Check Valves: International Site For Spirax Sarco

Diunggah oleh

khali54Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Check Valves: International Site For Spirax Sarco

Diunggah oleh

khali54Hak Cipta:

Format Tersedia

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

International site for Spirax Sarco

Home

About Us

Products & Services

You are here:

Pipeline Ancillaries

Isolation Valves - Linear

Movement

Isolation Valves - Rotary

Movement

Check Valves

Home

Industries & Applications

Resources

Tel: +44 (0)1242 521361

Fax: +44 (0)1242 573342

Enquiries@SpiraxSarco.com

Training

Resources

Contact

http://www.SpiraxSarco.com/

Steam Engineering Tutorials

Pipeline Ancillaries

Check Valves

Check Valves

Check (non-return) valves are installed in

pipelines to allow flow in one direction only;

helping to protect equipment and processes. The

operation, benefits, applications and selection of

different designs, including lift, disc, swing and

wafer check valves are explained in this tutorial.

The printable version of this page has

now been replaced by

The Steam and Condensate Loop Book

View the complete collection of Steam

Engineering Tutorials

Strainers

Contact Us

Separators

Gauges, Sight Glasses,

Vacuum Breakers

Related Content

Check Valves

View a complete range of

check valves available to

suit any application.

Sizing Check Valves

Use the valve sizing

calculator to determine

the pressure drop across

check valves.

Check valves, or non-return valves, are installed in pipeline systems to allow flow in one direction only. They

are operated entirely by reaction to the line fluid and therefore do not require any external actuation. In this

text, the expected, or desired direction of flow is termed 'forward flow', flow in the opposite direction is

'reverse flow'.

There are a number of reasons for using check valves, which include:

Protection of any item of equipment that can be affected by reverse flow, such as flowmeters,

strainers and control valves.

To check the pressure surges associated with hydraulic forces, for example, waterhammer. These

hydraulic forces can cause a wave of pressure to run up and down pipework until the energy is

dissipated.

Prevention of flooding.

Prevention of reverse flow on system shutdown.

Prevention of flow under gravity.

Relief of vacuum conditions.

Feature

The Steam and

Condensate Loop Book

Although check valves can effectively shut off reverse flow, they should never be used in place of an

isolation valve to contain live steam, in a section of pipe.

As with isolation valves, there are a number of different check valve designs, each suited to specific

applications. The different types of check valve and their applications are discussed in this tutorial, along with

the correct sizing method.

Lift check valves

Lift check valves are similar in configuration to globe valves, except that the disc or plug is automatically

operated. The inlet and outlet ports are separated by a cone shaped plug that rests on a seat typically metal;

in some valves, the plug may be held on its seat using a spring. When the flow into the valve is in the forward

direction, the pressure of the fluid lifts the cone off its seat, opening the valve. With reverse flow, the cone

returns to its seat and is held in place by the reverse flow pressure.

A comprehensive best

practice guide to saving

energy and optimising

plant performance, this

book covers all aspects of

steam and condensate

systems.

Order your copy today

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 1 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

Fig. 12.3.1 A lift check valve

If a metal seat is used, the lift check valve is only suitable for applications where a small amount of leakage,

under reverse flow conditions, is acceptable. Furthermore, the design of a lift check valve generally limits its

use to water applications, subsequently, they are commonly used to prevent reverse flow of condensate in

steam traps and on the outlets of cyclic condensate pumps.

The main advantage of the lift check valve lies in its simplicity, and as the cone is the only moving part, the

valve is robust and requires little maintenance. In addition, the use of a metal seat limits the amount of seat

wear. The lift check valve has two major limitations; firstly, it is designed only for installation in horizontal

pipelines, and secondly, its size is typically limited to DN80, above which, the valve would become too bulky.

The piston-type lift check valve is a modification of the standard lift check valve. It incorporates a piston

shaped plug instead of the cone, and a dashpot is applied to this mechanism. The dashpot produces a

damping effect during operation, thereby eliminating the damage caused by the frequent operation of the

valve, for example, in pipeline systems, which are subject to surges in pressure, or frequent changes in flow

direction (one example would be a boiler outlet).

Swing check valves

A swing check valve consists of a flap or disc of the same diameter as the pipe bore, which hangs down in

the flow path. With flow in the forwards direction, the pressure of the fluid forces the disc to hinge upwards,

allowing flow through the valve. Reverse flow will cause the disc to shut against the seat and stop the fluid

going back down the pipe. In the absence of flow, the weight of the flap is responsible for the closure of the

valve; however, in some cases, closure may be assisted by the use of a weighted lever. As can be seen from

Figure 12.3.2, the whole mechanism is enclosed within a body, which allows the flap to retract out of the flow

path.

Fig. 12.3.2 A full-bodied, swing check valve

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 2 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

Swing check valves produce relatively high resistance to flow in the open position, due to the weight of the

disc. In addition, they create turbulence, because the flap 'floats' on the fluid stream. This means that there is

typically a larger pressure drop across a swing check valve than across other types.

With abrupt changes in flow, the disc can slam against the valve seat, which can cause significant wear of the

seat, and generate waterhammer along the pipe system. This can be overcome by fitting a damping

mechanism to the disc and by using metal seats to limit the amount of seat wear.

Wafer check valves

Both lift and swing check valves tend to be bulky which limits their size and makes them costly. To overcome

this, wafer check valves have been developed. By definition wafer check valves are those that are designed

to fit between a set of flanges. This broad definition covers a variety of different designs, including disc check

valves and wafer versions of swing or split disc check valves.

Disc check valves

The disc check valve consists of four main components: the body, a disc, a spring and a spring retainer. The

disc moves in a plane at right angles to the flow of the fluid, resisted by the spring that is held in place by the

retainer. The body is designed to act as an integral centring collar that facilitates installation. Where a 'zero

leakage' seal is required, a soft seat can be included.

Fig. 12.3.3 A disc check valve

When the force exerted on the disc by the upstream pressure is greater than the force exerted by the spring,

the weight of the disc and any downstream pressure, the disc is forced to lift off its seat, allowing flow through

the valve. When the differential pressure across the valve is reduced, the spring forces the disc back onto its

seat, closing the valve just before reverse flow occurs. This is shown in Figure 12.3.4. The presence of the

spring enables the disc check vale to be installed in any direction.

Fig. 12.3.4 Operation of a disc check valve

The differential pressure required to open the check valve is mainly determined by the type of spring used. In

addition to the standard spring, there are several spring options available:

No spring - Used where the differential pressure across the valve is small.

Nimonic spring - Used in high temperature applications.

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 3 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

Heavy-duty spring - This increases the required opening pressure. When installed in the boiler

feedwater line, it can be used to prevent steam boilers from flooding when they are unpressurised.

As with all wafer check valves, the size of the disc check valve is determined by the size of the associated

pipework. This usually ensures that the valve is correctly sized, but there are cases where the valve is over or

undersized.

An oversized check valve is often indicated by continuous valve chatter, which is the repeated opening and

closing of the valve that occurs when the valve is only partially open. It is caused by the fact that when the

valve opens, there is a drop in the upstream pressure; if this pressure drop means that the differential

pressure across the valve falls below the required opening pressure, the valve will slam shut. As soon as the

valve shuts, the pressure begins to build up again, and so the valve opens and the cycle is repeated.

Oversizing can usually be rectified by selecting a smaller valve, but it should be noted that this will increase

the pressure drop across the valve for any one flow. If this is not acceptable, it may be possible to overcome

the effects of chatter by reducing the closing force on the disc. This can be done either by using a standard

spring instead of a heavy-duty one, or by removing the spring altogether. Another alternative is to use a soft

seat; this does not prevent the chatter but rather, reduces the noise. Care must be taken however, as this

may cause excessive wear on the seat.

Undersizing results in excessive pressure drop across the valve and, in the extreme, it may even prevent

flow. The solution is to replace the undersized valve with a larger one.

Disc check valves are smaller and lighter than lift and standard swing check valves and subsequently cost

less. The size of a disc check valve is however limited to DN125; above this, the design becomes

complicated. Typically, such a design would include a cone shaped disc and a small diameter spring that is

retained and guided along the centre line of the cone, which is more difficult and expensive to manufacture.

Even then, such designs are still limited in size to DN250.

Standard disc check valves should not be used on applications where there is heavily pulsating flow, for

example, on the outlet of a reciprocating air compressor, as the repeated impact of the disc can lead to failure

of the spring retainer and high levels of stress in the spring. Specifically designed retainers are available for

such applications. These designs typically reduce the amount of disc travel, which effectively increases the

resistance to flow and therefore increases the pressure drop across the valve.

The design of disc check valves allows them to be installed in any position, including vertical pipelines where

the fluid flows downwards.

Swing type wafer check valves

These are similar to the standard swing check valves, but do not have the full-bodied arrangement, instead,

when the valve opens, the flap is forced into the top of the pipeline. Subsequently, the flap must have a

smaller diameter than that of the pipeline, and because of this, the pressure drop across the valve, which is

often high for swing type valves, is further increased.

Swing type check valves are used mainly on larger pipeline sizes, typically above DN125, because on

smaller pipelines the pressure drop, caused by the disc 'floating' on the fluid stream, becomes significant.

Furthermore, there are significant cost savings to be made by using these valves on larger sizes, due to the

small amount of material required for the construction of the valve.

There is however one problem with using larger size valves; due to their size, the discs are particularly heavy,

and therefore possess a large amount of kinetic energy when they close. This energy is transferred to the

seat and process fluid when the valve slams shut, which could cause damage to the seat of the valve and

generate waterhammer.

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 4 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

Fig. 12.3.5 Swing type wafer check valve

Wafer check valve applications

Wafer check valves are becoming the preferred type of check valve for most applications, due to their

compact design and relatively low cost. The following is a list of some of their most common applications:

Boiler feedlines - The check valve is used to prevent boiler water being forced back along the

feedline into the storage tank when the feedpump stops running. Furthermore, a disc check valve with

a heavy-duty spring and a soft seat can be fitted in the boiler feedline to prevent flow under gravity

into the boiler when the feedpump is shut off.

Fig. 12.3.6 Boiler feedline applications

Steam traps - Other than with steam traps discharging to atmosphere, check valves should always

be inserted after a steam trap to prevent back flow of condensate flooding the steam space. The

check valve will also prevent the steam trap from becoming damaged by any hydraulic shock in the

condensate line. It should be noted that when using blast discharge type steam traps, the check valve

should be fitted at least 1 m downstream of the trap.

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 5 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

Fig. 12.3.7 Steam trap applications

Hot water circuits - A check valve should be installed after each pump to prevent reverse flow

through the pump when it has been shut off (see Figure 12.3.8).

Fig. 12.3.8 Duplex pump set

Vacuum breakers - Check valves can be used as vacuum breakers, by fitting them in reverse. When

a vacuum is created, the valve opens, allowing air to be drawn in from the atmosphere (see Figure

12.3.9).

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 6 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

Fig. 12.3.9 Steam injection into a tank

Blending - A check valve should be fitted in each supply line to prevent reverse flow along the

different lines which will lead to contamination. A common blending application is the mixing of hot

and cold water to provide hot water (see Figure 12.3.10).

Fig. 12.3.10 Blending applications

Pipeline fitting protection - Check valves are used to prevent damage to equipment such as

flowmeters and control valves, all of which can be damaged by reverse flow. Check valves also stop

the contents of strainers from being deposited in upstream pipework by back flowing fluid.

Multiple boiler applications - A check valve must be inserted on the outlet of each boiler to prevent

any steam flowing into boilers, which may be on hot stand-by (see Figure 12.3.11).

Fig. 12.3.11 Multiple boiler applications

Blowdown vessels - When a blowdown vessel receives blowdown from more than one boiler, a

wafer check valve should be installed on each separate blowdown line. This will prevent the

blowdown from one boiler flowing back into another boiler. In many countries, this is a statutory

requirement.

Flash vessels - A wafer check valve is installed at the flash steam outlet from the flash vessel; this

ensures that steam from any make-up valve does not flow back into the flash vessel (see Figure

12.3.12). A check valve is also installed after the steam trap that drains the flash vessel.

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 7 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

Fig. 12.3.12 Flash vessel applications

Split disc check valves

The split disc check valve or dual plate check valve is designed to overcome the size and pressure drop

limitations of the swing and disc type wafer check valves. The flap of the swing check valve is essentially split

and hinged down its centre, such that the two disc plates will only swing in one direction. The disc plates are

held against the seat by a torsion spring mounted on the hinge.

In order to hold the hinge in the centre of the flow path, externally mounted retainer pins can be used. These

retainer pins are a common source of leakage from the valve. An improved design secures the hinge

internally, and as the valve mechanism is entirely sealed within the body, leakage to atmosphere is prevented

(see Figure 12.3.13).

Fig. 12.3.13 A split disc check valve (retainerless design)

The valve is normally closed, as the disc plates are kept shut by the torsion spring. When fluid flows in the

forwards direction, the pressure of the fluid causes the disc plates to hinge open, allowing flow. The check

valve is closed by the spring as soon as flow ceases, before any reverse flow can occur.

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 8 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

Fig. 12.3.14 Operation of a split disc check valve

The frequent opening and closing of the split disc check valve would soon cause seat damage if the heels of

the disc plates were allowed to scuff against the seat during opening. To overcome this, the heel of the disc

plates lift during the initial opening of the valve and the plates rotate purely on the hinge as opposed to the

seat face.

The split disc type of check valve has several advantages over other types of check valves:

The split disc design is not limited in size and these valves have been produced in sizes of up to

DN5400.

The pressure drop across the split disc check valve is significantly lower than across other types.

They are capable of being used with lower opening pressures.

Split disc check vales can be installed in any position, including vertical pipelines.

Other check valve types

The above mentioned types of check valve are the most commonly encountered types in steam, condensate,

and liquid systems. However, several other types are also available. The three types listed below are mainly

suited to liquid applications and subsequently may be found in condensate systems:

Ball check valve - This consists of a rubber-coated ball that is normally seated on the inlet to the

valve, sealing off the inlet. When pressure is exerted on the ball, it is moved off its seat along a guide

rail, allowing fluid to pass through the inlet. When the fluid pressure drops, the ball slides back into its

position on the inlet seat. Note: Ball check valves are typically only used in liquid systems, as it is

difficult to obtain a tight seal using a ball.

Diaphragm check valve - A flexible rubber diaphragm is placed in a mesh or perforated cone with

the point in the direction of flow in the pipeline (see Figure 12.3.15). Flow in the forwards direction

deflects the diaphragm inwards, allowing the free passage of the fluid. When there is no flow or a

backpressure exists, the diaphragm returns to its original position, closing the valve. Note: The

diaphragm material typically limits the application of the diaphragm check valve to fluids below 180C

and 16 bar.

Fig. 12.3.15 A diaphragm check valve

Tilting disc check valve - This is similar to the swing type check valve, but with the flap pivoted in

front of its centre of pressure and counterweighted or spring loaded to assume a normally closed

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 9 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

position (see Figure 12.3.16). When flow is in the forwards direction, the disc lifts and 'floats' in the

stream offering minimum resistance to flow. The disc is balanced so that as flow decreases, it will

pivot towards its closed position, closing before reverse flow actually commences. The operation is

smooth and silent under most conditions. Note: due to the design of the tilting disc check valve, it is

limited to use on liquid applications only.

Fig. 12.3.16 Operation of a tilting disc check valve

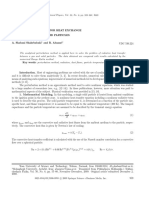

Pressure loss charts

As most types of check valve are suitable for use on both liquid and gas systems, manufacturers typically

show the pressure drop across a valve in the form of a pressure loss chart for water. A typical pressure loss

chart is shown in Figure 12.3.17. It shows the pressure drop across a particular check valve for a given valve

size and water flowrate in m/h.

Fig. 12.3.17 A typical manufacturers pressure loss diagram

In order to determine the pressure drop across the check valve for other liquids, the equivalent water volume

flowrate needs to be calculated, this is done using the formula in Equation 12.3.1:

Equation 12.3.1

Once the equivalent water volume flowrate has been determined, the pressure drop across the valve can be

read off the chart using the same method as for water, selecting the equivalent water volume flowrate instead

of the actual volume flowrate.

It should be noted that the volumetric flowrate (in m/h) is typically quoted for liquid applications, whereas, in

steam applications, the mass flowrate (in kg/h) is normally used. To convert from kg/h to m/h, the mass

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 10 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

flowrate is multiplied by the specific volume (in kg/m) for the particular working pressure and temperature

(see Equation 12.3.2).

Equation 12.3.2

Alternatively, if the Kv value of the valve is specified, the pressure drop across the valve can be determined

using the method outlined in Tutorial 12.2.

Example 12.3.1

Determine the pressure drop across a DN65 check valve passing 1200 kg/h of saturated steam at 8 bar g.

Use the pressure drop characteristics shown in Figure 12.3.17.

Solution:

The first step is to calculate the volumetric flowrate:

From steam tables at 8 bar gauge g = 0.2149 m/kg

Using Equation 12.3.2

Using Figure 12.3.18, the pressure drop across the valve would be approximately 0.085 bar.

Fig. 12.3.18

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 11 sur 12

Check Valves : International site for Spirax Sarco

09/10/2014 11:42

What do I do now?

The printable version of this page has now been replaced by The Steam and Condensate Loop Book

View the complete collection of Steam Engineering Tutorials

Contact Us

http://www.spiraxsarco.com/resources/steam-engineering-tutorials/pipeline-ancillaries/check-valves.asp

Page 12 sur 12

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Friction in PipesDokumen15 halamanFriction in PipesShivesh SohawanBelum ada peringkat

- Measurement of Pressure Distribution Over A Cambered AirfoilDokumen8 halamanMeasurement of Pressure Distribution Over A Cambered AirfoilPraketa SaxenaBelum ada peringkat

- Fathom 9 Slurry ModelDokumen12 halamanFathom 9 Slurry ModeljjirwinBelum ada peringkat

- Burner Management System Safety Integrity Level SelectionDokumen12 halamanBurner Management System Safety Integrity Level SelectionpeterholidayBelum ada peringkat

- Chemical Kinetics of Biomass PyrolysisDokumen10 halamanChemical Kinetics of Biomass Pyrolysiskhali54Belum ada peringkat

- Yao R. MATLAB Programming in 8 Hours. For Beginners... 2021Dokumen121 halamanYao R. MATLAB Programming in 8 Hours. For Beginners... 2021khali54Belum ada peringkat

- La Propagation de FlammeDokumen3 halamanLa Propagation de Flammekhali54Belum ada peringkat

- Ws 2016 13-Pdf-EnDokumen2 halamanWs 2016 13-Pdf-EnMuhammadUsmanSaeedBelum ada peringkat

- OSHA To Inspect Plants Like Ga. Refinery: News NationDokumen2 halamanOSHA To Inspect Plants Like Ga. Refinery: News Nationkhali54Belum ada peringkat

- Pumping Fluids and Getting Fluid To The PumpDokumen3 halamanPumping Fluids and Getting Fluid To The PumpTeng Chuan OngBelum ada peringkat

- Solving ODEs With Matlab Instructors Manual - L.F. ShampineDokumen36 halamanSolving ODEs With Matlab Instructors Manual - L.F. ShampineHermes®Belum ada peringkat

- Pipe Labeling To Ansi Asme A13.1Dokumen3 halamanPipe Labeling To Ansi Asme A13.1khali54Belum ada peringkat

- The Call of The Wild Illustrated - Cs PDFDokumen108 halamanThe Call of The Wild Illustrated - Cs PDFkhali54Belum ada peringkat

- Calculating The Probability of Failure On Demand (PFD) of Complex Structures by Means of Markov ModelsDokumen5 halamanCalculating The Probability of Failure On Demand (PFD) of Complex Structures by Means of Markov ModelsfoamtrailerBelum ada peringkat

- Loss Prevention in Heavy Industry Risk Assessment of LargeDokumen8 halamanLoss Prevention in Heavy Industry Risk Assessment of Largekhali54Belum ada peringkat

- Introduction To MATLAB - Sikander M. MirzaDokumen45 halamanIntroduction To MATLAB - Sikander M. MirzaNasir JumaniBelum ada peringkat

- DEC09ts PDFDokumen19 halamanDEC09ts PDFBoomdayBelum ada peringkat

- Calculating The Probability of Failure On Demand (PFD) of Complex Structures by Means of Markov ModelsDokumen5 halamanCalculating The Probability of Failure On Demand (PFD) of Complex Structures by Means of Markov ModelsfoamtrailerBelum ada peringkat

- Net Positive Suction Head or NPSHDokumen4 halamanNet Positive Suction Head or NPSHsateesh chandBelum ada peringkat

- Pipe Flow Expert Quick Start GuideDokumen35 halamanPipe Flow Expert Quick Start GuideHadrianus Handoko SaputroBelum ada peringkat

- Chemcad 6 User GuideDokumen202 halamanChemcad 6 User Guideerhan ünal100% (1)

- Valeur KV Calcul de Vanne PDFDokumen2 halamanValeur KV Calcul de Vanne PDFkhali54Belum ada peringkat

- Control System Design PDFDokumen6 halamanControl System Design PDFkhali54Belum ada peringkat

- Valeur KV Calcul de Vanne PDFDokumen2 halamanValeur KV Calcul de Vanne PDFkhali54Belum ada peringkat

- Explosions in The Process IndustriesDokumen19 halamanExplosions in The Process Industrieskhali54Belum ada peringkat

- DocuVS7 1 4Dokumen8 halamanDocuVS7 1 4khali54Belum ada peringkat

- Valeur KV Calcul de Vanne PDFDokumen2 halamanValeur KV Calcul de Vanne PDFkhali54Belum ada peringkat

- Perturbation Method For Heat Exchange Between A Gas and Solid Particles 2010 Journal of Applied Mechanics and Technical PhysicsDokumen6 halamanPerturbation Method For Heat Exchange Between A Gas and Solid Particles 2010 Journal of Applied Mechanics and Technical Physicskhali54Belum ada peringkat

- Chapter 14D1 15Dokumen15 halamanChapter 14D1 15khali54Belum ada peringkat

- Chemical Exposure IndexDokumen23 halamanChemical Exposure IndexwankartikaBelum ada peringkat

- Inherent SafetyDokumen16 halamanInherent Safetykirandevi1981Belum ada peringkat

- ExlopaDokumen8 halamanExlopakhali54Belum ada peringkat

- Simplified Risk Analysis (LOPA)Dokumen8 halamanSimplified Risk Analysis (LOPA)hmatora72_905124701Belum ada peringkat

- Fundamentals of Aerodynamics 6 EditionDokumen14 halamanFundamentals of Aerodynamics 6 EditionFernando AlexisBelum ada peringkat

- Descargar PDF W-XDokumen2 halamanDescargar PDF W-XEDWIN VACABelum ada peringkat

- UOA - Cold Water Pipe SizingDokumen4 halamanUOA - Cold Water Pipe SizingDuoc Su HoangBelum ada peringkat

- (Chapter 5) The Energy EquationDokumen14 halaman(Chapter 5) The Energy EquationKarwan GoodBelum ada peringkat

- Investigation On A Blockerless Cascade Thrust Reverser System Based On Response Surface MethodDokumen13 halamanInvestigation On A Blockerless Cascade Thrust Reverser System Based On Response Surface MethodNguyễn Đức HuyBelum ada peringkat

- ChemEngineering 04 00063 v2Dokumen22 halamanChemEngineering 04 00063 v2Akademski TrudoviBelum ada peringkat

- An Openfoam Implementation of Ice Accretion For Rotorcraft: June 2010Dokumen17 halamanAn Openfoam Implementation of Ice Accretion For Rotorcraft: June 2010Rahul Kumar SoniBelum ada peringkat

- BIOMEDE 331 - The Belmont LabDokumen13 halamanBIOMEDE 331 - The Belmont LabjimBelum ada peringkat

- Experiment - 6: Cascade ControlDokumen13 halamanExperiment - 6: Cascade ControlMilan PoudelBelum ada peringkat

- Unit 4 Ideal Fluid Flow: StructureDokumen20 halamanUnit 4 Ideal Fluid Flow: Structureanon_739713012Belum ada peringkat

- Convection in Internal FlowsDokumen7 halamanConvection in Internal Flowsmsnaghavi100% (1)

- CFD Analysis of Steam Boiler Tube Used in Power Plant Ijariie15034Dokumen10 halamanCFD Analysis of Steam Boiler Tube Used in Power Plant Ijariie15034ADVOKASI PPI MALAYSIABelum ada peringkat

- Chapter 2 - Open ChannelDokumen51 halamanChapter 2 - Open Channeladeliene 25Belum ada peringkat

- Chapter 6 - Flow in A Process Injection Mixing PipeDokumen16 halamanChapter 6 - Flow in A Process Injection Mixing PipeFausto Ali Salomon Guerrero ParraBelum ada peringkat

- Vortex Breakdown: A Review: O. Lucca-Negro, T. O'DohertyDokumen51 halamanVortex Breakdown: A Review: O. Lucca-Negro, T. O'DohertySALAH EDDINE SALAHBelum ada peringkat

- 2020-10-MEC441-Assignment 2Dokumen3 halaman2020-10-MEC441-Assignment 2Raziq Haiqal MuhammadBelum ada peringkat

- In47 Instrument Impulse Piping Hook-UpDokumen20 halamanIn47 Instrument Impulse Piping Hook-UpTTRRTTGFBelum ada peringkat

- Ebook College Physics 4Th Edition Giambattista Test Bank Full Chapter PDFDokumen55 halamanEbook College Physics 4Th Edition Giambattista Test Bank Full Chapter PDFkennethalandlj1f100% (11)

- Mechanical Engineering Fluid-Mechanics Differential-Equations Notes PDFDokumen167 halamanMechanical Engineering Fluid-Mechanics Differential-Equations Notes PDFAditya GirgeBelum ada peringkat

- EmpiricalDokumen1 halamanEmpiricalBrijesh GajjarBelum ada peringkat

- DS62 - (1985) The Relationship Between High-Temperature Oil Rheology and Engine OperationDokumen104 halamanDS62 - (1985) The Relationship Between High-Temperature Oil Rheology and Engine OperationJacques StrappeBelum ada peringkat

- Dental Materials Lecture - Mechanical PropertiesDokumen27 halamanDental Materials Lecture - Mechanical PropertiesFatima SiddiquiBelum ada peringkat

- Hpu 17H007 - enDokumen401 halamanHpu 17H007 - enJIMYJONBelum ada peringkat

- Highlights in The History of Hydraulics ROUSEDokumen16 halamanHighlights in The History of Hydraulics ROUSEAlberto Polo CuetoBelum ada peringkat

- The in Uence of Contact Zone Configuration On The Ow Structure in A Dissolved Air Otation Pilot PlantDokumen11 halamanThe in Uence of Contact Zone Configuration On The Ow Structure in A Dissolved Air Otation Pilot PlantAnaSouzaEQBelum ada peringkat

- Design and Construction of A Remote Piloted Flying WingDokumen187 halamanDesign and Construction of A Remote Piloted Flying WinglufabaoBelum ada peringkat