Abc Del RGB

Diunggah oleh

Cesar VilledaJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Abc Del RGB

Diunggah oleh

Cesar VilledaHak Cipta:

Format Tersedia

www.omc-uk.

com

The Optoelectronic Manufacturing Corporation

4W RGB High Power LED

Technical Datasheet

The Optoelectronic Manufacturing Corporation

A 4W, RGB (red, green, blue) light emitting diode device combining three individually

addressable high power chips in a single compact package, facilitating the production of low

spatial profile, high output full-colour-range products.

Key Features:

3 high power colours in one package

Very compact RGB high power source

Heatspreader option

High luminous flux per source

Low thermal resistance

Chips individually addressable

6 pin device for ultimate control

In-built electrostatic protection

In-built reverse polarity protection

RoHS Compliant

All specifications correct at time of publishing. In the interests of continual improvement, OMC reserve the right

to alter specifications without notice.

Typical Applications:

Accent lights

Up- and down-lighters

Battery powered torches

Automotive illumination

Colour changing strip lights

Mood lighting

Wall washers

Signalling

Colour changing lamps

Machinery

Part numbers:

P3RGB1H - with heatspreader

P3RGB1 - without heatspreader

The Optoelectronic Manufacturing Corporation

All specifications correct at time of publishing. In the interests of continual improvement, OMC reserve the right

to alter specifications without notice.

Colour Dominant Luminous Flux

(typ.) lumens

Luminous Flux

(max.) lumens

Forward

Voltage (V)

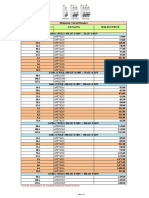

Red chip Red 625nm 23 30 2.3

Green chip Green 525nm 30 40 3.6

Blue chip Blue 465nm 10 14 3.5

Typical electro-optical characteristics at forward current = 350mA per chip and Ta=25C

Colours are for ease of reference only and do not indicate exact shade of LED output.

Quantity Rating

Thermal Resistance (Semiconductor Junction to Board) 15 K/W

Thermal Characteristics at If = 350mA per chip, Ta=25C

Absolute Maximum Ratings per Chip at Ta=25C

Quantity Rating

Reverse Voltage 5V

Semiconductor Junction Temperature 120C

Operating Temperature Range -35C to +75C

Temperature Range in Storage -35C to +100C

Lead soldering temperature (at 2mm from LED body for max 5 sec) 260C

Forward DC Current per Chip 350mA

Power dissipation 1.4W

The Optoelectronic Manufacturing Corporation

All specifications correct at time of publishing. In the interests of continual improvement, OMC reserve the right

to alter specifications without notice.

Power Spectra for Blue, Green, Amber and Red

B(-) G(-) R(-)

2

1

.

6

6

G(+) R(+)

1 2 3

B(+)

3

1

2

3

1

1 2 3

24.3

2

3

.

7

5

1.64

5

.

7

0

Package Dimensions

All dimensions are in mm. Tolerance 0.5mm.

The Optoelectronic Manufacturing Corporation

The Optoelectronic Manufacturing Corporation (UK) Ltd.

Cardrew Industrial Estate,

Redruth,

Cornwall

TR15 1SS

Tel: 01209 215424

Fax: 01209 215197

General e-mail: omc-sales@omc-uk.com

www.omc-uk.com

Application notes

Junction temperature should be kept below maximum by managing power dissipation.

Current spikes should be avoided, especially during power up. It is best practice to initially connect LED to

inactivated supply, then gradually ramp up supply to desired level.

Proper management of the thermal path from the junction should be observed. Relevant thermal

resistances should be used to calculate temperature increase from ambient to junction by multiplying by

power dissipation, to determine maximum ambient temperature of application.

Proper thermal conduction layers should be introduced at all interfaces to prevent insulating air gaps in the

thermal path from junction to ambient.

If the LED package has a lens fitted, do not use reflow soldering as the lens should not be taken above

110C.

As with all semiconductor devices, it is good practice to avoid electrostatic discharge.

High power LEDs are best driven using constant-current power supplies.

Do not connect to a constant voltage source without suitable current limiting measures.

Further information regarding soldering and storage precautions may be obtained by contacting OMCs

technical department.

Typical beam pattern when unlensed

Anda mungkin juga menyukai

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Bigben01 e A4Dokumen0 halamanBigben01 e A4Marcelo TorresBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- Neuschwanstein e A4Dokumen9 halamanNeuschwanstein e A4mariosergio05Belum ada peringkat

- Neuschwanstein e A4Dokumen9 halamanNeuschwanstein e A4mariosergio05Belum ada peringkat

- Polydoros It / It-S Polydoros It / It-SDokumen52 halamanPolydoros It / It-S Polydoros It / It-Smikepower00788% (8)

- Portable Hand Tools Inspection ProcedureDokumen1 halamanPortable Hand Tools Inspection ProcedureHamza NoumanBelum ada peringkat

- Calculation For Short Circuit Current Calculation Using IEC / IEEE StandardDokumen11 halamanCalculation For Short Circuit Current Calculation Using IEC / IEEE StandardibmmoizBelum ada peringkat

- I-Line Circuit Breaker PanelboardsDokumen32 halamanI-Line Circuit Breaker PanelboardsGabriel GonzalezBelum ada peringkat

- Mitsubhishi S500 ManualDokumen200 halamanMitsubhishi S500 ManualDeepak GuptaBelum ada peringkat

- Droop Mode Setting in Governor - CaterpillarDokumen36 halamanDroop Mode Setting in Governor - CaterpillarSrinivasan TR100% (1)

- FR-F800 Instruction Manual PDFDokumen614 halamanFR-F800 Instruction Manual PDFelivandrojuniorBelum ada peringkat

- Pic16f 2 PDFDokumen124 halamanPic16f 2 PDFCesar VilledaBelum ada peringkat

- BC548 - Datashet PDFDokumen2 halamanBC548 - Datashet PDFBraian KonzgenBelum ada peringkat

- Compuertas Logicas or ChipDokumen3 halamanCompuertas Logicas or ChipCesar VilledaBelum ada peringkat

- Led InfrarrojoDokumen7 halamanLed InfrarrojoPatrick SteinerBelum ada peringkat

- PT1302B C2Dokumen7 halamanPT1302B C2G Ivan Torres RBelum ada peringkat

- 16 F 716Dokumen136 halaman16 F 716Andreyna Emilia Guevara GalindezBelum ada peringkat

- Ups Apc BR900GIDokumen1 halamanUps Apc BR900GICesar VilledaBelum ada peringkat

- 3D Paper Heart: HEART BOX © Minieco - Co.uk. To Be Used For Non-Commercial Purposes Only. Do Not Link Directly To PDFDokumen1 halaman3D Paper Heart: HEART BOX © Minieco - Co.uk. To Be Used For Non-Commercial Purposes Only. Do Not Link Directly To PDFCesar VilledaBelum ada peringkat

- Standing PentagramDokumen5 halamanStanding PentagramCesar VilledaBelum ada peringkat

- Asymetric Square PyramidDokumen5 halamanAsymetric Square PyramidCesar VilledaBelum ada peringkat

- Tecaldo Inalambico 6139Dokumen2 halamanTecaldo Inalambico 6139Cesar VilledaBelum ada peringkat

- Lampara de HalloweenDokumen1 halamanLampara de HalloweenCesar VilledaBelum ada peringkat

- BC548 - Datashet PDFDokumen2 halamanBC548 - Datashet PDFBraian KonzgenBelum ada peringkat

- Paper Star Lantern TemplatesDokumen3 halamanPaper Star Lantern TemplatesGrace ImanuelBelum ada peringkat

- Tecaldo Inalambico 6139Dokumen2 halamanTecaldo Inalambico 6139Cesar VilledaBelum ada peringkat

- PT1302B C2Dokumen7 halamanPT1302B C2G Ivan Torres RBelum ada peringkat

- Arduino RGB LedDokumen1 halamanArduino RGB LedBigHeadLittleFeetBelum ada peringkat

- BC548 - Datashet PDFDokumen2 halamanBC548 - Datashet PDFBraian KonzgenBelum ada peringkat

- Led InfrarrojoDokumen7 halamanLed InfrarrojoPatrick SteinerBelum ada peringkat

- Led InfrarrojoDokumen7 halamanLed InfrarrojoPatrick SteinerBelum ada peringkat

- SMP4 RGB PDFDokumen5 halamanSMP4 RGB PDFCesar VilledaBelum ada peringkat

- Disco Duro ST380011ADokumen54 halamanDisco Duro ST380011ARaul Carlos Ramirez AguirreBelum ada peringkat

- BC1602B2 Flyer PDFDokumen1 halamanBC1602B2 Flyer PDFCesar VilledaBelum ada peringkat

- Whitepaper EN c6906 Xperia z1 2 PDFDokumen25 halamanWhitepaper EN c6906 Xperia z1 2 PDFCesar VilledaBelum ada peringkat

- Opti RGB PDFDokumen6 halamanOpti RGB PDFCesar VilledaBelum ada peringkat

- Atf22v10cqz PDFDokumen19 halamanAtf22v10cqz PDFCesar VilledaBelum ada peringkat

- BOQ Ashuganj Rev2Dokumen21 halamanBOQ Ashuganj Rev2MD. Mazidul Islam MahfujBelum ada peringkat

- ELECTROMAGNETISMDokumen39 halamanELECTROMAGNETISMAgnibho GuruBelum ada peringkat

- 15 HPL2010-En. TransformadoresDokumen20 halaman15 HPL2010-En. TransformadoresDennis GuaniloBelum ada peringkat

- CA102GBDokumen34 halamanCA102GBMENELADOBelum ada peringkat

- ThesisDokumen26 halamanThesisSajid Mehmood ArainBelum ada peringkat

- DiodeDokumen8 halamanDiodeLoeThpie CjdwBelum ada peringkat

- E-02-Final A3Dokumen1 halamanE-02-Final A3kitnaBelum ada peringkat

- LF TwoWireTrans 133TSDokumen2 halamanLF TwoWireTrans 133TSBASHAMOHUDDIN SHEIKBelum ada peringkat

- HAN-L5 2S 058V2-WiringDokumen1 halamanHAN-L5 2S 058V2-WiringonealBelum ada peringkat

- IKR270Dokumen2 halamanIKR270e.montgomeryBelum ada peringkat

- CRT2324 Deh-P900rDokumen89 halamanCRT2324 Deh-P900rbiophanteraBelum ada peringkat

- EEE225 - Pre-Final Exam Section 1 - Google FormsDokumen11 halamanEEE225 - Pre-Final Exam Section 1 - Google FormsDavid Louie BediaBelum ada peringkat

- MOTORTECH SalesFlyer Spark Plug Extensions For WAUKESHA Gas Engines 01.15.051 en 2017 04Dokumen4 halamanMOTORTECH SalesFlyer Spark Plug Extensions For WAUKESHA Gas Engines 01.15.051 en 2017 04RobertBelum ada peringkat

- Cylindric Fuse DisconnectorDokumen3 halamanCylindric Fuse DisconnectorArianit ZeqiriBelum ada peringkat

- URS Part 4 Electrical StandardDokumen36 halamanURS Part 4 Electrical StandardSushil RajputBelum ada peringkat

- Anual ShutdownDokumen2 halamanAnual ShutdownanurapwBelum ada peringkat

- Multiple Choice Questions and Answers On Semiconductor DiodeDokumen9 halamanMultiple Choice Questions and Answers On Semiconductor DiodeCharene BernabeBelum ada peringkat

- POINTER Miniature Circuit Breaker 1Dokumen4 halamanPOINTER Miniature Circuit Breaker 1Angelo Mark Ordoña PorgatorioBelum ada peringkat

- 4614 PDFDokumen7 halaman4614 PDFshafiuddin7326Belum ada peringkat

- Transformer Testing Diagnostics ToolDokumen1 halamanTransformer Testing Diagnostics ToolOsi MalickBelum ada peringkat

- Semi Lab 2Dokumen17 halamanSemi Lab 2Fatima AmjadBelum ada peringkat

- 2SD592, 2SD592A: Silicon NPN Epitaxial Planer TypeDokumen3 halaman2SD592, 2SD592A: Silicon NPN Epitaxial Planer TypeJosé LaranjoBelum ada peringkat

- CR Systems Parts Compatbility - 8G1319 - RevC 2023-01-30Dokumen11 halamanCR Systems Parts Compatbility - 8G1319 - RevC 2023-01-30thiago silverio pessoaBelum ada peringkat