Dissimilar Stainless Steel Welding Consumable

Diunggah oleh

craccerHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Dissimilar Stainless Steel Welding Consumable

Diunggah oleh

craccerHak Cipta:

Format Tersedia

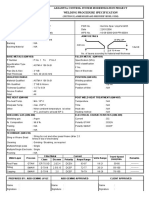

PREQUALIFIED WELDING CONSUMABLES

Reference Source Australian Standards AS/NZS 1554.6:1994 *

To

304

304L

309

310

316

316L

317

317L

316Ti

321

347

Weld

30815

(253MA)

904L

08028

4003

405

409

4105

430

444

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

316L

410

403

420

31803

32304

32750

Nickel

Alloys

To

Austenitic Grades

304

304L

309

310

316

316L

317

317L

316Ti

321

347

30815 (253MA)

904L

08028

308

308

308

308

308

308

308

308

308

347

308

308

308

308

4003

405

409

4105

430

444

316L

309

309

309

309

316L

316L

309

309

309

309

316L

309

309

309

309

309

316L

309

309

309

309

309

316L

316L

309

309

309

309

316L

316L

309

309

309

309

316L

309

309

309

309

309

316L

309

309

309

309

309

316L

309

309

309

309

309

316L

309

309

309

309

309

316L

309

309

309

309

309

316L

309

309

309

309

309

316L

410

403

420

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

Martensitic Grades

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

309

31803

32304

32750

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

Duplex Grades

2209

2209

2209

2209

2510

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2209

2510

2209

2510

2510

Nickel Alloys

309

309L

309

309

309Mo

309Mo

309Mo

309Mo

309Mo

309

309

Nickel Alloys

22.12HT

904L

028L

309L

309

309

309

309

309Mo

309

309

309

2209

2209

2510

NiCr3

Carbon Steel

309

309L

309

309

309

309Mo

309Mo

309Mo

309Mo

309Mo

309

309

309Mo

309

309

309

309

309Mo

309

309

309

2209

2209

2510

NiCr3

304

304L

309

310

316

316L

317

317L

316Ti

321

347

30815

(253MA)

4003

405

409

4105

430

444

410

403

420

31803

32304

32750

Nickel

Alloys

To

308L

308

309

308

309

310

308

316

316

316

308L

316

316

316

316L

308

309

317

316

316

317

308L

309

317

316

316L

317L

317L

308L

316

318

318

318

318

318

318

347

347

347

347

347

347

347

347

347

347

347

347

347

347

347

347

347

347

347

308

22.12HT 22.12HT 22.12HT 22.12HT 22.12HT 22.12HT 22.12HT 22.12HT 22.12HT 22.12HT

308L

309

309

316

316L

904L

904L

904L

904L

904L

904L

308L

309

309

316

316L

028L

028L

028L

028L

028L

028L

904L

028L

028L

Ferritic Grades

309

309

309

309

309

309

309

309

309

309

316L

316L

Carbon Steel

309Mo 309Mo

904L

08028

Notes to Table:

1

2

3

4

5

6

7

8

9

The recommended prequalified consumable for welding one grade to itself, i.e. similar metal welding, is given in bold

For dissimilar metals, welding the grade listed at the intersection of the row and column is recommended. Both this grade and the grade in bold on the intersecting row are prequalified, e.g. for welding 316L to 304L, both 308L and 316L are prequalified.

For parent metals designations, refer to AISI, UNS or SEW designations, as appropriate. For welding consumables designations, refer to AS 1167.2, AS 1553.3, AS 2717.3, ANSI/AWS A5.4 or ANSI/AWS A5.9, as appropriate.

Silicon containing designations in accordance with AS 2717.3 is also deemed prequalified.

Also applies to grades 201, 202, 301, and 302

Grade 316L is not prequalified for these dissimilar joints.

Reference Source: Australian Standards AS/NZS 1554.6:1994

Some common grades used in refractory applications.

Disclaimer: The above data is based on information provided in Australian Standards AS/NZS 1554.6:1994. Therefore, any liability for such recommendations or any oral advice is expressly excluded unless Antec Engineering Pty Ltd

has acted wilfully or by gross negligence. Due to different materials and conditions of application, which are beyond the control of Antec Engineering Pty Ltd, we recommend in any case carrying out sufficient tests in order to ensure

that weld procedures are suitable for the intended processes and applications. It is always the responsibility of the welder installer / purchaser to guarantee correct preparation of all Materials. Antec Engineering Pty Ltd is not responsible

for installation or faulty installation. Antec Engineering Pty Ltd does NOT warrant or Guarantee installation. It is always the responsibility of the welder installer / purchaser to guarantee and certify the welding and installation of materials.

Anda mungkin juga menyukai

- Welding Metallurgy and Weldability of Nickel-Base AlloysDari EverandWelding Metallurgy and Weldability of Nickel-Base AlloysPenilaian: 5 dari 5 bintang5/5 (1)

- GMAWDokumen12 halamanGMAWsushant47Belum ada peringkat

- Weld Filler Metal SelectionDokumen7 halamanWeld Filler Metal SelectionsusanwebBelum ada peringkat

- Brazing BPS 107-1 PDokumen5 halamanBrazing BPS 107-1 Pmbe josephBelum ada peringkat

- Welding BisplateDokumen12 halamanWelding BisplateLim Senglin100% (1)

- Electrode Selection ChartDokumen4 halamanElectrode Selection Chartsunitbhaumik100% (2)

- Interpass Temperature WeldingDokumen2 halamanInterpass Temperature Weldinghareesh13hBelum ada peringkat

- Brazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Dokumen3 halamanBrazing Procedure Specification (BPS) : (Automatic, Manual, Machine, or Semi-Automatic)Joyce GordonioBelum ada peringkat

- Mild Steel to Stainless Steel Welding Materials CatalogDokumen334 halamanMild Steel to Stainless Steel Welding Materials CatalogTran Chi Binh DDC100% (1)

- Duplex & Super Duplex InformationDokumen7 halamanDuplex & Super Duplex InformationrajeshBelum ada peringkat

- BHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelDokumen2 halamanBHEL Welding Procedure for Fillet and Socket Welding 18Cr8Nri Stainless SteelpradhankruhsnaBelum ada peringkat

- Selection of Welding Electrodes for RailwaysDokumen43 halamanSelection of Welding Electrodes for Railwayssalman ali100% (1)

- TWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Dokumen68 halamanTWI Cswip 3.1wis 5 Welding Inspection Welding Symbols BSEN ISO 22553 /AWS A2Ali ClubistBelum ada peringkat

- Weldability of Cr-Mo SteelsDokumen20 halamanWeldability of Cr-Mo SteelsNitin Bajpai100% (2)

- Metrode Dissimilar Consumable SelectorDokumen7 halamanMetrode Dissimilar Consumable SelectorClaudia MmsBelum ada peringkat

- Electrode Codes For Use in BoilersDokumen4 halamanElectrode Codes For Use in Boilersh_patnaikBelum ada peringkat

- Weld GaugesDokumen15 halamanWeld Gaugesraobabar21100% (1)

- Welding Electrode Classifications WallchartDokumen1 halamanWelding Electrode Classifications Wallchartask101100% (1)

- AWS List of Welding CodesDokumen16 halamanAWS List of Welding CodesLee Chong EeBelum ada peringkat

- Garcia Welding: Filler Metal Selection GuideDokumen8 halamanGarcia Welding: Filler Metal Selection GuideGustavo MorilloBelum ada peringkat

- 8474l 000 Jss 6300 001 1 General Requirements For WeldingDokumen69 halaman8474l 000 Jss 6300 001 1 General Requirements For WeldinglebienthuyBelum ada peringkat

- Welding of Nonferrous Metal and Their AlloysDokumen62 halamanWelding of Nonferrous Metal and Their AlloysKhin Aung ShweBelum ada peringkat

- The Heat Affected ZoneDokumen24 halamanThe Heat Affected ZoneRatan PanditBelum ada peringkat

- ASME Welding PositionsDokumen3 halamanASME Welding PositionsMicheal MurphyBelum ada peringkat

- ASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Dokumen2 halamanASME Section IX (ASME Pressure Vessel Code) : Welding Procedure Specifications (WPS)Virk Farms100% (1)

- A Study On Transverse Weld Cracks PDFDokumen8 halamanA Study On Transverse Weld Cracks PDFRifani ImamBelum ada peringkat

- Visual Inspection of Weld Joints Welding and NDTDokumen7 halamanVisual Inspection of Weld Joints Welding and NDTALFA ENGINEERING100% (2)

- Heat Input CalculatorDokumen2 halamanHeat Input Calculatormahi1437Belum ada peringkat

- ตารางเหล็กDokumen163 halamanตารางเหล็กMaster TowerBelum ada peringkat

- Welding Filler Metals For Power Plant EngineeringDokumen20 halamanWelding Filler Metals For Power Plant EngineeringgogotigBelum ada peringkat

- Welding Inspection Handbook PDF 1623987530Dokumen29 halamanWelding Inspection Handbook PDF 1623987530Dross AlssBelum ada peringkat

- BPQ REV. 0 Interactive FormDokumen2 halamanBPQ REV. 0 Interactive FormcosmicbunnyBelum ada peringkat

- Selection of Welding ConsumablesDokumen13 halamanSelection of Welding ConsumablesbassemaeBelum ada peringkat

- Electrodes EnglishDokumen139 halamanElectrodes Englishcostelino72Belum ada peringkat

- Critére D'acceptation PT API 650 ASME VIIIDokumen4 halamanCritére D'acceptation PT API 650 ASME VIIITahar DabbarBelum ada peringkat

- Thermanit MTS 3 - GTAWDokumen1 halamanThermanit MTS 3 - GTAWdnageshm4n244Belum ada peringkat

- ASTM Welding Tips A410 To A643Dokumen20 halamanASTM Welding Tips A410 To A643MARIO HUAMANBelum ada peringkat

- ASME & ISO ComparisonDokumen5 halamanASME & ISO Comparisonr0m14rBelum ada peringkat

- Highlights On ASME Essential VariablesDokumen8 halamanHighlights On ASME Essential VariableschowhkBelum ada peringkat

- Welding ElotrodeDokumen3 halamanWelding ElotrodeNiranjan khatuaBelum ada peringkat

- Welder Qualification Test CertificateDokumen1 halamanWelder Qualification Test CertificateManivannanMudhaliar100% (1)

- All Materials DocumentsDokumen1 halamanAll Materials DocumentsHarnish BariaBelum ada peringkat

- WPS-2 InchDokumen2 halamanWPS-2 InchKarthikeyan MpBelum ada peringkat

- ASME SECTION IX INTERPRETATIONSDokumen77 halamanASME SECTION IX INTERPRETATIONSहेमंत कुमार मीणाBelum ada peringkat

- Aalco Datasheet ST ST SpecificationsDokumen5 halamanAalco Datasheet ST ST Specificationsorea1Belum ada peringkat

- PIPA POP003 Butt Fusion Jointing of PE Pipes and Fittings Recommended Parameters Issue 7Dokumen4 halamanPIPA POP003 Butt Fusion Jointing of PE Pipes and Fittings Recommended Parameters Issue 7BOBBelum ada peringkat

- Astm d3261 1997Dokumen4 halamanAstm d3261 1997Nassim Ben AbdeddayemBelum ada peringkat

- Powers Screws Tech Guide 2013 PDFDokumen5 halamanPowers Screws Tech Guide 2013 PDFprasadhingankarBelum ada peringkat

- 5313ub Usg Boral Sheet Ceiling SystemsDokumen5 halaman5313ub Usg Boral Sheet Ceiling SystemsJessie Jr CuisonBelum ada peringkat

- Structural SteelDokumen6 halamanStructural SteelKevin VargheseBelum ada peringkat

- Brochure 2010Dokumen20 halamanBrochure 2010shankarsreekumarBelum ada peringkat

- Reach Compliance With AS / NZS 61439 Series: Switchboard Manufacturers & Designers Partner With InsulectDokumen8 halamanReach Compliance With AS / NZS 61439 Series: Switchboard Manufacturers & Designers Partner With InsulectManav IyerBelum ada peringkat

- Gas Turbine Super Alloy CompositionsDokumen3 halamanGas Turbine Super Alloy Compositionsleading_aliBelum ada peringkat

- Es LFTP300Dokumen2 halamanEs LFTP300WattsBelum ada peringkat

- 4534-2006 Pre PDFDokumen6 halaman4534-2006 Pre PDFAhmad Jukliv Pandu YoedhawanBelum ada peringkat

- f03 - Ds csm18Dokumen4 halamanf03 - Ds csm18danyan92Belum ada peringkat

- Educational Bulletin No 2Dokumen2 halamanEducational Bulletin No 2nagc12Belum ada peringkat

- Xchange Parts DeutzDokumen9 halamanXchange Parts DeutzFernando Alanis100% (1)

- IPP STATEMENT SSP Duolok Swagelok Interchange Intermix Pages From ASTM F1387 GE 362A2915 Test PlanDokumen5 halamanIPP STATEMENT SSP Duolok Swagelok Interchange Intermix Pages From ASTM F1387 GE 362A2915 Test PlanAnonymous otUd3TzIBelum ada peringkat

- Road DescriptionDokumen5 halamanRoad DescriptionfuzahjamilBelum ada peringkat

- Josefino D. Minguillan JR.: Block 51 Lot 11 Dela Costa Homes V Ph1 Brgy. Burgos, Rodriguez, RizalDokumen2 halamanJosefino D. Minguillan JR.: Block 51 Lot 11 Dela Costa Homes V Ph1 Brgy. Burgos, Rodriguez, RizalCatherine RenanteBelum ada peringkat

- Astm A 795Dokumen6 halamanAstm A 795djfreditoBelum ada peringkat

- Report by KKParthiban On Boiler Explosion of A Shell Type High PR BoilerDokumen97 halamanReport by KKParthiban On Boiler Explosion of A Shell Type High PR Boilerparthi20065768100% (1)

- Pds - Floor Hardener NMDokumen2 halamanPds - Floor Hardener NMkasivisanadhBelum ada peringkat

- Amphenol: Amphenol /pyle Industrial Connectors Star-Line, Star-Line EX, Star-LokDokumen85 halamanAmphenol: Amphenol /pyle Industrial Connectors Star-Line, Star-Line EX, Star-Lokrolando laffontBelum ada peringkat

- Catalogue Surface Electric Pumps 50HzDokumen32 halamanCatalogue Surface Electric Pumps 50HzHenry SBelum ada peringkat

- 110 Block Termination Instructions For Feeder Pair Cabling.Dokumen4 halaman110 Block Termination Instructions For Feeder Pair Cabling.Victor L. HartBelum ada peringkat

- An Experimental Study On Construction and Demolition WasteDokumen6 halamanAn Experimental Study On Construction and Demolition WasteDEEPAK KUMAR SINGHBelum ada peringkat

- Socketweldspacerrings SoluGapBrochureDokumen2 halamanSocketweldspacerrings SoluGapBrochureRamzi BEN AHMEDBelum ada peringkat

- Prof (1) - Zahid Ahmad Siddiqi Formwork Design-IIIDokumen32 halamanProf (1) - Zahid Ahmad Siddiqi Formwork Design-IIIasdasBelum ada peringkat

- 24-LIGHTING - BOQ Rev. 00Dokumen7 halaman24-LIGHTING - BOQ Rev. 00Arasan SKBelum ada peringkat

- General Specification - Roads and BridgesDokumen165 halamanGeneral Specification - Roads and BridgesEnea BogdanBelum ada peringkat

- NHA concrete pouring permitDokumen8 halamanNHA concrete pouring permiterjieBelum ada peringkat

- Elems 15Dokumen101 halamanElems 15Reynald de VeraBelum ada peringkat

- PresentationDokumen2 halamanPresentation076bch031.ritishaBelum ada peringkat

- Notes of CH 6 Physical and Chemical Changes Class 7th ScienceDokumen3 halamanNotes of CH 6 Physical and Chemical Changes Class 7th ScienceVicky SharmaBelum ada peringkat

- Plan - Recover A 7Dokumen1 halamanPlan - Recover A 7jet toledoBelum ada peringkat

- WOOD As A BUILDING MATERIAL 2Dokumen9 halamanWOOD As A BUILDING MATERIAL 2Jays Tioxon IIIBelum ada peringkat

- Portland Cement ConcreteDokumen15 halamanPortland Cement ConcreteIm ChinithBelum ada peringkat

- Limit Values For LubricantsDokumen28 halamanLimit Values For LubricantsSindley LimaferBelum ada peringkat

- Spreadsheets To BS 8110: The Concrete CentreDokumen12 halamanSpreadsheets To BS 8110: The Concrete CentreAnil kumar RBelum ada peringkat

- Construction Logbook Sheet - Staff HouseDokumen33 halamanConstruction Logbook Sheet - Staff HouseJet Espejon JavierBelum ada peringkat

- TDS Brushbond IndiaDokumen2 halamanTDS Brushbond IndiapankajsinghBelum ada peringkat

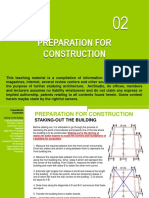

- 02 Preparation For Construction PDFDokumen61 halaman02 Preparation For Construction PDFMiguel David100% (2)

- Saej 524 V 002Dokumen5 halamanSaej 524 V 002Marcos Verissimo Juca de PaulaBelum ada peringkat

- BPI-Company ProfileDokumen19 halamanBPI-Company Profilesunny vachhaniBelum ada peringkat

- Z211 Inst Tube FittingsDokumen44 halamanZ211 Inst Tube FittingsSajeen100% (1)

- Weight and dimensions of water-filled steel and PVC pipesDokumen11 halamanWeight and dimensions of water-filled steel and PVC pipesmoh. rusli bahtiarBelum ada peringkat

- Quick Release Couplings: HT-Series ISO16028 Flushface InterchangeDokumen3 halamanQuick Release Couplings: HT-Series ISO16028 Flushface InterchangerweidlingBelum ada peringkat

- University of Chicago Press Fall 2009 CatalogueDari EverandUniversity of Chicago Press Fall 2009 CataloguePenilaian: 5 dari 5 bintang5/5 (1)

- University of Chicago Press Fall 2009 Distributed TitlesDari EverandUniversity of Chicago Press Fall 2009 Distributed TitlesPenilaian: 1 dari 5 bintang1/5 (1)