B&W Wheel Pulverizer

Diunggah oleh

dancielzHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

B&W Wheel Pulverizer

Diunggah oleh

dancielzHak Cipta:

Format Tersedia

B&WROLLWHEELPULVERIZERS

T H E P U LV E R I Z E R O F C H O I C E

The B&W Roll Wheel pulverizer

design results in superior mill

performance and cost benefits.

Value and dependability built into every pulverizer

Successfully managing the assets of todays coalfired power plant requires an understanding of

the many components that make up a complete

system. Reliable coal pulverizer performance

is one element that is essential for sustained

responsive power plant operation.

More than the name has changed

Since introducing the roll wheel pulverizer,

Babcock & Wilcox Power Generation Group,

Inc. (B&W) has made substantial and extensive

modifications and improvements to the original

design. These major design changes have

significantly improved boiler load-following

capability and overall performance of the roll

wheel pulverizer.

B&W has designed, manufactured and placed

in operation more than 1,100 roll wheel

pulverizers, grinding a wide range of coals at

power stations throughout the world. The B&W

Roll Wheel pulverizer has set the standard for

high availability, reliable operation and low

maintenance. These benefits contribute to stable

steam generator performance regardless of

station duty.

No other suppliers roll wheel mill is interchangeable with the B&W Roll Wheel pulverizer. It is the

one and only roll wheel pulverizer designed for

U.S. service.

Performance and cost benefits of

the B&W Roll Wheel pulverizer:

Reduced operating and maintenance costs

Capacity maintained throughout wear cycle

Lower pressure drop

Flexible load-following capability

Excellent turndown

The B&W Roll Wheel pulverizer has set the standard for value

high availability, reliability, durability and ease of maintenance.

Improved component wear life via

ceramic protection

Improved combustion efficiency

(reduced unburned carbon) when

used with a DSVS classifier

Ability to achieve optimum fineness

when grinding a wide range of coals

via on-line adjustment of roll wheel

pressure and classifier speed

Easy maintenance through a single,

large access door

Fully backed by B&W technical

design experts and local field

engineering support personnel

Design features for new and retrofit

pulverizer applications

Cera-VAM

Turret Lining

Segment

B&W continuously develops new technologies to improve the

reliability and overall performance, and to reduce the operation

and maintenance costs of the roll wheel pulverizer. Our design

innovations have proven effective in applications worldwide.

WEARESISTOR tires increase wear life

B&Ws patented WEARESISTOR asymmetric roll wheel tires are

designed for extended service life. Each tire includes additional

material in the high-wear areas of the tires cross-section. B&W also

offers the WEARESISTOR LP (low-profile) tire and LP grinding ring

segments. This grinding element design combines the extended

wear life of the asymmetric design with a low-profile geometry.

Field results have shown a reduction of pulverizer power

consumption while maintaining fineness, capacity and turndown.

The extra wear material incorporated in the WEARESISTOR and

WEARESISTOR LP tire/segment designs extends the grinding

element wear life, and thus reduces maintenance costs.

Erosion-resistant ceramic components

B&W pioneered the use of Cera-VAM lining, a high density

alumina ceramic, for erosion resistance in coal-pulverizing systems.

Cera-VAM outperforms cast abrasion-resistant steels, irons, silicon

carbides and cast basalt to protect against destructive erosion by

abrasive coals. Cera-VAM reduces maintenance requirements by

extending wear-life cycles. For many coals, Cera-VAM protected

components outlast several sets of grinding parts.

Cera-VAM lining outperforms cast abrasion-resistant

steels, irons, silicon carbides and cast basalt to significantly extend the wear life of pulverizer components.

Gearbox options provide reliable operation

and less maintenance

B&Ws triple-reduction, spiral-bevel geardrive was the first

removable coal pulverizer drive in the United States. Our design

has demonstrated an unsurpassed record for reliability and lower

maintenance costs. B&Ws planetary geardrive, with its compact

construction, offers an economical option for select pulverizer

models.

To return geardrives to as-new conditions for superior operation,

we offer a comprehensive remanufacturing program for

geardrive assemblies.

The planetary geardrive is

a compact option for select

pulverizer installations.

B&Ws WEARESISTOR and WEARESISTOR LP tires incorporate

extra wear material into high-wear areas to extend service life

and reduce maintenance costs.

B&W provides flexible shipping and

assembly arrangements based on

each customers unique requirements.

B&Ws original triple-reduction

geardrive has demonstrated an

unsurpassed record for reliability

and low maintenance costs.

Rotating throat provides optimal primary

air control

The vertical-wall low pressure drop rotating throat provides

optimal primary air distribution, permitting pulverizer

operation at recommended primary air-to-fuel ratios. As a

result, the rotating throat reduces coal spillage that can occur

with poor air distribution and high pressure drop that occurs

when operating at higher than recommended primary air-tocoal ratios. It also more than doubles the wear life compared

to the stationary throat. On new applications, the rotating

throat minimizes fan power requirements, and in upgrade

installations, reduces operating costs. It also allows removal of

the gearbox without disassembling the throat components.

DSVS rotating classifier

B&Ws exclusive DSVS rotating classifier incorporates the

best features of both the stationary (static) and rotating

classifiers, and can be installed in new or retrofit applications.

The DSVS classifier offers increased flexibility to take

advantage of a wide (and sometimes lower quality) range

of coal. For existing equipment, the DSVS classifier helps in

low-NOx burner retrofits by providing higher fineness that

reduces unburned carbon. Fineness levels can be adjusted

by changing the classifier speed while the mill is on-line. The

compact DSVS classifier can be easily installed on existing

B&W and non-B&W pulverizer equipment.

Spring Frame

Springs

Pressure

Frame

Loading Rod

Auto-spring loading system for improved

turndown and coal quality variation

Hydraulic

Cylinder

B&Ws Auto-Spring pulverizer loading system controls roll

wheel loading on-line based on the coal feed rate. As a result,

the Auto-Spring loading system can extend the turndown

range. It allows improved high load pulverizer performance

while maintaining important low load operating capability.

The springs allow the rollers to move with the irregularities

of the coal bed, isolating the motion from other pulverizer

components.

To Pump Set/

Valve Stand

Retaining the features of our standard fixed loading system, B&Ws

Auto-Spring pulverizer loading system controls roll wheel loading

on-line to provide extended turndown capability.

Raw Coal

Pipe

Gearbox

Variable Speed

Motors

Smooth ID grinding segments for easy removal

Second-Stage

Rotating

Vanes

First-Stage

Stationary

Louvers

Smooth inside diameter (ID) grinding segments allow easy wedge

bolt removal with improved access to wedge bolt heads. This

permits easier removal of the grinding segment at the end of its

useful life.

The DSVS rotating classifier provides operators the

flexibility to take advantage of a wide range of coal

grades and realize potential fuel cost reductions.

B&W Roll Wheel pulverizer features translate

to operation and maintenance benefits

Feature

Benefit

Availability

Cera-VAM Ceramic lining:

Intermediate housing

Classifier cone

Turret

Roll wheel wear bracket

Extended wear life and lower maintenance

Standard

Rotating throat

Reduces pulverizer pressure drop: optimal primary air control;

reduces throat maintenance

Standard

Planetary geardrive

Economical and dependable drive

Optional

Triple-reduction geardrive

If desired to match existing equipment

Optional

Smooth ID segments

Easier removal from ring seat

Standard

Original profile tires

Available option

WEARESISTOR asymmetric tires

Extended wear life

WEARESISTOR LP asymmetric tires

Extended wear life and reduction in power consumption

Single, large access door

Easy access to internal components

Standard

Stationary louver classifier

Economical where coal quality is consistent

Standard

Adjustable louver classifier

Economical on-line fineness adjustment; improves operating

flexibility where coal quality varies

Optional

DSVS classifier

Reduces pressure drop; improves particle size distribution with

less coarse end material; greater operating flexibility

Optional

Fixed loading system

Economical and dependable where coal quality is consistent and

pulverizers are primarily base loaded

Standard

Auto-Spring loading system

Extends turndown range; reduces pressure drop at high loads;

improves operating flexibility

Optional

Based on owners

specific application

The B&W Roll Wheel pulverizer can be custom designed to meet

specific operational or product challenges. The above table

highlights those features that are standard on each pulverizer, as

well as the options available to meet specific needs. These design

features can be installed on existing B&W Roll Wheel pulverizers.

Designed for easy maintenance

The B&W Roll Wheel pulverizer is designed with lower maintenance

in mind. The components are arranged so that work can be

performed through a single, large maintenance door. Specially

designed tooling is provided with the pulverizer allowing a crew to

handle pulverizer components efficiently and safely. The gearbox

design permits easy removal without pulverizer teardown.

With our pulverizers small footprint and large maintenance door,

360-degree access is not necessary, making it the perfect choice for

both new and retrofit applications.

The B&W Roll Wheel pulverizer is a very reliable, low-maintenance

plant component.

A single, large access door, small footprint and specially

designed tooling are features of the B&W Roll Wheel

pulverizer that help reduce maintenance costs.

Babcock & Wilcox Power Generation Group, Inc. is a

subsidiary of The Babcock & Wilcox Company (B&W).

Established in 1867, B&W is a world leader in providing

steam generating and emissions control equipment,

nuclear operations and components, and defense

program management services.

For more information, or a complete listing of our sales

and service offices, call 1-800-BABCOCK (222-2625),

send an e-mail to info@babcock.com, or access

our website.

www.babcock.com

Today, with more than 1,100 B&W Roll Wheel pulverizers sold

worldwide and six different sizes burning a variety of coals,

B&W has the proven design and operating experience to meet

your specific project requirements. This performance has made

the B&W Roll Wheel pulverizer the pulverizer of choice for

coal-fired boiler operators and owners.

Babcock & Wilcox Power Generation Group, Inc.

20 S. Van Buren Avenue

Barberton, Ohio 44203 USA

Phone: 330.753.4511

Fax: 330.860.1886

The information contained herein is provided for general information

purposes only and is not intended nor to be construed as a warranty, an

offer, or any representation of contractual or other legal responsibility.

B&W Roll Wheel, B&W-56, B&W-67, B&W-75, B&W-89, B&W-98,

B&W-118, DSVS, WEARESISTOR, Cera-VAM, and Auto-Spring are

trademarks of Babcock & Wilcox Power Generation Group, Inc.

2013 Babcock & Wilcox Power Generation Group, Inc.

All rights reserved.

E101-3143C 1KDC3C

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Data Monitoring CEMSDokumen1 halamanData Monitoring CEMSdancielzBelum ada peringkat

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- JC Catalogue 6000 7000 150Dokumen10 halamanJC Catalogue 6000 7000 150dancielzBelum ada peringkat

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- ABOUT CV (FLOW COEFFICIENTS)Dokumen1 halamanABOUT CV (FLOW COEFFICIENTS)NiksUnglasBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Japanase Industrial StandardDokumen6 halamanJapanase Industrial StandarddancielzBelum ada peringkat

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Pressure Gauge Siphons Type 910.15.100 Pigtail Type 910.15.200 CoilDokumen2 halamanPressure Gauge Siphons Type 910.15.100 Pigtail Type 910.15.200 CoilbehnamatgBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Perhitungan NPVDokumen12 halamanPerhitungan NPVdancielzBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Enclosure Types Motors AC Induction Single PhaseDokumen17 halamanEnclosure Types Motors AC Induction Single PhasechesschessanBelum ada peringkat

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Ganti Wajah N Rambut PemainDokumen1 halamanGanti Wajah N Rambut PemaindancielzBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

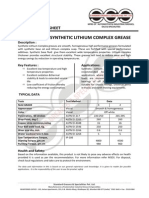

- Synthetic Lithium Complex GreaseDokumen1 halamanSynthetic Lithium Complex GreasedancielzBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Koop - Koop Island BluesDokumen1 halamanKoop - Koop Island BluesdancielzBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

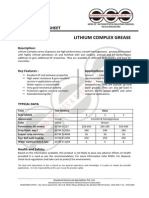

- Product Detail Lithium EP GreaseDokumen1 halamanProduct Detail Lithium EP GreasedancielzBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Product Detail Lithium Complex GreaseDokumen1 halamanProduct Detail Lithium Complex GreasedancielzBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- T SigntestDokumen1 halamanT SigntestdancielzBelum ada peringkat

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Optimal Reliability Allocation: Preventive MaintenanceDokumen2 halamanOptimal Reliability Allocation: Preventive MaintenancedancielzBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Cover Laporan IpaDokumen1 halamanCover Laporan IpadancielzBelum ada peringkat

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Information On Numbers For Parking Information Using PLCDokumen2 halamanInformation On Numbers For Parking Information Using PLCdancielzBelum ada peringkat

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- Higher Algebra - Hall & KnightDokumen593 halamanHigher Algebra - Hall & KnightRam Gollamudi100% (2)

- 1204E-ELE Perkins PDFDokumen254 halaman1204E-ELE Perkins PDFHenry Huayhua100% (6)

- AVC791B SpecDokumen2 halamanAVC791B SpecAhmadsyamsuddin Pangkalpinang100% (1)

- A Successful Electrical Power and Lighting Project Depends On Effective Planning in The Form ofDokumen22 halamanA Successful Electrical Power and Lighting Project Depends On Effective Planning in The Form ofMuhammad Faiz bin Ahmad ShafiBelum ada peringkat

- Mru Z: The Ideal Heave, Roll and Pitch SensorDokumen2 halamanMru Z: The Ideal Heave, Roll and Pitch SensorAdi VBelum ada peringkat

- Dlro 600 High Current, Low Resistance Ohmmeter: User ManualDokumen15 halamanDlro 600 High Current, Low Resistance Ohmmeter: User ManualAnonymous m65TTcfOTBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Itil and Iso 20000Dokumen56 halamanItil and Iso 20000Anshuman Tiwari100% (2)

- Group 1 Introduction To EIADokumen125 halamanGroup 1 Introduction To EIARhea Marie AlabatBelum ada peringkat

- Spider III Standard and Premium Line Switches - English - Original - 96284Dokumen8 halamanSpider III Standard and Premium Line Switches - English - Original - 96284Luis RobertoBelum ada peringkat

- Class II, Type B2 (Total Exhaust) Biological Safety CabinetsDokumen12 halamanClass II, Type B2 (Total Exhaust) Biological Safety CabinetsDexa Arfindo PratamaBelum ada peringkat

- Electrical ForumalsDokumen75 halamanElectrical ForumalsDinesh Raj G80% (10)

- QP - Mat Ntse STG 1 (2014-15)Dokumen18 halamanQP - Mat Ntse STG 1 (2014-15)V.Belum ada peringkat

- BS en 12583 - 2014 - Gas Infrastructure. Compressor Stations. Functional Requirements.Dokumen56 halamanBS en 12583 - 2014 - Gas Infrastructure. Compressor Stations. Functional Requirements.SDP02Belum ada peringkat

- JMT Machine Tools (Press Brakes, Fiber Laser, Plasma Machines, Iron Worker, Shears, Angle Rolls,)Dokumen78 halamanJMT Machine Tools (Press Brakes, Fiber Laser, Plasma Machines, Iron Worker, Shears, Angle Rolls,)Ermal HamzajBelum ada peringkat

- Portable Ladder Safety Program 09Dokumen6 halamanPortable Ladder Safety Program 09Patrick BolenBelum ada peringkat

- CommonIssues PDFDokumen133 halamanCommonIssues PDFJobin JoseBelum ada peringkat

- PT 2.6.1 Packe Tracer Skills Integration ChallengeDokumen4 halamanPT 2.6.1 Packe Tracer Skills Integration ChallengeGrey Elis0% (1)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- ARF - 01 - Pendahuluan - Bahan Konstruksi Teknik Kimia (BKTK)Dokumen13 halamanARF - 01 - Pendahuluan - Bahan Konstruksi Teknik Kimia (BKTK)nurmaBelum ada peringkat

- ELTR115 Sec21Dokumen115 halamanELTR115 Sec21ifeniyiBelum ada peringkat

- Methods of Physical Tests For Hydraulic Cement: Indian StandardDokumen7 halamanMethods of Physical Tests For Hydraulic Cement: Indian StandardPIT TeamBelum ada peringkat

- How To Setup Local Area Connection in Windows 7 Xclusive4all PDFDokumen10 halamanHow To Setup Local Area Connection in Windows 7 Xclusive4all PDFMorshed Mahbub AbirBelum ada peringkat

- ISODokumen20 halamanISODharam Raj100% (1)

- Hiab 055: Range 4-6 TMDokumen92 halamanHiab 055: Range 4-6 TMMike GuerrerosBelum ada peringkat

- Workingholding Devices: Types of Work Holding DevicesDokumen12 halamanWorkingholding Devices: Types of Work Holding DevicesAitzazMurtazaBelum ada peringkat

- HILTI HSA Anchor DesignDokumen6 halamanHILTI HSA Anchor DesignJay PBelum ada peringkat

- IPDokumen4 halamanIPHarry Harshaw100% (4)

- Ship RepairDokumen27 halamanShip RepairMuhammed Razeem100% (1)

- New Liebherr PDFDokumen28 halamanNew Liebherr PDFAlexandrKozlenok100% (6)

- PRACHDokumen41 halamanPRACHmonem777Belum ada peringkat

- PackethDokumen4 halamanPackethAditya Kumar SinghBelum ada peringkat

- CCNA Exam Answer CCNA 2 Chapter 1Dokumen5 halamanCCNA Exam Answer CCNA 2 Chapter 1Calvin Ohsey100% (1)

- Arizona, Utah & New Mexico: A Guide to the State & National ParksDari EverandArizona, Utah & New Mexico: A Guide to the State & National ParksPenilaian: 4 dari 5 bintang4/5 (1)