WSD2000 Check - Nominal Load Method: SAP2000 SAP2000 SAP2000

Diunggah oleh

Andre OliveiraJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

WSD2000 Check - Nominal Load Method: SAP2000 SAP2000 SAP2000

Diunggah oleh

Andre OliveiraHak Cipta:

Format Tersedia

Design Parameters Page 1 of 5

COMPUTERS AND STRUCTURES, INC., BERKELEY, CALIFORNIA FEBRUARY 2003

TUBULAR STEEL FRAME PUNCHING LOAD CHECK

Technical Note

WSD2000 Check Nominal Load Method

This Technical Note describes the methodology used for the punching load

check when the steel design code is set to API RP2A-WSD2000 and the

nominal load method is specified to be used to calculate the punching load

stresses. Note that both the steel design code and the punching load method,

which can be punching shear or nominal load for the API RP2A-WSD2000

design code, are specified in the steel design preferences. The preferences

are accessed using the Options > Preferences >Steel Frame Design

command.

The design check is based on criteria published in Sections 4.3.1 and 4.3.2 of

the American Petroleum Institute 2000 reference.

Design Parameters

Joint Geometric Parameters

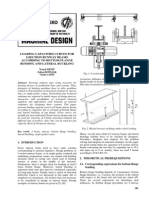

Figure 1 illustrates some of the geometric parameters used in the punching

load check. They are:

= Angle measured from the chord to the brace.

g = Gap distance.

t = Brace thickness.

T = Chord thickness.

d = Brace diameter.

D = Chord diameter.

In addition, three more geometric parameters are derived from those shown

in Figure 1. They are as follows:

T

t

=

D

d

=

2T

D

=

SAP2000

SAP2000

SAP2000

Tubular Steel Frame Punching Load Check WSD2000 Check Nominal Load Method

Overview of Punching Load Check Page 2 of 5

T

D

g

d

t

Chord

Brace

Brace

Figure 1: Joint Geometric Parameters

Chord Yield Strength

The chord yield strength is designated F

yc

. It is taken as the smaller of the

yield strength, F

y

, of the considered chord member and two-thirds of the

tensile strength, F

u

, of the chord member.

Overview of Punching Load Check

The program performs the punching load check based on the requirements for

simple joints presented in Section 4.3.1 of the American Petroleum Institute

2000 reference. In addition, if the joint classification associated with the

considered brace is specified as K Overlap, the punching load check also

considers the equations present in Section 4.3.2 of the reference.

Allowable Loads

The allowable axial load, P

a

, and allowable bending load, M

a

, are calculated

using API equations 4.3.1-4a and 4.3.1-4b. The one-third allowable stress

increase is included for P

a

and M

a

where applicable.

sin 1.7

T F

Q Q P

2

yc

f u a

= Eqn. 1

Tubular Steel Frame Punching Load Check WSD2000 Check Nominal Load Method

Simple Joint Check Ratios Page 3 of 5

( ) 0.8d

sin 1.7

T F

Q Q M

2

yc

f u a

= Eqn. 2

Equation 2 is used for both in-plane and out-of-plane bending. In Equations 1

and 2, Q

u

is determined from API Table 4.3.1-2 and Q

f

is calculated as

described in the following subsection. Note that it is also possible for the user

to directly specify values for Q

u

and Q

f

.

Calculation of Q

f

The Q

f

value used in Equation 2 is calculated as follows.

2

f

A 1.0 Q = Eqn. 3

where,

= 0.030 for brace axial stress.

= 0.045 for in-plane bending stress.

= 0.021 for out-of-plane bending stress.

and,

yc

2

OPB

2

IPB

2

AX

0.6F

f f f

A

+ +

= Eqn. 4

The one-third allowable stress increase is included in the denominator of

Equation 4 where applicable. In Equation 4, the terms

AX

f ,

IPB

f and

OPB

f are

the nominal axial, in-plane bending and out-of-plane bending stresses in the

chord.

Q

f

is set to 1.0 when all extreme fiber stresses in the chord are tensile. The

program considers this condition to be met when the axial stress in the chord

is tensile and 0 f f f

OPB IPB AX

.

Simple Joint Check Ratios

The two ratios given in API equations 4.3.1-5a and 4.3.1-5b are calculated for

all joints.

Tubular Steel Frame Punching Load Check WSD2000 Check Nominal Load Method

Overlapping Joints Page 4 of 5

0 . 1

M

M

M

M

Ratio1

2

OPB

a

2

IPB

a

= Eqn. 5

1.0

M

M

M

M

arcsin

2

P

P

Ratio2

2

OPB

a

2

IPB

a

AX

a

+ = Eqn. 6

In Equation 6, the arcsin term is in radians. In Equations 5 and 6, AX means

axial load, IPB means in-plane-bending, and OPB means out-of-plane

bending.

Overlapping Joints

For braces that are assigned a K Overlap joint classification, the additional

check described in this section is performed. The axial load component of the

brace perpendicular to the chord, P , is first calculated.

Psin P = Eqn. 7

where P is the axial load in the brace.

The allowable axial load component of the brace perpendicular to the chord,

a

P , is calculated using API equation 4.3.2-2.

2 w wa

1

a a

l t v 2

l

l

sin P P + = Eqn. 8

where,

v

wa

= Allowable shear stress for weld between braces.

t

w

= The lesser of the weld throat thickness and the thickness of the

thinner brace.

l = Circumference of brace contact with the chord, neglecting the

presence of the overlap.

l

1

= Circumference for that portion of the brace that contacts the chord.

l

2

= Projected chord length (one side) of the overlapping weld measured

perpendicular to the chord.

Tubular Steel Frame Punching Load Check WSD2000 Check Nominal Load Method

References Page 5 of 5

The ratio for overlapping joints is calculated using Equation 9.

a

P

P

Ratio3

= Eqn. 9

References

American Petroleum Institute (API). 2000. Recommended Practice for

Planning, Designing, and Constructing Fixed Offshore Platforms

Working Stress Design; API Recommended Practice 2A-WSD (RP 2A-

WSD). Twenty-First Edition. December.

Anda mungkin juga menyukai

- Structural Steel Design to Eurocode 3 and AISC SpecificationsDari EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsBelum ada peringkat

- Flight Test Instrumentation: Proceedings of the Third International Symposium 1964Dari EverandFlight Test Instrumentation: Proceedings of the Third International Symposium 1964M. A. PerryBelum ada peringkat

- S TN Pun 005Dokumen5 halamanS TN Pun 005Batepola BacBelum ada peringkat

- Api Rp2a-Lrfd97 P L CDokumen5 halamanApi Rp2a-Lrfd97 P L CBatepola BacBelum ada peringkat

- Trunnion N392-3 R0Dokumen30 halamanTrunnion N392-3 R0Sergio Smith100% (1)

- Indian Institute of Technology Hyderabad (IITH) : Experiment-1: OC, SC and Load Tests on 1-ϕ TransformerDokumen4 halamanIndian Institute of Technology Hyderabad (IITH) : Experiment-1: OC, SC and Load Tests on 1-ϕ TransformerSristi Ram DyuthiBelum ada peringkat

- 181-186 For Web PDFDokumen6 halaman181-186 For Web PDFdiego.peinado8856100% (1)

- 4.designfor AASHTO 1997Dokumen18 halaman4.designfor AASHTO 1997Aku PalsuBelum ada peringkat

- Stress ReportDokumen6 halamanStress Reportasif_vzaBelum ada peringkat

- 0000001743-Calculation Report Conveyor Structure T-1022Dokumen29 halaman0000001743-Calculation Report Conveyor Structure T-1022Shada Mohammed96% (27)

- Effect of Nozzle Stiffness On Nozzle Loads and StressesDokumen12 halamanEffect of Nozzle Stiffness On Nozzle Loads and StressesJafer SayedBelum ada peringkat

- Chapter 2 CDokumen21 halamanChapter 2 CYasser AlghrafyBelum ada peringkat

- Block Shear Load Capacity Predictions1994Dokumen16 halamanBlock Shear Load Capacity Predictions1994Mohammed Essam ShatnawiBelum ada peringkat

- Norma Aisc-Asd89 Sap2000Dokumen29 halamanNorma Aisc-Asd89 Sap2000IVAN SAAVEDRA TBelum ada peringkat

- Design Properties For Crane Runway BeamsDokumen4 halamanDesign Properties For Crane Runway BeamsToni RenedoBelum ada peringkat

- Avaliação de Integridade de Tubos Inox Austeníticos em Falhas AxiaisDokumen8 halamanAvaliação de Integridade de Tubos Inox Austeníticos em Falhas AxiaisRafael FerreiraBelum ada peringkat

- Evolution of Shear Lag and Block Shear Provisions in The AISC SpecificationDokumen4 halamanEvolution of Shear Lag and Block Shear Provisions in The AISC SpecificationSergioAlcantaraBelum ada peringkat

- 17 TonsDokumen8 halaman17 Tonsabuzahrau100% (3)

- GRP Pipe Analysis - Write Up - 1Dokumen8 halamanGRP Pipe Analysis - Write Up - 1Marie SaundersBelum ada peringkat

- ASI TN004 V2 Design Properties Crane BeamsDokumen4 halamanASI TN004 V2 Design Properties Crane Beamskayakeras3335Belum ada peringkat

- Homework #5:: Material-Property Relations & Yield/Failure CriterionDokumen1 halamanHomework #5:: Material-Property Relations & Yield/Failure CriterionPranjal SinghBelum ada peringkat

- Allowable Pipe Spans LoadsDokumen84 halamanAllowable Pipe Spans LoadsMalcolm Hutton100% (5)

- LRFD Aashto 4-22-39Dokumen18 halamanLRFD Aashto 4-22-39Eduardo SilvaBelum ada peringkat

- Strap: 6.5.5.7 National Building Code of CanadaDokumen32 halamanStrap: 6.5.5.7 National Building Code of CanadakanchanabalajiBelum ada peringkat

- ACI ITG/T1.1R-99: Reported by ACI Innovation Task Group 1 and CollaboratorsDokumen7 halamanACI ITG/T1.1R-99: Reported by ACI Innovation Task Group 1 and CollaboratorsCorui Mihai ValerBelum ada peringkat

- Design of Aluminium Columns PDFDokumen7 halamanDesign of Aluminium Columns PDFdjordjeueBelum ada peringkat

- AISC-LRFD93 Untuk Perencanaan Stuktur Baja Dengan SAP2000Dokumen30 halamanAISC-LRFD93 Untuk Perencanaan Stuktur Baja Dengan SAP2000irbar.darmansyah.alwi100% (2)

- Parametric Study of Flexibility Factor For Curved Pipe and Welding ElbowsDokumen9 halamanParametric Study of Flexibility Factor For Curved Pipe and Welding Elbowsbam_1962Belum ada peringkat

- Strut and Tie UploadDokumen4 halamanStrut and Tie UploadEngr Sher KhanBelum ada peringkat

- Offshore TechDokumen351 halamanOffshore Techmarkengineer100% (2)

- Pipe Stress Analysis Information For FRPDokumen10 halamanPipe Stress Analysis Information For FRPchemy5Belum ada peringkat

- Design of Pipe RacksDokumen23 halamanDesign of Pipe RacksDushyant Varshney100% (1)

- Software Verification: Example 17Dokumen8 halamanSoftware Verification: Example 17sancloudBelum ada peringkat

- EC3 Design (Staad Manual)Dokumen29 halamanEC3 Design (Staad Manual)chidsalazarBelum ada peringkat

- (1966) Basic Facts Concerning Shear Failure PDFDokumen37 halaman(1966) Basic Facts Concerning Shear Failure PDFMohammad AshrafyBelum ada peringkat

- API RP 2A 21st 2000 Vs 2007-FatigueDokumen16 halamanAPI RP 2A 21st 2000 Vs 2007-Fatiguesm8575Belum ada peringkat

- Design of Pipe Rack StructureDokumen23 halamanDesign of Pipe Rack Structureibson045001256Belum ada peringkat

- 006 Wilkowski - editedDokumen17 halaman006 Wilkowski - editedFilip Van den AbeeleBelum ada peringkat

- Engineering Critical Assessment of Vintage Girth WeldsDokumen16 halamanEngineering Critical Assessment of Vintage Girth WeldspsBelum ada peringkat

- Vfielav Cyrus ) : 6 C + Ao, + A6Dokumen7 halamanVfielav Cyrus ) : 6 C + Ao, + A6csmistryBelum ada peringkat

- ASME Ch38 p001-018 11-8-08Dokumen18 halamanASME Ch38 p001-018 11-8-08Dan MorganBelum ada peringkat

- A New Approach For Design of Steel Beam-Columns Our A.Dokumen32 halamanA New Approach For Design of Steel Beam-Columns Our A.mbrown4382Belum ada peringkat

- Ans.: Larger ConnectionDokumen1 halamanAns.: Larger Connectiontibor121774_66173108Belum ada peringkat

- Flange stress analysis questionsDokumen1 halamanFlange stress analysis questionstibor121774_66173108Belum ada peringkat

- WRC 107Dokumen1 halamanWRC 107tibor121774_66173108Belum ada peringkat

- Api 650Dokumen1 halamanApi 650tibor121774_66173108Belum ada peringkat

- Piperack PresentationDokumen23 halamanPiperack PresentationOmar AlkubaiciBelum ada peringkat

- Indian Roads June 2009 ExtractDokumen57 halamanIndian Roads June 2009 ExtractSaurav TalukdarBelum ada peringkat

- NozzleQualification WRC537Dokumen13 halamanNozzleQualification WRC537hung tran dinhBelum ada peringkat

- APPENDjnklhIXW3 25 09Dokumen9 halamanAPPENDjnklhIXW3 25 09Marimuthu AyyamperumalBelum ada peringkat

- Example Problem 4.1 Given:: Results SummaryDokumen32 halamanExample Problem 4.1 Given:: Results SummarynguyenduccuongactBelum ada peringkat

- Applying The Wheatstone Bridge CircuitDokumen36 halamanApplying The Wheatstone Bridge CircuitMichael Kang0% (1)

- Calculation of steel beam to column moment connection capacityDokumen25 halamanCalculation of steel beam to column moment connection capacityZulfikar N JoelBelum ada peringkat

- Casing Desain PengeboranDokumen52 halamanCasing Desain PengeboranDhenny Adriana Rachman100% (1)

- Shear Wall - BS8110-97-007Dokumen4 halamanShear Wall - BS8110-97-007Kavin TamBelum ada peringkat

- 2ESR-2461 - MKT Metall-Kunststoff-Technik GMBH & Co. KGDokumen2 halaman2ESR-2461 - MKT Metall-Kunststoff-Technik GMBH & Co. KGbisagantiBelum ada peringkat

- Cylindrical Compression Helix Springs For Suspension SystemsDari EverandCylindrical Compression Helix Springs For Suspension SystemsBelum ada peringkat

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsDari EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionDari EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionBelum ada peringkat

- ANSYS Mechanical ANSYS Mechanical Structural Nonlinearities: Rate Independent PlasticityDokumen56 halamanANSYS Mechanical ANSYS Mechanical Structural Nonlinearities: Rate Independent PlasticityGz2239Belum ada peringkat

- Example 13Dokumen10 halamanExample 13Andre OliveiraBelum ada peringkat

- Autodyn Theory ManualDokumen235 halamanAutodyn Theory ManualAndre OliveiraBelum ada peringkat

- Principe de AsturiasDokumen2 halamanPrincipe de AsturiasAndre OliveiraBelum ada peringkat

- Non Linear Concrete: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ADokumen12 halamanNon Linear Concrete: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.AAndre OliveiraBelum ada peringkat

- T03ENGDokumen128 halamanT03ENGAndre OliveiraBelum ada peringkat

- T11BENGDokumen159 halamanT11BENGAndre OliveiraBelum ada peringkat

- T08ENGDokumen32 halamanT08ENGAndre OliveiraBelum ada peringkat

- Example 21Dokumen14 halamanExample 21Andre OliveiraBelum ada peringkat

- E03ENGDokumen12 halamanE03ENGAndre OliveiraBelum ada peringkat

- Example 5Dokumen23 halamanExample 5Andre OliveiraBelum ada peringkat

- Seismic Design According To Eurocode No. 8 and Ncse94: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ADokumen16 halamanSeismic Design According To Eurocode No. 8 and Ncse94: Civilfem Manual of Essential Examples. 300609 .Ingeciber, S.ACamv VenturaBelum ada peringkat

- E10ENGDokumen41 halamanE10ENGAndre OliveiraBelum ada peringkat

- Example 7Dokumen11 halamanExample 7Andre OliveiraBelum ada peringkat

- DM DeletFaceThicknesses ACT Extension Description v160 v1Dokumen1 halamanDM DeletFaceThicknesses ACT Extension Description v160 v1Andre OliveiraBelum ada peringkat

- Example #14 Tunnel With Concrete Lining: Civilfem Manual of Advanced Examples - Ingeciber, S.A.Dokumen14 halamanExample #14 Tunnel With Concrete Lining: Civilfem Manual of Advanced Examples - Ingeciber, S.A.Andre OliveiraBelum ada peringkat

- TDAS ACT Extension Description v160 v1Dokumen1 halamanTDAS ACT Extension Description v160 v1Andre OliveiraBelum ada peringkat

- DM Cross Section Lib ACT Extension Description v160 v1Dokumen1 halamanDM Cross Section Lib ACT Extension Description v160 v1Andre OliveiraBelum ada peringkat

- Example 2Dokumen16 halamanExample 2Andre OliveiraBelum ada peringkat

- Example 8Dokumen11 halamanExample 8Andre OliveiraBelum ada peringkat

- Push-Over Analysis: Problem DescriptionDokumen51 halamanPush-Over Analysis: Problem DescriptionAndre OliveiraBelum ada peringkat

- 4 Polyflow - 12.1 Polyflow BDokumen17 halaman4 Polyflow - 12.1 Polyflow BAndre OliveiraBelum ada peringkat

- Mech-UCO 120 WS-07 FilterDokumen32 halamanMech-UCO 120 WS-07 FilterAndre OliveiraBelum ada peringkat

- Example 5Dokumen23 halamanExample 5Andre OliveiraBelum ada peringkat

- ReadmeDokumen1 halamanReadmeAndre OliveiraBelum ada peringkat

- Tut 16Dokumen36 halamanTut 16Andre OliveiraBelum ada peringkat

- CivilBay Crane Load Crane Runway Beam Design 1.0.0 ManualDokumen112 halamanCivilBay Crane Load Crane Runway Beam Design 1.0.0 Manualwudongxiao3953100% (2)

- Tutorial For Ansys Fluent Porous MediaDokumen30 halamanTutorial For Ansys Fluent Porous MediaLykaios Schultz DohrnBelum ada peringkat

- Bekum Industrial Packagung ENDokumen8 halamanBekum Industrial Packagung ENخبراء التصنيع الدوائي-اليمنBelum ada peringkat

- Guia TP Completa 2018 Version2Dokumen113 halamanGuia TP Completa 2018 Version2epuchuluBelum ada peringkat

- Piping Stress AnalysisDokumen36 halamanPiping Stress AnalysisSugumar S100% (1)

- Welding TestDokumen21 halamanWelding TestryantoBelum ada peringkat

- Mini VRFDokumen34 halamanMini VRFPaulo Vitor Santos100% (1)

- Consider A Simple Steam-Turbine Engine With The Tu.Dokumen4 halamanConsider A Simple Steam-Turbine Engine With The Tu.Din TescoBelum ada peringkat

- 6.fluid Mechanics-1-10Dokumen10 halaman6.fluid Mechanics-1-10Vijeesh VijayalayamBelum ada peringkat

- Grados Termicos TN55TH y TN80THDokumen10 halamanGrados Termicos TN55TH y TN80THgfwtBelum ada peringkat

- Corrosion PDFDokumen73 halamanCorrosion PDFRajat VarshneyBelum ada peringkat

- Problem Sheet - 2 PDFDokumen2 halamanProblem Sheet - 2 PDFJyotirmoy DekaBelum ada peringkat

- Macam-Macam Dan Sifat Bahan Resin Kedokteran Gigi - Bimo RintokoDokumen18 halamanMacam-Macam Dan Sifat Bahan Resin Kedokteran Gigi - Bimo Rintokodayanara_245104654Belum ada peringkat

- Question: An Air-Conditioning Unit Weighing 1200 LB Is Bolted at The MidDokumen3 halamanQuestion: An Air-Conditioning Unit Weighing 1200 LB Is Bolted at The MidblehalaBelum ada peringkat

- Hf-Erw Hf-Erw: Pipes & Tubes Pipes & TubesDokumen8 halamanHf-Erw Hf-Erw: Pipes & Tubes Pipes & Tubesmoechamad_aditiaBelum ada peringkat

- Development of Database of Cyclic Soil Properties From 94 Tests On 47 SoilsDokumen10 halamanDevelopment of Database of Cyclic Soil Properties From 94 Tests On 47 SoilsJulio BetancurBelum ada peringkat

- Air Cooled Heat Exchangers - BrochureDokumen16 halamanAir Cooled Heat Exchangers - Brochurenorthstarleo100% (1)

- Documents 5401 G 5Dokumen2 halamanDocuments 5401 G 5ductoan32Belum ada peringkat

- Raytools BM109 spare parts listDokumen1 halamanRaytools BM109 spare parts listremus popescuBelum ada peringkat

- Technical Thermodynamics For Engineers: Achim SchmidtDokumen987 halamanTechnical Thermodynamics For Engineers: Achim SchmidtVictor PalaciosBelum ada peringkat

- Refractory Dry Out Procedures SummaryDokumen18 halamanRefractory Dry Out Procedures SummaryRajendran Srn100% (6)

- Thermalrock S Data Sheet - inDokumen2 halamanThermalrock S Data Sheet - inlac ngoBelum ada peringkat

- Kelton Calculation DetailsDokumen17 halamanKelton Calculation DetailsronziesBelum ada peringkat

- 2017 3-Dimensional Numerical Modeling of Geosynthetic-Encased Granular ColumnsDokumen11 halaman2017 3-Dimensional Numerical Modeling of Geosynthetic-Encased Granular ColumnsS R Kumar KonathalaBelum ada peringkat

- Solvent Improvement For Separating C4 With ACNDokumen9 halamanSolvent Improvement For Separating C4 With ACNBacBelum ada peringkat

- Hydrology Report Part 1Dokumen19 halamanHydrology Report Part 1Cherry PieBelum ada peringkat

- Study Materials Level 3Dokumen6 halamanStudy Materials Level 3Krishna Vacha50% (2)

- Isentropic+Expansion+for+Fluids+-+SRK EOSDokumen12 halamanIsentropic+Expansion+for+Fluids+-+SRK EOSsdrtfgBelum ada peringkat

- Flying Windmills: Conventional WindmillDokumen7 halamanFlying Windmills: Conventional WindmillGógul100% (1)

- COSMOS-L Scientific ReportDokumen186 halamanCOSMOS-L Scientific ReportNikesh ChowrasiaBelum ada peringkat

- Wassce / Waec Chemistry Syllabus: 1. Structure of The AtomDokumen30 halamanWassce / Waec Chemistry Syllabus: 1. Structure of The AtomJesse Lartey100% (1)

- Fundamentals of Diffuse Optics and Tissue ApplicationsDokumen115 halamanFundamentals of Diffuse Optics and Tissue ApplicationsRom Kno SanBelum ada peringkat