A Multilayer Ultra-Wideband Directional Coupler

Diunggah oleh

agmnm1962Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

A Multilayer Ultra-Wideband Directional Coupler

Diunggah oleh

agmnm1962Hak Cipta:

Format Tersedia

A Multilayer Ultra-Wideband

Directional Coupler

Mario Leib, Dennis Mack, Felix Thurow and Wolfgang Menzel

Abstract In this contribution, the well-known vertically installed planar coupler is introduced briefly, and an

improved assembly technique is proposed increasing the mechanical stability of the coupler. Then, the

design of a novel multilayer planar, ultra-wideband, five-sectional 3 dB directional coupler with an easier

fabrication process andlower height is presented. Inthis approach, the necessary tight coupling at the center

section for the desired ultra-broadband behavior is achieved with a multilayer configuration instead of a

vertically installed substrate. The manufactured multilayer coupler has a coupling and insertion loss of

3.4 dB 1.1 dB and an isolation and return loss of better than 14 dB in the operating bandwidth between

3.110.6 GHz. The design procedure, identical for both coupler types, needs no time-consuming full-wave

analysis and will be described in detail for the novel multilayer coupler.

Index Terms Microstrip directional couplers, ultra-wideband, multilayer, planar

1. Introduction

Directional couplers are core components for many micro-

wave systems, subsystems andmeasurement devices. Since the

Federal Communications Commission (FCC) released a

generic admission for ultra-wideband systems between

3.1 GHz and 10.6 GHz in 2002 [1], a lot of communication

and radar systems for different applications are under

investigation [2]. Directional couplers are of general interest

for power division and combination, duplexers and beam-

forming networks for array antennas. In addition to the

required ultra-wide operational bandwidth, planar realiza-

tions, e. g. in microstrip technique, are desired for an easy

integration and low cost of production.

A well-known and established method to realize a planar

broadband coupler is the use of multiple sections of TEM

coupled microstrip lines [3]. A common problem is the

necessary tight coupling at the inner sections which is difficult

to obtain with a standard PCB fabrication process. Several

approaches exist to overcome this problem. So a tandem

configuration [4], [5] or a re-entrant coupler type [6], [7] are

possible solutions. The first method requires undesired wire

crossovers, and the latter one occupies much more substrate

area as two couplers with a reduced coupling are combined. In

[8] a multilayer structure with a single slot coupling is

proposed. The broadband behavior is achieved there due to

the elliptical shape of the slot. An even better ultra-wideband

performance with a high isolation is possible, when multiple

coupling sections are applied [9]. However, the general

structure is difficult to integrate, because the microstrip

feeding lines are positioned on both sides of the multilayer

substrate.

Another way to obtain a tight coupling is to use a vertically

installedplanar (VIP) hybrid[10]. Inthe following section this

approach and its drawbacks will be presented briefly. After-

wards, the design of a novel multilayer, ultra-wideband, five-

sectional 3 dB directional coupler will be shown leading to a

more compact, robust and easily producible realization

compared to the VIP coupler.

2. Multisectional VIP coupler

In the VIP coupler, a thin substrate with metallization on both

sides is added perpendicular to the main substrate with

coupled lines. Therewith, a medium coupling can be obtained

(see Fig. 1, left). An even higher coupling can be achieved

removing the sideways mircostrip lines and reducing the

ground plane area (cf. Fig. 1, right). For stabilization purposes

and equalization of the modal phase velocities, additional

dielectric blocks can be put at the sides of the vertical

substrate. In [11] a five-sectional ultra-wideband directional

coupler is realized in such a way with a relative bandwidth of

160 %. The disadvantage of this structure is the necessary

manual attachment of the vertical substrate and the fixing by

soldering which is a difficult and time-consuming fabrication

process. Furthermore, the vertically installed substrate is very

sensitive to mechanical forces and therefore quite fragile. In

order to stabilize the overall structure, a slot can be milled in

the base substrate leading to a significant stability improve-

ment and, furthermore, the mounting of the vertical substrate

is eased. The electrical performance of a coupler is not

affected by this as demonstrated by a realized coupler

operating at 3.110.6 GHz (see Fig. 2).

However, the milling leads to another fabrication step.

Therefore, a modified version of this coupler is proposed.

Instead of a vertical installed substrate, the high coupling

sections are rotated by 908 resulting in a simple multilayer

configuration with an additional height reduction and a robust

overall structure. This multilayer structure and the general

Fig. 1: Cross section of the VIP coupler for medium (left) and tight (right)

coupling [11] .

Fig. 2: Measured S-parameters for a five-sectional ultra-wideband VIP

coupler (realization see inset).

Frequenz

62 (2008)

9 10

211

design procedure will be described in detail in the following

section.

3. Novel Multilayer Coupler Design

3.1 General Design Procedure

The concept of the broadband couplers is based on multiple

sections of coupled microstrip lines. The sections are usually

symmetric regarding the middle section. Each section has a

length of l/4 and can be described by the even- and odd-mode

characteristic impedance (Z

0,even

, Z

0,odd

). In [12] tables with

values for Z

0,even

and Z

0,odd

are provided for different

bandwidths and ripples in order to design a specific coupler.

The characteristic values for coupled microstrip lines can be

determined easily with circuit simulators like e. g. [13]. For a

wide bandwidth a high coupling is mandatory and leads to line

distances, which are impossible to realize in microstrip

technique. Instead of implementing an additional coupling

using a perpendicular installed substrate like in the VIP

hybrid, two multilayer section types are proposed and are

shown in Fig. 3.

Both section types consist of two substrates and three metal

layers and their structure was chosen to allow for cascading.

Section type A has two transmission lines in the center

separated by the top substrate and, additionally, a trans-

mission line at each side. Both inner transmission lines are

connected to one of the outer transmission lines by the help of

thin lines located at the center and the edges along the line.

Vias are needed at one side to get a connection to the top side

of the second substrate. For the design the degrees of freedom

are the parameters w, s, w

2

, and h

2

. In section type B the outer

transmissionlines are removedand the groundarea is reduced

to two ground lines in order to achieve a tight coupling.

Adjustable parameters in section type B are the width w

gnd

and distance s

gnd

of the ground lines and the width of the top

lines w

2

.

The characteristic impedances for both modes are calcu-

lated by an EM simulation software [14]. Therewith, the

characteristic impedance Z

0

and the coupling value c can be

obtained for the sections by the following equations:

Z

0

Z

0; even

Z

0; odd

p

; (1)

cj

dB

20 lg

Z

0;even

=Z

0;odd

1

Z

0;even

=Z

0;odd

1

: (2)

In Fig. 4 and Fig. 5 typical values for different design

parameters are shown for section type A and section type B,

respectively. There, the same substrate material (RO4003C

with h

1

= 0.5 mm and h

2

= 0.2 mm) is used to obtain similar

phase velocities for both modes of section type A. Finally, the

physical dimensions of each section for given coupler values

can be read out from these diagrams.

For section type A the difference between the modal phase

velocities is uncritical as the electromagnetic fields are mainly

confined within the substrate for both modes and are there-

fore quite constant (see Fig. 6). But for section type B the

value of s

gnd

has to be chosen carefully, as the effective

dielectric constant e

r,eff

of the even mode and, hence, the

isolation performance is mainly affected by this parameter.

Fig. 3: Cross sections of the novel multilayer coupler (left : section type A,

right : section type B).

Fig. 4: Typical coupling factors and characteristic impedances with varying

s and w for section type A (w

2

is fixed to 0.08 mm).

Fig. 5: Typical coupling factors and characteristic impedances with varying

parameters for section type B (w

gnd

= 2.25 mm).

Frequenz

62 (2008)

9 10

212

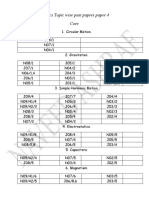

Tab. 1: Design values and dimensions of the coupler.

Design values according to [12]

c

/ dB

ripple /

dB

section

Z

0,even

/ W Z

0,odd

/ W c

i

/ dB

1,5 53.9 46.4 22.4

3.0 0.1 2,4 68.6 36.4 10.3

3 198.8 12.6 1.1

Physical dimensions / mm

section w s w

2

w

gnd

s

gnd

1,5 1.11 0.73 - - -

2,4 0.3 2.5 0.08 - -

3 - - 1.3 2.25 2.5

3.2 Design of an Ultra-Wideband Coupler

The design values for a five-sectional 3 dB coupler with a

theoretical relative bandwidth of 132 % and a center fre-

quency of 6.85 GHz are listed in Tab. 1 together with the

physical dimensions obtained by the previously described

design procedure for the multilayer coupler. The first and last

section of the coupler are realized by standard coupled

microstrip lines, while section type A is used for the second

and forth segment acting as a transition to the middle section

of type B. For section type Athe distance s between the lines is

chosen to avoid a discontinuity to the fixed first and last

section. The final values are then obtained with the charts

partially provided in Fig. 4 and Fig. 5. There, a compromise

between a characteristic impedance of 50 Ohm and the ideal

coupling value has to be made. In order to obtain an operating

frequency range of 3.110.6 GHz, the length of each section is

adjusted to be l/4 at the center frequency. The propagation

constant of the even and odd mode is determined for each

section, then the mean value is calculated and, therewith, the

wavelength is calculated.

In Fig. 7 the structure of the complete five-section coupler is

depicted, where the top substrate is lifted and the substrates

are drawn trans

parent to get a better view of the different metal parts. The

small, high impedance lines and the vias for the connections in

section type A can be recognized. This circuit is simulated

without any additional optimization and the results are shown

in Fig. 8. As can be seen, the desired ultra-broadband

behavior is obtained.

4. Realization and Measurement Results

The coupler according to the previous chapter has been

fabricated and fixed on an aluminum mount (see Fig. 9). The

top and basic substrates are joined by epoxy and conductive

glue. The proper positioning of the substrates is ensured by

alignment pins. At the center of the mount an invisible cavity

is located to retain the electrical characteristic of section type

B. The dimensions of this cavity are optimized for minimum

influence on the original structure and space. If only small

cavities for integration purposes are applicable, the influence

of a fixed cavity could be included in the design procedure.

SMA connectors are used for the transition from microstrip

lines to coaxial cables. The dimensions of the complete

structure are 60 mm x 30 mm.

The measurement results of the realized coupler, shown in

Fig. 10, are recorded by an HP8510 network analyzer using a

TRL calibration. The return loss and isolation in the intended

operating frequency range 3.110.6 GHz are better than

14 dB. In Fig. 11 a comparison with the simulation results for

the transmission and coupling case is depicted, showing that

simulation and measurement results agree quite well. For

Fig. 6: Effective dielectric constant of the even and odd mode for section

type A with w

2

= 0.08 mm (top) and section type B with w

gnd

= 2.25 mm

(bottom).

Fig. 7: Detailed view of the two separate substrates of the multilayer

coupler.

Fig. 8: Simulation results for the designed ultra-wideband coupler.

Frequenz

62 (2008)

9 10

213

lower frequencies the gap between coupling and transmission

increases, so the coupling and insertion loss in the interesting

frequency range is 3.4 dB 1.1 dB.

The group delay of the coupler is presented in Fig. 12 for

simulation and measurement, where a smoothing is per-

formed for the measured data in order to be able to compare

the curves. As can be seen both results agree very well, and the

obtained flat characteristics with a variation of 25 ps

indicate that the coupler is suited for impulse radiating

systems.

5. Comparison Multilayer and VIP Coupler

A similar electrical performance is obtained for the manufac-

tured multilayer and the VIP coupler (compare Fig. 2 and

Fig. 10), when both couplers are designed with the same

specifications (frequency range, ripple). The maximumvalues

for isolation and return loss are 15 dB 1 dB for both

couplers and the group delay variations are almost identical.

However, there are some differences in the transmission and

coupling behavior. In Fig. 13 the amplitude and phase errors

of both couplers are shown. The amplitude difference is

slightly better for the VIP coupler with 0.75 dB in compar-

ison to the multilayer coupler with 1.1 dB. Regarding phase

error, the multilayer coupler achieves a better performance

with 88 38 compared to 84 58 for the VIP coupler.

6. Conclusion

In this paper a general design procedure has been presented

showing how to realize multisectional ultra-wideband direc-

tional couplers. This method has been applied to the design of

Fig. 9: Picture of the realized multilayer 3 dB directional coupler.

Fig. 10: Measurement results for the ultra-wideband 3 dB directional

coupler.

Fig. 11: Comparison between measurement and simulation for the trans-

mission and coupling case.

Fig. 12: Simulated and measured group delay for the transmission and

coupling.

Fig. 13: Amplitude and phase difference between the transmission and

coupling port for the measurement results of both coupler types.

Frequenz

62 (2008)

9 10

214

a novel multilayer coupler. There, two structures for medium

and tight coupling are derived by the VIP coupler structure

leading to a robust overall structure and easily producible

coupler with a similar electrical performance like the VIP

coupler.

In the design process for the multilayer coupler several

parameters like height and permittivity of the top substrate

are kept constant. For different coupler specifications these

parameters could be changed gaining more flexibility in the

design.

7. References

[1] Federal Communications Commission, Revision of part 15 of the

commissions rules regarding ultra-wideband transmission systems,

Washington D.C. , USA, First Report & Order 4802, Apr. 2002.

[2] R. J. Fontana, Recent system applications of short-pulse ultra-

wideband (UWB) technology, IEEE Transactions on Microwave

Theory and Techniques, vol. 52, no. 9, pp. 20872104, Sep. 2004.

[3] Matthaei, George L. ; Young, Leo; Jones, E. M. T. , Microwave Filters,

Impedance-Matching Networks, and Coupling Structures. McGraw-

Hill Book Company, 1964.

[4] G. Kemp, J. Hobdell, and J. Biggin, Ultra-wideband quadrature

coupler, Electronics Letters, vol. 19, no. 9, pp. 197199, Mar. 1983.

[5] J. Walker, Analysis and design of Kemp-type 3-dB quadrature

couplers, IEEETransactions on Microwave Theory and Techniques,

vol. 38, no. 1, pp. 8890, Jan. 1990.

[6] S. B. Cohn, The re-entrant cross section and wide-band 3-dB hybrid

couplers, IRE Transactions on Microwave Theory and Techniques,

vol. 3, pp. 2938, 1955.

[7] M. M. Fahmi, J. A. Ruiz-Cruz, K. A. Zaki, and A. J. Piloto,

Multilayer multi-section broadband LTCC stripline directional

couplers, in IEEE International Symposium on Microwave Theory

and Techniques, Jun. 2007, pp. 173176.

[8] A. M. Abbosh and M. E. Bialkowski, Design of compact directio-

nalcouplers for UWB application, IEEE Transactions on Micro-

wave Theory and Techniques, vol. 55, no. 2, pp. 189193, Feb. 2007.

[9] A. M. Abbosh and M. E. Bialkowski, Design of ultra wideband

quadrature microstrip/slot coupler, Microwave and Optical Tech-

nology Letters, vol. 49, no. 9, pp. 21012103, Sep. 2007.

[10] Y. Konishi, I. Awai, Y. Fukuoka, and M. Nakajima, A directional

coupler of a vertically installed planar circuit structure, IEEE

Transactions on Microwave Theory and Techniques, vol. 36, no. 6,

pp. 10571063, Jun. 1988.

[11] H.-C. Chen and C.-Y. Chang, Modified vertically installed planar

couplers for ultrabroadband multisection quadrature hybrid, IEEE

Microwave and Wireless Components Letters, vol. 16, no. 8, pp. 446

448, Aug. 2006.

[12] E. Cristal and L. Young, Theory and tables of optimumsymmetrical

TEM-mode coupled-transmission-line directional couplers, IEEE

Transactions on Microwave Theory and Techniques, vol. 13, no. 5,

pp. 544558, Sep. 1965.

[13] Advanced Design System 2006, Agilent Technologies Inc, website:

http://eesof.tm.agilent.com.

[14] Microwave Studio 2006B, CST-Computer Simulation Technology,

website: http://www.cst.com.

This work has been funded by the German Research

Foundation (DFG) under the program UKoLoS.

Website: http://www-emt.tu-ilmenau.de/ukolos/

Mario Leib, Dennis Mack, Felix Thurow and Wolfgang Menzel

Microwave Techniques, University of Ulm

Albert-Einstein-Allee 41, 89081 Ulm

Fax: +49 (0)731/5026359

E-mail : mario.leib@uni-ulm.de

Frequenz

62 (2008)

9 10

215

Anda mungkin juga menyukai

- Solution Manual for 100 Genesys Design Examples: Second EditionDari EverandSolution Manual for 100 Genesys Design Examples: Second EditionBelum ada peringkat

- Wideband RF Technologies and Antennas in Microwave FrequenciesDari EverandWideband RF Technologies and Antennas in Microwave FrequenciesBelum ada peringkat

- Printed AntennasDokumen463 halamanPrinted AntennasvasikasBelum ada peringkat

- Microwave Imaging and Electromagnetic Inverse Scattering ProblemsDokumen172 halamanMicrowave Imaging and Electromagnetic Inverse Scattering ProblemsChinaski BukowskiBelum ada peringkat

- Design of Broadband Lumped Element BalunsDokumen4 halamanDesign of Broadband Lumped Element BalunsA. Villa100% (1)

- Rectangular Waveguide To Coax Transition DesignDokumen8 halamanRectangular Waveguide To Coax Transition DesignmmasoumianBelum ada peringkat

- Phased Antenna Arrays and Application Wireless in Connectivity, BATCH 14Dokumen63 halamanPhased Antenna Arrays and Application Wireless in Connectivity, BATCH 14nareshBelum ada peringkat

- Alejandrino, Michael S. Bsee-3ADokumen14 halamanAlejandrino, Michael S. Bsee-3AMichelle AlejandrinoBelum ada peringkat

- 570914000AntennaArray CST MWS - SimulationDokumen9 halaman570914000AntennaArray CST MWS - SimulationkaranBelum ada peringkat

- A4FD1924d01 Wilkinson TheoryDokumen4 halamanA4FD1924d01 Wilkinson TheorymrzahzBelum ada peringkat

- Ku Band RF ThesisDokumen113 halamanKu Band RF ThesisJohn ErhinyoBelum ada peringkat

- Amit Singh Smart Antenna DesignDokumen24 halamanAmit Singh Smart Antenna DesignYasha IrBelum ada peringkat

- Ultra Wideband DividerDokumen68 halamanUltra Wideband DividerOkanÜnlüBelum ada peringkat

- Wood Pole KN RatingsDokumen3 halamanWood Pole KN Ratingsjobpei2Belum ada peringkat

- Saw FilterDokumen350 halamanSaw FilterAnonymous h80fVW100% (1)

- PWR Dividers and CombinersDokumen26 halamanPWR Dividers and CombinerscftrutaBelum ada peringkat

- Customized Post Processing Using The Result Template ConceptDokumen13 halamanCustomized Post Processing Using The Result Template ConceptshochstBelum ada peringkat

- Ibis Behavioral Models Technical NoteDokumen3 halamanIbis Behavioral Models Technical NoteAnonymous T9zQADFxZRBelum ada peringkat

- Low Power Optimization of Full Adder Circuit Based On Gdi Logic For Biomedical ApplicationsDokumen11 halamanLow Power Optimization of Full Adder Circuit Based On Gdi Logic For Biomedical ApplicationsIJAR JOURNALBelum ada peringkat

- Models - Rf.circular Waveguide FilterDokumen10 halamanModels - Rf.circular Waveguide FilterDr-Mandeep SinghBelum ada peringkat

- Tia Eia 613Dokumen19 halamanTia Eia 613NeatMarineBelum ada peringkat

- EDICONChina2019 - (87) - Vye, David - Designing A Narrowband 28-GHz Bandpass Filter For 5G Applications PDFDokumen41 halamanEDICONChina2019 - (87) - Vye, David - Designing A Narrowband 28-GHz Bandpass Filter For 5G Applications PDFkhyatichavdaBelum ada peringkat

- A Cavity Filter Using Stepped Impedance ResonatorDokumen4 halamanA Cavity Filter Using Stepped Impedance ResonatorDo SonBelum ada peringkat

- Marchand BalunsDokumen4 halamanMarchand BalunsYouli TianBelum ada peringkat

- Jetson Agx Xavier Platform Adaptation and Bring-Up GuideDokumen41 halamanJetson Agx Xavier Platform Adaptation and Bring-Up GuideafdgtdsghfBelum ada peringkat

- bizurado-silvaco-PIN Detector Thesis PDFDokumen143 halamanbizurado-silvaco-PIN Detector Thesis PDFombraga1896Belum ada peringkat

- Circuit Design For Wireless CommunicationsDokumen216 halamanCircuit Design For Wireless Communicationsravi010582Belum ada peringkat

- Long Term VisionDokumen102 halamanLong Term VisionGabriel DonovanBelum ada peringkat

- Miniaturized 90 Degree Hybrid Coupler Using High Dielectric Substrate For QPSK Modulator PDFDokumen4 halamanMiniaturized 90 Degree Hybrid Coupler Using High Dielectric Substrate For QPSK Modulator PDFDenis CarlosBelum ada peringkat

- Ultra-Wideband Radio Propagation ChannelsDokumen243 halamanUltra-Wideband Radio Propagation Channelsvaldesc_tol100% (1)

- A 1.5-V, 1.5-GHz CMOS Low Noise Amplifier - Solid-State Circuits, IEEE Journal of PDFDokumen15 halamanA 1.5-V, 1.5-GHz CMOS Low Noise Amplifier - Solid-State Circuits, IEEE Journal of PDFAnirban HomroyBelum ada peringkat

- 01050528Dokumen12 halaman01050528Mohanavelu SadasivamBelum ada peringkat

- D-Band Frequency Tripler For Passive Imaging - Final 13th JulyDokumen4 halamanD-Band Frequency Tripler For Passive Imaging - Final 13th JulyTapas SarkarBelum ada peringkat

- LearnEMC - Magnetic-Field Coupling (Inductive Coupling)Dokumen3 halamanLearnEMC - Magnetic-Field Coupling (Inductive Coupling)danitranoster8512Belum ada peringkat

- TLM 2D TutorialDokumen52 halamanTLM 2D TutorialNicolae Crisan100% (1)

- Study of A 145 MHZ TranceiverDokumen170 halamanStudy of A 145 MHZ TranceivernaranjitoBelum ada peringkat

- Transistorized Series Voltage RegulatorDokumen4 halamanTransistorized Series Voltage RegulatorIpsita MishraBelum ada peringkat

- A Broadband Planar Magic-T Using Microstrip-Slotline TransitionsDokumen6 halamanA Broadband Planar Magic-T Using Microstrip-Slotline TransitionsSarvesh HireBelum ada peringkat

- MEEp Tutorial For ICE CubeDokumen39 halamanMEEp Tutorial For ICE CubeSadat KhanBelum ada peringkat

- Linear Diversity Combining TechniquesDokumen26 halamanLinear Diversity Combining TechniquesKash BDBelum ada peringkat

- The Transmission-Line Modeling (TLM) Method in ElectromagneticsDokumen132 halamanThe Transmission-Line Modeling (TLM) Method in ElectromagneticsRafael CoelhoBelum ada peringkat

- P-I-N Diode HandbookDokumen137 halamanP-I-N Diode HandbookChangjian LiBelum ada peringkat

- Siemens Absolute EncoderDokumen4 halamanSiemens Absolute EncoderAditya Pavan VinjamuriBelum ada peringkat

- Cavity FilterDokumen2 halamanCavity FilterCartesius NugrohoBelum ada peringkat

- CST StudioDokumen4 halamanCST StudiomountyzoaBelum ada peringkat

- PCIe Interposer Datasheet v1113 PDFDokumen12 halamanPCIe Interposer Datasheet v1113 PDFEduardo CastilloBelum ada peringkat

- Package TypesDokumen4 halamanPackage TypesDickson LamBelum ada peringkat

- HFSS Tutorial 1Dokumen7 halamanHFSS Tutorial 1Tushar DebnathBelum ada peringkat

- Stackup Planning AN2011 2Dokumen8 halamanStackup Planning AN2011 2lavaskumarBelum ada peringkat

- Optimum Array Processing: Part IV of Detection, Estimation, and Modulation TheoryDari EverandOptimum Array Processing: Part IV of Detection, Estimation, and Modulation TheoryBelum ada peringkat

- Quantum Well LasersDari EverandQuantum Well LasersPeter S. Zory Jr.Belum ada peringkat

- Introduction to Optical Waveguide Analysis: Solving Maxwell's Equation and the Schrödinger EquationDari EverandIntroduction to Optical Waveguide Analysis: Solving Maxwell's Equation and the Schrödinger EquationBelum ada peringkat

- Fundamentals of Electronics 2: Continuous-time Signals and SystemsDari EverandFundamentals of Electronics 2: Continuous-time Signals and SystemsBelum ada peringkat

- Infrared and Millimeter Waves V11: Millimeter Components and Techniques, Part IIIDari EverandInfrared and Millimeter Waves V11: Millimeter Components and Techniques, Part IIIBelum ada peringkat

- ADF4355 54-6800 MHZ Microwave Wideband Synthesizer With Integrated VCODokumen35 halamanADF4355 54-6800 MHZ Microwave Wideband Synthesizer With Integrated VCOagmnm1962Belum ada peringkat

- Scr's & Triacs Cross ReferenceDokumen11 halamanScr's & Triacs Cross Referenceagmnm1962Belum ada peringkat

- 51W 10540 1Dokumen16 halaman51W 10540 1Mitrofan AnduBelum ada peringkat

- A Compact Ultra-Wideband Power Divider With High Isolation 3.1-10.6 GHZDokumen2 halamanA Compact Ultra-Wideband Power Divider With High Isolation 3.1-10.6 GHZagmnm1962Belum ada peringkat

- 200watt Active Load UnitDokumen14 halaman200watt Active Load Unitagmnm1962Belum ada peringkat

- Data Sheet: UHF Push-Pull Power MOS TransistorDokumen15 halamanData Sheet: UHF Push-Pull Power MOS Transistoragmnm1962Belum ada peringkat

- Variable High Voltage BJT Regulator User ManualDokumen7 halamanVariable High Voltage BJT Regulator User Manualagmnm1962Belum ada peringkat

- Sp431 High Voltage Adjustable Precision Shunt RegulatorsDokumen11 halamanSp431 High Voltage Adjustable Precision Shunt Regulatorsagmnm1962Belum ada peringkat

- A Review of Implantable Antennas For Wireless Biomedical DevicesDokumen11 halamanA Review of Implantable Antennas For Wireless Biomedical Devicesagmnm1962Belum ada peringkat

- LXA-7500 Series X-Band Low Noise AmplifiersDokumen4 halamanLXA-7500 Series X-Band Low Noise Amplifiersagmnm1962Belum ada peringkat

- (Leslie Green) RF-Inductor Modeling For The 21st CDokumen5 halaman(Leslie Green) RF-Inductor Modeling For The 21st CBeeresha R SBelum ada peringkat

- Driven Right Leg Circuit DesignDokumen5 halamanDriven Right Leg Circuit Designagmnm1962Belum ada peringkat

- A New Calculation For Designing Multilayer Planar Spiral InductorsDokumen4 halamanA New Calculation For Designing Multilayer Planar Spiral Inductorsagmnm1962Belum ada peringkat

- Bio Amps NotesDokumen9 halamanBio Amps Notesagmnm1962Belum ada peringkat

- LT1167 Instr AmpDokumen20 halamanLT1167 Instr Ampagmnm1962Belum ada peringkat

- A Compact Dual-Band Dual-Polarized Patch AntennaDokumen7 halamanA Compact Dual-Band Dual-Polarized Patch Antennaagmnm19620% (1)

- Unit 4Dokumen76 halamanUnit 4Hemant TulsaniBelum ada peringkat

- Form 4 Chapter 2 Paper 1Dokumen82 halamanForm 4 Chapter 2 Paper 1FakhriahBelum ada peringkat

- 8 X Y 16 X 8 Y: 3. Compounds Are Composed of Atoms of More Than OneDokumen10 halaman8 X Y 16 X 8 Y: 3. Compounds Are Composed of Atoms of More Than OneSamantha DumagpiBelum ada peringkat

- Lightolier Calculite HID Downlighting Catalog 1994Dokumen36 halamanLightolier Calculite HID Downlighting Catalog 1994Alan MastersBelum ada peringkat

- Chapter 4Dokumen24 halamanChapter 4afewerkBelum ada peringkat

- PHYSICSDokumen24 halamanPHYSICS21SO204 AnvithaBelum ada peringkat

- Physics Topic Wise Past Papers Paper 4Dokumen3 halamanPhysics Topic Wise Past Papers Paper 4Naveed AshrafBelum ada peringkat

- Name/s: JEAN A. CAMAY Subject: Dimensional AnalysisDokumen4 halamanName/s: JEAN A. CAMAY Subject: Dimensional AnalysisJean CamayBelum ada peringkat

- Wolfson Eup3 Ch15 Test BankDokumen16 halamanWolfson Eup3 Ch15 Test Bankifghelpdesk100% (1)

- CBSE Model QP Class XIDokumen4 halamanCBSE Model QP Class XIroythomascBelum ada peringkat

- Relation To Other Fields: Difference Between Classical and Modern PhysicsDokumen1 halamanRelation To Other Fields: Difference Between Classical and Modern Physicspiping stressBelum ada peringkat

- Gyromagnetic Ratio WikiDokumen4 halamanGyromagnetic Ratio Wikibugoff7000% (1)

- Pumping Tests: R R T Q S S H HDokumen6 halamanPumping Tests: R R T Q S S H HGonzalo Salazar PanequeBelum ada peringkat

- Physics 2008 P2Dokumen11 halamanPhysics 2008 P2Rishi Gopie100% (3)

- Hydraulic Calculations Safe RainDokumen21 halamanHydraulic Calculations Safe RaingonleoBelum ada peringkat

- Fundamentals of Molecular CatalysisDokumen537 halamanFundamentals of Molecular CatalysisSandeep SaiBelum ada peringkat

- AS Chemistry - Revision Notes Unit 2 - Foundation Physical and Inorganic ChemistryDokumen10 halamanAS Chemistry - Revision Notes Unit 2 - Foundation Physical and Inorganic Chemistry24681097Belum ada peringkat

- Mole Concept BOUNCEBACKDokumen154 halamanMole Concept BOUNCEBACKabhinav kota100% (2)

- Unit Ii. Nuclear Chemistry Learning Objectives: at The End of This Chapter, The Student Will Be Able ToDokumen11 halamanUnit Ii. Nuclear Chemistry Learning Objectives: at The End of This Chapter, The Student Will Be Able ToIvyy Joyce BuanBelum ada peringkat

- Siemens Motor PDFDokumen1 halamanSiemens Motor PDFsumitsharma2010Belum ada peringkat

- ClayMineralogy SivakuganDokumen31 halamanClayMineralogy SivakuganMath ManiaBelum ada peringkat

- 1463486214physical ChemistryDokumen4 halaman1463486214physical ChemistryShilp ShahBelum ada peringkat

- Scientific Reasons Physics II HSCDokumen37 halamanScientific Reasons Physics II HSCSIR USMAN KHANBelum ada peringkat

- Comissioning and Verification of 10 MV Elekta Synergy Platform Linac Photon BeamDokumen9 halamanComissioning and Verification of 10 MV Elekta Synergy Platform Linac Photon BeamAbdurraouf AghilaBelum ada peringkat

- Questions On KTGDokumen21 halamanQuestions On KTGAkshat JoshiBelum ada peringkat

- MathCAD - Retaining Wall FoundationDokumen6 halamanMathCAD - Retaining Wall FoundationValentinBelum ada peringkat

- Tutorial-2 Module 7Dokumen17 halamanTutorial-2 Module 7salkr30720Belum ada peringkat

- Thermal Properties of Ab MaterialsDokumen17 halamanThermal Properties of Ab MaterialsFrences Lois DURANBelum ada peringkat

- Cebu Institute of Technology University: ECE 162 W1Dokumen8 halamanCebu Institute of Technology University: ECE 162 W1meshin yuBelum ada peringkat