NAA .32 ACP专利 PDF

Diunggah oleh

Jin SongDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

NAA .32 ACP专利 PDF

Diunggah oleh

Jin SongHak Cipta:

Format Tersedia

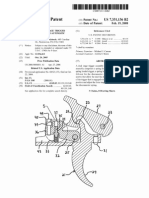

United States Patent [19]

[111.

Seecamp

[451

[54]

DOUBLE-AC1ION TRIGGER MECHANISM

WITH TRIGGER-BLOCKING MAGAZINE

SAFETY FOR FIREARMS

[76] Inventor:

Louis W. Seecamp, 487 Wolcott La.,

Orange, Conn. 06477

[51]

J an. 31, 1984

OTHER PUBLICATIONS

Parts Lists for Astra Camper, Cub, and Firecat Auto

matic Pistols.

Primary Examiner~Charles T. Jordan

Assistant ExaminerTed L. Parr

[21] Appl. No.: 369,604

[22] Filed:

4,428,138

[57]

ABSTRACT

A double-action trigger mechanism for ?rearms having

Apr 19 1982

Int. Cl.3 ............................................ .. F41C 17/02

[52]

a pivoted trigger and hammer with a draw-bar connect

ing them for cooking the hammer by means of the trig

[58]

Field of Search .................................. .. 42/70 A, 7

[56]

ger, together with a trigger-blocking magazine safety

for preventing ?ring of the gun when the cartridge

References C'ted

magazine is removed. A multiple purpose spring is pro

U_S, PATENT DOCUMENTS

vided which acts as a trigger-return spring, a magazine

safety spring and a draw-bar spring. In addition, provi

sion is made for limiting the retraction of the breech

2

2:296,998 9/1942 Koehler

2,464,427 3/1949 Wilson

3,722,358

________ " 42/3

264/427

3/1973 Seecamp ............................. .. 89/147

FOREIGN PATENT DOCUMENTS

bolt or slide when the magazine is removed so that a

live cartridge in the chamber can not be extracted or :1

fresh cartridge can not be inserted into an empty cham

ber until the magazine is replaced.

107894 11/1927 Austria ............................. .. 42/70 A

[2

7 Claims, 7 Drawing Figures

//8

US. Patent

Jan. 31, 1984

Sheet 1 Of3

4,428,138

US. Patent

Jan. 31, 1984-

//8

EIEW 4

Sheet 2 (3

4,428,138

U.S. Patiint

Jan. 31, 1984

Sheet 3 of3

4,428,138

4,428,138

signed to be ?red only in double-action, some only in

single-action, and others in either mode. The present

invention is applicable to guns designed to be ?red in

double-action, whether by itself or in addition to single

action. Pistols capable of being ?red in single-action as

DOUBLE-ACTION TRIGGER MECHANISM WITH

TRIGGER-BLOCKING MAGAZINE SAFETY FOR

FIREARMS

BACKGROUND OF THE INVENTION

The invention relates to ?rearms, and it relates more

well as in double-action are shown in U.S. Pat. No.

2,464,427 to G. A. Wilson and in my prior U.S. Pat. No.

particularly to a trigger-blocking magazine-safety sys

tem for auto-loading pistols having a trigger-cocking

3,722,358.

In U.S. Pat. No. 885,436 to C. P. Clement, a single

mechanism in which a pivoted hammer is cocked when 10 spring is employed which functions both as a trigger

the trigger is pulled. In accordance with one aspect of

return spring and as a positioning spring by urging a link

the invention a utility spring is provided which com

between the trigger and sear upward and forward. In

bines the functions of three separate springs: one for

this case, however, the trigger mechanism is not double

returning the trigger when it is released following a

action, and the spring employed could not be used with

triggering cycle; one for resiliently maintaining the

a trigger-cocking draw-bar due to the amount of move

cocking link or draw-bar in engagement with the ham

mer; and one for actuating a safety member in order to

ment required in such an action. A spring similar to that

shown in the Clement patent, but adapted for double

action, is employed in the Browning BDA .45 caliber

semi-automatic pistol manufactured in West Germany.

However, neither the Clement nor the Browning BDA

springs function to activate a magazine safety.

positively prevent firing the pistol when the cartridge

magazine is not in the pistol.

A so-called magazine safety is a device which is actu

ated upon removal of the cartridge magazine to block

or disconnect the trigger mechanism so that the gun can

U.S. Pat. No. 2,138,213 to A. Seidel shows a spring

which acts both as a trigger spring and as a positioning

be ?red only when the magazine is in place. The pur

pose of rendering the gun incapable of ?ring without

the cartridge magazine is to prevent those accidental

shootings which occur because people not versed in

spring for a connecting rod between the trigger and

sear. However, the trigger mechanism is single-action,

and the spring does not activate the magazine safety.

gun safety or operation may believe the gun is com

pletely unloaded when the magazine is withdrawn,

Accordingly, while trigger-blocking magazine

the elderly and handicapped, who ?nd it dif?cult to

safety. The object of the present invention is therefore

springs, as well as multiple-function link or draw-bar

whereas actually a round is still in the chamber. Addi

tionally, a magazine safety allows the gun owner to 30 springs have been employed before, none to my knowl

edge discloses a single trigger-mechanism spring which

keep his gun ready for self-defense yet safe from unau

operates the entire linkage from returning the trigger to

thorized use during brief periods when it may be left

cocking the hammer, as well as to activate a magazine

unattended. There are also people, particularly among

retract the slide of a semi-automatic pistol in order to 35 to provide a double-action trigger mechanism having a

single spring which serves as the trigger-return spring,

ready the weapon for ?ring. A magazine safety permits

such people to safely keep a round in the chamber at all

the magazine-safety spring and the draw-bar spring. A

times by removing the magazine so that the gun can not

be ?red by children or others who may gain unautho

rized access to it. The gun can nevertheless be quickly

further and important object of the invention is to pro

vide a magazine safety system in which the slide or

breech-bolt of the gun is partially blocked when the

cartridge magazine is removed preventing insertion of a

cartridge into the chamber until the magazine is re

placed, thereby permitting the slide to be retracted only

brought to a state of readiness by simply inserting the

cartridge magazine, which can be kept in a safe place on

ones person or elsewhere.

A magazine safety which blocks the trigger, as distin

guished from disconnecting it, is shown in U.S. Pat. No.

far enough to determine whether or not the chamber is

45 empty, but not far enough to allow a cartridge to be

2,296,998 to E. F. Koehler. In this case the blocking

member is actuated by a spring which is depressed

when the blocking member is moved out of its blocking

position as the magazine is inserted into the pistol. Un

like the present invention, however, the only function

of this spring is to actuate the blocking member.

Magazine safeties, which block the trigger, are also

employed in the Astra Camper, Cub and Firecat

extracted if one is in the chamber, or to be chambered if

the chamber is empty.

SUMMARY OF THE INVENTION

50

In accordance with one aspect of the invention, a

single spring is pivotally mounted on the pivot pin for a

trigger-blocking magazine-safety member with one end

of the spring engaging the blocking member so that it is

pistols manufactured in Spain by Unceta and Co. S.A.,

resiliently urged toward its blocking position. The other

but in these cases only a single-action ?ring mechanism

end of the spring is ?xed to the draw-bar of the trigger

is employed, and the spring has just one function,

whereas the spring of the present invention performs a

multiple of functions.

Trigger-cocking mechanisms, so-called because the

both into operative relationship with the hammer and in

a direction generally opposite to that in which it is

drawn by the trigger, so that the trigger is returned

mechanism in such a way that it urges the draw-bar

hammer is cooked by the trigger, are used in what are 60 when it is released.

commonly known as double-action pistols, which

have a pivoted hammer that is engaged by a draw-bar

Desirably the spring is pivoted adjacent one of its

ends at a ?xed point near the blocking member and is

?xed to the draw-bar at its other end. One or more small

coils may be provided which encircle a pivot pin at the

connected to the trigger so that the hammer is ?rst

cocked as the trigger is pulled and then released to ?re

a cartridge in the chamber. Single-action pistols, on the 65 pivoted end with an end portion extending into engage

other hand, are those in which the trigger performs the

ment with, and exerting a force against, the blocking

single function of releasing the hammer, which must

member in order to urge it into its blocking position

?rst be cocked directly by hand. Some guns are de

with respect to the trigger, the reaction to such force

4,428,138

being in such a direction as to urge the draw-bar into

operative relationship with the hammer. In addition a

large coil may also be provided midway between the

ends of the spring with two lengths of the spring extend

charging a cartridge 28 in the cartridge chamber at the

rear of the bore of barrel 12.

A hammer 30 is pivoted to frame 10 on a hammer pin

32 for engagement of its striker portion 33 with the rear

end of the ?ring pin 26. Hammer 30 is driven through a

ing therefrom which tend to spread apart in order to

urge the draw-bar in the direction to return the trigger

when pulled. The magnitude and direction of the force

stirrup 34, pivoted thereto at 35, by a mainspring 36 in

a spring tunnel in the backstrap of grip 14. The lower

exerted by the spring on the draw-bar is thereby en

hanced as it is drawn by the trigger over a relatively

end of mainspring 36 presses against a magazine catch

38, which is pivotally mounted so that it is urged clock

wise into latching engagement with the footplate of a

long span while the hammer is being cocked.

In accordance with another important aspect of the

invention, the draw-bar may be formed such that when

the trigger~blocking magazine-safety member blocks

the trigger, the breech-bolt or slide is partially blocked

by the hammer, preventing it from being retracted far

enough to insert a cartridge into the chamber manually,

while permitting it to be retracted far enough in order

to check whether a cartridge is still in the chamber.

DETAILED DESCRIPTION OF PREFERRED

EMBODIMENT OF THE INVENTION

One embodiment of the invention as it applies in a

straight double-action, trigger mechanism, which does

cartridge magazine 40 slidably retained thereby within

the grip portion 14 of frame 10. Magazine 40 is of con

ventional design to hold a spring-loaded column of

cartridges which are fed one by one into the cartridge

chamber as the slide is driven rearward either by hand

or on recoil when the gun is ?red.

A trigger 42 is pivoted to the frame 10 on a pin 44 and

has an upward extension 43, to which is pivoted at 45

one end of an elongated, hammer-cocking draw-bar 46.

The rear end of draw-bar 46 is provided with a claw 48

which engages a cocking lug 50 on the lower end of the

hammer 30 below the hammer pin 32. Accordingly,

when draw-bar 46 is drawn forward (to the left as

shown in the drawings) by pulling the trigger 42 coun

not include a single-action function in that it is not pro

vided with a cocking sear, is illustrated in the accompa 25 terclockwise, the hammer 30 is pivoted clockwise

nying drawings, in which

FIG. 1 is a side elevational view, partially broken

away and in section, of a semi-automatic pistol incorpo

rating the invention;

FIG. 2 is an exploded view of the trigger mechanism

and trigger-blocking magazine-safety system shown in

FIG. 1;

FIG. 3 is a view similar to FIG. 1, but with the barrel

against the pressure of mainspring 36 until the claw 48

passes under the lug 50 releasing the hammer to strike

the ?ring pin.

The claw-end of draw-bar 46 is urged upward and

rearward (to the right as viewed in the drawings) by a

multiple-purpose torsion spring 52 which has a foot 54

(FIG. 2) at one end extending laterally therefrom into a

hole 55 in the claw-end of draw-bar 46. Torsion spring

52 extends from the hammer-engaging, claw-end of

removed and portions cut-away and in section in order

to expose the parts below, showing the trigger, draw 35 draw-bar 46 forwardly to, and is pivotally supported

on, a pin 56 ?xed in the frame 10, by means of a nest of 7

bar and hammer in the normal positions, prior to initia

small coils 58 at the forward end of spring 52 which

tion of a triggering cycle;

encircle the pin 56. A large coil 60 is provided midway

FIG. 4 is a more-or-less diagrammatic view of only

between the ends of spring 52 and, in its unstressed

the trigger mechanism, hammer and portions of the

magazine and frame, showing the trigger in the process 40 condition as shown in FIG. 2, has two arms 61 and 62

extending away from each .other in substantially oppo

of being pulled so that the hammer is partially cocked;

FIG. 5 is a view similar to FIG. 4, showing the trig

ger pulled, the hammer having been released and piv

oted by the mainspring to the position at which it strikes

the ?ring pin;

site directions. The arm 61 extends forward to the small

coils 58, while the arm 62 extends rearward and is ?xed

to the claw-end of draw-bar 46 by means of the foot 54.

45 In order to install the spring, the arms 61 and 62 must be

FIG. 6 is another view similar to FIG. 4, but with the

?exed toward each other stressing the large coil 60, so

trigger, cocking-bar and hammer in their normal posi

that a rearward force is exerted on the draw-bar 46,

which in turn urges the trigger 42 in a clockwise direc

tion. Spring 52 therefore acts as a trigger-retum spring.

tions as in FIG. 3, and with the magazine withdrawn,

thereby activating the trigger-blocking safety;

FIG. 7 is a view similar to FIG. 6, but also showing

Immediately rearward of trigger 42 and pivoted to

the slide and the chamber portion of the barrel, the slide

frame 10 on the pin 56 is a trigger-blocking, magazine

safety member 64, best seen in FIG. 2. A fnger 65 of

member 64 extends above pin 56 for engagement by the

being retracted as far as it can go with the magazine

removed.

upper front edge of magazine 40 when the magazine is

Referring more particularly to FIGS. 1 to 3, the gun

in which the invention is illustrated in a semi-automatic 55 in place. Below pin 56 and extending laterally from the

blow-back pistol having a frame 10, which in this in

stance includes, as integral parts thereof, the barrel 12,

grip portion 14 and trigger guard 16. A slide 18 is

blocking member 64, is an arcuately shaped blocking

_lug 66 which is provided with a notch 68 on its rear

edge. A short end-section 70 extending from the inner

most coil of the nest 58 on torsion spring 52 is inserted

mounted in conventional manner on the frame 10 for

reciprocal movement from a chamber-closing or bat 60 into notch 68, so that when spring 52 is stressed in order

tery position as shown in FIG. 1 to a retracted position

for extracting an empty case from the chamber and

feeding a fresh cartridge into the chamber on return to

to align and af?x the foot 54 in the hole 55 in draw-bar

46, the end 70 of the spring exerts a downward force on

the blocking lug 66, thereby urging the pivoted block

ing member 64 in a clockwise direction, while exerting

its battery position. A recoil spring 20 in a spring tunnel

22 below barrel 12 urges slide 18 into battery by apply 65 an upward force on the claw-end of the pivoted draw

ing its pressure against an abutment 24 at the front of

bar 46.

slide 18. A spring-loaded ?ring pin 26 of standard inertia

design extends longitudinally through the slide for dis

As long as the magazine 40 is in place the blocking

lug 66 is held by engagement of the magazine with the

4,428,138

?nger 65 of the member 64 in the position shown in

FIG. 1 where it is clear of the trigger 42, so that the

trigger can be pulled in a counterclockwise direction to

cock the hammer (FIG. 4) and ?re a chambered car

As hereinbefore mentioned, when the magazine 40 is

removed the trigger-blocking member 64 is free to pivot

clockwise under the force of the end 70 of spring 52

until it engages the rear edge of the extension 43 of

tridge. However, when the magazine 40 is removed, the

?nger 65 is free to move rearward, permitting blocking

trigger 42, as shown in FIG. 6. If the trigger is pulled its

shelf 74 engages the underside 72 of the blocking lug 66,

member 64 to pivot clockwise under the pressure of the

end 70 of torsion spring 52. Such movement brings the

blocking lug 66 into its blocking position, as shown in

FIG. 6, where the underside 72 of lug 66 is disposed in

the path of a shelf 74 on the back edge of trigger 42,

a counterclockwise direction as viewed in the drawings.

Since the trigger can not be moved any appreciable

amount, it can not cook the hammer to ?re the gun. It

should be noted, moreover, that when the trigger is

positively blocking the trigger from being pulled be

yond a predetermined point, which. is insuf?cient to

fully cock and release the hammer.

'

It will be noted from FIG. 2.that when the spring 52

' is unstressed the end section 70 is disposed nearly 180

from the arm 61. Consequently, when spring 52 is in

stalled, the small coils 58 are stressed by ?exing the arm

61 in a clockwise direction toward the end 70, forcing it

against the blocking lug 66 and at the same time causing

the rest of spring 52 to exert an upward reaction-force

against the claw-end of draw-bar 46, in order to main

tain it in operative position with the cocking lug 50 of

thereby limiting the trigger to only slight movement in

pulled with the magazine safety 64 in its blocking posi

tion, the shelf 74 engages the underside 72 of blocking

member 64 at a point which tends to pivot member 64

toward its blocking position, rather than out of it. Con

seqnently, there is no way the blocking member can be

moved out of its blocking position when the trigger is

pulled. In other words a positive safety is provided

against inadvertent or unauthorized ?ring of the

weapon when the magazine 40 has been removed.

Referring now more particularly to FIG. 7, it will be

noted that the trigger-blocking magazine-safety of the

present invention not only positively prevents ?ring the

pistol when the magazine has been removed, but also

the hammer.

25 can be employed to prevent insertion of a fresh car

As shown in FIG. 2, a side plate 75 is provided, hav

tridge directly into the chamber instead of by means of

ing three holes which fit loosely over the trigger pin 44,

the magazine safety pin 56 and the hammer pin 32. A

side grip (not shown) is fastened over side plate 75 by

the magazine. Thus, as before, when the cartridge mag

azine is removed, blocking member 64 is pivoted by the

end 70 of spring 52 into its blocking position. If the slide

means of a suitable screw through a hole 77 in frame 10. 30 18 is then retracted manually pivoting the hammer 30

Referring again to the hammer-cocking draw-bar 46,

clockwise, the cocking lug 50 is moved within the space

it will be noted that an upwardly extending positioning

between the claw 48 and hump 76 of the draw-bar 46

hump 76 is provided on the upper edge thereof forward

until it engages a projection 82 on the rear edge of the

of the claw 48, and forming therewith a U-shaped sec

hump 76 which lies in the path of lug 50, as illustrated in

tion that surrounds the cocking lug 50 on hammer 30. 35 FIG. 7. Only a slight further retraction of slide 18 from

Hump 76 is urged upward by spring 52 against a guide

the position shown can be made, as the cocking lug 50

surface 78 on the frame 10, so that as the hammer 30 is

cocked during a triggering-cycle, claw 48 moves down

ward so that the cocking lug 50 on the hammer rides up

the front edge of the claw as illustrated in FIG. 4 until

moves upward and forward against the projection 82

pushing hump 76 on the draw-bar 46 upward against the

guide surface 78 of the frame and at the same time mov

ing bar 46 longitudinally to the left as viewed in the

it escapes the tip of the claw releasing the hammer,

drawing, thereby pivoting trigger 42 counterclockwise

which is then free to fall under the force exerted on it by

until its shelf 74 comes into engagement with the under

side 72 of lug 66 on the blocking member 64. Conse

the mainspring 36.

Since the trigger mechanism of the pistol here shown

is a straight double-action (i.e. no sear), the hammer will

then be located in the position shown in FIG. 5 regard

less of whether or not a cartridge was ?red. At this

quently, with the magazine removed, the slide can be

45 retracted only far enough to determine whether or not

a cartridge is in the chamber, but not far enough to

permit a cartridge to be inserted into an empty chamber.

The amount of retraction of the slide permitted under

these conditions can be predetermined by the size and

point in the triggering cycle, a straight surface 80 on the

upper edge of claw 48 rests on the underside of cocking

lug 50, so that when the trigger is released, spring 52 50 shape of the projection 82, which can be readily

drives the draw-bar 46 rearward, with the surface 80

changed by a simple ?ling operation. Moreover, if it is

sliding along the bottom of lug 50 until claw 48 returns

desired to eliminate this safety feature, the projection 82

to the position shown in FIG. 1, the upward force ex

can be removed completely so that the hammer 30 can

erted by the small coils 58 of spring 52 causing the claw

be pivoted back as far as necessary by the slide 18 to

48 to move upward as soon as the tip of the claw passes 55 permit full retraction of the slide.

rearward of the lug 50. The upward movement of claw

I claim:

48 is then again limited by engagement of hump 76 with

1. In a double-action trigger mechanism for semi

the guide surface 78 on the frame. It will be noted that

automatic ?rearms having a trigger and a hammer both

the surface 80 is only slightly sloped relative to the

pivotally mounted on a frame in spaced relation to each

direction in which draw-bar 46 moves lengthwise, in

other, a trigger-blocking member pivoted to said frame

order to reduce the resistance to the rearward force

for movement out of a blocking position when a car

tridge-magazine is inserted into place, and a draw-bar

exerted by spring 52. Furthermore, the force exerted by

spring 52 rearwardly should be substantially greater

pivotally connected to said trigger and extending into

operative relation with said hammer for cocking said

than its upward force. This is readily obtained by prop

erly coiling spring 52 and in selecting the point at which 65 hammer when said trigger is pulled moving said draw

spring 52 engages bar 46 such that the desired amount

bar in one direction,

a spring pivotally mounted on a pivot pin for said

and direction of the force exerted by the foot 54 on the

trigger-blocking member and having one end

draw-bar is attained.

4,428,138

urging said trigger-blocking member toward its

small coil encircling said blocking-member pivot pin

blocking position,

with one end engaging said blocking member and

the other end of said spring being ?xed to said draw

urging it into its blocking position, the other end of said

bar and urging it in a direction both into operative

relationship with said hammer and generally in a

torsion spring being ?xed to said draw-bar such that

said draw-bar is urged into operative relationship with

direction for returning said trigger when it is re

said hammer by the reaction force of said one end of

leased.

2. A trigger device as de?ned in claim 1, wherein said

said torsion spring against said blocking member, said

torsion spring having a large coil disposed intermediate

spring is provided with a coil encircling said pivot pin

said pin-encircling coil and said other end with substan

and stressed such that the reaction to the force exerted

tially straight sections extending therefrom in different

by said one end against said blocking member is exerted

in a direction against said draw-bar to pivot it into oper

directions stressed inwardly toward each other such

that they exert a force outwardly of each other against

the draw-bar in order to urge said draw-bar in the direc

ative relationship with said hammer.

3. A trigger device as de?ned in claim 2, wherein said

tion for returning said trigger.

spring is also provided with a large coil intermediate its 15

6. A double-action trigger mechanism as de?ned in

ends, a substantially straight section extending from said

claim 5, wherein a plurality of said small coils encircle

small coil to said large coil and a second substantially

said blocking-member pivot pin.

straight section extending from said large coil to said

7. A double-action trigger mechanism as de?ned in

other end of said spring, said straight sections being

either

claim 5 or 6, wherein said hammer is provided

stressed inwardly toward each other such that they 20

with a cocking lug by which said draw-bar cocks said

exert a force outwardly of each other against said draw

hammer when said trigger is pulled, said draw-bar hav

bar in order to urge said draw-bar in said direction for

ing a claw at its other end for engaging said cocking lug,

returning said trigger.

said draw-bar having a projection disposed within the

4. A trigger device as de?ned in either claim 2 or 3,

wherein a plurality of said coils encircle said pivot pin. 25 path of said cocking lug on said hammer, such that said

cocking lug engages said projection when said hammer

5. A double-action trigger mechanism having a piv

is pivoted toward a cocking position other than by

oted trigger and a pivoted hammer in spaced relation

means of said trigger and draw-bar, whereby such piv

therewith, a draw-bar pivoted at one end to said trigger

otal movement of said hammer toward its cocking posi

with its other end disposed adjacent said hammer for

cocking engagement therewith, a trigger-blocking,

magazine-safety member pivoted on a pin adjacent said

trigger and pivotable into and out of a blocking position

relative to said trigger for positively preventing said

trigger from cocking said hammer when the cartridge

magazine is removed, and a torsion spring having a

30

35

45

50

55

65

tion is positively limited by engagement of said cocking

lug with said projection when said blocking-member is

disposed in its blocking position on withdrawal of the

cartridge magazine, preventing substantial movement

of of said trigger and draw-bar.

*

Anda mungkin juga menyukai

- Patented June 1, 1901. No. 675,999.: L. HellfritzschDokumen4 halamanPatented June 1, 1901. No. 675,999.: L. HellfritzschСлэйтер Строительная компанияBelum ada peringkat

- Gun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsDari EverandGun Digest American Arms ATI GSG-5 Assembly/Disassembly InstructionsBelum ada peringkat

- 870 Detent Staking PunchDokumen1 halaman870 Detent Staking PunchZardoz10900% (1)

- 撞针选择的枪 PDFDokumen9 halaman撞针选择的枪 PDFJin SongBelum ada peringkat

- Mannlicher Pistol PatentDokumen10 halamanMannlicher Pistol PatentAndrew NicolleBelum ada peringkat

- Old Model B392-OM1Dokumen9 halamanOld Model B392-OM1Just4HimBelum ada peringkat

- Mossberg Brownie Barrel PDFDokumen1 halamanMossberg Brownie Barrel PDFCarlos sandoval100% (2)

- AR Module Trigger System: JARD, IncDokumen4 halamanAR Module Trigger System: JARD, IncJames McEwenBelum ada peringkat

- Manuale CZ200Dokumen11 halamanManuale CZ200gatto61Belum ada peringkat

- Uzi Semi-Auto Carbine Fixed Stock Installation InstructionsDokumen4 halamanUzi Semi-Auto Carbine Fixed Stock Installation Instructionselvergonzalez1Belum ada peringkat

- Ifle ASIX, Inc.: Instruction Sheet For Rifle Basix Cz-52 CZ 452 Bolt Action Rimfire RiflesDokumen1 halamanIfle ASIX, Inc.: Instruction Sheet For Rifle Basix Cz-52 CZ 452 Bolt Action Rimfire Riflesjean.phBelum ada peringkat

- Us 4207797Dokumen7 halamanUs 4207797fghdfjerBelum ada peringkat

- Collection - PDF .44 SpecialDokumen5 halamanCollection - PDF .44 SpecialRonnie RensburgBelum ada peringkat

- Carabina SpencerDokumen15 halamanCarabina SpencerercorreaBelum ada peringkat

- Swiss K31 K11 Manual PDFDokumen81 halamanSwiss K31 K11 Manual PDFbjmooseBelum ada peringkat

- Steyr S40-A1Dokumen63 halamanSteyr S40-A1AUGieDogie1Belum ada peringkat

- Patented Nov. I3, 900.: A. V0N Zeke A. K. RédlDokumen3 halamanPatented Nov. I3, 900.: A. V0N Zeke A. K. Rédlcll1968Belum ada peringkat

- Chauchat LMG PDFDokumen9 halamanChauchat LMG PDFS84SBelum ada peringkat

- Model 1894 Sights: WinchesterDokumen34 halamanModel 1894 Sights: WinchesterMárcio MontenegroBelum ada peringkat

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDokumen7 halaman1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongBelum ada peringkat

- CarriageDokumen25 halamanCarriageSamir SinghBelum ada peringkat

- BSASupertenDokumen11 halamanBSASupertenapi-3695814Belum ada peringkat

- Pressure Air GunDokumen7 halamanPressure Air GunyuehanBelum ada peringkat

- Navy Arms Lemat RevolverDokumen4 halamanNavy Arms Lemat RevolverpercyolivasBelum ada peringkat

- FM23-45 Browning 1919 Machine GunDokumen35 halamanFM23-45 Browning 1919 Machine GunjeffBelum ada peringkat

- Ruger 22-45 Parts PicturesDokumen4 halamanRuger 22-45 Parts Picturesapi-3840428Belum ada peringkat

- Remington 700 Adjustment Guide: Safety PlungerDokumen2 halamanRemington 700 Adjustment Guide: Safety PlungerRod PhillipsBelum ada peringkat

- United States Patent 1111 3,595,128Dokumen9 halamanUnited States Patent 1111 3,595,128rte678Belum ada peringkat

- Percussion Lock TerminologyDokumen2 halamanPercussion Lock TerminologyCharlie0% (1)

- Post 6 38604 Reifgraber AutoDokumen14 halamanPost 6 38604 Reifgraber AutoAoolf ManBelum ada peringkat

- ??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Dokumen7 halaman??????zzzzzzzzzzzzzzzzzzzzzz!é:1: Patented Sept. 24, 1901Слэйтер Строительная компания100% (1)

- IAI Automag III PDFDokumen11 halamanIAI Automag III PDFab212amisarBelum ada peringkat

- Thompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866Dokumen28 halamanThompson/Center Arms Co., Inc. P.O. Box 5002 Rochester, New Hampshire 03866johndone100% (1)

- ChicopeerfDokumen15 halamanChicopeerfRomG78Belum ada peringkat

- Budischowsky Tp-70Dokumen5 halamanBudischowsky Tp-70JustinBelum ada peringkat

- Lee Turret PressDokumen2 halamanLee Turret Pressa928315100% (1)

- UZI Action Arms .22 Conversion ManualDokumen5 halamanUZI Action Arms .22 Conversion Manualgreaternorthroad8820Belum ada peringkat

- Dynamic Analysis Stranded Wire SpringsDokumen71 halamanDynamic Analysis Stranded Wire SpringsJoseph J. ZajkBelum ada peringkat

- AR15 Roller Cam Pin - Reducing Friction and Wear vs. Conventional Cam Pins HydraFireAR15RollerCamPinFrictionStudyDokumen10 halamanAR15 Roller Cam Pin - Reducing Friction and Wear vs. Conventional Cam Pins HydraFireAR15RollerCamPinFrictionStudyRob ZelBelum ada peringkat

- Klashnikovak 47 130330015107 Phpapp01Dokumen15 halamanKlashnikovak 47 130330015107 Phpapp01elvergonzalez1100% (2)

- BSA Scorpion & T10Dokumen2 halamanBSA Scorpion & T10Pera DjetlicBelum ada peringkat

- Ada 006146Dokumen98 halamanAda 006146Oskar DirlewangerBelum ada peringkat

- List of Multiple Barrel FirearmsDokumen10 halamanList of Multiple Barrel FirearmsLuiz Fernando Nogueira Henrique100% (1)

- Savage 187JDokumen1 halamanSavage 187Jspanky6276100% (1)

- Us 4407085Dokumen5 halamanUs 4407085rte678Belum ada peringkat

- Tool Kit Small Arms 01-462-4254Dokumen18 halamanTool Kit Small Arms 01-462-4254Mark FenwickBelum ada peringkat

- M1 Garand Barrel Replacement  " New BarrelDokumen35 halamanM1 Garand Barrel Replacement  " New BarrelToschanoBelum ada peringkat

- Colt Cap and BallDokumen5 halamanColt Cap and BallkensintBelum ada peringkat

- UZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Dokumen60 halamanUZI PRO Pistol Operator Manual 08 011 05 09 30 - 1Ricardo C TorresBelum ada peringkat

- Types of Firearm ActionsDokumen3 halamanTypes of Firearm ActionssharlynfaithloquireBelum ada peringkat

- Bauska Brill Korean Magnum MauserDokumen2 halamanBauska Brill Korean Magnum MauserIM_JohnnyVBelum ada peringkat

- MD Profiler Instruction ManualDokumen11 halamanMD Profiler Instruction ManualTatiana Trenogina100% (1)

- The Precision Rifle Made in BavariaDokumen8 halamanThe Precision Rifle Made in BavariaThomas WiesnerBelum ada peringkat

- Us 5596162Dokumen9 halamanUs 5596162Stanley PinesBelum ada peringkat

- CZ 40PDokumen14 halamanCZ 40PpreceptiveinquirerBelum ada peringkat

- The GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid RangeDokumen1 halamanThe GOLD MEDAL TRIGGER The Field Target Trigger For The Rapid Rangegraham4877Belum ada peringkat

- QB78 TuneDokumen11 halamanQB78 TuneSadBoiH0urs 1100% (1)

- 撞针选择的枪 PDFDokumen9 halaman撞针选择的枪 PDFJin SongBelum ada peringkat

- 偏心枪支噪音抑制器和组装方法定位装置 PDFDokumen6 halaman偏心枪支噪音抑制器和组装方法定位装置 PDFJin SongBelum ada peringkat

- 螺栓枪口装步枪 PDFDokumen7 halaman螺栓枪口装步枪 PDFJin SongBelum ada peringkat

- 枪炮声抑制器 PDFDokumen11 halaman枪炮声抑制器 PDFJin SongBelum ada peringkat

- (GUNSMITHING) Sten Submachine Gun WWIIDokumen7 halaman(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- Unlted States Patent (10) Patent N0.2 US 7,421,937 B1Dokumen24 halamanUnlted States Patent (10) Patent N0.2 US 7,421,937 B1Jin SongBelum ada peringkat

- 可调式双级触发机制半自动武器 PDFDokumen12 halaman可调式双级触发机制半自动武器 PDFJin SongBelum ada peringkat

- 安装装置,枪支消声器 PDFDokumen28 halaman安装装置,枪支消声器 PDFJin Song100% (1)

- 1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonDokumen7 halaman1,322,227. L - Y Patented Nov. 18, Í919.: F. F. BurtonJin SongBelum ada peringkat

- Ulllted States Patent (10) Patent N0.: US 8,069,602 B2Dokumen13 halamanUlllted States Patent (10) Patent N0.: US 8,069,602 B2Jin Song100% (1)

- Nov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Dokumen6 halamanNov. 24, 1953 M. W. Yale: Self-Loading Semiautomatic Pistol Zsheets-Sheet 1Jin SongBelum ada peringkat

- 块化插入触发器的方法和装置5 PDFDokumen23 halaman块化插入触发器的方法和装置5 PDFJin SongBelum ada peringkat

- 级触发自动武器 PDFDokumen15 halaman级触发自动武器 PDFJin SongBelum ada peringkat

- Us6772548 PDFDokumen8 halamanUs6772548 PDFJin SongBelum ada peringkat

- 锤执行器的枪支 PDFDokumen7 halaman锤执行器的枪支 PDFJin SongBelum ada peringkat

- Us4358986 PDFDokumen9 halamanUs4358986 PDFJin SongBelum ada peringkat

- Us4522105 PDFDokumen10 halamanUs4522105 PDFJin SongBelum ada peringkat

- United States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Dokumen15 halamanUnited States: (12) Patent Application Publication (10) Pub. No.: US 2010/0229446 A1Jin Song100% (1)

- Us4854065 PDFDokumen7 halamanUs4854065 PDFJin SongBelum ada peringkat

- Limited States Patent: LngramDokumen7 halamanLimited States Patent: LngramJin SongBelum ada peringkat

- Us4467698 PDFDokumen11 halamanUs4467698 PDFJin Song100% (1)

- Us4522106 PDFDokumen13 halamanUs4522106 PDFJin Song100% (1)

- TEPZZ 6 - 54Z A T: European Patent ApplicationDokumen30 halamanTEPZZ 6 - 54Z A T: European Patent ApplicationJin SongBelum ada peringkat

- Us2297693 PDFDokumen8 halamanUs2297693 PDFJin SongBelum ada peringkat

- Sept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Dokumen16 halamanSept. 2, 1958 R, J, KQPF: 6 Sheets-Sheet 1 Filed Feb. 3. 1955Jin SongBelum ada peringkat

- Us1517483 PDFDokumen10 halamanUs1517483 PDFJin SongBelum ada peringkat

- Firearms Silencers Ingram Mac-10 11 SilencerDokumen7 halamanFirearms Silencers Ingram Mac-10 11 SilencerPaulSprngr100% (5)

- Us965386 PDFDokumen6 halamanUs965386 PDFJin SongBelum ada peringkat

- Us1446763 PDFDokumen7 halamanUs1446763 PDFJin SongBelum ada peringkat

- (GUNSMITHING) Sten Submachine Gun WWIIDokumen7 halaman(GUNSMITHING) Sten Submachine Gun WWIIMago Invisivel100% (10)

- Operational M Anual: Grenade Launchers "FORT" Caliber 40x46 MMDokumen10 halamanOperational M Anual: Grenade Launchers "FORT" Caliber 40x46 MMluca ardenziBelum ada peringkat

- RTT TasksDokumen18 halamanRTT Tasksfoxbat1988Belum ada peringkat

- Phantom 12 Ga. Shotgun Instructional Manual: Century International Arms IncDokumen9 halamanPhantom 12 Ga. Shotgun Instructional Manual: Century International Arms IncJustinBelum ada peringkat

- Barrett 2022 RETAIL Price List Q3Dokumen4 halamanBarrett 2022 RETAIL Price List Q3Bobby GillBelum ada peringkat

- 2016 Trijicon RMRDokumen4 halaman2016 Trijicon RMRVictor Diaz PerezBelum ada peringkat

- Glock RefurbDokumen4 halamanGlock RefurbMark GranthamBelum ada peringkat

- SHTF 50Dokumen6 halamanSHTF 50Tonyf6188Belum ada peringkat

- Anatomy of FirearmsDokumen9 halamanAnatomy of Firearmswerdna67Belum ada peringkat

- Catalog 2019 PDFDokumen48 halamanCatalog 2019 PDFCatalin Tudoriu100% (1)

- Bren LMG ManualDokumen7 halamanBren LMG ManualGasMaskBobBelum ada peringkat

- Colt Custom Shop Order FormDokumen8 halamanColt Custom Shop Order FormAmmoLand Shooting Sports NewsBelum ada peringkat

- Sas12 Shotgun ExplodedDokumen8 halamanSas12 Shotgun Explodedsjdarkman1930Belum ada peringkat

- Concealed Carry Magazine Your BestDokumen18 halamanConcealed Carry Magazine Your BestRed PhoenixBelum ada peringkat

- Ruger New 2010 Catalog (LCR and LCP)Dokumen7 halamanRuger New 2010 Catalog (LCR and LCP)rreyesa2001Belum ada peringkat

- User Manual: Pump Action Shotgun Instruction ManualDokumen11 halamanUser Manual: Pump Action Shotgun Instruction ManualNorth WeaponBelum ada peringkat

- Hatsan PCP Air RiflesDokumen16 halamanHatsan PCP Air RiflesCyrusTk100% (1)

- 2010 Rossi CatalogDokumen28 halaman2010 Rossi Catalogb46550214949Belum ada peringkat

- Firearms The Illustrated HistoryDokumen322 halamanFirearms The Illustrated HistoryShubham PriyamBelum ada peringkat

- Mauser M03 Manual enDokumen11 halamanMauser M03 Manual enbuggubBelum ada peringkat

- Weapon and Ammunition Technical Manual Infantry Regiment ParachuteDokumen55 halamanWeapon and Ammunition Technical Manual Infantry Regiment ParachuteKa Lay Thar100% (1)

- Mi.50 M2HB QCB InfanteriaDokumen305 halamanMi.50 M2HB QCB InfanteriaLibcad Laberinto100% (4)

- Goatguns Collector S Guide 5.9.18 Cmyk PrintFINAL2Dokumen24 halamanGoatguns Collector S Guide 5.9.18 Cmyk PrintFINAL2nguymikeBelum ada peringkat

- Winchester Super x2 Practical ShotgunDokumen4 halamanWinchester Super x2 Practical Shotguncarlosfanjul1Belum ada peringkat

- The 1903 Colt 'Hammerless' Pocket ModelDokumen8 halamanThe 1903 Colt 'Hammerless' Pocket Modelblowmeasshole1911Belum ada peringkat

- Taurus 1911 ManualDokumen14 halamanTaurus 1911 Manualmedlaw100% (2)

- Nigcoy 8 Ecomig Arms and Ammunition HoldingDokumen7 halamanNigcoy 8 Ecomig Arms and Ammunition HoldingWisdom AbrahamBelum ada peringkat

- TRG-42 Tech SpecsDokumen1 halamanTRG-42 Tech SpecsDicko Perdana PutraBelum ada peringkat

- Concealed Carry Handguns December 2017Dokumen132 halamanConcealed Carry Handguns December 2017Rodney Charles75% (4)

- Ed Brown's 1911 Bench ReferenceDokumen96 halamanEd Brown's 1911 Bench ReferenceMogwan Boggie100% (6)

- The Baby BrowningDokumen9 halamanThe Baby Browningblowmeasshole1911100% (1)