hydraulically Bound MaterialsDokumen34 halamanPart 6 Aggregates For Unbound and Hydraulically Bound MaterialsCristian Giurgea100% (2)

- BS en 480-4-2005 PDFDokumen8 halamanBS en 480-4-2005 PDFBesmir BeqiriBelum ada peringkat

- Air Content - Pressure PDFDokumen28 halamanAir Content - Pressure PDFMuhammad ImranBelum ada peringkat

- Testing Fresh Concrete: BS EN 12350-2:2019Dokumen12 halamanTesting Fresh Concrete: BS EN 12350-2:2019resty manuel100% (2)

- BS en 12350-4Dokumen9 halamanBS en 12350-4Noble Obeng-Ankamah100% (1)

- BS en 1097-1-2011Dokumen18 halamanBS en 1097-1-2011Kavitha ArumugamBelum ada peringkat

- 12350-10 Fresh ConcreteDokumen14 halaman12350-10 Fresh ConcreteTeguh Farid Nurul Iman100% (3)

- BS en 12390-1-2012Dokumen18 halamanBS en 12390-1-2012Ashraf Tomizeh60% (5)

- Bsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsDokumen14 halamanBsi 6073-2 Concrete Specifying Pre-Cast Masonry UnitsEngr. Jahanzeb MaharBelum ada peringkat

- En 14721Dokumen7 halamanEn 14721Kaan TekinturhanBelum ada peringkat

- 7-00Dokumen20 halaman7-00Anonymous ouZFaSBR100% (1)

- BS en 14487-2-2006Dokumen20 halamanBS en 14487-2-2006Thanh Hai QB50% (2)

- BS en 1015 - 17 Chloride ContentDokumen12 halamanBS en 1015 - 17 Chloride ContentpboliverBelum ada peringkat

- EN 933 PT 1-12Dokumen22 halamanEN 933 PT 1-12龙琦Belum ada peringkat

- BS en 12350 8 PDFDokumen14 halamanBS en 12350 8 PDFAhmad Khreisat0% (1)

- BS en 13139 PDFDokumen10 halamanBS en 13139 PDFanilkumar_bojja97600% (1)

- BS en 12350-12-2010Dokumen14 halamanBS en 12350-12-2010cevivekt100% (1)

- BS en 933-8-1999 PDFDokumen12 halamanBS en 933-8-1999 PDFMohammad Twaha JaumbocusBelum ada peringkat

- Concrete - en 206 ExampleDokumen11 halamanConcrete - en 206 ExampleKelvin Bong100% (1)

- BS en 12390-3Dokumen18 halamanBS en 12390-3Vaqif Ahmedov100% (2)

- Testing Fresh Concrete: BS EN 12350-7:2019Dokumen28 halamanTesting Fresh Concrete: BS EN 12350-7:2019resty manuel0% (1)

- BS 1881 Part 120 83Dokumen8 halamanBS 1881 Part 120 83tss13723100% (1)

- 090629173312preview - SS EN 12620-2008+amd1Dokumen6 halaman090629173312preview - SS EN 12620-2008+amd1Majid Al-Gburi100% (1)

- BS en 1926:2006Dokumen20 halamanBS en 1926:2006lkzasj dksikBelum ada peringkat

- BS 1881 - 109-1983 Testing ConcreteDokumen10 halamanBS 1881 - 109-1983 Testing ConcreteAlsonChinBelum ada peringkat

- En-1504 NitttrDokumen37 halamanEn-1504 Nitttrdevinderchawla100% (3)

- BS-EN 12504-1 Cored Specimen PDFDokumen12 halamanBS-EN 12504-1 Cored Specimen PDFArisan IqmaBelum ada peringkat

- BS EN 12390-6-2009 - Testing Hardened Concrete Part 6 - Tensile Splitting Strength of Test SpecimensDokumen14 halamanBS EN 12390-6-2009 - Testing Hardened Concrete Part 6 - Tensile Splitting Strength of Test SpecimensSarif100% (1)

- BS 1881-122 2011 (Water Absorption Test For Concrete)Dokumen7 halamanBS 1881-122 2011 (Water Absorption Test For Concrete)Babafemi Adewumi JohnBelum ada peringkat

- BS en 13286-2-2010 (2012)Dokumen34 halamanBS en 13286-2-2010 (2012)Vag Katsikopoulos100% (2)

- Testing Fresh Concrete-BS EN 12350-12:2010Dokumen14 halamanTesting Fresh Concrete-BS EN 12350-12:2010Muhammad Imran100% (1)

- BS en 480-1-2006+A1+2011 Admixtures For Concrete, Mortar and Grout - Test Methods - Part 1 - Reference Concrete and Reference Mortar For TestingDokumen14 halamanBS en 480-1-2006+A1+2011 Admixtures For Concrete, Mortar and Grout - Test Methods - Part 1 - Reference Concrete and Reference Mortar For TestingIvan Filipović100% (2)

- C 940 - 98 Qzk0mc05oeeDokumen2 halamanC 940 - 98 Qzk0mc05oeeAlexAndreMostaceroLeon100% (2)

- BS en 1367 PART 4 1998 (Thermal & Weathering Properties of Aggregate, Drying Shrinkage) - 1Dokumen9 halamanBS en 1367 PART 4 1998 (Thermal & Weathering Properties of Aggregate, Drying Shrinkage) - 1ghhhhBelum ada peringkat

- BS en 12390-1Dokumen14 halamanBS en 12390-1Vaqif AhmedovBelum ada peringkat

- BS en 00480-2-2006Dokumen14 halamanBS en 00480-2-2006Shan Sandaruwan Abeywardene100% (1)

- BS 5075 3 PDFDokumen17 halamanBS 5075 3 PDFJayakumar Anantha100% (1)

- 34 PDFDokumen16 halaman34 PDFVag Katsikopoulos100% (1)

- En 12504 1Dokumen8 halamanEn 12504 1Temur Lomidze33% (3)

- BS en 12697-25-2016 - (2020-07-07 - 11-30-14 Am)Dokumen40 halamanBS en 12697-25-2016 - (2020-07-07 - 11-30-14 Am)HANAN HUSSBelum ada peringkat

- Concrete Repair According To The New European Standard EN 1504Dokumen10 halamanConcrete Repair According To The New European Standard EN 1504MKOZERDEM100% (1)

- BS en 12350-8Dokumen14 halamanBS en 12350-8Ayo Osho50% (2)

- Admixtures For Concrete, Mortar and Grout ÐDokumen12 halamanAdmixtures For Concrete, Mortar and Grout Ðhz135874Belum ada peringkat

- BS 1881 116 1983 Testing Concrete. Method For Determination of Compressive Strength of Concrete CubesDokumen10 halamanBS 1881 116 1983 Testing Concrete. Method For Determination of Compressive Strength of Concrete Cubeskhairulhakam100% (1)

- BS en 1996 1 2 2005Dokumen20 halamanBS en 1996 1 2 2005Meganathan MegaBelum ada peringkat

- Aggregates For Unbound and Hydraulically Bound Materials For Use in Civil Engineering Work and Road Construction.Dokumen44 halamanAggregates For Unbound and Hydraulically Bound Materials For Use in Civil Engineering Work and Road Construction.eee100% (4)

- BS en 310-1993Dokumen14 halamanBS en 310-1993Jack Somensi100% (1)

- BS EN 14488 6 2006 Testing Sprayed Concrete - Part 6 Thickness ofDokumen10 halamanBS EN 14488 6 2006 Testing Sprayed Concrete - Part 6 Thickness ofhesham alhelaleeBelum ada peringkat

- BS 1881 2006Dokumen12 halamanBS 1881 2006zaidBelum ada peringkat

- BS en 14630-2006Dokumen12 halamanBS en 14630-2006JEMAYER75% (8)

- En 10138-4 2000 Prestressing Steels Part 4 BarDokumen6 halamanEn 10138-4 2000 Prestressing Steels Part 4 BarDigantBelum ada peringkat

- BS en 12390 8 2009 Testing Hardened Concrete Depth of Penetration of Water Under Pressure PDFDokumen10 halamanBS en 12390 8 2009 Testing Hardened Concrete Depth of Penetration of Water Under Pressure PDFKING OF VIDEO GAMES xBelum ada peringkat

- Non-destructive Testing and Evaluation of Civil Engineering StructuresDari EverandNon-destructive Testing and Evaluation of Civil Engineering StructuresJean-Paul BalayssacBelum ada peringkat

- Specs For Highway and Bridge ConstructionDokumen629 halamanSpecs For Highway and Bridge ConstructionmsohaibazizBelum ada peringkat

- DOE MethodDokumen20 halamanDOE MethodNor Khuzaimah Ab HamidBelum ada peringkat

- Is 2502 1963Dokumen31 halamanIs 2502 1963Lokesh SharmaBelum ada peringkat

- 4 Construction Standard Cs3 2013 Aggregates For ConcreteDokumen37 halaman4 Construction Standard Cs3 2013 Aggregates For ConcretesavsengineeringBelum ada peringkat

- ARC (AU) - Reinforcement Handbook, Your Guide To Steel ReinformecentDokumen78 halamanARC (AU) - Reinforcement Handbook, Your Guide To Steel Reinformecentmica100% (1)

- LaDOTD - 2002 - Drilled Shaft Foundation Construction Inspection ManualDokumen49 halamanLaDOTD - 2002 - Drilled Shaft Foundation Construction Inspection ManualdjerollemanBelum ada peringkat

- 2014amended4 7 2014Dokumen971 halaman2014amended4 7 2014Ant TtlBelum ada peringkat

- Mix Design of ConcreteDokumen14 halamanMix Design of ConcreteRaju Shetty CjBelum ada peringkat

- Chapter 6 Recommendations and AppendicesDokumen25 halamanChapter 6 Recommendations and AppendicesmsohaibazizBelum ada peringkat

- Mix Design of ConcreteDokumen14 halamanMix Design of ConcreteRaju Shetty CjBelum ada peringkat

- A Simple Guide To Concrete Cube TestingDokumen4 halamanA Simple Guide To Concrete Cube TestingmsohaibazizBelum ada peringkat

- Structural Engineer Division: (Page - 1/2)Dokumen6 halamanStructural Engineer Division: (Page - 1/2)msohaibazizBelum ada peringkat

- Is 1343 1980 R 1990Dokumen65 halamanIs 1343 1980 R 1990Venu PrasathBelum ada peringkat

- Astm D0448 - 1 (En)Dokumen3 halamanAstm D0448 - 1 (En)msohaibazizBelum ada peringkat

- Astm Standart A416.1974Dokumen7 halamanAstm Standart A416.1974SetyasasmitaBelum ada peringkat

- Mil STD 129Dokumen163 halamanMil STD 129Steele Wagemaker100% (1)

- Cylinder Strength Versus Cube StrengthDokumen26 halamanCylinder Strength Versus Cube Strengthfsirfan100% (2)

- Fed STD 123Dokumen7 halamanFed STD 123msohaibazizBelum ada peringkat

- STD 129 RDokumen165 halamanSTD 129 RmsohaibazizBelum ada peringkat

- Fed STD 123Dokumen7 halamanFed STD 123msohaibazizBelum ada peringkat

- BS en 12390-7 2000 (En) PDFDokumen12 halamanBS en 12390-7 2000 (En) PDFmsohaibaziz100% (1)

- Astm C0567 - 1 (En)Dokumen3 halamanAstm C0567 - 1 (En)msohaibazizBelum ada peringkat

- BS en 12390-7 2000 (En) PDFDokumen12 halamanBS en 12390-7 2000 (En) PDFmsohaibaziz100% (1)

- ACI 301 Specifications For Structural Concrete For Buildings - tcm45-346207Dokumen3 halamanACI 301 Specifications For Structural Concrete For Buildings - tcm45-346207msohaibaziz50% (4)

- Metric ConversionDokumen1 halamanMetric ConversionKS CheeBelum ada peringkat

- AASHTO T265 Moisture of SoilsDokumen2 halamanAASHTO T265 Moisture of SoilsRuss NesterBelum ada peringkat

- Autocad and LispDokumen65 halamanAutocad and LispmsohaibazizBelum ada peringkat

- Compressive Strength OF Cylindrical Concrete Specimens Aashto T 22 ApparatusDokumen2 halamanCompressive Strength OF Cylindrical Concrete Specimens Aashto T 22 ApparatusmsohaibazizBelum ada peringkat

- Combustion TheoryDokumen44 halamanCombustion TheoryyaidragonBelum ada peringkat

- Case/Duct System (Automobile)Dokumen7 halamanCase/Duct System (Automobile)Tran xuan ThuyBelum ada peringkat

- OBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895Dokumen7 halamanOBIEE 11g Training Details: Contact Name: Rao Contact No: 919948713895SwapnasaritBelum ada peringkat

- Presentation of DC Power System in Telecom by Muhammad QasimDokumen42 halamanPresentation of DC Power System in Telecom by Muhammad QasimMuhammad Qasim100% (1)

- Slope Stability Manual 8Dokumen12 halamanSlope Stability Manual 8YawgmothBelum ada peringkat

- ND BRG GuideDokumen32 halamanND BRG Guidemohammed barghothiBelum ada peringkat

- A Project Report On Financial Performance Evaluation With Key Ratios at Vasavadatta Cement Kesoram Industries LTD Sedam Gulbarga PDFDokumen82 halamanA Project Report On Financial Performance Evaluation With Key Ratios at Vasavadatta Cement Kesoram Industries LTD Sedam Gulbarga PDFK Sagar Kondolla100% (1)

- NJ Res Chapter10Dokumen10 halamanNJ Res Chapter10Anonymous bVFHovBelum ada peringkat

- Job Application and Cover LettersDokumen1 halamanJob Application and Cover LettersDyah AgBelum ada peringkat

- NAJRAN Quarter 4 NAJRAN Quarter 4 DDT Report DDT Report: December 2012 December 2012Dokumen50 halamanNAJRAN Quarter 4 NAJRAN Quarter 4 DDT Report DDT Report: December 2012 December 2012Shaheryar KhanBelum ada peringkat

- Chapter 1Dokumen65 halamanChapter 1Jad Antonios JelwanBelum ada peringkat

- C1107Dokumen4 halamanC1107Pankaj PaulBelum ada peringkat

- Sizing Columns in HysysDokumen4 halamanSizing Columns in HysysemebusamuelBelum ada peringkat

- Design of Queensland Road Infrastructure For High Risk EnvironmentsDokumen7 halamanDesign of Queensland Road Infrastructure For High Risk EnvironmentsAnonymous fS6Znc9Belum ada peringkat

- 04Dokumen2 halaman04Vishesh negiBelum ada peringkat

- Readytoprocess Wave 25Dokumen172 halamanReadytoprocess Wave 25Ashish GowandeBelum ada peringkat

- En 19Dokumen3 halamanEn 19Sanjay GoreBelum ada peringkat

- DSE7410 MKII DSE7420 MKII Installation Instructions PDFDokumen2 halamanDSE7410 MKII DSE7420 MKII Installation Instructions PDFyao nestorBelum ada peringkat

- Chapter 3 IPCDokumen53 halamanChapter 3 IPCkirubelBelum ada peringkat

- Std-Insp-0002 (Incoming Material Inspection Procedure)Dokumen3 halamanStd-Insp-0002 (Incoming Material Inspection Procedure)airbroomBelum ada peringkat

- Junction Box PDFDokumen2 halamanJunction Box PDFMohan ShanmugamBelum ada peringkat

- Astm A722 PDFDokumen5 halamanAstm A722 PDFNguyễn ThạnhBelum ada peringkat

- A Bendable and Wearable Cardiorespiratory Monitoring Device Fusing Two Noncontact Sensor PrinciplesDokumen10 halamanA Bendable and Wearable Cardiorespiratory Monitoring Device Fusing Two Noncontact Sensor PrinciplesMd arshatBelum ada peringkat

- Application of FiberDokumen33 halamanApplication of FiberReem OmerBelum ada peringkat

- Script Das Cores Iqoption ScriptDokumen2 halamanScript Das Cores Iqoption ScriptStallkie67% (3)

- MS301L11 Navigational Methods and Route Planning LADokumen3 halamanMS301L11 Navigational Methods and Route Planning LASam HollidayBelum ada peringkat

- Fracture Toughness Evaluation of WC-Co Alloys by Indentation TestingDokumen12 halamanFracture Toughness Evaluation of WC-Co Alloys by Indentation TestingFjodorSergBelum ada peringkat

- Sonali MondalDokumen2 halamanSonali MondalSonali MondalBelum ada peringkat

- S8 PDFDokumen184 halamanS8 PDFsrdsosonpurBelum ada peringkat

- Atom Laboratory CalibratorDokumen90 halamanAtom Laboratory CalibratorDhoy GaviolaBelum ada peringkat