Inst Question and Answer

Diunggah oleh

Jose JohnDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Inst Question and Answer

Diunggah oleh

Jose JohnHak Cipta:

Format Tersedia

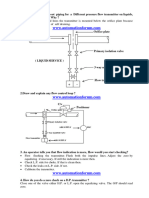

1.

How do you carry out piping for a Different pressure flow transmitter on liquids,

Gas and steam services Why ?

Liquid lines On liquid lines the transmitter is mounted below the orifice plate because

liquids have a property of self draining.

!rifice plate

"low direction

#rimary isolation valve

$ L%&'%D ()*+%,) -

. way manifold valve

"low transmitter

+ -

/.Draw and e0plain any flow control loop ?

,1v

#ositioner

!rifice plate

#rimary isolation valve

2%* ('##L3 "*,

. way manifold valve

"low transmitter

2%* ('##L3

.. 2n operator tells you that flow indication is more, How would you start chec4ing?

First flushing the transmitter. Flush both the impulse lines. Adjust the zero by

equalizing if necessary. f still the indication is more then.

!hec" #.$. side for cho"e. f that is clean then.

!hec" the lea"s on #.$. side. f not.

!alibrate the transmitter.

5. How do you do a 6ero chec4 on a D.#. transmitter ?

!lose one of the valve either %.$. or #.$. open the equalizing valve. &he O'$ should read

zero.

7. How would you do Glycol filling or fill seal liquids in seal pots 8 Draw and e0plain.

&he procedure for glycol filling is (

!lose the primary isolation valves.

Open the vent on the seal pots.

)rain the used glycol if present.

!onnect a hand pump on #.$. side while filling the %.$. side with glycol.

*eep the equalizer valve open.

*eep the #.$. side valve closed.

+tart pumping and fill glycol.

+ame repeat for #.$. side by connecting pump to %.$. side, "eeping equalizer open and

%.$. side isolation valve closed.

!lose the seal pot vent valves.

!lose equalizer valve.

Open both the primary isolation valves.

7. What are the primary elements for measuring pressure?

&he primary elements used for measuring pressure are (

-ourdon tube.

)iaphragm.

!apsule.

-ellows.

$ressure +prings.

&he above are "nown as elastic deformation pressure elements.

&ype of -ourdon tubes.

. ! . type.

+piral.

%eli/.

Diaphragm &he diaphragm is best suited for low pressure measurement.

,apsules &wo circular diaphragms are welded together to form a pressure capsule.

0aterial 1sed ( phosphor bronze, 2i-spanc stainless steel.

9ellows -ellows is a one - piece, collapsible, seamless metallic unit with deep folds

formed from very tin walled tubing.

0aterial used ( -rass, phosphor bronze, stainless steel. 1sed for high

pressure.

#re.spring $ressure springs of helical or spiral shape used for measuring high pressures.

:. 9riefly e0plain the different methods of level measurement ?

&here are two ways of measuring level (

3. )irect

4. ndirect.

&A$5 05A+165

3.)irect level measurement (

7 a 8 -ob and tape(

;2<=

%eighest point reached by

A bob weight and measuring liquid

tape provide the most simple

and direct method of

measuring liquid livel. )istance to be measured

L%&'%D after tape is ta"en out of

&an".

-ob 7weight8

7 b 8 +ight glass (

&his consists of a graduated glass tube mounted on the side of the vessel. As the level of the

liquid in the vessel change, so does the level of the liquid in the glass tube.

ndirect level measurement (

7 a 8 $ressure gauge (

&his is the simplest method, for pressure gauge is located at the zero level of the liquid in

the vessel. Any rise in level causes an increase of pressure which can be measured by a

gauge.

7 b 8 $urge system (

n this method a pipe is installed vertically with the open and at zero level. &he other end of

the pipe is connected to a regulated air r supply and to a pressure gauge. &o ma"e a level

measurement the air supply is adjusted so that pressure is slightly higher than the pressure

due to height of the liquid. &his is accomplished by regulating the air pressure until bubbles

cab be seen slowly leaving the open end of the pipe.

#ressure gauge

2s level gauge

2ir regulator

<

/

purge

2ir supply rotameter

&he air pressure to the bubbler pipe is minutely in

e/cess of the liquid pressure in the vessel, so that

air pressure indicated is a measure of the level in

the tan".

&he method above are suitable for open tan" applications. when a liquid is in a pressure

vessel, the liquid column pressure can.t be used unless the vessel pressure is balanced out.

&his is done through the use of different pressure meters.

7 c 8 )ifferential pressure meter (

!onnection are made at the vessel top and bottom, and to the two columns of the ).$. meter.

&he top connection is made to the #.$. column of the transmitter and the bottom to %.$.

column of the transmitter. &he difference in pressure in the vessel is balanced out, since it is

fed to both the column of the meter. &he difference in pressure deducted by the meter will be

due only to the changing, level of the liquid.

7 d 8 )isplacer type level measurement (

&he leveltrol is one of the most common instruments used measuring level in closed tan"s.

&his instrument wor"s of Archimedes principle. &he displacer in immersed in the liquid due

to which there is loss of weight depending on the specified gravity of the liquid. &his

displacer hangs freely on a "nife transmitted to the pneumatic or electronic counterpart at the

other end.

8. )0plain the wor4ing of a leveltrol.

&he leveltrol is used for measuring level of liquids in a closed vessel.

3. $62!$#5. ( t wor"s on Archimedes principle 9&he loss in weight of a body immersed

in a liquid is equal to amount of liquid displaced by the body9. &he leveltrol basically

consists of the following (

4. )+$#A!56 ( t is consists of a cylindrical shape pipe sealed and filled inside with sand

or some weight. &he purpose of this is to convert change in level to primary motion. &he

variation in buoyancy resulting from a change in liquid level varies the net weight of the

displacer increasing or decreasing the load on the torque arm. &his change is directly

proportional to change in level and specific gravity of the liquid.

:. 65#A; ( Amplifies pressure variations at the nozzles.

<. 65=56+2> A6! ( t is used for the following purposes.

0otion ta"e of from &orque tube.

0eans of reverse control action.

Adjustment for specific gravity.

$6O$56&O2A# 12&. ( !onverts primary motion to a proportional output air pressure.

?. !O2&6O# +5&&2> 12& ( $rovides a motions of varying the set point.

>. )0plain the wor4ing an electronic leveltrol.

65>

+

6=)& )! 0O)

O+!

+ +

- - )! A0$#F56

+$A2

@ A56O

&he variation in buoyancy resulting from a change in liquid level, varies the net weight of the

displacer increasing or decreasing the load on the torque arm. &his change is directly

proportional to the change in level and specific gravity of the liquid. &he resulting torque

tube movement varies the angular motion of the rotor in the 6=)& 76otary =ariable

)ifferential. &ransformer8 providing a voltage change proportional to the rotor displacement,

which is converted and amplified to a ).!. current.

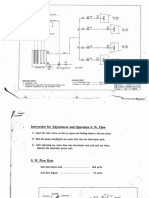

?. How will you cali@rate a leveltrol in the field?

)isplacer chamber

#evel transmitter.

&ransparent $.=.! tube

O$

A

0$

!alculation B 3 f the calibrating liquid is water( $rocess #iquid )ensity ' 3C )isplacer

height D mm of %4O.

!alculation B 4 f the calibrating liquid is Other liquid( $rocess #iquid )ensity ' !alibrating

liquid density C )isplacer height D mm of %4O. 7 !alibrating liquid height in mm 8.

3. First close both the primary isolation valves and drain the liquid inside the chamber.

4. Adjust the zero to get EF output.

:. !onnect a transparent $=! tube to the drain point as shown in hoo" up.

<. Fill it to the center of the top flange.

?. Adjust the specific gravity or span adjustment 7 5lectronic #evel 8.

G. Fill it up to ?E F, chec" linearity.

1A. What is the used of (uppression and elevation ?

+uppression and elevation are used on #evel applications where 738 transmitters are not

mounted on some level 748 Het leg. i.e. condensable vapors are present

11. What is @urnout feature ? )0plain.

-urnout provides the warning feature of driving indicator the end of scale if the input circuit

should open.

A burnout resistor is provided which develops a voltage drop between the measuring circuit

and the amplifier. &he polarity of the signal determines the direction of the servo drive upon

an open circuit in the input.

1pscale burnout ( 6 value 3E 0

)ownscale burnout ( 6 value 4.4 0

1/. What type of sensing element would you use to measure very low temperature ?

&he sensing element used for measuring very low temperature is 6. &. ).

7 6esistance &emperature )etector 8

1.. What are s4in temperature thermocouples ?

+"in thermocouples are those which are directly connected to the process without any

thermowell. 1sed for measuring the s"in temperature of heaters furnaces, flue gas etc

15. )0plain the application of proportional integral and derivative action?

#roportional control only

$roportional control only attempts to return a measurement to the set point after a load upset

has occurred. %ow ever it is impossible for a proportional controller to return the

measurement e/actly to the set point.

'se ( t is normally used for level controls. t reduces the effect of a load change but it can

not eliminate it.

#roportional plus reset control

6eset action is introduced to eliminate offset. t will integrate any difference between

measurement and setpoint and cause the controller.s output to change until the difference

between the measurement and set point is zero. 6eset will act as long as the error e/ists.

'se $roportional + 6eset controllers are by far the common types used in industrial process

control and where predominate dead times occur.

#roportional plus reset plus derivative

)erivative or rate action helps the controller overcome system inertia and result in faster,

more precise control. )erivative action occurs whenever the measurement signal changes.

1nder study conditions the rate action does not act. )erivative allows the controller to inject

more corrective action.

'se On temperature controls.

17. What is difference gap control ?

)ifferential gap control is similar to on off control e/cept that a band or gap e/ists around the

control point.

'se n industry differential gap control is often found in non critical level control

applications where it is desirable only to prevent a tan" from flooding or drying. When a

measured variable e/ceeds the upper gap the control valve will open fully or be closed fully.

+imilarly when it e/ceeds the lower gap it will open or close fully.

1:. Where is on off control used ?

On off control is used when

3. $recise control is not needed.

4. $rocesses that have sufficient capacity to allow the final operator to "eep up with the

measurement cycle.

:. t is mainly used in refrigeration and are conditioning systems.

18. )0plain the wor4ing of *otameter?

!'; L);

&he flow rate varies directly

&apered glass tube as the float rises and falls in the tapered tube.

%< L);

=ariable area meters are special form of head meters. Hhere in the area of flow restrictor is

varied. +o as to hold the differential pressure constant. &he rotameters consists of a vertical

tapered tube through which the metered fluid flows in upward direction. A 9float9 either

spherical or cone shaped, actually more dense than the fluid being measured, creates an

annular passage between its ma/imum circumference and the weight of the tapered tube. As

the flow varies the 9float9 rises or falls to vary the area of the passage so that the differential

across it just balances the gravitational force on the 9float9 i.e. the differential pressure is

maintained constant. &he position of the 9float9 is the measured of the rate of flow.

1>. )0plain the wor4ing of a magnetic meter.

An electric potential is developed when a conductor is moved across the magnetic field. n

most electrical machinery the conductor is a 9wire9I the principle is equally applicable to a

moving, electrically conductive liquid. &he primary device of commercial magnetic meters

consists of a straight cylindrical electrically insulated tube with a pair of electrodes nearly

flush with the tube wall and located at opposite ends of a tube diameter. A uniform a.c.

magnetic field is provided at right angles to electrode diameter and to the a/is of the tube.

&he a.c. voltage developed at the electrodes is proportional to the volume flow rate of fluid,

and to a magnetic field strength. &his device is limited to electrically conducting liquids. &he

+cale

magnetic meter is particularly suited to measurement of slurries and dirty fluids, since there

are no location for solids to collect e/cept the walls of the tube itself.

1?. )0plain the wor4ing of a tur@ine meter.

&urbine meters consist of a straight flow tube within which a turbine or fan is free to rotate,

about its a/is which is fi/ed along the center line of the tube. +traightening vanes upstream

of the turbine minimizes possible rotational components of fluid flow. n most units a

magnetic pic"-up system senses the rotation of the rotor through the tube wall. &he turbine

meter is a flow rate device, since the rotor speed is directly proportional to flow rate. &he

output is usually in the form of electrical pulses from the magnetic pic"-up with a frequency

proportional to flow rate. &urbine meter are primarily applied to measurement of clean and

non-corrosive hydrocarbons.

/A. )0plain the wor4ing of a #itot tu@e.

&he pitot tube measures the velocity at point in the conduct. f quantity rate measurement is

desired, it must be calculated from the ratio of average velocity to the velocity at the point of

measurement.

#rinciple f a tube is placed with its open and facing into a stream of fluid, then the fluid

impinging on the open end will be brought to rest, and the "inetic energy converted to

pressure energy. &his the pressure built up in the tube will be greater than that in the free

stream by the impact pressure or pressure produced by loss of "inetic energy. &he increase in

pressure will depend upon the square of the velocity of the stream. &he difference is

measured between the pressure in the tube and static pressure of the stream. &he static

pressure is measured by a tapping in the wall of the main or by a tapping incorporated in the

pitot static tube itself. &he difference between the pressure in the tube and static pressure will

be a measure of the impact pressure and therefore of the velocity of the stream oil.

/1. Where is the integral orifice used ?

ntegral orifice is used to measure small flow rates. t is mounted directly on the secondary

device. &he integral orifice diameter varies between E.E4E inch and E.4?E inch diameter. &he

integral orifice finds considerable use in laboratory and pitot plants.

!alculation of flow rate (

&n 1 "c B =s 0 ,wi 0 "a 0 "m 0 Gp 1 Ge , hw

Anda mungkin juga menyukai

- Instrumentation Question and AnswerDokumen7 halamanInstrumentation Question and AnswerYounis MolayBelum ada peringkat

- Hydraulics and Pneumatics Lab: Amee 310: Laboratory Handout Experiment 6: "Pressure Drop Vs Flow Relationship"Dokumen12 halamanHydraulics and Pneumatics Lab: Amee 310: Laboratory Handout Experiment 6: "Pressure Drop Vs Flow Relationship"info5280Belum ada peringkat

- Instrumentation Questions and AnswersDokumen45 halamanInstrumentation Questions and AnswersSajid RazaBelum ada peringkat

- 1 Productivity: 1 Items in The Production SystemDokumen12 halaman1 Productivity: 1 Items in The Production SystemAnonymous iCFJ73OMpDBelum ada peringkat

- Level and Viscotherm From Reeds Vol 10 Instrumentation and Control Systems - NodrmDokumen12 halamanLevel and Viscotherm From Reeds Vol 10 Instrumentation and Control Systems - Nodrmprashant manhasBelum ada peringkat

- Operating and ControlDokumen378 halamanOperating and Controlباسم باسمBelum ada peringkat

- An920 Rev2Dokumen38 halamanAn920 Rev2glamuraBelum ada peringkat

- Losses in Pipe BendDokumen5 halamanLosses in Pipe BendsourajpatelBelum ada peringkat

- Instrumentation Engineer InterviewDokumen24 halamanInstrumentation Engineer InterviewNGASSAKI ATONGUI Christ HubertBelum ada peringkat

- Lab 3 Reynolds NumberDokumen9 halamanLab 3 Reynolds NumberShahrah Man0% (1)

- Field InstrumentationDokumen85 halamanField InstrumentationSavana Prasanth100% (3)

- Lab 5 Flow Over Weir ExampleDokumen19 halamanLab 5 Flow Over Weir ExampleAmy FarhanaBelum ada peringkat

- AssignmentDokumen13 halamanAssignmentPaul RwomwijhuBelum ada peringkat

- Ic & S r16 - Unit-3Dokumen28 halamanIc & S r16 - Unit-3nclary lazurBelum ada peringkat

- Waterdraw Calibration For Bi-Directional and Unidirectional Mechanical Displacement Meter ProversDokumen34 halamanWaterdraw Calibration For Bi-Directional and Unidirectional Mechanical Displacement Meter ProversSim Yun Young100% (3)

- Unit-4 (Ind Instru Notes)Dokumen11 halamanUnit-4 (Ind Instru Notes)rep domBelum ada peringkat

- Leader Ls 8022 8050 Service ManualDokumen84 halamanLeader Ls 8022 8050 Service Manualjonathan calderaBelum ada peringkat

- Level MeasurementDokumen15 halamanLevel Measurementdivzz97Belum ada peringkat

- Lab 7: The Influence of Reynolds Number in Pipe Flows PurposeDokumen4 halamanLab 7: The Influence of Reynolds Number in Pipe Flows PurposeXubair WajidBelum ada peringkat

- Advance Fluid Lab ManualDokumen55 halamanAdvance Fluid Lab ManualchristianBelum ada peringkat

- Control Chapter 5 - RemoteDokumen86 halamanControl Chapter 5 - RemoteWilmar Antonio Zuluaga ArangoBelum ada peringkat

- Feed Water System: Language UK Page 1/1Dokumen16 halamanFeed Water System: Language UK Page 1/1Alexander BaziotisBelum ada peringkat

- Unit-4 Level MeasurementDokumen11 halamanUnit-4 Level MeasurementARUNKUMAR MBelum ada peringkat

- CHE 253M Experiment No. 3 Liquid Flow MeasurementDokumen12 halamanCHE 253M Experiment No. 3 Liquid Flow MeasurementAdellBelum ada peringkat

- Valve Sizing and SelectionDokumen7 halamanValve Sizing and SelectionDevendra BangarBelum ada peringkat

- Valve Control 0406Dokumen15 halamanValve Control 0406Catalin PruncuBelum ada peringkat

- Instrumentation Questions For Freshers - 2: 1. Briefly Explain The Different Methods of Level Measurement?Dokumen10 halamanInstrumentation Questions For Freshers - 2: 1. Briefly Explain The Different Methods of Level Measurement?EvbaruBelum ada peringkat

- GAPS Guidelines: Water Measurement Using Two Inch (50 MM) Drain TestsDokumen5 halamanGAPS Guidelines: Water Measurement Using Two Inch (50 MM) Drain Testsasad khanBelum ada peringkat

- Unit 4Dokumen15 halamanUnit 4Hemanth Kumar VuribindiBelum ada peringkat

- Vcone To Orifice Plate Noise ComparisonDokumen8 halamanVcone To Orifice Plate Noise ComparisonDavid P. MonjureBelum ada peringkat

- Lesson Piston Valves: Sub-ObjectiveDokumen4 halamanLesson Piston Valves: Sub-Objectivemister pogiBelum ada peringkat

- Experiment 2 - Flow Measurement: Page 1 of 6Dokumen6 halamanExperiment 2 - Flow Measurement: Page 1 of 6fadyaBelum ada peringkat

- Cav - Valvulas. Mariposa - CavitacionDokumen6 halamanCav - Valvulas. Mariposa - CavitacionzmudioBelum ada peringkat

- MGPSDokumen9 halamanMGPSMikhail BagliukBelum ada peringkat

- EXP 2 - Control SystemsDokumen6 halamanEXP 2 - Control SystemsMark Charles TarrozaBelum ada peringkat

- LTSpice Ac AnalysisDokumen5 halamanLTSpice Ac AnalysisJuan PerezBelum ada peringkat

- Bernoulli and The Free JetDokumen3 halamanBernoulli and The Free JetrishanshawkatBelum ada peringkat

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGDari EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGBelum ada peringkat

- Procedure For Busbar Differential Stability: PRD by NSHDokumen1 halamanProcedure For Busbar Differential Stability: PRD by NSHyazensalehBelum ada peringkat

- Flow - OrificeDokumen86 halamanFlow - Orificemahadev jadhavBelum ada peringkat

- WEKA Magnetic Level IndicatorsDokumen5 halamanWEKA Magnetic Level IndicatorsDimitry SilinshBelum ada peringkat

- EX A6 Reynolds NumberDokumen13 halamanEX A6 Reynolds NumberSadieBelum ada peringkat

- WATER Flow Over WeirDokumen9 halamanWATER Flow Over WeirNutan PrakashBelum ada peringkat

- EXP 7 Pipe FrictionDokumen10 halamanEXP 7 Pipe Frictionsiva ramBelum ada peringkat

- CE142P Lecture Rev.0 (Robles) PDFDokumen180 halamanCE142P Lecture Rev.0 (Robles) PDFErnel TosocBelum ada peringkat

- CV Exp 6Dokumen7 halamanCV Exp 6Mohd RehanBelum ada peringkat

- Op Tim IzationDokumen8 halamanOp Tim IzationJulia Turpo SuarezBelum ada peringkat

- Automatic Water Level Controller Using NDokumen15 halamanAutomatic Water Level Controller Using Nsaadahmedkalidaas100% (2)

- Sizing Valve: STEP #1: Define The SystemDokumen9 halamanSizing Valve: STEP #1: Define The SystemFahad RockingBelum ada peringkat

- Liquid Level Control System V2Dokumen14 halamanLiquid Level Control System V2Shisanu SenBelum ada peringkat

- Arts Fluid FlowDokumen142 halamanArts Fluid Flowchem.tahirBelum ada peringkat

- Ministry Higher Scientific Research: of Education andDokumen38 halamanMinistry Higher Scientific Research: of Education andtalbkhfajy4Belum ada peringkat

- J6 AB ExperimentationJHR1994 OCRDokumen18 halamanJ6 AB ExperimentationJHR1994 OCRBaja BajabajasziBelum ada peringkat

- POINTDokumen12 halamanPOINTMervin GautaneBelum ada peringkat

- Orifice Sizing PrinciplesDokumen12 halamanOrifice Sizing Principlesjlcheefei9258100% (1)

- Displacer Type Level Switches: FeaturesDokumen2 halamanDisplacer Type Level Switches: FeaturesJose JohnBelum ada peringkat

- Norgren Filter RegulatorDokumen4 halamanNorgren Filter RegulatorJose JohnBelum ada peringkat

- Engineering Manhours Estimation Sheet - PIPING - 917Dokumen1 halamanEngineering Manhours Estimation Sheet - PIPING - 917Jose JohnBelum ada peringkat

- Coversheet For Functional SchematicsDokumen2 halamanCoversheet For Functional SchematicsJose JohnBelum ada peringkat

- Product Data Sheet Rosemount 2120 Level Switch Vibrating Fork en 73576Dokumen26 halamanProduct Data Sheet Rosemount 2120 Level Switch Vibrating Fork en 73576Jose JohnBelum ada peringkat

- hpr2 Regulator For Model 933 Analyzer PN 300-9478Dokumen7 halamanhpr2 Regulator For Model 933 Analyzer PN 300-9478Jose JohnBelum ada peringkat

- Pressure Measurement: Applying Remote Seal, Isolation Diaphragms Between Process Fluids and TransmittersDokumen8 halamanPressure Measurement: Applying Remote Seal, Isolation Diaphragms Between Process Fluids and TransmittersJose JohnBelum ada peringkat

- Control System Architecture - Rev.A PDFDokumen6 halamanControl System Architecture - Rev.A PDFJose JohnBelum ada peringkat

- SCD - Dumad 1 PDFDokumen6 halamanSCD - Dumad 1 PDFJose JohnBelum ada peringkat

- EN Specification Sheet VEGAPULS 31 Two Wire 4 20 Ma HARTDokumen3 halamanEN Specification Sheet VEGAPULS 31 Two Wire 4 20 Ma HARTJose JohnBelum ada peringkat

- EN Specification Sheet VEGAPULS 63 4 20 Ma HART Two Wire PDFDokumen2 halamanEN Specification Sheet VEGAPULS 63 4 20 Ma HART Two Wire PDFJose JohnBelum ada peringkat

- Second Floor Partial Lighting Plan (Pe2) : KAP4 - Security Planning and Development Agency KAP4 ProjectDokumen1 halamanSecond Floor Partial Lighting Plan (Pe2) : KAP4 - Security Planning and Development Agency KAP4 ProjectJose JohnBelum ada peringkat

- Is 3624 1987 PDFDokumen56 halamanIs 3624 1987 PDFpanduranganraghuramaBelum ada peringkat

- 44-117 Model T20 and T21 Top Mounting Liquid Level SwitchesDokumen8 halaman44-117 Model T20 and T21 Top Mounting Liquid Level SwitchesJose JohnBelum ada peringkat

- Searchline Excel Install GuideDokumen2 halamanSearchline Excel Install GuideJose JohnBelum ada peringkat

- 35 Cooling and Heating Load CalculationsDokumen21 halaman35 Cooling and Heating Load CalculationsPRASAD326100% (32)

- Frequency Modulated Continuous Wave Technology: Improving Radar Accuracy and Reliability in Challenging ApplicationsDokumen9 halamanFrequency Modulated Continuous Wave Technology: Improving Radar Accuracy and Reliability in Challenging ApplicationstetioBelum ada peringkat

- Direct Insert Type Level Switches: FeaturesDokumen3 halamanDirect Insert Type Level Switches: FeaturesJose JohnBelum ada peringkat

- MI RTD AssembliesDokumen14 halamanMI RTD Assemblieskmanik78Belum ada peringkat

- Is 3624 1987 PDFDokumen56 halamanIs 3624 1987 PDFpanduranganraghuramaBelum ada peringkat

- First Floor Partial Lighting Plan (Pe2) : 1:100 KAP4-DWG-119-MBXX-EL-0063Dokumen1 halamanFirst Floor Partial Lighting Plan (Pe2) : 1:100 KAP4-DWG-119-MBXX-EL-0063Jose JohnBelum ada peringkat

- 80101E272 Roof Floor Partial Power Plan (Pe2)Dokumen1 halaman80101E272 Roof Floor Partial Power Plan (Pe2)Jose JohnBelum ada peringkat

- 80101E271 Roof Floor Partial Power Plan (Pe1)Dokumen1 halaman80101E271 Roof Floor Partial Power Plan (Pe1)Jose JohnBelum ada peringkat

- BS EN 837-2 Pressure Gauges Installation PDFDokumen10 halamanBS EN 837-2 Pressure Gauges Installation PDFIslam Fawzy100% (2)

- Vegawave 62: Contactless Electronic Switch Vibrating Level Switch With Suspension Cable For PowdersDokumen2 halamanVegawave 62: Contactless Electronic Switch Vibrating Level Switch With Suspension Cable For PowdersJose JohnBelum ada peringkat

- Document Number Rev. Document Title Number: Click On The Document Title To Go To That Section of The DocumentDokumen48 halamanDocument Number Rev. Document Title Number: Click On The Document Title To Go To That Section of The Documentharshkumar patelBelum ada peringkat

- Second Floor Partial Lighting Plan (Pe1) : Kap4-Dwg-Dd-119-Mbxx-El-6206-A Cable Routing Design Second Floor Part (E)Dokumen1 halamanSecond Floor Partial Lighting Plan (Pe1) : Kap4-Dwg-Dd-119-Mbxx-El-6206-A Cable Routing Design Second Floor Part (E)Jose JohnBelum ada peringkat

- Issue Note For Typical DWG PDFDokumen1 halamanIssue Note For Typical DWG PDFJose JohnBelum ada peringkat

- JobCI054 Al Dabbiya Inst List Rev0Dokumen4 halamanJobCI054 Al Dabbiya Inst List Rev0Jose JohnBelum ada peringkat

- BDx-A-T-TK-PBI-T-0348 - Instrument Hook-Up, Typical, Plot Plan, WiringDokumen2 halamanBDx-A-T-TK-PBI-T-0348 - Instrument Hook-Up, Typical, Plot Plan, WiringJose JohnBelum ada peringkat

- SP 1211Dokumen87 halamanSP 1211Anoop gokhaleBelum ada peringkat

- Mechanism of LubricationDokumen1 halamanMechanism of LubricationsushilBelum ada peringkat

- Theory Questions Asked in Mid Sem and CVMU QP - 07072023Dokumen26 halamanTheory Questions Asked in Mid Sem and CVMU QP - 07072023a9157272235Belum ada peringkat

- Irc 076-1979Dokumen21 halamanIrc 076-1979kruttika_apBelum ada peringkat

- Exam 3 Material Science MATS 2001 UMN Fall 2012Dokumen7 halamanExam 3 Material Science MATS 2001 UMN Fall 2012Zaki Smn100% (1)

- Answer: 6872.23 LBFT: Problem 304 Problem 327Dokumen2 halamanAnswer: 6872.23 LBFT: Problem 304 Problem 327Bianca GuevarraBelum ada peringkat

- ASTM D 2434 (Contant Head Method)Dokumen31 halamanASTM D 2434 (Contant Head Method)jawad100% (5)

- Designing & Managing Drilling FluidDokumen11 halamanDesigning & Managing Drilling Fluidfisco4rilBelum ada peringkat

- NH-Armaflex SpecificationDokumen2 halamanNH-Armaflex SpecificationPanya PurahongBelum ada peringkat

- A Pipe Is Gradually Tapering in SizeDokumen2 halamanA Pipe Is Gradually Tapering in SizeRez AdolfoBelum ada peringkat

- Glossory of CompositeDokumen125 halamanGlossory of CompositeIshfaq AhmadBelum ada peringkat

- Agission ADU451802 Datasheet PDFDokumen1 halamanAgission ADU451802 Datasheet PDFGiang Nguyễn TrườngBelum ada peringkat

- BT - 2004 SyllabusDokumen95 halamanBT - 2004 SyllabusMohamad SyazwanBelum ada peringkat

- Steel Design 1Dokumen26 halamanSteel Design 1Gracielle NebresBelum ada peringkat

- DataLog Drilling Fluids ManualDokumen57 halamanDataLog Drilling Fluids ManualJohnSmithBelum ada peringkat

- Local Winds: Land and Sea BreezesDokumen8 halamanLocal Winds: Land and Sea Breezesravi rathodBelum ada peringkat

- Best Explanations EIS PDFDokumen13 halamanBest Explanations EIS PDFAmbrish SinghBelum ada peringkat

- Well StimulationDokumen58 halamanWell StimulationRizwan FaridBelum ada peringkat

- Electrical Imaging: 2D Resistivity Tomography As A Tool For Groundwater Studies at Mahmudia Village, West Sulaimani City, Kurdistan Region/ IraqiDokumen1 halamanElectrical Imaging: 2D Resistivity Tomography As A Tool For Groundwater Studies at Mahmudia Village, West Sulaimani City, Kurdistan Region/ IraqiAcademecian group100% (1)

- Pipe Friction Loss Spreadsheet - Hazen Williams Apr17Dokumen6 halamanPipe Friction Loss Spreadsheet - Hazen Williams Apr17Kapil BairagiBelum ada peringkat

- Reflection of Light RaysDokumen66 halamanReflection of Light Raysp_k_soni_iit_physics0% (1)

- Gas Dynamics 3rd Edition John Solutions ManualDokumen35 halamanGas Dynamics 3rd Edition John Solutions Manualamandawrightrwfdcombka100% (22)

- A Study On The Peculiar Problems of Cold Formed Steel DesignDokumen3 halamanA Study On The Peculiar Problems of Cold Formed Steel DesignarjunBelum ada peringkat

- ESAS Quiz4Dokumen5 halamanESAS Quiz4Birthley RagasaBelum ada peringkat

- Reinforced Concrete DesignDokumen43 halamanReinforced Concrete DesignWilbert Carlo RachoBelum ada peringkat

- Influence of Liquid and Gas Flow Rates On SulfuricDokumen7 halamanInfluence of Liquid and Gas Flow Rates On SulfuricNathanBelum ada peringkat

- Thermal StressDokumen104 halamanThermal Stressmanishtopsecrets100% (1)

- Non-returns-DampersDokumen1 halamanNon-returns-DampersProject enghvacBelum ada peringkat

- 1 Welding Materials Control Procedure PDFDokumen3 halaman1 Welding Materials Control Procedure PDFMustafa MubderBelum ada peringkat

- EXP 1 Lab Rep For PrintDokumen6 halamanEXP 1 Lab Rep For PrintJohn leo-mar PadillaBelum ada peringkat