Chilled Water Pipe Installation - ACMV

Diunggah oleh

binhjuki100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

934 tayangan4 halamanJudul Asli

Chilled water pipe installation - ACMV.docx

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

934 tayangan4 halamanChilled Water Pipe Installation - ACMV

Diunggah oleh

binhjukiHak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 4

1

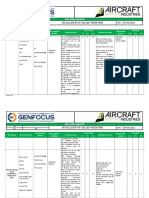

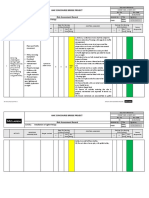

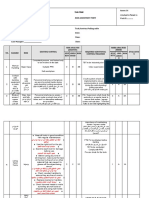

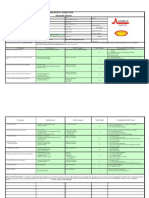

LIST OF HAZARDS AND RISKS

F-OSH-P-02-a

RISK ASSESSMENT FORM

Company: United Engineers (S) Pte Ltd *Conducted by: Name: Crisanto C. Derrick S. Tang TM Eric Kan Andrew T.

Process/Location: SC/HP Project @ Orchard Rd Designation: Project Mgr. Proj Mgr. PM-ACMV PM-ACMV Snr WSHO

Approved by:

(Name,

Designation,

Signature & Date)

Edgardo C. Balagtas

Project Director

______________________________

Signature:

Date: 20/9/11 20/9/11 20/9/11 20/9/11 20/9/11

Previous Review

Date:

20 Sep 2011 Next Review Date: 20 Sep 2012

Main Work

Activity:

Chilled water pipe installation -

ACMV

Revision No: 2 No. of Pages: 4

1.Hazard Identification 2.Risk Evaluation 3.Risk Control 4. Reference

1a. 1b. 1c. 1d. 2a. 2b. 2c. 2d. 3a 3b 4

No Work Activity Hazard

Possible Accident/ Ill

Health & Persons-at-Risk

Existing Risk

Control (if any)

S

e

v

e

r

i

t

y

L

i

k

e

l

i

h

o

o

d

R

i

s

k

L

e

v

e

l

Additional Risk

Control

Action Officer,

Designation

(Follow-up

date)

Safe Work

Procedure

Document

No.

1.

Delivery & Hoisting

of Materials (Chilled

Water pipes/Ducting)

Please refer to

delivery and hoisting

of materials &

equipment RA

1.1 Delivery of

materials to site

Person/public

property might be hit

by vehicle

Physical injury/property

damage

1. Assess the travel path

before moving objects

and ensure clearance from

other materials

2. Barricade the area

before moving to prevent

other workers from

accessing through.

3. Close supervision by

the site Foreman

Ma

R

M

Provide banks

men to guide the

vehicle while

maneuvering

Site Supv.

Safety Supv

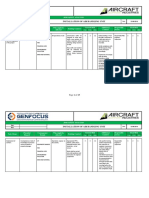

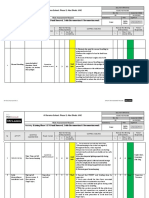

1.Hazard Identification 2.Risk Evaluation 3.Risk Control 4. Reference

1a. 1b. 1c. 1d. 2a. 2b. 2c. 2d. 3a 3b 4

No Work Activity Hazard

Possible Accident/ Ill

Health & Persons-at-Risk

Existing Risk

Control (if any)

S

e

v

e

r

i

t

y

L

i

k

e

l

i

h

o

o

d

R

i

s

k

L

e

v

e

l

Additional Risk

Control

Action Officer,

Designation

(Follow-up

date)

Safe Work

Procedure

Document

No.

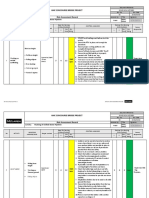

2

2

Installation of chilled

water pipe

2.1 Drilling hole and

install wall plug

2.2 Installation of

anchor point for

chain block using

scissor lift/mobile

platform

Use of hand tools

Flying objects/Dust

Falling from height

Falling objects

Cuts, lacerations

Eye irritation

- Death

- Fractures

- Sprains, bruises, cuts,

laceration, scratches

- Bruises, cuts,

laceration, abrasion

1. Brief workers on SWP

in using hand tools

2. Wear appropriate PPE

3. Close supervision

1. Use of full face shield

2. Wear dust musk

1. Valid LP cert

2. Testing & checking of

functionality of scissor lift

before use.

3. Wearing of compulsory

PPE

4. Use of safety harness

5. Only trained operators to

operate the machine

- PPE (helmet) usage

- Brief workers on SWP

- Proper housekeeping

Mi

Mi

Ma

Mo

Mi

Mi

O

O

R

O

O

O

L

L

M

M

L

L

- Ensure to apply

PTW at height

- 2

nd

person as

look out while

scissor lift is

maneuvering.

Site Supv.

Safety Supv

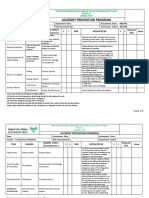

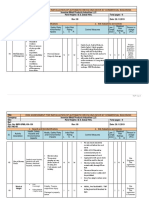

1.Hazard Identification 2.Risk Evaluation 3.Risk Control 4. Reference

1a. 1b. 1c. 1d. 2a. 2b. 2c. 2d. 3a 3b 4

No Work Activity Hazard

Possible Accident/ Ill

Health & Persons-at-Risk

Existing Risk

Control (if any)

S

e

v

e

r

i

t

y

L

i

k

e

l

i

h

o

o

d

R

i

s

k

L

e

v

e

l

Additional Risk

Control

Action Officer,

Designation

(Follow-up

date)

Safe Work

Procedure

Document

No.

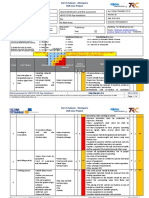

3

2.3 Fabrication of

Chilled water Pipe.

Caught in-between

scissors lift cage and

overhead/ceiling

installations

Expose to sharp

tools,(Hand Saw)

Exposure to

excessive noise

(Noise Pollution)

Flying object/ dust

1. Death

2. Crushing / Fractures /

Concussions

3. Sprains, Bruises, Cuts,

Lacerations, Abrasions,

Scratches.

Deep cut/ lacerations

Hearing impairment

Irritation/ Eye injury

1. Valid Lifting Machine

certificate.

2. Testing & checking of

functionality of equipment

before use (Daily).

3. Compulsory PPE.

4. Safety harness usage for

working at height >4m.

5. All operators are trained

& competent in operating

equipment.

6. Adherence to Safe Work

Procedure for Use of

Scissors Lifts.

7. Demarcate work zone to

prevent unauthorised

access.

8. Direct supervision of all

lifts in operation

- Appropriate PPE must be

worn at all times.

- Machine must be place

on top of bench.

- RA briefing prior to work

- Ear Plugs/ Muffs to be

worn.

- Carry out work in an

open area to disperse noise.

- RA briefing prior to work

- Appropriate PPE must be

worn at all times

Ma

Mo

Mi

Mo

Mo

Mo

R

O

O

O

R

O

M

M

L

M

L

M

1. Ensure floor

of work area free

of debris.

2. Ensure good

housekeeping.

3. Park lift at

lowest height

while shifting

location &

idling.

4. Buddy system

while working

on lifts.

5. Installation of

vertical

standards as

preventive

measure for

getting caught

in-between

- Regular

briefing/ training

to usage of such

tools.

- No wearing of

blur/ dirty safety

goggles.

Site Supv.

Safety Supv

Site Supv.

Safety Supv.

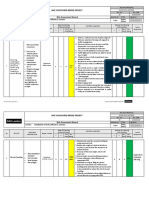

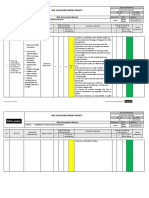

1.Hazard Identification 2.Risk Evaluation 3.Risk Control 4. Reference

1a. 1b. 1c. 1d. 2a. 2b. 2c. 2d. 3a 3b 4

No Work Activity Hazard

Possible Accident/ Ill

Health & Persons-at-Risk

Existing Risk

Control (if any)

S

e

v

e

r

i

t

y

L

i

k

e

l

i

h

o

o

d

R

i

s

k

L

e

v

e

l

Additional Risk

Control

Action Officer,

Designation

(Follow-up

date)

Safe Work

Procedure

Document

No.

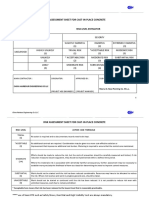

4

2.4 Hoisting of pipes

using chain block

2.5Tightening of

bracket for support

Falling

objects/materials

Falling objects/

materials

Bracket support

collapse (chilled

water pipe collapse)

- Death

- Fractures

- Cuts, bruises, abrasion

- Cuts, bruises, abrasion

- Death

- Fractures

- Cuts, bruises, abrasion

1. Valid LG/LA cert for

chain block

2. Only trained and

competent person to

operate

3. Briefing of SWP to

workers before operation

4. Close supervision by

supervisor

5. Chain block to be

inspected by competent

person before lifting

operation

1. Hand tools must be tied

to the workers body to

avoid it from falling

2. Barricade the work area

while work is still in

progress

1. Competent person to

inspect the work

immediately after its

completion

Ma

Mo

Mi

Mi

Ma

Mo

Mi

R

O

O

O

R

O

O

M

M

L

L

M

M

L

Apply PTW for

lifting

Barricade the

area

Site Supv.

Safety Supv

RA should be conducted by at least 2 person

Likelihood

Severity

Remote

(R)

Occasional

(O)

Frequent

(F)

Major (Ma) M H H

Moderate (Mo) L M H

Minor (Mi) L L M

H = High Risk, M = Medium Risk, L = Low Risk

Anda mungkin juga menyukai

- RA For Installation of Air Colled ChillersDokumen8 halamanRA For Installation of Air Colled ChillersAnandu Ashokan100% (2)

- Installation of Chilled Water PipesDokumen6 halamanInstallation of Chilled Water PipesAnandu Ashokan0% (1)

- Risk Assessment of Installation of Chilled Water PipesDokumen19 halamanRisk Assessment of Installation of Chilled Water PipesAnandu Ashokan80% (10)

- RA For Installation of FanDokumen8 halamanRA For Installation of FanAnandu AshokanBelum ada peringkat

- Risk Assessment For Installation of SMDB&DBDokumen15 halamanRisk Assessment For Installation of SMDB&DBAnandu Ashokan78% (9)

- Risk Assessment For Installation of Diesel Generator111111Dokumen8 halamanRisk Assessment For Installation of Diesel Generator111111Baher Mohamed100% (1)

- Risk Assessment For Installation of Sanitary WaresDokumen14 halamanRisk Assessment For Installation of Sanitary WaresAnandu Ashokan67% (6)

- Risk Assessment For Installation of Toilet Exhaust FanDokumen11 halamanRisk Assessment For Installation of Toilet Exhaust FanAnandu Ashokan67% (3)

- Installation of Air Handling UnitDokumen15 halamanInstallation of Air Handling UnitAnandu Ashokan100% (2)

- 20-RAS-Transformer InstallationDokumen2 halaman20-RAS-Transformer InstallationWalid MarhabaBelum ada peringkat

- Risk Assessment For MEP Isolation WorksDokumen8 halamanRisk Assessment For MEP Isolation WorksAnandu Ashokan100% (5)

- Ra Testing & Commissioning of Irrigation SystemDokumen14 halamanRa Testing & Commissioning of Irrigation Systemamal100% (2)

- Risk Assessment For Installation of Fan Coil UnitsDokumen18 halamanRisk Assessment For Installation of Fan Coil UnitsAnandu Ashokan67% (3)

- Risk Assessment For Installation of Grill, Diffuser and LouversDokumen13 halamanRisk Assessment For Installation of Grill, Diffuser and LouversAnandu Ashokan100% (7)

- MS For Installation of Light FittingsDokumen11 halamanMS For Installation of Light FittingsAnandu Ashokan100% (2)

- RA For Phase 1 Existing LV Panel and Cable Dismantling WorkDokumen9 halamanRA For Phase 1 Existing LV Panel and Cable Dismantling WorkAnandu Ashokan100% (1)

- Risk Assessment For Installation of Fire Fighting SystemDokumen12 halamanRisk Assessment For Installation of Fire Fighting Systemطارق رضوان100% (3)

- Painting WorksDokumen2 halamanPainting WorksAhoyAoaBelum ada peringkat

- 009 Installation of Pumps Risk AssessmentDokumen2 halaman009 Installation of Pumps Risk Assessmentgangadharan000100% (13)

- Risk Assess Plastering 2006 Tcm17 26368Dokumen2 halamanRisk Assess Plastering 2006 Tcm17 26368Anonymous QGHbz92uBelum ada peringkat

- Risk Assessment For MEP Services in P6 Existing ParkingDokumen16 halamanRisk Assessment For MEP Services in P6 Existing ParkingAnandu Ashokan100% (2)

- Risk Assessment For Piping ErectionDokumen6 halamanRisk Assessment For Piping ErectionAzhar MushtaqBelum ada peringkat

- Risk Assessment (Installation of Cables & Wires)Dokumen6 halamanRisk Assessment (Installation of Cables & Wires)michael acosta100% (3)

- RA For Hvac Duct InstallationDokumen10 halamanRA For Hvac Duct InstallationAnandu Ashokan88% (8)

- Risk Assessments For ACTIVITY BASEDDokumen4 halamanRisk Assessments For ACTIVITY BASEDhello3232Belum ada peringkat

- Testing and Commissioning of BMS Rev ADokumen8 halamanTesting and Commissioning of BMS Rev Aanish7785100% (3)

- Amc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineDokumen8 halamanAmc Concourse Bridge Project: Activity: Flushing of Chilled Water PipelineEm Niax100% (1)

- Risk AssessmentDokumen3 halamanRisk AssessmentSam HodgsonBelum ada peringkat

- Risk Assessment For Installation of HVAC Duct and AccessoriesDokumen15 halamanRisk Assessment For Installation of HVAC Duct and AccessoriesAnandu Ashokan67% (3)

- Risk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitDokumen17 halamanRisk Assessment For Installation, Testing & Commissioning of Copper, Silver Ionization UnitAnandu Ashokan100% (1)

- Risk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaDokumen12 halamanRisk Assessment For Rerouting of MEP Services in New Substation, Phase 1 AreaAnandu Ashokan100% (3)

- Risk Assessment For Installation of Automatic Revolving Door InstallationDokumen8 halamanRisk Assessment For Installation of Automatic Revolving Door Installationsabirbdk100% (1)

- 007 - Risk Ass. - CE-0994-MEP WorksDokumen9 halaman007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Mobilization and Installation of CHW PipesDokumen8 halamanMobilization and Installation of CHW PipesYounis KhanBelum ada peringkat

- RISK ASSES-82 - Installation of Condenser Unit 2Dokumen8 halamanRISK ASSES-82 - Installation of Condenser Unit 2Rochdi BahiriBelum ada peringkat

- Risk Assessment For Installation of Ducts and AccessoriesDokumen17 halamanRisk Assessment For Installation of Ducts and AccessoriesAnandu Ashokan83% (12)

- Risk Assessment For Installation of Electrical Wiring & Cable PullingDokumen13 halamanRisk Assessment For Installation of Electrical Wiring & Cable PullingAnandu Ashokan94% (17)

- Risk Assessment For Water Heaters InstallationDokumen6 halamanRisk Assessment For Water Heaters Installationfidgety100% (1)

- 005 Risk Assessment T&C Fire Suppression SystemDokumen10 halaman005 Risk Assessment T&C Fire Suppression SystemJohn RazaBelum ada peringkat

- Risk Assessment & Control Register - Grease Trap CleaningDokumen7 halamanRisk Assessment & Control Register - Grease Trap CleaningAbdul RahmanBelum ada peringkat

- Risk Assessment of Fire Hose Reel InstallationDokumen9 halamanRisk Assessment of Fire Hose Reel Installationfidgety100% (2)

- Risk Assessment For Installation & Testing of BMS UnitDokumen15 halamanRisk Assessment For Installation & Testing of BMS UnitAnandu Ashokan100% (3)

- Job Hazard Analysis: Rohan Builders (I) PVT LTDDokumen6 halamanJob Hazard Analysis: Rohan Builders (I) PVT LTDsoubhagya100% (1)

- RA MEWP 0003 Dec 2011Dokumen3 halamanRA MEWP 0003 Dec 2011Anup George Thomas100% (1)

- 2 - Pulling CablesDokumen5 halaman2 - Pulling CablesAhmed KhaledBelum ada peringkat

- Risk-Ahu Fcu FansDokumen5 halamanRisk-Ahu Fcu FansUmair Liaqat75% (4)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Dokumen3 halamanRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment For Flushing of Chilled Water PipingDokumen9 halamanRisk Assessment For Flushing of Chilled Water PipingAnandu AshokanBelum ada peringkat

- DSM-FRM-0001-27-0, HDPE PE-100 Pipe InstallationDokumen4 halamanDSM-FRM-0001-27-0, HDPE PE-100 Pipe Installationkadir tanzaniaBelum ada peringkat

- Risk AssessmentDokumen6 halamanRisk Assessmentkaruppusamymari100% (1)

- Risk Assessment For Installation of Sanitary Fixtures and Mixers (New)Dokumen12 halamanRisk Assessment For Installation of Sanitary Fixtures and Mixers (New)Anandu Ashokan100% (1)

- Risk AssessmetDokumen9 halamanRisk AssessmetAshoka Indunil WickramapalaBelum ada peringkat

- Risk Assessment HVAC DuctingDokumen5 halamanRisk Assessment HVAC DuctingAsad Zakria100% (6)

- Risk Assessment For Installation of HVAC Systems (RA34)Dokumen19 halamanRisk Assessment For Installation of HVAC Systems (RA34)Anandu Ashokan75% (4)

- Risk Assessment - Pre-Internal Wiring of Patch PanelDokumen3 halamanRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Cast-In Place Concrete - Risk Assessment SheetDokumen3 halamanCast-In Place Concrete - Risk Assessment SheetYash SharmaBelum ada peringkat

- JHA Civil WorksDokumen2 halamanJHA Civil Worksethelchudi100% (11)

- RA - 018 01 Scaffolding Erection and DismantlingDokumen14 halamanRA - 018 01 Scaffolding Erection and DismantlingVuong Bui95% (63)

- 5X5 Matrix RA For Installation Fo CHC-2A Conveyor SystemDokumen16 halaman5X5 Matrix RA For Installation Fo CHC-2A Conveyor SystemSandeep Jain100% (2)

- How To Size and Design DuctsDokumen91 halamanHow To Size and Design DuctsPrabir Bhowmik100% (1)

- Heat Recovery VentilatorsDokumen36 halamanHeat Recovery VentilatorsShiyamraj ThamodharanBelum ada peringkat

- Design Options For HVAC Distribution SystemsDokumen68 halamanDesign Options For HVAC Distribution Systemscathybravo100% (3)

- Fire Service Features of Buildings and Fire Protection SystemsDokumen129 halamanFire Service Features of Buildings and Fire Protection Systemsyêu animeBelum ada peringkat

- Duct SystemsDokumen19 halamanDuct SystemsShiyamraj ThamodharanBelum ada peringkat

- HVAC Design For Healthcare FacilitiesDokumen60 halamanHVAC Design For Healthcare Facilitiesaymanibrahim_71Belum ada peringkat

- HVAC Design For Pharmaceutical FacilitiesDokumen57 halamanHVAC Design For Pharmaceutical FacilitiesShams MInhaz Monzur100% (4)

- Duct Sealing in Large BuildingsDokumen31 halamanDuct Sealing in Large BuildingsShiyamraj ThamodharanBelum ada peringkat

- HVAC System PDFDokumen79 halamanHVAC System PDFBülent KabadayiBelum ada peringkat

- Engine Cooling and Lubrication Systems R1Dokumen43 halamanEngine Cooling and Lubrication Systems R1pasu pathiBelum ada peringkat

- HVAC Cooling Systems For Data CentersDokumen65 halamanHVAC Cooling Systems For Data CentersShiyamraj Thamodharan100% (1)

- Battery Room Ventilation and SafetyDokumen62 halamanBattery Room Ventilation and SafetyingatvBelum ada peringkat

- Cooling Towers PDFDokumen60 halamanCooling Towers PDFRamakrishnaBelum ada peringkat

- HVAC Design For Cleanroom FacilitiesDokumen55 halamanHVAC Design For Cleanroom FacilitiesMadhu Gajulapalli100% (1)

- Description of Useful HVAC TermsDokumen64 halamanDescription of Useful HVAC TermsShiyamraj Thamodharan100% (1)

- HVAC System PDFDokumen79 halamanHVAC System PDFBülent KabadayiBelum ada peringkat

- The MEP Design of Building Sevices PDFDokumen98 halamanThe MEP Design of Building Sevices PDFMoideen Thashreef100% (3)

- HVAC Design For Healthcare FacilitiesDokumen60 halamanHVAC Design For Healthcare Facilitiesaymanibrahim_71Belum ada peringkat

- Ventilation and Exhaust SystemsDokumen95 halamanVentilation and Exhaust SystemsbinhjukiBelum ada peringkat

- HVAC Cooling Systems For Data CentersDokumen65 halamanHVAC Cooling Systems For Data CentersShiyamraj Thamodharan100% (1)

- Stairwell Pressurization SystemsDokumen67 halamanStairwell Pressurization SystemsShiyamraj ThamodharanBelum ada peringkat

- Hvac GreenDokumen201 halamanHvac GreenShiyamraj ThamodharanBelum ada peringkat

- Edmt34-635a VRV3S PDFDokumen308 halamanEdmt34-635a VRV3S PDFbinhjuki100% (1)

- Steam Distribution CourseDokumen79 halamanSteam Distribution CoursebinhjukiBelum ada peringkat

- Att WY CatalogDokumen8 halamanAtt WY CatalogbinhjukiBelum ada peringkat

- Siemens Building ManagementDokumen266 halamanSiemens Building ManagementGirish Jha100% (2)

- IMF Flyer 100-200 PDFDokumen2 halamanIMF Flyer 100-200 PDFbinhjukiBelum ada peringkat

- Pipe Spacing CalculatorDokumen9 halamanPipe Spacing CalculatorJuan Pablo ApazaBelum ada peringkat

- 141 Dke FF BD MB 443 PDFDokumen1 halaman141 Dke FF BD MB 443 PDFbinhjukiBelum ada peringkat

- Specification FFU (Model 2x4 AH) PDFDokumen3 halamanSpecification FFU (Model 2x4 AH) PDFbinhjukiBelum ada peringkat

- Mooring Integrity Guidance - O&GUK - RevFDokumen113 halamanMooring Integrity Guidance - O&GUK - RevFTristan ChapmanBelum ada peringkat

- Acut Hepatic FailureDokumen11 halamanAcut Hepatic FailureDennis CobbBelum ada peringkat

- Tracheostomy Jurnal IDokumen4 halamanTracheostomy Jurnal ILalu Reza AldiraBelum ada peringkat

- Parenteral Therapy:: Intravenous Therapy (IVT) or VenipunctureDokumen3 halamanParenteral Therapy:: Intravenous Therapy (IVT) or VenipunctureMabes100% (1)

- SWP ExcavatorDokumen2 halamanSWP ExcavatorSayed AbbasBelum ada peringkat

- Fluid & Electrolytes and Acid Base BalanceDokumen108 halamanFluid & Electrolytes and Acid Base Balanceapi-3701489100% (12)

- Lean Hybrid Muscle Training DemoDokumen4 halamanLean Hybrid Muscle Training DemoStrong SpearBelum ada peringkat

- Spastic ParaplegiaDokumen7 halamanSpastic ParaplegiaDio ResnaBelum ada peringkat

- Avulsion and Degloving InjuryDokumen12 halamanAvulsion and Degloving InjuryandicaBelum ada peringkat

- USFD ManualDokumen133 halamanUSFD ManualRadha KrishnanBelum ada peringkat

- Procedure Sick Bay 2017Dokumen6 halamanProcedure Sick Bay 2017Syed FareedBelum ada peringkat

- Anatomical Explanation of "Mayurasana"Dokumen4 halamanAnatomical Explanation of "Mayurasana"Editor IJTSRDBelum ada peringkat

- Syndrome Acute Lung InjuryDokumen7 halamanSyndrome Acute Lung InjuryJiezl Abellano AfinidadBelum ada peringkat

- 9-34 Hand IIIDokumen40 halaman9-34 Hand IIIMario100% (1)

- Sonography of The Knee Joint PDFDokumen8 halamanSonography of The Knee Joint PDFChavdarBelum ada peringkat

- Modul Anatomy Blok 2-2Dokumen46 halamanModul Anatomy Blok 2-2AyuBelum ada peringkat

- NCLEX PracticeDokumen18 halamanNCLEX Practiceandrew504777Belum ada peringkat

- Youth Speed TrainingDokumen3 halamanYouth Speed TrainingIan Flack100% (1)

- Dragon Lance - Age of Mortals 1 - ConundrumDokumen156 halamanDragon Lance - Age of Mortals 1 - ConundrumvspscribdBelum ada peringkat

- Souls Growth Through Reincarnation - OrionDokumen220 halamanSouls Growth Through Reincarnation - OrionLucrezia AlvarezBelum ada peringkat

- Radiologic History Exhibit Musculoskeletal EponymsDokumen19 halamanRadiologic History Exhibit Musculoskeletal EponymsSangeetha KumariBelum ada peringkat

- CLG930E/936E Hydraulic ExcavatorDokumen970 halamanCLG930E/936E Hydraulic ExcavatorAli Kuncoro100% (1)

- 17-19 Use of Force, Fitness For Duty (Exonerated)Dokumen14 halaman17-19 Use of Force, Fitness For Duty (Exonerated)Whitman County WatchBelum ada peringkat

- Osteoarthritis of The KneeDokumen634 halamanOsteoarthritis of The KneeSergiu Plesca100% (2)

- Strength Training For KidsDokumen8 halamanStrength Training For KidsMike HaughtBelum ada peringkat

- Trauma-Case ScenarioDokumen1 halamanTrauma-Case ScenarioLearsi Ray AfableBelum ada peringkat

- Environemtnal Theory, Florence NightingaleDokumen10 halamanEnvironemtnal Theory, Florence NightingaleAngel Grace Golingay100% (1)

- Final Year BDS Pre-Prof Examination Nov-2020 Oral & Maxillofacial Surgery Sir Syed College of Medical SciencesDokumen15 halamanFinal Year BDS Pre-Prof Examination Nov-2020 Oral & Maxillofacial Surgery Sir Syed College of Medical SciencesHajra Muhammad siddiqueBelum ada peringkat

- Neurology Clerkship Study GuideDokumen84 halamanNeurology Clerkship Study GuideShunqing ZhangBelum ada peringkat

- Facet Joint SyndromeDokumen17 halamanFacet Joint Syndromepaulvaso27100% (1)