Combination Air Valves Guide for Pipelines

Diunggah oleh

Felipe OliverosJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Combination Air Valves Guide for Pipelines

Diunggah oleh

Felipe OliverosHak Cipta:

Format Tersedia

2008

6 2 3

Edition

SERIES 140C

STANDARD COMBINATION

ISO FLANGE CONNECTIONS

AVAILABLE

SERIES 1800

CUSTOM COMBINATION

DUPLEX BODY

AIR VALVES

MANUFACTURED TO AWWA C-512

STANDARDS

COMBINATION AIR VALVES

SINGLE BODY

VALVE & PRIMER CORPORATION

1420 WRIGHT BLVD.

SCHAUMBURG, IL 60193-4599

847.524.9000

FAX:847.524.9007

800.323.6969

website: www.apcovalves.com e-mail: factory@apcovalves.com

139

1

COMBINATION AIR VALVES

MATERIALS USED IN BOTH STYLE

COMBINATION AIR VALVES

SINGLE BODY Double Orifice

Body, Cover, 1-4 . . . . . . . . . . . . . Ductile Iron

Body, Cover, 6-8 . . . . . . . . . . . . . . . Cast Iron

Float . . . . . . . . . . . . . . . . . . . . . Stainless Steel

Seat. . . . . . . . . . . . . . . . . . . . . . . . . . . . Buna-N

Lever Frame (1-4 size) . . . . . . . . . . . . Delrin

Lever Frame (6-8 size) . . . . . . . . . Cast Iron

Option: Mushroom caps for outlet

LARGE ORIFICE

GIVES ABSOLUTE PROTECTION TO PIPE LINES

ELIMINATES RISK OF COLLAPSING LINE DUE

ALL OTHER INTERNAL PARTS

STAINLESS STEEL OR BRONZE

8 STYLE

TO VACUUM

EXHAUSTS AIR WHEN LINE IS BEING FILLED

ALLOWS AIR TO RE-ENTER IMMEDIATELY WHEN

LINE DRAINS

151C

BUILT FOR

300 PSI SERVICE

SMALL ORIFICE

EXHAUSTS SMALL POCKETS OF AIR WHICH

COLLECT WHEN LINE IS OPERATING UNDER PRESSURE

INSURES FULL EFFICIENCY OF LINE OPERATION

CONSERVES PUMP HORSEPOWER

NO RESTRICTED HIGH POINTS

SPECIFY IF

OPERATING PRESSURES

BELOW 50 P.S.I.

1 THROUGH 6

STYLE

TO SIZE AIR VALVES FOR PIPELINE SERVICE USE APCO AIR VALVE COMPUTER or APSLIDE COMPUTER SOFTWARE

1

143C

ILLUSTRATED ABOVE *

2

145C

ILLUSTRATED ABOVE

ILLUSTRATED ABOVE

ILLUSTRATED ABOVE

ILLUSTRATED ABOVE

SEE ABOVE DRAWING

PHYSICAL DIMENSIONS

PHYSICAL DIMENSIONS

PHYSICAL DIMENSIONS

PHYSICAL DIMENSIONS

PHYSICAL DIMENSIONS

PHYSICAL DIMENSIONS

Height 10

Width 7

Length 11

Weight 35 lbs.

Height 12 1/4

Width 8

Length 14

Weight 75 lbs.

3

147C

Height 15 1/2

Width 10

Length 16

Weight 100 lbs.

4

149C

Height 17 1/8

Width 11

Length 18

Weight 170 lbs.

6

150C

Height 27 1/4

Width 13

Length 18 3/8

Weight 205 lbs.

8

151C

Height 25 3/4

Width 17 1/2

Length 22 1/4

Weight 300 lbs.

INLET

OUTLET

1 PIPE THREAD

* EXCEPT POPPET

INLET

OUTLET

2 PIPE THREAD

INLET

OUTLET

3 PIPE THREAD

125 & 250 LB. FLANGES

ALSO AVAILABLE

HEIGHT FLANGED

161/2

INLET

OUTLET

4 PIPE THREAD

125 & 250 LB. FLANGES

ALSO AVAILABLE

HEIGHT FLANGED

19

INLET

INLET

125 & 250 LB. FLANGE

125 & 250 LB. FLANGE

OUTLET OPTIONS

OUTLET OPTIONS

PLAIN WITH HOOD

THREADED

FLANGED

PLAIN WITH HOOD

(AS SHOWN)

FLANGED

SINGLE BODY SPECIFICATIONS

Combination Air Valve sizes 1 through 8, (single body, double orifice) allows large volumes of air to escape out the large orifice when filling a pipeline

and closes when liquid enters the valve. When the valve is closed and pressurized, the small air release orifice will open to allow small pockets of air to

escape automatically and independently of the large orifice.

The large orifice shall also allow large volumes of air to enter during pipeline drainage to break the vacuum. The body inlet must be baffled to protect

the float from direct forces of rushing air and water to prevent premature valve shut-off.

The Buna-N seat must be fastened to the valve cover without distortion for drop tight shut-off. The floats shall be heavy stainless steel. The plug or

float shall be center guided through hex bushings for positive shut-off.

Valve exterior to be painted with Universal Metal Primer Paint as accepted by the FDA for use in Potable Water.

All materials of construction shall be certified in writing to conform to A.S.T.M. specifications as follows:

Body & Cover (1-4)

Ductile Iron

ASTM A536 GR 65-45-12

Body & Cover (6-8)

Cast Iron

ASTM A126 GR.B

Float

Stainless steel

ASTM A240

Needle & seat

Buna-N

Plug

Bronze

ASTM B124

Leverage frame

Delrin/Cast iron

ASTM D4181/ASTM A126 GR.B

Valve to be APCO Model (Engineer to Name) Combination Air Valve as manufactured by Valve & Primer Corporation, Schaumburg, Illinois, U.S.A.

140

2

6 2 3

N

L

HOW IT WORKS: Sizes 1 through 6 incorporate a poppet (or plug) which rests freely inside the lever frame. The center stem

of the poppet has a SMALL ORIFICE through it. When water enters the main valve body it raises the float and float arm which puts the

needle, attached to the arm, in contact with the poppet stem while lifting the poppet to the shut-off position against the LARGE ORIFICE.

AIR/VACUUM VALVES with 1 LARGE ORIFICE to vent large volumes of air for efficient filling and draining of

pipelines. This protects against vacuum and water column separation or pipeline collapse.

TYPE 2. AIR RELEASE VALVES with 2 SMALL ORIFICE for continuous venting of air pockets as they accumulate in a pressurized

pipeline.

When the above types are combined, the result is a COMBINATION AIR VALVE.

The Combination Air Valve is available in a SINGLE BODY DOUBLE ORIFICE shown here, or in a DUPLEX arrangement (see Back Page).

The single body is most popular due to its smaller overall size and resulting space saving inside a valve vault. It is available in 1 to 8 sizes.

TYPE 1.

THERE ARE BASICALLY TWO TYPES OF AIR VALVES:

As air accumulates inside the main valve body the water is displaced. The float arm falls away from the poppet stem to expose the

small orifice and the pocket of air is vented. Water re-enters the main valve body lifting the float arm back to the shut-off position and

the cycle repeats as air accumulates. As long as the main valve body is under pressure, the poppet stays closed because the pressure

differential across the large orifice is more than the poppet can overcome.

If, however, a negative pressure occurs inside the main valve body, the poppet will drop open to allow air in and prevent a vacuum

from forming in the pipeline.

Size 8 functions in the same manner, but, instead of a poppet, a float is used for shutting off the large orifice and a separate internal

float operated lever mechanism is incorporated with a small orifice for venting smaller pockets of air when the system is pressurized.

Every Combination Air Valve is hydrostatically seat and shell tested before it leaves our factory to insure quality performance in the field.

AIR/VACUUM VALVE on pump discharge before check valve (not necessary for pumps with positive suction head) or hydraulically CONTROLLED AIR/VACUUM VALVE where a discharge gate valve is normally closed during pump start-up to develop head.

NOTE: INSTALLING MANWAYS AT INTERVALS IN LARGER SIZE PIPELINES PROVIDES AN EXCELLENT POINT TO INSTALL AIR VALVES.

NOTE: Please specify if pressure is below 20 psi.

DISCHARGE CAPACITIES FOR COMBINATION AIR VALVE

ORIFICE SIZES

for 300 psi

working pressure

AIR VALVES

PRESSURE DIFFERENTIAL ACROSS VALVE, PSI

CURVES SHOWN ARE ACTUAL FLOW CAPACITIES AT 14.7 PSI BAROMETRIC PRESSURE AND 70 F TEMPERATURE BASED ON ACTUAL TEST.

THESE FIGURES ARE NOT ONLY THE FLOW CAPACITIES ACROSS THE ORIFICE BUT FLOW ACROSS THE ENTIRE VALVE. IN THE TEST SET-UP,

APPROACH VELOCITY TO THE VALVE IS NEGLIGIBLE THEREFORE ACTUAL CAPACITY EXCEEDS THE VALUES SHOWN ON CHART.

TEST CONDUCTED BY: PHILLIP PETROLEUM COMPANY ENGINEERING DEPARTMENT - TEST DIVISION EDMOND PLANT OCTOBER 1, 1961.

COMBINATION AIR VALVES

TYPICAL PIPELINE SHOWING ITS HYDRAULIC GRADIENT

& THE POSITION OF NECESSARY

AIR VALVES

WHERE

TO

INSTALL

AIR FLOW THROUGH VALVE IN STANDARD CUBIC FEET OF FREE AIR PER SECOND (SCFS)

141

3

CUSTOM COMBINATION AIR VALVES

SERIES 1100A

SERIES 1800

200A

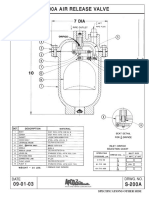

AIR

RELEASE

VALVE

SEAT DETAIL

AIR/VACUUM

EACH CUSTOM COMBINATION AIR VALVE

CONSISTS OF ONE APCO AIR/VACUUM VALVE,

ONE APCO AIR RELEASE VALVE &

OPTIONAL ONE APCO BUTTERFLY VALVE...SHIPPED

COMPLETELY PIPED AND ASSEMBLED.

200A

AIR

RELEASE

VALVE

PRICE OF EACH CUSTOM COMBINATION

AIR VALVE INCLUDES 1 PIPING AND

1 GATE OR BALL VALVE.

AIR

&

VACUUM

VALVE

VALVE

125 LB: 14

& LARGER

250 LB:

GATE or

BALL VALVE

ALL SIZES

AIR

&

VACUUM

VALVE

SEAT DETAIL

AVV

125 LB: 14

& LARGER

250 LB:

Available in 125, 250, 600 and 900 psi classes for

those special jobs where you want the very best!

GATE or

BALL VALVE

ALL SIZES

RETAINER PLATE

COMBINATION

AIR/VACUUM

w/AIR RELEASE VALVE

VALVE

SIZE

4

6

8

10

12

14

16

18

20

24

MODEL WIDTH

NO.

1804

1806

1808

1810

1812

1814

1816

1818

1820

1824

HEIGHT

125 LB. 250 LB.

1/2

19

22 3/4

25 1/2

27 7/8

32 7/8

41 7/8

45 1/2

42

46

53

3/16

ORIFICE

5/32

ORIFICE

1/4

20 5/8

23 1/8

25 1/4

27 3/8

31 3/8

30 3/4

32

34

40

48

20

22 3/4

24 3/4

26 3/4

31 3/8

30 3/4

32

34

40

48

Custom Combination Air Valves are recommended where operating

pressures exceed 300 psi or size requirements exceed 4*

BUTTERFLY

VALVE

COMBINATION

AIR/VACUUM

w/ AIR RELEASE

WITH BUTTERFLY VALVE

SIZING

To determine the correct size Single Body or Duplex Body Combination

Air Valves to use on each high point of the pipeline, refer to Bulletin 610,

use the APCO Air Valve Computer (available on request) or you may

send a copy of your pipeline profile to our Engineering Department.

VALVE

SIZE

* Another feature to recommend the use of Custom Combination Air

Valves is the side mounted Air Release Valve which can be any of

four valves as shown in the chart below. With the addition of the Air

Release Valve the orifice is much larger and hence the venting capacity much greater than the orifices in the single body Combination Air

Valve. This is important where large volumes of air are anticipated

after the pipeline is filled and operating.

4

6

8

10

12

14

16

MODEL WIDTH

NO.

1104A

1106A

1108A

1110A

1112A

1114A

1116A

19 1/2

22 3/4

25 1/2

27 7/8

32 7/8

41 7/8

45 1/2

HEIGHT

125 LB. 250 LB.

3/16

ORIFICE

5/32

ORIFICE

23 1/2

27 1/4

31

33 1/2

40 3/4

39 1/2

43 1/4

25

27 1/4

31 1/2

34

40 3/4

39 1/2

43 1/4

TABLE OF ORIFICE SIZES

MAXIMUM ORIFICE WHICH CAN BE USED WITH FOLLOWING PRESSURES

200A

200

205

206

5/16

5/16

5/16

1/4

1/2

1/2

1/2

1/2

1/2

3/8

3/8

7/32

7/32

3/16

3/8

3/16

3/8

3/16

3/8

5/32

5/32

5/32

7/32

7/32

7/32

7/32

7/32

1/8

3/32

STANDARD ORIFICES ARE IN BLUE

DUPLEX BODY SPECIFICATIONS

The Custom Combination Air Valve Series 1800 shall be heavily designed cast iron body to allow large volumes of air to escape through the orifice when filling the pipeline and shall shut off water tight, when the water enters the valve. The Custom Combination Air Valve shall also permit large volumes of air to

enter through the orifice when the pipeline is being drained to prevent vacuum from forming and water column separation. The valve shall consist of a body,

cover, baffle, float and seat. The baffle will be an integral part of the body, designed to protect the float from direct contact of the rushing air and slugs of

water to prevent premature shut-off. The seat shall be Buna-N fastened into the valve cover without distortion and be easily replaced. The float shall be stainless steel and be center guided at each end for positive seating.

The Air/Vacuum Valve shall have the outlet covered with either a steel protector hood or be threaded or flanged. (Engineer to select outlet.)

The Automatic Air Release Valve shall be designed to operate under pressure to allow entrapped air inside the pipeline to escape. The shut-off prevents water

from escaping. The Air Release Valve will then stay closed until more air accumulates and the opening cycle will repeat automatically. The Air Release Valve

float shall be heavy stainless steel.

When Series 1100A is specified, an APCO Butterfly Valve wafer style shall be supplied for isolation service. The Butterfly Valve shall be freely interchangeable without the need for special tools. The seat must be Buna-N, molded with a steel flanged ring inside for high strength and tight seating. The disc must

pivot eccentrically to minimize operating torque. The shafts must be stainless steel and double sealed with O-rings to prevent leakage.

The Custom Combination Air Valve Series 1800 and Series 1100A shall be furnished completely assembled and pressure tested from the factory as a complete unit ready for installation on the pipeline.

All materials of construction shall be certified in writing to conform to A.S.T.M. specifications as follows:

Valve bodies

Shafts

Seats

Floats

Exterior primer

Cast iron

Stainless steel

Buna-N

Stainless steel

Universal Metal Primer

ASTM A126 GR. B

ASTM A270

ASTM A240

FDA approved for potable water

Valve to be Series 1800 Custom Combination Air/Vacuum/Air Release Valve or Series 1100A Custom Combination Air/Vacuum/Air Release Valve with

isolation Butterfly Valve as manufactured by Valve & Primer Corporation, Schaumburg, Illinois, U.S.A.

VALVE & PRIMER CORPORATION

142

4

1420 WRIGHT BLVD.

SCHAUMBURG, IL 60193-4599

847.524.9000

FAX:847.524.9007

800.323.6969

website: www.apcovalves.com e-mail: factory@apcovalves.com

VALVE

&

PRIMER CORPORATION HEREBY RESERVES THE RIGHT TO CHANGE ANY

COMPONENT PARTS WHICH, IN THE OPINION OF ITS ENGINEERING DEPARTMENT,

WILL IMPROVE THE PRODUCT OR INCREASE ITS SERVICEABILITY.

DIMENSIONS ARE

FOR ILLUSTRATIVE PURPOSES ONLY.

INFORMATION WITH

PLEASE CONFIRM ALL DIMENSIONAL

VALVE & PRIMER CORPORATION ENGINEERING DEPARTMENT.

Anda mungkin juga menyukai

- APCO Air Valve 613Dokumen4 halamanAPCO Air Valve 613jones0055Belum ada peringkat

- Air Vacuum ValvesDokumen4 halamanAir Vacuum ValvesmariuspiBelum ada peringkat

- Air Release 2014Dokumen4 halamanAir Release 2014Aly AnisBelum ada peringkat

- Apco Air Release Valves Arv Arv Air Release Valves Sales 600Dokumen4 halamanApco Air Release Valves Arv Arv Air Release Valves Sales 600RashedBelum ada peringkat

- APCO. S-200a Air Release ValveDokumen2 halamanAPCO. S-200a Air Release ValveAlberto Diaz100% (2)

- Air Valves ValmaticDokumen28 halamanAir Valves Valmaticnimm1962100% (1)

- Pressure Reducing ValveDokumen3 halamanPressure Reducing ValveSasa JadrovskiBelum ada peringkat

- OZKAN Butterfly ValvesDokumen11 halamanOZKAN Butterfly ValvesAhmed AbdelwaneesBelum ada peringkat

- CT 5550 Pumping Stations and Transport PipelinesDokumen45 halamanCT 5550 Pumping Stations and Transport PipelineshamanoelgenBelum ada peringkat

- SERIES 3000: Angle Surge Relief ValveDokumen6 halamanSERIES 3000: Angle Surge Relief ValveMd Aamir AnsariBelum ada peringkat

- Dynamic Testing of CheckvalveDokumen10 halamanDynamic Testing of Checkvalveamirthraj74Belum ada peringkat

- Pressure Surges and Air Valve Specification PDFDokumen22 halamanPressure Surges and Air Valve Specification PDFTONBelum ada peringkat

- Avk Saudi National Price ListDokumen46 halamanAvk Saudi National Price Listjanpaul2481Belum ada peringkat

- Pump station design recommendations for midrange centrifugal pumpsDokumen8 halamanPump station design recommendations for midrange centrifugal pumpsalan toomeyBelum ada peringkat

- Bell and Gossett Sump DesignDokumen8 halamanBell and Gossett Sump DesignVelpandian ManiBelum ada peringkat

- Air in Pipelines 1-19Dokumen9 halamanAir in Pipelines 1-19BhuvanaBelum ada peringkat

- Pressure Reducing Valve CatalogueDokumen4 halamanPressure Reducing Valve CatalogueSteveBelum ada peringkat

- Air Vessel Sizing For Water Hammer Prevention in PipelinesDokumen4 halamanAir Vessel Sizing For Water Hammer Prevention in PipelinesHeiner PalaciosBelum ada peringkat

- Reverse WaterhammerDokumen10 halamanReverse WaterhammerjygomezBelum ada peringkat

- ANCIENT ROMAN VALVE DESIGNDokumen7 halamanANCIENT ROMAN VALVE DESIGNmaria romeroBelum ada peringkat

- Module 2 OM of Water PumpsDokumen101 halamanModule 2 OM of Water PumpsJeji Hirbora100% (1)

- ELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDokumen17 halamanELMO-F Vacuum Units with Vacuum Pumps, Range 2BE Selection GuideDSdds0% (1)

- Helical Oil SeparatorsDokumen6 halamanHelical Oil SeparatorsGauravBelum ada peringkat

- Pressure RegulatorDokumen4 halamanPressure RegulatorRICHIHOTS2Belum ada peringkat

- Design Input - Pressure Reducing ValveDokumen8 halamanDesign Input - Pressure Reducing ValvekausikrBelum ada peringkat

- Gas Jet Pump Paper Oct03 Ipa03 e 059Dokumen11 halamanGas Jet Pump Paper Oct03 Ipa03 e 059kglorstadBelum ada peringkat

- Theory Application and Sizing of Air ValvesDokumen9 halamanTheory Application and Sizing of Air ValveskcplemmonsBelum ada peringkat

- 2 Centrifugal Pumps ROTODYNAMIC TwoDokumen70 halaman2 Centrifugal Pumps ROTODYNAMIC TwoAbdallah Mansour100% (1)

- Pump Intake Design - ANSIDokumen79 halamanPump Intake Design - ANSIrizkboss8312Belum ada peringkat

- Submersible+Borehole+Pumps 60+HzDokumen114 halamanSubmersible+Borehole+Pumps 60+HzNong Noc100% (1)

- Surge Tank Thoma and Svee CriteriaDokumen79 halamanSurge Tank Thoma and Svee CriteriaManikandanBelum ada peringkat

- Goulds PumpsDokumen44 halamanGoulds PumpscridavarBelum ada peringkat

- ANSI Vs APIDokumen2 halamanANSI Vs APIMohd Effiezool YaserBelum ada peringkat

- Centrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryDokumen18 halamanCentrifugal Pump Basics: Terms Commonly Used in The Pumping IndustryshunmugeshBelum ada peringkat

- 003 Cover StoryDokumen8 halaman003 Cover StoryVaibhav GuptaBelum ada peringkat

- Centrifugal Pumps: How They Work and Their Performance CurvesDokumen8 halamanCentrifugal Pumps: How They Work and Their Performance CurvesSaleem Chohan100% (1)

- Mechanical Component - PumpsDokumen28 halamanMechanical Component - PumpsLijo ThoamsBelum ada peringkat

- Self-Priming Pumps GuidelinesDokumen4 halamanSelf-Priming Pumps GuidelinesBagus KristiantaraBelum ada peringkat

- Water Distribution in High Rise Buildings: Cover StoryDokumen8 halamanWater Distribution in High Rise Buildings: Cover StoryAdilah NrsmBelum ada peringkat

- Pump Selection, AJAX 2000Dokumen33 halamanPump Selection, AJAX 2000Asad Hayat WarraichBelum ada peringkat

- Pump MathsDokumen10 halamanPump MathsSakib RafeeBelum ada peringkat

- Sludge and Grit Removal SolutionsDokumen20 halamanSludge and Grit Removal SolutionsdrramsayBelum ada peringkat

- Friction Loss On SuctionDokumen2 halamanFriction Loss On SuctionSathish LingamBelum ada peringkat

- IIT-Intake and Exhaust Manifold DesignDokumen28 halamanIIT-Intake and Exhaust Manifold DesignVasudev GuptaBelum ada peringkat

- Knowledge Sharing Water HammerDokumen16 halamanKnowledge Sharing Water HammerNaveen NagisettiBelum ada peringkat

- Handout A14 Water-HammerDokumen77 halamanHandout A14 Water-HammerAlexandreCaironiBelum ada peringkat

- The Mathematics of Pumping Water: AECOM Design BuildDokumen9 halamanThe Mathematics of Pumping Water: AECOM Design Buildmabrouk2013Belum ada peringkat

- Air Valve 460Dokumen6 halamanAir Valve 460amrezzatBelum ada peringkat

- b3311 722-2Dokumen7 halamanb3311 722-2Arnaldo BenitezBelum ada peringkat

- Presentation On - : Horizontal Centrifugal PumpDokumen78 halamanPresentation On - : Horizontal Centrifugal Pumplifemillion2847100% (1)

- Mep All QuestionsDokumen79 halamanMep All QuestionsbabaBelum ada peringkat

- Pump & Pump Piping PresentationDokumen55 halamanPump & Pump Piping PresentationEduard Gonzalo Rojas Cervantes100% (1)

- TN 010-Drip Traps Rev ADokumen6 halamanTN 010-Drip Traps Rev AMariusCapraBelum ada peringkat

- Water Hammer PressuresDokumen39 halamanWater Hammer PressurescharbelBelum ada peringkat

- Water Hammer in Pipes: Causes, Effects and Prevention MethodsDokumen12 halamanWater Hammer in Pipes: Causes, Effects and Prevention MethodsLoga MadishBelum ada peringkat

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDari EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryBelum ada peringkat

- Apco Airvacuum Valves Avv Sales 601Dokumen8 halamanApco Airvacuum Valves Avv Sales 601Jhony MedranoBelum ada peringkat

- Fire HydrantDokumen6 halamanFire HydrantdileepsiddiBelum ada peringkat

- Series 600: Globe Style Sizes 3 Through 42 InchesDokumen8 halamanSeries 600: Globe Style Sizes 3 Through 42 Inchesrizviabbas2012Belum ada peringkat

- Engineering CatalogDokumen70 halamanEngineering CatalogFihawangoBelum ada peringkat

- Product Data Sheet Magtech Magnetic Level Indicators en 2883066Dokumen22 halamanProduct Data Sheet Magtech Magnetic Level Indicators en 2883066Daniel MarshalBelum ada peringkat

- Grove Regulator Engineering Handbook Sections 1-8Dokumen212 halamanGrove Regulator Engineering Handbook Sections 1-8Alfredo CastravelliBelum ada peringkat

- Fivalco CatalogDokumen34 halamanFivalco CatalogsimonsecurityBelum ada peringkat

- Ameron Info - Summary 2000 SeriesDokumen11 halamanAmeron Info - Summary 2000 Serieslinkinpark11129116Belum ada peringkat

- Design of Pipe Strut ConnectionsDokumen4 halamanDesign of Pipe Strut ConnectionsMonal RajBelum ada peringkat

- Pc100-5 Custom Operational ManualDokumen53 halamanPc100-5 Custom Operational ManualPHÁT NGUYỄN THẾBelum ada peringkat

- Glossary of Valve TerminologyDokumen8 halamanGlossary of Valve Terminologyfaizrul yusoffBelum ada peringkat

- Invitation To Tender FOR Mechanical and E&I Works Project (Phase Ii)Dokumen120 halamanInvitation To Tender FOR Mechanical and E&I Works Project (Phase Ii)leftkarthikeyanBelum ada peringkat

- Technical Information Cleanfit CPA450Dokumen12 halamanTechnical Information Cleanfit CPA450Pravin BoteBelum ada peringkat

- Peilglas Level Gauge Reflex Transparant BicolourDokumen72 halamanPeilglas Level Gauge Reflex Transparant BicolourRUBENBelum ada peringkat

- Primary Oil Separator M.T.RDokumen21 halamanPrimary Oil Separator M.T.RHanuman RaoBelum ada peringkat

- SP 80 01Dokumen50 halamanSP 80 01aminBelum ada peringkat

- Grundfosliterature 1580Dokumen268 halamanGrundfosliterature 1580Zeljko RisticBelum ada peringkat

- 4 FlangesDokumen27 halaman4 Flangesvu ngocBelum ada peringkat

- Chapter 12 Vacuum ValvesDokumen46 halamanChapter 12 Vacuum ValvesPardhu YellaBelum ada peringkat

- ORTON - Company Profile 31-12-09Dokumen14 halamanORTON - Company Profile 31-12-09Fabrizio DelledonneBelum ada peringkat

- Bridas Back-UpDokumen2 halamanBridas Back-UpOficina Técnica Santa RosaBelum ada peringkat

- PREPARED MS For Piping FabricationDokumen9 halamanPREPARED MS For Piping Fabricationvishal bailurBelum ada peringkat

- CADWorx Plant 2016 Capability Review - Material Assignment SetupDokumen31 halamanCADWorx Plant 2016 Capability Review - Material Assignment Setupkad-7Belum ada peringkat

- CS2500Dokumen528 halamanCS2500David Muñoz CastroBelum ada peringkat

- Separador de Bridas PDFDokumen56 halamanSeparador de Bridas PDFCesar Augusto Arias CastroBelum ada peringkat

- Group Models Listed Excessive Oil ConsumptionDokumen20 halamanGroup Models Listed Excessive Oil Consumptionkomodo30Belum ada peringkat

- Operating Manual For TEST RIG SHIP - Pres-Vac Engineering ApsDokumen14 halamanOperating Manual For TEST RIG SHIP - Pres-Vac Engineering ApsGarry Bernard NelsonBelum ada peringkat

- Smart Trap PDFDokumen2 halamanSmart Trap PDFdmitos100% (1)

- ASTM F 1508 2021, Standard Specification For Angle Style, PressureDokumen15 halamanASTM F 1508 2021, Standard Specification For Angle Style, PressurelaythBelum ada peringkat

- ICT In-Cylinder Transducers: SeriesDokumen12 halamanICT In-Cylinder Transducers: SeriesMehmet CELİKBelum ada peringkat

- JI2048-974-MS-DAT-0038 - Rev001 (T-1003)Dokumen9 halamanJI2048-974-MS-DAT-0038 - Rev001 (T-1003)Tech DesignBelum ada peringkat

- Pulsar RS200 (2020)Dokumen92 halamanPulsar RS200 (2020)zonabike.infoBelum ada peringkat

- Schottel - SCP 077 4XG - Technical SpecificationDokumen12 halamanSchottel - SCP 077 4XG - Technical SpecificationGesiel SoaresBelum ada peringkat