Power System of ESMO PDF

Diunggah oleh

harshaxdDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Power System of ESMO PDF

Diunggah oleh

harshaxdHak Cipta:

Format Tersedia

Acta Astronautica 64 (2009) 244255

www.elsevier.com/locate/actaastro

Power systemdesign of ESMO

Steve Ulrich

a,

, Jean-Franois Veilleux

b

, Franois Landry Corbin

b

a

NGC Aerospace Ltd., 1650 King Ouest, Ofce 202, Sherbrooke, Qubec, Canada J1J 2C3

b

Universit de Sherbrooke, 2500 boul. de lUniversit, Sherbrooke, Qubec, Canada J1K 2R1

Received 5 December 2007; received in revised form 3 September 2008; accepted 3 September 2008

Available online 1 November 2008

Abstract

The European Student Moon Orbiter (ESMO) spacecraft is a student-built mini satellite being designed for a mission to the

Moon. Designing and launching mini satellites are becoming a current trend in the space sector since they provide an economic

way to perform innovative scientic experiments and in-ight demonstration of novel space technologies. The generation, storage,

control, and distribution of the electrical power in a mini satellite represents unique challenges to the power engineer since the

mass and volume restrictions are very stringent. Regardless of these problems, every subsystem and payload equipment must

be operated within their specied voltage band whenever they required to be turned on. This paper presents the preliminary

design of a lightweight, compact, and reliable power system for ESMO that can generate 720W. Some of the key components

of the EPS include ultra triple-junction (UTJ) GaAs solar cells controlled by maximum power point trackers, and high efciency

Li-ion secondary batteries recharged in parallel.

2008 Elsevier Ltd. All rights reserved.

Keywords: Mini satellite; Moon mission; Electrical power subsystem design

1. Introduction

Since the last few decades, there has been a large in-

terest in operating mini satellites, mainly because they

are cheaper to build and to launch. These satellites pro-

vide space agencies and researchers an ideal testbed

for in-ight demonstration of innovative and high risk

technologies. Used in an educational context, they also

Presented as paper IAC-07-B4.6.13 at the 58th International As-

tronautical Congress, Hyderabad, India, 2428 September, 2007.

Corresponding author. Tel.: +18193489483;

fax: +18193489430.

E-mail addresses: steve.ulrich@ngcaerospace.com

(S. Ulrich), Jean-Francois.Veilleux2@USherbrooke.ca

(J.-F. Veilleux), Francois.Landry.Corbin@USherbrooke.ca

(F. Landry Corbin).

0094-5765/$- see front matter 2008 Elsevier Ltd. All rights reserved.

doi:10.1016/j.actaastro.2008.09.002

prepare students for their future careers in the space

sector by giving them valuable hands-on experience. In

fact, the number of student-built mini satellites is rapidly

growing, especially in Europe and in North America.

The MITs SPHERES [1] (synchronized position hold

engage and reorient experimental satellites) experiment

uses the space environment provided by the Space Shut-

tle and the International Space Station (ISS) in order

to validate dynamics and control algorithms for mini

satellites in formation. Rendezvous and docking of two

SPHERES satellites on-board the ISS has been achieved

in 2006.

CanX-1 [2] is the rst spacecraft developed within

the Canadian Advanced Nanospace eXperiment (CanX)

program, which was initiated by the University of

Toronto in 2001. This technology demonstration space-

craft was a single CubeSat and built according to the

S. Ulrich et al. / Acta Astronautica 64 (2009) 244255 245

California Polytechnic State University (CalPoly) and

Stanford University CubeSat standards [3]. Following

the successful ight of this 101010cm spacecraft, the

3.5kg milk carton-sized CanX-2 [4] will be launched

in early 2008 to evaluate technologies that will be used

on the expected formation ying missions, CanX-4/

CanX-5 [5].

SSETI Express, which was sponsored by the Student

Space Exploration and Technology Initiative (SSETI)

association, was successfully launched in October 2005.

This rst SSETI spacecraft was carrying three Cube-

Sats, a propulsion module, an imaging camera and an

amateur radio transponder [6]. Unfortunately, due to an

unrecoverable fault in the electrical power subsystem

(EPS), the mission was aborted in 2005. The next SSETI

satellite is the European Student Earth Orbiter (ESEO),

which is planned to be launched in 2008 [7]. The

European Student Moon Orbiter (ESMO) is the third

SSETI spacecraft and was ofcially approved in 2006

for a phase A study by the Education Department

of the European Space Agency (ESA). Just like his

SSETI predecessors, ESMO will be completely de-

signed, built, and operated by European and Canadian

students in a highly distributed way. This 150kg satel-

lite will play a valuable role in the international space

community, namely by: (1) providing new scientic

measurements relevant to lunar science and the future

human exploration of the Moon, (2) by providing ight

demonstration of innovative space technologies devel-

oped under university research activities, and (3) by

acquiring images of the Moon for public relations and

education outreach purposes. Moreover, it will stim-

ulate space awareness among students and give them

technical abilities related to space-oriented projects.

The ESMO spacecraft will be launched either on-

board Ariane 5s Arianespace Support for Auxiliary

Payload (ASAP) or on-board Soyuz in 2011 from the

Guiana Space Center (GSC) in Kourou. Few thousands

of seconds after the launch, ESMO will be separated

from the launcher with a spin rate of 5rpm and deployed

in a GTO orbit dened by an inclination (i) of 7

, a lon-

gitude of ascending node () of 10

west, an argument

of periapsis () of 178

, an eccentricity (e) of 0.716,

and a semimajor axis (a) of 24630km. The spacecraft

will stay in this GTO phase for one week and then,

continuous tangential thrust will start at the last perigee

passage. No thrusting will occur during eclipses. This

rst phase of the mission ends once the apogee reaches

200000km. From this point, ESMO will use 21kg of

its xenon propellant for delivering 6.5km/s of total V,

transferring ESMO to its polar lunar orbit in 1 year. The

desired stable operational lunar orbit (SOLO) is dened

by an inclination (i

L

) of 90

, an argument of perisele-

nium (

L

) of 295

, an eccentricity (e

L

) of 0.481, and a

semimajor axis (a

L

) of 3500km. Then, the 2kg primary

imager payload will start transmitting data to Earth for

a period of approximately 6 months.

Through the last ESAs call for proposals which took

place in July 2006, several teams have ofcially been

selected to conduct a phase A study for the ESMO mis-

sion. These teams and their responsibility in term of

subsystems are dened as follows:

Power

Universit de Sherbrooke, Canada

Payload

University of Liege, Belgium

University of Toronto, Canada

Propulsion

University of Southampton, UK

University of Warwick, UK

Politecnico di Milano, Italy

University di Napoli, Italy

AOCS

Narvik University College, Norway

University of Lisbon, Portugal

SUPAERO, France

Ryerson University, Canada

On-board data handling

University of Munich, Germany

Communications

Wroclaw University of Technology, Poland

Structure

University of Southampton, UK

Thermal

Politecnico di Milano, Italy

Mechanisms

University of Porto, Portugal

246 S. Ulrich et al. / Acta Astronautica 64 (2009) 244255

Mission analysis

University of Glasgow, UK

Ground segment

University of Rome, Italy (ground station Kenya)

University of Munich, Germany (ground station

Germany)

Flight dynamics

University of Rome, Italy

Simulations

Warsaw University of Technology, Poland

Contrary to conventional, large satellites that have

signicant power generation and storage capability,

mini satellites such as ESMO do not offer the same

advantages, being of small mass. For this reason, most

mini satellites are being operated in Earth orbits (LEO

or GEO) where large Vs and demanding communi-

cation power are typically not required. Sometimes,

propulsive maneuvers are not even necessary and small

thrusters are only used for attitude maneuvers. In that

case, the required power may be less that 100W, which

translates a lightweight power system, which is coher-

ent with the philosophy behind the small satellite world.

As example, ESAs PROBA-1 [8], a washing machine-

size earth observation satellite, operates autonomously

with only a few watts.

On the other hand, an interplanetary ESMO-like

satellite mission that uses ion engines represents a great

challenge. Indeed, in order to generate the thrust levels

of interest for the mission, the power need is quite high,

of the order of 650750W at beginning of life (BOL).

Therefore, given the strict mass constraint imposed by

the fact that most mini satellites are launched as piggy-

back, a state of the art, highly efcient and lightweight

EPS becomes mandatory.

This paper presents the preliminary design of the EPS

for the ESMO mission conducted by the ESMOs EPS

team. The remainder of this paper is as follows. In Sec-

tion 2, salient features of ESMO are given. In Section 3,

the EPS functional architecture is outlined and in Sec-

tion 4 the power budget is detailed. Sections 58 present

the preliminary design of each element of the EPS (the

solar array, the secondary batteries, the power control

unit (PCU), and the power distribution unit (PDU), re-

spectively). Finally, Section 9 provides the conclusion.

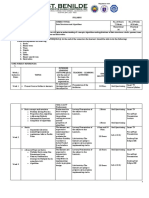

Fig. 1. ESMO internal view.

2. Features of ESMO

Some of the features of ESMO are illustrated in

Fig. 1 and are listed below:

Dimensions: 700700800mm (cuboid).

Mass: 150kg.

Lunar orbit: polar orbit with a periselenium of

100km.

Structure: aluminium alloy honeycomb covered with

two skins of CFRP.

Payload: imaging narrow angle camera (NAC).

Electric propulsion: T5 ion engine.

Uplink: 2275MHz, 2kbps.

Downlink: 2275MHz, 2.5kbps.

Antennas: S-band omnidirectional2.

Transmit power: 5W.

Attitude control: 3-axis actuation capability.

Thermal: passive control/radiating panel.

Mission lifetime: 18 months.

3. Functional architecture

The general layout, or the functional architecture,

of the EPS is shown in Fig. 2. In this gure, four

components of the EPS can be identied: (1) the solar

array which generates power, (2) the PCU which condi-

tions the energy, (3) the secondary batteries which are

a rechargeable mean of energy storage used for eclipse

and peak power demand periods, and (4) the PDU

which distributes the power to each load, or subsystem,

of the spacecraft. All components other than the solar

array are located inside the spacecraft body. From the

conceptual design presented in a previous work [9], the

Canadian team has identied that ESMO will be

S. Ulrich et al. / Acta Astronautica 64 (2009) 244255 247

Solar Array

Secondary

Batteries

Power Control

Unit

Power

Distribution

Unit

To

Loads

Fig. 2. EPS functional architecture.

powered by ultra triple-junction (UTJ) GaAs solar cells

controlled by maximum power point trackers (MPPT).

For energy storage, high efciency Lithium (Li)-ion

secondary batteries recharged in parallel will be used. A

distributive load regulation approach is also baselined.

4. Power budget

Throughout the mission phases, different subsystems

require different power levels in order to operate in a

nominal way. Table 1 shows the maximum operating

power requirement of every ESMO subsystems. From

this table, it is obvious that the main driver for the power

generation system sizing is the power processing unit

(PPU) of the T5 ion engine. Fortunately, all the sub-

systems/components do not require to be turned on at

the same time during the mission. In order to assess

accurately the power consumption throughout the mis-

sion, an analysis of dynamic power budgets must be

performed. Basically, dynamic power budgets are built,

based on which subsystems are turned on and off for a

given period of time. Dynamic power budgets were built

for the three critical mission phases, which were de-

ned from an EPS perspective: (1) initial operations in

low Earth orbit phase (LEOP), (2) injection into SOLO,

and (3) SOLO phase.

In early LEOP, several check-up and routine opera-

tions must be performed, such as de-spin, sun acqui-

sition, and solar array deployment. Because all these

early operations are achieved with unfolded solar pan-

els, no energy coming from the Sun can be converted

into electricity. ESMO will then have to rely entirely on

its energy storage system.

The injection into SOLO is a critical phase since

thrusting maneuvers are required to place ESMO into

the desired nal lunar orbit. Orbital elements of this

phase are considered to be the same as those of the

SOLO phase. During the injection into SOLO, the T5

ion engine is expected to operate in its low power mode

during attitude maneuvers (where the hollow cathode

thruster are used) and during eclipse periods. The max-

imum power demand during this phase is of 663W.

Table 1

Operating power requirement values .

Subsystem/component Power (W)

AOCS

Star tracker 4.0

Gyroscope 1.0

Reaction wheels 12.0

Communications

Receiver (Rx) and RF distribution unit 6.0

Transmitter (Tx) 25.0

On-board data handling

On-board computer 22.0

Payload

Narrow angle camera 10.0

Propulsion

T5 Ion engine PPUHIGH 600.0

T5 Ion engine PPULOW 38.0

Hollow cathode thruster PPU 80.0

Power

Power control unit 7.0

Power distribution unit 3.0

Battery heaters 60.0

Mechanism

Solar array drive mechanism 9.0

Table 2

Power requirement for initial LEOP operation phase .

Subphase Power (W) Duration (h)

Separation and AOS 28.0 5.00

Check-up 53.0 1.00

De-spin 54.0 0.50

Sun acquisition 47.0 0.50

Solar array deployment 63.0 0.25

Finally, the SOLO phase is quite similar to the SOLO

injection phase, except that during SOLO, the T5 ion

engine is always turned off. Also, the imaging camera is

assumed to be used for 30min around the periselenium

followed by a 1h of transmit (TX) activity around the

aposelenium in order to send back to Earth the stored

data.

The details of the power requirement for each of these

three mission phases are given in Tables 24 and il-

lustrated in Figs. 35. It should be noted that in these

gures, some parts of the graphs have been highlighted

in gray to represent the eclipse periods. After a closer

analysis of these tables and gures, it can be concluded

the LEOP and the SOLO injection phases represent

the sizing cases for the battery and for the solar array,

248 S. Ulrich et al. / Acta Astronautica 64 (2009) 244255

Table 3

Power requirement for SOLO orbital injection phase .

Table 4

Power requirement for SOLO phase .

respectively. Considering power losses, array degrada-

tion, and the battery charge power with some margins,

the required solar array output is estimated to 720W at

BOL. The computation of the required battery capacity

will be performed in Section 6.

5. Solar arrays

The design of the solar array presents unique chal-

lenges to the power system engineer since the mass and

Fig. 3. Power requirement for initial LEOP operation phase.

Fig. 4. Power requirement for SOLO orbital injection phase.

volume available are all very limited. However, in the

last years, solar cells manufacturers have greatly im-

proved cell efciency and power production. Solar cells

with greater than 28% efciency are now commercially

available. With multi-junction cells, layers of different

materials and doping levels are used to extract energy

from different portions of the light spectrum, converting

more of the spectrum into power.

For the ESMO spacecraft, the proposed solar array

consists of UTJ GaAs solar cells manufactured by Boe-

ing Spectrolab, which have an efciency of 28.3% at

BOL and of 24.3% at EOL [10]. The UTJ GaAs cell

consists of Ge, GaAs, and GaInP2 semiconductors in-

terconnected by two tunnel junctions.

S. Ulrich et al. / Acta Astronautica 64 (2009) 244255 249

Fig. 5. Power requirement for SOLO phase.

Fig. 6. IV characteristics of the UTJ GaAs cell [10].

5.1. IV characteristics

The performance of a solar cell at BOL is mainly

characterized by the output voltage and current at its

terminals, which can be determined by an accurately

measured IV characteristics curve of the solar cell.

Fig. 6 illustrates the IV curve for an UTJ cell, as sup-

plied by Spectrolab [10].

On this curve, the two extreme points, the open cir-

cuit voltage, V

oc

and the short circuit current, I

sc

are of

a great importance. Indeed, the maximum power, P

max

that can be generated by the cell is given by the follow-

ing equation:

P

max

=CFF V

oc

I

sc

(1)

where the curve ll factor CFF denes the quality

of the voltagecurrent characteristics. From Fig. 6,

V

oc

is 2.665V and I

sc

is 17.05mA/cm

2

, and the

maximum power point (MPP) is at 2.350V (V

mp

) and

16.30mA/cm

2

(I

mp

). From Spectrolabs data sheet

[10], the CFF is 0.84. Therefore, from Eq. (1), P

max

is

0.03816W/cm

2

.

5.2. Array design

The solar cells on the array are segmented in many

strings connected in parallel. The following equations

are used to determine the parameters needed to design

the array:

N

series cells per string

=

array volt age

V

mp

(2)

N

parallel panels

=

array current

I

panel

(3)

N

strings per panel

=

I

panel

I

mp

(4)

With a desired array voltage equal to 28V and using

the numerical value of V

mp

dened previously, Eq. (2)

yields a total of 12 cells in series per string. Considering

that six panels (three per wing) will be used on ESMO,

and that the array current must be equal to 25.7 A in

order to generate the required 720W, Eq. (3) gives a

panel current (I

panel

) of 4.3 A. Finally, assuming cell

size of 24cm

2

(5.54.4cm), Eq. (4) gives 11 strings per

panel. The total size of one panel is 765567mm, which

respects the maximum allowed size of 800600mm.

Since the effective area of a single panel is 3146cm

2

,

each panel will generate 120W for a total of 720W

for six panels. Both sets of three rigid panels will be

initially stowed with the spacecraft during the launch

and will be deployed at the end of the LEOP phase.

6. Secondary batteries

Li-ion battery cells were selected for ESMO mainly

because they provide the best compact and weight-

saving solution to ensure continuous operation of space-

craft at times when the solar cells are not in sunlight or

when peak-power demands exceed the power generated

by the solar array (namely before the solar array deploy-

ment) [9]. In comparison to other type of secondary bat-

teries, Li-ion batteries have the following advantages:

Their high density of energy (twice as much as NiH

2

)

provides a signicant saving of weight (approxi-

mately 3050%). This reduction in weight leaves

more room for larger payloads.

250 S. Ulrich et al. / Acta Astronautica 64 (2009) 244255

Li-ion batteries do not require reconditioning since

they do not suffer from memory effect.

Li-ions low thermal radiation enables the use of

smaller battery radiators, which further reduces the

EPS weight.

Li-ion batteries retain their charge for longer pe-

riod, thus do not require charging while awaiting the

launch. This reduction in launch pad operations con-

tributes to the mission cost reduction.

As explained by Patel [11], the electrical performance

requirement of the secondary batteries depends on the

electrochemistry and on many other parameters in a

highly nonlinear manner. In fact, this is why the battery

design is one of the most difcult tasks for the power

system engineer. However, the required capacity of the

secondary battery, in Wh, can be estimated with a sim-

ple relation, as follows:

Cr =

1

nDOD

5

i =1

P

i

T

i

(5)

Considering that the LEOP phase is the sizing case for

the battery, the term

5

i =1

P

i

T

i

represents the ideal ca-

pacity, i.e., the summation of power load (in W) times

the duration (in h) for each of the ve initial LEOP op-

erations (check-up, de-spin, etc.). This ideal capacity is

then increased to include the battery-to-load transmis-

sion efciency, n, and the depth-of-discharge constraint,

DOD. The DOD is dened as the percentage of the bat-

tery capacity discharged during a discharge period. The

required DOD is typically based on the type of mission.

In the case of a rapid cycling LEO satellite, the DOD

will be limited in order to not overstress the batteries.

For a GEO satellite, it will be higher as the battery is

only used a few days per year. After a discussion with

SAFT, and because only a few thousand of cycles will

occur, the maximum DOD has been xed to 65%. The

transmission efciency is considered to be 90%.

Using Eq. (5) with the numerical values given in

Table 2, the ideal capacity requirement during the initial

LEOP operation phase is 265Wh. With the DOD and

efciency considerations, the required battery capacity

is 452Wh, or 16.2 Ah at 28V.

To fulll these requirements, the proposed battery

consists in the ight-proven Li-ion MicroSat battery

module, from SAFT [12]. This standard conguration

battery is assembled from MPS 176065 Li-ion cells

[13], which individually operates at 3.6V and delivers

5.7Ah. The resulting 8s3p conguration battery deliv-

ers 480Wh, or 17Ah at 28V, which is sufcient to meet

the requirement of the ESMO mission. Some of the key

Fig. 7. SAFT Li-ion MicroSat module [12].

Table 5

SAFT Li-ion MicroSat module characteristics .

Battery characteristic Value

Capacity, Ah 16.8

Capacity, Wh 480.0

Voltage, V 3.6

Conguration 8s3p

Weight, kg 4.5

Height, mm 95.0

Length, mm 170.0

Width, mm 220.0

features of this battery include an autonomous heat-

ing circuit, sensors for thermal modeling, over-charge

protection, and built-in redundant safety protections.

The complete battery module is illustrated in Fig. 7 and

its characteristics are summarized in Table 5.

7. Power control unit

In order to fully optimize the power/mass ratio of the

mini satellite, a commercial off-the-shelf (COTS) PCU

is not considered suitable for the ESMO mini satellite.

Instead, a custom-built PCU tailored to the missions

constraints is considered as the baseline solution.

The PCU consists of the following components: (1)

two maximumpower point tracker units (MPPTU), (2) a

battery monitor (BM), and (3) a power management unit

(PMU). The internal and external interfaces between the

components of the PCU are illustrated in Fig. 8. The

two MPPTs are used to interface the power from the

S. Ulrich et al. / Acta Astronautica 64 (2009) 244255 251

From Solar

Panel 1

From Solar

Panel 2

MPPTU 1

MPPTU 2

PMU

Power Control Unit

BM

From/To

OBDH

From/To

Secondary Batteries

Data

Unregulated

Power Bus

~ 28 V

Fig. 8. Internal and external interfaces of the PCU.

two solar arrays to the main 28V unregulated power

bus and the Li-ion batteries will be interfaced directly

to the main power bus through the BM, which monitors

the state-of-charge and to prevent the overcharging of

the batteries. The PMU basically fullls the functions

of a telecommand and telemetry module (TC/TM). In

this section, the design of these three PCU components

is presented.

7.1. Maximum power point tracker unit

The MPPTU functionality is to monitor the voltage

and current output of the solar array at all times, in order

to force the solar array output to operate at the MPP. To

do so, a DCDC converter in a given conguration is

rst used. Then, with an MPPT algorithm implemented

in a dedicated microprocessor, the peak power operating

point of the solar array on its IV curve is detected and

tracked.

7.1.1. Maximum power point tracker unit

Typical DCDC converter congurations are the

boost, the buck, and the buckboost and a series of

hybrid versions of those. An overview of all of these

congurations can be found in Walkers work [14].

As with any other EPS components, redundancy

should be limited to the minimum, in order to reduce

the mass as much as possible. Therefore, typical se-

rial congurations are considered too risky. Indeed, a

failure of a series connected DCDC converter would

prevent the current to ow, creating a disconnection be-

tween the solar arrays and the main power bus, causing

a major EPS failure.

SCBC

Solar Array

Voltage

Solar Array

Voltage

Solar Array

Voltage

SCBC

Standard DC-DC Buck Converter

Standard DC-DC Buck Converter

DC-AC

Inverter

DC-AC

Inverter

Failure

~ 28 V

Fig. 9. (a) Schematic of a functional SCBC and (b) functionality in

a case of a failure.

The series connected boost converter (SCBC), which

simple principle of operation is explained elsewhere

[15], overcome this problem. As illustrated in Fig. 9, if

a converter failure occurs, the current would still ow

from the solar arrays to the power bus. The solar array

voltage would just not be conditioned anymore. That

situation can quickly become a serious problem if the

solar arrays and the secondary battery are operated at

different voltage levels. However, for ESMO, because

the operating voltage of the solar arrays has been cho-

sen to match the battery voltage, a converter failure

would only cause an uncontrolled charging of the bat-

tery, thus slightly reducing their operational lifetime.

Another great advantage of this conguration is its great

efciency; around 9598% in comparison to 8590%

available with the standard converter topologies [14].

This translates directly into mass and costs saving. Fi-

nally, the SCBC conguration is considered the base-

line solution to provide a simple and reliable way to

achieve a high efciency and a fault tolerant DCDC

conversion for ESMO.

7.1.2. MPPT algorithms

Nowadays, several MPPT algorithms are available

and can be considered by the power engineer. However,

many of them are still under development. Every single

algorithm has its own advantages and drawbacks has

discussed in Chapmans survey on MPPT algorithms

[16]. In order to ensure robust and risk-free MPPT op-

erations, only well known and in-ight demonstrated

MPPT algorithms are considered for this mini satellite

mission to the Moon. The considered algorithms are

the so-called perturb and observe (P&O) algorithm and

the incremental conductance (IncCond) algorithm.

252 S. Ulrich et al. / Acta Astronautica 64 (2009) 244255

The fundamental operation principle of a P&OMPPT

algorithm is to generate a perturbation in the operating

voltage of the solar array, and to observe the resulting

gain (or loss) on the output power. This technique is

very similar to the hill-climbing method [17,18] which

generates a perturbation in the duty cycle, thus produc-

ing a perturbation in the operating voltage of the solar

array. The P&O algorithm is one of the easiest algo-

rithms to implement, in which both current and volt-

age are monitored for computation needs. The speed of

convergence toward the MPP varies according to the

perturbation frequency. Smaller steps between pertur-

bations offer a faster tracking algorithm, but yields os-

cillations around the MPP once reached, causing loss

of power. For better performance, the P&O algorithm

can be implemented in a two-stage algorithm includ-

ing a fast tracking stage and then a slow, ner tracking

stage, to keep a good convergence speed and to limit

the power loss of uctuation around the MPP [16].

The second algorithm, the IncCond algorithm, is

based on the fact that the slopes of the powervoltage

array power curve is zero at the MPP, positive on the

left of the MPP, and negative on the right, as given by

dP/dV =0

dP/dV >0

dP/dV <0

(6)

Since

dP/dV = I + VdI /dVI + VI /V (7)

Eq. (6) can be rewritten as

I /V =I /V

I /V > I /V

I /V < I /V

(8)

Hence, the MPP can be tracked by comparing the

instantaneous conductance (I/V) to the incremental

conductance (I/V). As with the P&O algorithm,

the increment size determines the convergence of the

IncCond algorithm speed toward the MPP and the os-

cillation around it. A two-stage solution can also be

implemented to overcome oscillation problems. More-

over, this two-stage solution ensures that the real MPP

is tracked in case of multiple local maxima. Again,

this technique must monitor current and voltage, but

since this slightly more complex method gives a better

accuracy and efciency compared to the P&O, this

technique has been selected for the ESMO spacecrafts

PCU.

Fig. 10. Tamura S22P025S05 hall effect current sensor [20].

7.2. Battery monitor

Since the secondary battery is a critical component

in ESMOs EPS, monitoring its state of health is impor-

tant. This is done with the BM. Because the choice of

using a MPPT led to the choice of an unregulated power

bus [9], the battery is directly connected to it through

the BM. Although complex techniques such as neural

network and fuzzy logic can be used for this purpose

[19], the typical approach consists of using a voltage

and a current sensor. This typical BM monitors the bat-

terys voltage and current drawn (which is also used as

a power bus monitor since it is directly connected to

it). This type of BM enables the control of the state-of-

charges of the batteries by the MPPT and prevents bat-

tery overcharging (by adjusting the point of operation

needed for both solar arrays).

For efciency reasons, the current sensor will be a

COTS hall effect current sensor (HECS). It can either

be an open-loop or a closed-loop sensor. Open-loop

sensors can be a good choice, but closed-loop current

sensors offer higher accuracy by correcting the linear-

ity and gain errors through a negative feedback. Since

both versions cost about the same price for a nominal

current specication, the decision of using closed-loop

HECS for ESMO was made. Moreover, this type of sen-

sor represents a simple and efcient way to monitor the

current source to or sink from the battery. Tamura Cor-

poration produces a great variety of COTS HECS which

are commonly available, thus reducing their price. The

S22P025S05 [20], which is illustrated in Fig. 10, rep-

resents an attractive and affordable baseline solution.

7.3. Power management unit

The PMU on-board ESMO will be used as a telecom-

mand and telemetry module (TC/TM) to (1) decode

commands from OBDH in order to switch loads on and

S. Ulrich et al. / Acta Astronautica 64 (2009) 244255 253

Unregulated

Power Bus

~ 28 V

Data

Power Distribution Unit

To High

Current

Loads

To Medium

Current

Loads

To Low

Current

Loads

Solid-State

Current

Limiters

Solid-State

Current

Limiters

Solid-State

Current

Limiters

Fig. 11. Internal and external interfaces of the PDU.

off and (2) to send monitoring data back to OBDH.

Considering the inherent complexity of this component,

a COTS solution is adopted. Moreover, this solution

will to reduce the risk of a PMU failure which would

be critical for the mission. The different COTS TM/TC

modules currently considered are the following: the Al-

catel Space TMTC-H5 and TMTC-S3 (both from the

9353 modular PCDU) [21] and the TERMA command

and monitoring (CM) module [22].

The Alcatel Space TMTC-S3 offers a low-mass

(1.25kg) and compact design (34019025.5mm)

with all the required features for the ESMO mission.

Moreover, between the three considered options, it is

the only one that offers a RS422 bus interface as re-

quired by the ESMO OBDH subsystem. For all these

reasons, for its ease of implementation and for its good

reliability, the TMTC-S3 PMU is selected for ESMO.

8. Power distribution unit

The PDU provides switch control and protection

between the main bus and the loads connected to it. A

simplied block diagram of the PDU is illustrated in

Fig. 11. Each load, depending on the current they

draw, are categorized as high (I > 2A), medium

(2A I 1A), or low (I < 1A) current load. Consid-

ering that the main power bus is unregulated at 28V

and that a distributive regulation has been adopted,

each subsystem must have their own regulators.

For over-current protection, solid-state current lim-

iters or fuse-relays can be used. Because of their higher

exibility, ease of testing and rearming capabilities over

fuse-relays, solid-states current limiters are baselined

for ESMO. The trade-off analysis between these two

protection devices can be found elsewhere [23]. The

PDU provides power distribution via two types of solid-

state current limiters:

Fold-back current limiters (FCLs) for powering re-

ceivers, transmitters, the on-board computer, the

PCU, the PDU, and essential AOCS units that are al-

ways powered on (star tracker and reaction wheels).

In the event of an overload, these current limiters

enter in a fold-back mode.

Latching current limiters (LCLs) which operate as

telecommanded switches with current limitation pro-

tection at selectable thresholds. The switch automati-

cally trips off if the current limitation period exceeds

a maximum time limit.

The PDU must also provide dedicated groups of

heater outlets, each outlet being controlled by a tran-

sistor switch (TSW) and protected by an LCL as other

loads. However, solid-state current limiters can be quite

complex to design (electronically and thermally). On

the other hand, by using a COTS PDU, such as the

Alcatel Space LCL and Heaters distribution module

(H3 or P2) [21] or the TERMA power distribution mod-

ule (PDM) [24], the design complexity drawback can

be avoided. The Alcatel Space P2 module offers nine

LCL up to 10A each, one permanent-on LCL up to 5A,

one FCL up to 1A and two heater group switch up to

10A (which are all found to be well-suited for ESMO

which requires 10 LCL/FCL as well as 26 heaters up

to 3.5A). This module also offers a low-mass (1.25kg)

and compact design (34019025.5mm) with all the

main performances required. Moreover, this solution

offers the advantage of being easily implemented with

the TMTC-S3 PMU since they are both from the same

manufacturer and are meant to be used together in a

modular PCDU.

9. Conclusion

In this paper, the preliminary design of a lightweight,

compact, and reliable EPS for the ESMO mini satel-

lite has been presented, where the detailed EPS block

diagram is provided in Annex A. Thanks to key com-

ponents such as the ultra triple-junction (UTJ) GaAs

solar cells and the Li-ion secondary battery, ESMOs

EPS will be able to provide the required energy to all

subsystems, even during thrusting and eclipse periods.

Whenever possible, the EPS design for this mission to

the Moon has been performed by selecting ight-proven

254 S. Ulrich et al. / Acta Astronautica 64 (2009) 244255

solutions and technologies, increasing as much as pos-

sible the reliability of the EPS, and thus of the entire

spacecraft and mission.

Acknowledgments

The authors wish to thank each member of the ESMO

mission for their contributions and dedication to the de-

velopment of the ESMO spacecraft, and Roger Walker,

fromESA, for his invaluable mentorship. Special thanks

to Yannick Borthomieu, Satellite and Launcher Product

UTJ GaAs

Solar Array 1

Power Control Unit

MPPTU 1

SBCS

DC-DC Conv.

SBCS

DC-DC Conv.

IncCond

MPPT

MPPTU 2

IncCond

MPPT

PMU

From/To

OBOH

UTJ GaAs

Solar Array 2

HECS

BM

Li-ion MicroSat

Batteries

Data

Unregulated

Power Bus

~ 28 V

Power Distribution Unit

T5 Ion Engine

PPU

Hollow Cathode

Thruster PPU

Receiver

Transmitter

On-Board

Computer

Battery Heaters

Star Tracker

Gyroscope

Reaction Wheels

Narrow Angle

Camera

Power Control Unit

Power Distribution

Unit

Solar Array Drive

Mechanism

Data

Power

High Current Load

Medium Current Load

Low Current Load

LCL

LCL

FCL

FCL

FCL

FCL

FCL

LCL

FCL

LCL

FCL

FCL

LCL

Fig. 12. Detailed EPS block diagram.

Manager at SAFT, for reviewing the battery design. Fi-

nally, the ESMOs EPS team gratefully acknowledges

the Canadian Space Agency (CSA) for the funding pro-

vided through a Space Awareness and Learning Grant,

which allowed the authors to participate in the 58th In-

ternational Astronautical Congress in Hyderabad, India.

Appendix A. Detailed EPS block diagram

The detailed block diagram of the EPS is illustrated

in Fig. 12.

S. Ulrich et al. / Acta Astronautica 64 (2009) 244255 255

References

[1] E.M. Kong1, A. Saenz-Otero, S. Nolet, D.S. Berkovitz,

D.W. Miller, SPHERES as a formation ight algorithm

development and validation testbed: current progress and

beyond, in: Proceedings of the Second International Symposium

on Formation Flying Missions and Technologies, Washington,

DC, USA, 1416 September, 2004.

[2] L.N. Stras, D.D. Kekez, G.J. Wells, T. Jeans, R.E. Zee,

F.M. Pranajaya, D.G. Foisy, The design and operation of

the Canadian advanced nanospace experiment (CanX-1), in:

Proceedings of AMSAT-NA 21st Space Symposium, Toronto,

Canada, 1719 October, 2003.

[3] R.J. Twiggs, N. Shinichi, et al., A CubeSat: a new generation

of picosatellite for education and industry low-cost space

experimentation, in: Proceedings of the 14th AIAA/USU

Conference on Small Satellites, Logan, Utah, 2124 August,

2000.

[4] K. Sarda, S. Eagleson, E.P. Caillibot, C. Grant, D.D. Kekez, F.

Pranajaya, R.E. Zee, Canadian advanced nanospace experiment

2: scientic and technological innovation on a 3-kg satellite,

Acta Astronautica 59 (15) (2006) 236245.

[5] K. Sarda, S. Eagleson, S. Mauthe, T. Tuli, R.E. Zee, C.C.

Grant, D.G. Foisy, E. Cannon, C.J. Damaren, CanX-4 and

CanX-5: precision formation ight demonstrated by low

cost nanosatellites, in: Proceedings of the 13th Canadian

Astronautics Conference, Montreal, Canada, 2527 April, 2006.

[6] L. Alminde, M. Bisgaard, N. Melville, J. Schaefer, The SSETI

Express mission: from idea to launch in one and a half year,

in: Proceedings of the 2nd International Conference on Recent

Advances in Space Technologies, Istanbul, Turkey, 911 June,

2005.

[7] T. Viscor, SSETIpast, present and future, in: Proceedings of

the 20th AIAA/USU Conference on Small Satellites, Logan,

Utah, 1417 August, 2006.

[8] F. Teston, R. Creasy, J. Bermyn, K. Mellab, PROBA:

ESAs autonomy and technology demonstration mission, in:

Proceedings of the 48th International Astronautical Congress,

Turin, Italy, 610 October, 1997.

[9] S. Ulrich, F.L. Corbin, H.N. Ct, Conceptual design of the

electrical power subsystem for the European Student Moon

Orbiter mission, in: Proceedings of the 57th International

Astronautical Congress, Valencia, Spain, 26 October, 2006.

[10] Spectrolab Inc., 28.3% Ultra triple junction (UTJ) solar cells,

Technical Document, 2004.

[11] M.R. Patel, Spacecraft Power Systems, CRC Press, Boca Raton,

FL, USA, 2004.

[12] SAFT batteries, Rechargeable Li-ion battery systems light

energy storage for space applications, Technical Document No.

33015-2-1006, 2006.

[13] SAFT batteries, Li-ion Microsat module, Technical Document

No. 33016-2-0607, 2007.

[14] G.R. Walker, P.C. Sernia, Cascaded DCDC converter

connection of photovoltaic modules, IEEE Transactions on

Power Electronics 19 (4) (2004) 11301139.

[15] A.A. Nadkarni, E. Beltran, S.L. Pillar, Preliminary design

review report for the DAWGSTAR project, Technical Report,

University of Washington, 1999.

[16] T. Esram, P.L. Chapman, Comparison of photovoltaic array

maximum power point tracking techniques, IEEE Transactions

on Energy Conversion 22 (2) (2007) 439449.

[17] W.J.A. Teulings, J.C. Marpinard, A.L. Cape, D. OSullivan, A

new maximum power point tracking system, in: Proceedings of

the 24th Annual IEEE Power Electronic Specialists Conference,

Seattle, WA, USA, 2024 June, 1993.

[18] W. Xiao, W.G. Dunford, A modied adaptive hill-climbing

MPPT method for photovoltaic power systems, in: Proceedings

of the 35th Annual IEEE Power Electronic Specialists

Conference, Aachen, Germany, 2025 June, 2004.

[19] J.D. Kozlowski, M.J. Watson, C.S. Byington, A.K. Garga, T.A.

Hay, Electrochemical cell diagnostics using on-line impedance

measurements, state estimation and data fusion techniques,

in: Proceedings of the 36th Intersociety Energy Conversion

Engineering Conference, Savannah, Georgia, 29 July2 August,

2001.

[20] Tamura Corporation, Hall effect current sensors, Technical

Document, 2005.

[21] Alcatel Alenia space, Alcatel 9353 power conditioning and

distribution unit, medium power, Technical Document, 2006.

[22] Terma space, Command and monitoring module, Technical

Document, 2004.

[23] W. Rubel, Satellite design, power system, Technical Document,

EADS Astrium, 2006.

[24] Terma Space, Power distribution module, Technical Document,

2004.

Anda mungkin juga menyukai

- The Design and Simulated Performance of the Attitude Determination and Control System of a Gravity Gradient Stabilized Cube SatelliteDari EverandThe Design and Simulated Performance of the Attitude Determination and Control System of a Gravity Gradient Stabilized Cube SatelliteBelum ada peringkat

- No. 134 - December 2008Dokumen68 halamanNo. 134 - December 2008European Southern ObservatoryBelum ada peringkat

- Global Positioning: Technologies and PerformanceDari EverandGlobal Positioning: Technologies and PerformancePenilaian: 5 dari 5 bintang5/5 (1)

- Design and Implementation of An Effective Electrical Power System For Nano Satellite 2Dokumen7 halamanDesign and Implementation of An Effective Electrical Power System For Nano Satellite 2Mohammad Chessab MahdiBelum ada peringkat

- A High Performance Very Low Cost Power System For MicrospacecraftDokumen11 halamanA High Performance Very Low Cost Power System For MicrospacecraftpulaoBelum ada peringkat

- Applied Superconductivity: Volume IIDari EverandApplied Superconductivity: Volume IIVernon L. NewhouseBelum ada peringkat

- Attitude Determination and Control System For CubeSatDokumen78 halamanAttitude Determination and Control System For CubeSatSiddhant DhallBelum ada peringkat

- ST K Certification ExerciseDokumen4 halamanST K Certification ExerciseAswanTajuddinBelum ada peringkat

- T Bajersvej Attitude Determination For AAU CubeSatDokumen142 halamanT Bajersvej Attitude Determination For AAU CubeSatanterog6Belum ada peringkat

- Analysis and Simulation of Photovoltaic Systems Incorporating BatDokumen118 halamanAnalysis and Simulation of Photovoltaic Systems Incorporating BatDaniel Gomes JulianoBelum ada peringkat

- Risat I:: OrbitDokumen35 halamanRisat I:: OrbitNirmalrahul_1990Belum ada peringkat

- Design and Implementation of Attitude Control For 3-Axes Magnetic Coil Stabilization of A SpacecraftDokumen146 halamanDesign and Implementation of Attitude Control For 3-Axes Magnetic Coil Stabilization of A SpacecraftManoj SaralayaBelum ada peringkat

- CubeSat Attitude Determination and Helmholtz Cage DesignDokumen105 halamanCubeSat Attitude Determination and Helmholtz Cage DesignMarion GarciaBelum ada peringkat

- The Realization of Virtual Reality of Launching Rocket Based On Simulink and VRMLDokumen4 halamanThe Realization of Virtual Reality of Launching Rocket Based On Simulink and VRMLIJEC_EditorBelum ada peringkat

- Lunar Space Elevator-TechnicalDokumen17 halamanLunar Space Elevator-TechnicalManikantagupta BommisettyBelum ada peringkat

- ARC Micro Nano Spacecraft and Missions Where's The Sweet Spot?Dokumen22 halamanARC Micro Nano Spacecraft and Missions Where's The Sweet Spot?Space Frontier FoundationBelum ada peringkat

- Astronomy and Computing: M. Beroiz, J.B. Cabral, B. SanchezDokumen8 halamanAstronomy and Computing: M. Beroiz, J.B. Cabral, B. SanchezCarlos Alexis Alvarado Silva100% (1)

- Molecular Electronics AbstractDokumen26 halamanMolecular Electronics AbstractMurali Krishna Chaitanya RajuBelum ada peringkat

- Space-Based Solar PowerDokumen18 halamanSpace-Based Solar PowerMuhammed Nihad PBelum ada peringkat

- Nano Satellite Separation Experiment Using A P-POD Deployment MechanismDokumen37 halamanNano Satellite Separation Experiment Using A P-POD Deployment MechanismJawhni DepBelum ada peringkat

- Automatic Solar Panel Positioning and Maintenance SystemDokumen9 halamanAutomatic Solar Panel Positioning and Maintenance SystemIJRASETPublicationsBelum ada peringkat

- Solar MicroWv FabricDokumen37 halamanSolar MicroWv FabricShawn Paul BoikeBelum ada peringkat

- Aee1 SkriptDokumen186 halamanAee1 SkriptCristian PanaBelum ada peringkat

- MIT16 522S15 Lecture16Dokumen10 halamanMIT16 522S15 Lecture16Erik Nicholas BallesterosBelum ada peringkat

- Final Year ProjectDokumen171 halamanFinal Year Projectneha jhaBelum ada peringkat

- Garrison - 1997 - Systems Engineering Trades For The Iridium Constellation PDFDokumen6 halamanGarrison - 1997 - Systems Engineering Trades For The Iridium Constellation PDFPabloHarriatzuBelum ada peringkat

- Orbital MechanicsDokumen28 halamanOrbital MechanicsMartin Schweighart MoyaBelum ada peringkat

- Wireless Power TransmissionDokumen24 halamanWireless Power TransmissionSandeep MedishettyBelum ada peringkat

- Advanced Fusion Energy SystemDokumen11 halamanAdvanced Fusion Energy SystemPhilip KadickBelum ada peringkat

- Design, Development and Testing Nitrous Oxide System of A Hybrid Rocket MotorDokumen36 halamanDesign, Development and Testing Nitrous Oxide System of A Hybrid Rocket MotorMohamed TarmiziBelum ada peringkat

- Solar CellsDokumen91 halamanSolar CellscmeliovBelum ada peringkat

- A Review of Photovoltaic Cells (David Toub)Dokumen13 halamanA Review of Photovoltaic Cells (David Toub)Arul SankaranBelum ada peringkat

- Cyborg Glove ExcerptNick and Tesla's Super Cyborg Gadget Glove (Excerpt)Dokumen67 halamanCyborg Glove ExcerptNick and Tesla's Super Cyborg Gadget Glove (Excerpt)Quirk BooksBelum ada peringkat

- Estimation of Electric Charge Output For PiezoelectricDokumen28 halamanEstimation of Electric Charge Output For PiezoelectricSumit PopleBelum ada peringkat

- Explaining The Working Principle of Photovoltaic CellsDokumen4 halamanExplaining The Working Principle of Photovoltaic CellsAneek Islam50% (2)

- Evaluation of High Power Energy Storage Devices For Use in Compact Pulsed Power SystemsDokumen19 halamanEvaluation of High Power Energy Storage Devices For Use in Compact Pulsed Power SystemsbijushresthBelum ada peringkat

- Plasma Propelled Rocket EnginesDokumen24 halamanPlasma Propelled Rocket EnginesRaunaq Singh100% (1)

- The Design and Performance of A Power System For The Galileo System Test Bed GSTB-V2ADokumen6 halamanThe Design and Performance of A Power System For The Galileo System Test Bed GSTB-V2AAndres Rambal VecinoBelum ada peringkat

- Project ReportDokumen96 halamanProject ReportDefid Ghpsi Isrel100% (2)

- Solar Cell Fundamentals: SJSU Short Course D. W. ParentDokumen9 halamanSolar Cell Fundamentals: SJSU Short Course D. W. ParentFaiz RangariBelum ada peringkat

- Current Status of ESC: Speech To The Staff at The ESO Garching Headquarters On December 6, 1994Dokumen56 halamanCurrent Status of ESC: Speech To The Staff at The ESO Garching Headquarters On December 6, 1994European Southern ObservatoryBelum ada peringkat

- SSP - Power Star PresentationDokumen28 halamanSSP - Power Star PresentationShawn Paul BoikeBelum ada peringkat

- Exercise1 2016Dokumen2 halamanExercise1 2016JadBelum ada peringkat

- Will The Martian Space Vehicle Return To Earth?Dokumen52 halamanWill The Martian Space Vehicle Return To Earth?Ardian RizaldiBelum ada peringkat

- Aero9500 STK T2Dokumen18 halamanAero9500 STK T2John SmithBelum ada peringkat

- A Micro-Satellite Thermal Control AnalysisDokumen25 halamanA Micro-Satellite Thermal Control AnalysisoliveirarenanfelipeBelum ada peringkat

- 2009 - IEEE - Comprehensive Approach To Modeling and Simulation of PV ArraysDokumen12 halaman2009 - IEEE - Comprehensive Approach To Modeling and Simulation of PV ArraysTalles VianaBelum ada peringkat

- Geomagnetic DisturbancesDokumen98 halamanGeomagnetic DisturbancesAlfonso GonzálezBelum ada peringkat

- The Principles of LCD TechnologyDokumen56 halamanThe Principles of LCD TechnologyClique for Applied Research in Electronic TechnologyBelum ada peringkat

- UAVL Final Thesis - ReportDokumen118 halamanUAVL Final Thesis - ReportHammadZenBelum ada peringkat

- Satellite SubsystemsDokumen4 halamanSatellite SubsystemsHatrick PoviousBelum ada peringkat

- Space Based Solar PowerDokumen21 halamanSpace Based Solar Powersrilu34100% (1)

- Oakton High School Sli CDR ReportDokumen52 halamanOakton High School Sli CDR Reportapi-482725014Belum ada peringkat

- Stability and Energy Absorption of A Lunar Lander by 1/6 Scale Drop Testing and Full-Scale SimulationDokumen17 halamanStability and Energy Absorption of A Lunar Lander by 1/6 Scale Drop Testing and Full-Scale SimulationAhmet Sahinoz100% (2)

- NearSpace Balloon LaunchDokumen687 halamanNearSpace Balloon Launchfranco.didio1945Belum ada peringkat

- Masaferro Et Al 2003 TLEDokumen8 halamanMasaferro Et Al 2003 TLEPatrick EllisBelum ada peringkat

- 1 - UAV Formation Flight Control and Formation Switch Strategy PDFDokumen6 halaman1 - UAV Formation Flight Control and Formation Switch Strategy PDFLuthfi YahyaBelum ada peringkat

- Wind Energy - An IntroductionDokumen5 halamanWind Energy - An IntroductionShailendra PratapBelum ada peringkat

- Combining Experimental Data, CFD, and 6-DOF Simulation To DevelopDokumen19 halamanCombining Experimental Data, CFD, and 6-DOF Simulation To Developchoiwon1Belum ada peringkat

- CCTV Guidelines - Commission Letter Dated 27.08.2022Dokumen2 halamanCCTV Guidelines - Commission Letter Dated 27.08.2022Sumeet TripathiBelum ada peringkat

- Cutler Hammer Dry Type TransformerDokumen220 halamanCutler Hammer Dry Type TransformernprajanBelum ada peringkat

- Planning Effective Advertising and Promotion Strategies For A Target AudienceDokumen16 halamanPlanning Effective Advertising and Promotion Strategies For A Target Audiencebakhoo12Belum ada peringkat

- QuerySurge Models Mappings DocumentDokumen28 halamanQuerySurge Models Mappings Documentchiranjeev mishra100% (1)

- Adhesive Film & TapeDokumen6 halamanAdhesive Film & TapeJothi Vel MuruganBelum ada peringkat

- Little: PrinceDokumen18 halamanLittle: PrinceNara Serrano94% (18)

- FMO ESG Toolkit (AutoRecovered)Dokumen149 halamanFMO ESG Toolkit (AutoRecovered)me.abhishekpBelum ada peringkat

- Enzyme Immobilization - Advances in Industry, Agriculture, Medicine, and The Environment-Springer International Publishing (2016)Dokumen141 halamanEnzyme Immobilization - Advances in Industry, Agriculture, Medicine, and The Environment-Springer International Publishing (2016)Komagatae XylinusBelum ada peringkat

- Invitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Dokumen2 halamanInvitation of Nomination For The Rajiv Gandhi Wildlife Conservation Award For The Year 2011&2012Naresh KadyanBelum ada peringkat

- Story 1Dokumen3 halamanStory 1api-296631749Belum ada peringkat

- The Consulting Industry and Its Transformations in WordDokumen23 halamanThe Consulting Industry and Its Transformations in Wordlei ann magnayeBelum ada peringkat

- 1ST Term J1 Fine Art-1Dokumen22 halaman1ST Term J1 Fine Art-1Peter Omovigho Dugbo100% (1)

- 3 A Sanitary Standards Quick Reference GuideDokumen98 halaman3 A Sanitary Standards Quick Reference GuideLorettaMayBelum ada peringkat

- Gifted Black Females Attending Predominantly White Schools Compressed 1 CompressedDokumen488 halamanGifted Black Females Attending Predominantly White Schools Compressed 1 Compressedapi-718408484Belum ada peringkat

- Crown BeverageDokumen13 halamanCrown BeverageMoniruzzaman JurorBelum ada peringkat

- CSCU Module 08 Securing Online Transactions PDFDokumen29 halamanCSCU Module 08 Securing Online Transactions PDFdkdkaBelum ada peringkat

- Intertext: HypertextDokumen8 halamanIntertext: HypertextRaihana MacabandingBelum ada peringkat

- Menara PMB Assessment Criteria Score SummaryDokumen2 halamanMenara PMB Assessment Criteria Score SummarySyerifaizal Hj. MustaphaBelum ada peringkat

- Bakteri Anaerob: Morfologi, Fisiologi, Epidemiologi, Diagnosis, Pemeriksaan Sy. Miftahul El J.TDokumen46 halamanBakteri Anaerob: Morfologi, Fisiologi, Epidemiologi, Diagnosis, Pemeriksaan Sy. Miftahul El J.TAlif NakyukoBelum ada peringkat

- ERP22006Dokumen1 halamanERP22006Ady Surya LesmanaBelum ada peringkat

- What Is An EcosystemDokumen42 halamanWhat Is An Ecosystemjoniel05Belum ada peringkat

- Propp Function's Types:: 1-Absentation: One of The Members of A Family Absents Himself From HomeDokumen10 halamanPropp Function's Types:: 1-Absentation: One of The Members of A Family Absents Himself From HomeRohith KumarBelum ada peringkat

- Onco Case StudyDokumen2 halamanOnco Case StudyAllenBelum ada peringkat

- POLYTHEOREMSDokumen32 halamanPOLYTHEOREMSYen LeeBelum ada peringkat

- Data Structures and Algorithms SyllabusDokumen9 halamanData Structures and Algorithms SyllabusBongbong GalloBelum ada peringkat

- Knitting in Satellite AntennaDokumen4 halamanKnitting in Satellite AntennaBhaswati PandaBelum ada peringkat

- Makerere University Is Inviting Applications For Undergraduate Admissions On Private Sponsorship For Academic Year 2015/2016Dokumen9 halamanMakerere University Is Inviting Applications For Undergraduate Admissions On Private Sponsorship For Academic Year 2015/2016The Campus TimesBelum ada peringkat

- Micronet TMRDokumen316 halamanMicronet TMRHaithem BrebishBelum ada peringkat

- AYUSH Warli Art 100628Dokumen10 halamanAYUSH Warli Art 100628adivasi yuva shakti0% (1)

- @InglizEnglish-4000 Essential English Words 6 UzbDokumen193 halaman@InglizEnglish-4000 Essential English Words 6 UzbMaster SmartBelum ada peringkat

- INCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesDari EverandINCOSE Systems Engineering Handbook: A Guide for System Life Cycle Processes and ActivitiesPenilaian: 5 dari 5 bintang5/5 (1)

- Electronics All-in-One For Dummies, 3rd EditionDari EverandElectronics All-in-One For Dummies, 3rd EditionPenilaian: 5 dari 5 bintang5/5 (2)

- Digital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosDari EverandDigital Filmmaking: The Ultimate Guide to Web Video Production for Beginners and Non-Professionals, Learn Useful Tips and Advice on How You Can Create, Film and Edit Your VideosPenilaian: 5 dari 5 bintang5/5 (1)

- Hacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsDari EverandHacking Electronics: An Illustrated DIY Guide for Makers and HobbyistsPenilaian: 3.5 dari 5 bintang3.5/5 (2)

- Practical Electrical Wiring: Residential, Farm, Commercial, and IndustrialDari EverandPractical Electrical Wiring: Residential, Farm, Commercial, and IndustrialPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Analog Design and Simulation Using OrCAD Capture and PSpiceDari EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceBelum ada peringkat

- Programming the Raspberry Pi, Third Edition: Getting Started with PythonDari EverandProgramming the Raspberry Pi, Third Edition: Getting Started with PythonPenilaian: 5 dari 5 bintang5/5 (2)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tDari EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tPenilaian: 4.5 dari 5 bintang4.5/5 (27)

- Teach Yourself Electricity and Electronics, 6th EditionDari EverandTeach Yourself Electricity and Electronics, 6th EditionPenilaian: 3.5 dari 5 bintang3.5/5 (15)

- Heat Transfer Engineering: Fundamentals and TechniquesDari EverandHeat Transfer Engineering: Fundamentals and TechniquesPenilaian: 4 dari 5 bintang4/5 (1)

- Conquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgeDari EverandConquering the Electron: The Geniuses, Visionaries, Egomaniacs, and Scoundrels Who Built Our Electronic AgePenilaian: 4.5 dari 5 bintang4.5/5 (10)

- 2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersDari Everand2022 Adobe® Premiere Pro Guide For Filmmakers and YouTubersPenilaian: 5 dari 5 bintang5/5 (1)

- Build Your Own Electronics WorkshopDari EverandBuild Your Own Electronics WorkshopPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- The Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionDari EverandThe Innovators: How a Group of Hackers, Geniuses, and Geeks Created the Digital RevolutionPenilaian: 4.5 dari 5 bintang4.5/5 (543)

- Upcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Dari EverandUpcycled Technology: Clever Projects You Can Do With Your Discarded Tech (Tech gift)Penilaian: 4.5 dari 5 bintang4.5/5 (2)

- The Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesDari EverandThe Phone Fix: The Brain-Focused Guide to Building Healthy Digital Habits and Breaking Bad OnesPenilaian: 5 dari 5 bintang5/5 (1)

- Current Interruption Transients CalculationDari EverandCurrent Interruption Transients CalculationPenilaian: 4 dari 5 bintang4/5 (1)