API 510 PC 20 31 Aug05 Final Exam Open

Diunggah oleh

nikafiqDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

API 510 PC 20 31 Aug05 Final Exam Open

Diunggah oleh

nikafiqHak Cipta:

Format Tersedia

FINAL EXAM (OPEN)

Instructions:

Choose only one answer, which you think is most appropriate.

Use the attached answer sheet in answering the following questions.

1.

8 mm

10 mm

12mm

14 mm

During the recent planned internal inspection showed two pits of following

description. (Min. vessel thickness required = 5/8 including C.A = 1/8). Pits

are separated by 12 inch distance (edge to edge).

Pit A: Available thickness at bottom of pit = 0.4 inch.

Pit dia. = 1.5

Pit B: Available thickness at bottom of pit = 0.34 inch.

Pit dia. = 0.75

Your assessment is:

a.

Pitting is not harmful hence acceptable

b.

Pit A may be ignored but not Pit B

c.

Pit B may be ignored but not Pit A

d.

Both pits can not be ignored

Following combination of Base metal and welding electrode was qualified by

a certain PQR. Impact testing is not required.

Base Metal = SA 285 Gr C Plates, 3/4" thk

Welding electrode = AWS E 7015,

This PQR will qualify which of the following combinations of Base Metal

Welding electrodes.

44 mm

47 mm

48.5 mm

50 mm

What will be the size of nozzle to shell weld for nozzle weld

configuration? Conforming to Fig.-j of UW-16. (Nom. Shell thickness =

28 mm., Nom. Nozzle thickness = 16mm., weld size t2= 12mm)

a.

b.

c.

d.

3.

4.

For UT examination using Pulse- Echo Technique, thickness calibration

was performed at 80F. An on-stream UT reading at a TML on a

pressure vessel (operating at 680F) was indicated as 50 mm. Its actual

thickness will be approximately:

a.

b.

c.

d.

2.

FINAL EXAM (OPEN)

5.

6.

7.

a.

1" thk SA 515gr 60 plates, E 6013 electrodes

b.

1 " thk SA 285 grc plates, E 6013 electrodes

c.

1 thk plates plates SA516gr70, E 7018 electrodes

d.

None of above

The recommended minimum development time in minutes allowed for a

material made of high temperature alloy is:

a.

5 min

b.

15 min

c.

10 min

d.

6 min

A weld procedure is qualified in 1G position. This procedure can be used for

welding in positions:

a.

1G

b.

2G

c.

4G

d.

All of the positions

A 1 thickness C.S. weld with 1/8 thk acceptable reinforcement was to be

radiographed. The applicable hole type penetrameter on (source side) and

essential hole shall be:

a.

b.

c.

d.

ASME 30 - 2T

ASME 25 - 2T

ASME 20 - 2T

ASME 30 - 4T

FINAL EXAM (OPEN)

8.

A radiograph for a long seam in new pressure vessel (UW 51) of 25mm thick

plate shows 3mm crack, and 6 mm long isolated slag. Your decision for

acceptance of the radiograph will be:

a.

b.

c.

d.

9.

10.

11.

c.

d.

13.

Full radiography

Spot radiography

5 to 32 mm

0 to 16 mm

Any thickness

0 to 32 mm

In liquid penetrant testing, a procedure is qualified to a temperature of 15

degree C. Pick up a correct statement.

a.

b.

c.

d.

15.

Normally required

Subject to approval of the jurisdiction , appropriate NDE shall be

required where pressure test is not performed

Substituting NDE for a pressure test after an alteration ay be

done only after consulting a pressure vessel engineer

experienced in pressure vessel design

All of the above

A procedure qualification test was carried out for a groove weld on a plate

with weld metal thickness of 16 mm thickness by SMAW process. The test

was found satisfactory. This procedure can be used with SMAW for weld

thickness of:

a.

b.

c.

d.

14.

May be a, or b depending on joint efficiency

Data is not adequate

After completion of alterations a pressure test is:

a.

b.

SA 515 GR 60 failed but 516 gr 60 would not have failed

516gr 60 would not have made any difference

Impact strength was not apparent reason for failure

b and c above

A pressure vessel constructed according to ASME Sec. VIII, Div. 1 with shell

thickness 7/8 (Material of Construction P No. 4, group no. 1) is to be

repaired by using insert plates. The requirement of radiography to be

incorporated in repair procedure shall be:

a.

b.

12.

2.0

mm

2.4

mm

1.2

mm

None of above

For vessel 2.5 inch thick, MDMT specified was 60F and material of

construction used was SA 515 gr 60, without impact testing. The vessel

failed later due to brittle failure. Maintainance Department says SA 516 GR

60 should have been used. What is your assessment?

a.

b.

c.

d.

c.

d.

Repair crack, repair slag

Repair slag, accept crack

Repair crack, accept slag

Accept crack, accept slag

For a vessel which is planned for internal inspection after 8 years what should

be the minimum remaining corrosion allowance in the vessel if corrosion rate

is 150 microns per year.

a.

b.

c.

d.

FINAL EXAM (OPEN)

The same procedure is qualified from 100C to 520C

The same procedure is restricted to maximum of 150C only

The same procedure shall be applied to 5 0C to 100C

The same procedure shall be applied to temperature more than

150C

An in-service vessel with seamless 2:1 Ellipsoidal head 60 inch ID, 400 psi

design pressure, (corrosion allowance = 0) and (S = 20000 psig) was

inspected. Available thickness of only 5/8 was observed on the crown

FINAL EXAM (OPEN)

FINAL EXAM (OPEN)

portion. The knuckle thickness was found to be adequate. Your assessment

is:

a.

b.

c.

d.

16.

Head thickness in crown portion is still ok for

operation.

Thickness is inadequate.

Depends on the opinion of third party inspector

Depends on the opinion of API 510 inspector

b.

c.

19.

Choose correct hydrostatic test pressure from given options for a vessel with

following data:

20.

Design pressure

Design temperature

M.O.C

Allow stress (Ambient)

Allow stress (675F)

a.

b.

c.

d.

17.

=

=

=

=

=

200 psi

675 F

SA 537 Cl.1

18,000 psi

15,000 psi

a.

Penetrant testing wet developer

b.

Magnetic particle testing with dry particles-prod type

c.

Magnetic particle testing with dry particles-yoke type

d. None of above

18.

A weld procedure is qualified on pipe OD = 2, in 1G position. This

procedure can be used for welding:

a.

6 OD pipe in 1G only

d.

Pipes smaller than 2 OD in 1G only

During the External inspection, observed resistance of electrical grounding

connections for Pressure vessels was 42 ohms. Your advice is:

a.

Accept

b.

Resistance must be reduced to 25 Ohms Maximum

c.

Resistance must be increased to 25 Ohms minimum

d.

Depends on opinion of electrical engineer.

For a certain nozzle to shell joint (No corrosion allowance is required.)

following data is presented.

Shell thickness provided

Nozzle I.D.

Pad size

Thickness of pad

350 psig

260 psig

312 psig

None of above

The temperature measured at a weld layer for a magnetic material is around

450C, but weld is in vertical position. It is decided to carryout a surface NDT

method. Choose a suitable NDT method.

2 OD pipe in 1G only

Any diameter pipe in any position

=

=

=

=

0.42 inch.

3.2 in.

6.4 in. O. D.

0.42.

Your assessment is:

21.

a.

Nozzle is adequately reinforced.

b.

Reinforcement is inadequate.

c.

Data is inadequate: nozzle thickness must be given.

d.

Data is inadequate: design shell thickness must be given.

For procedure qualifications with the GTAW process _______ is Nonessential variable.

a.

b.

c.

d.

Change of P No.

Change of A No.

Change of F No.

Groove design

FINAL EXAM (OPEN)

22.

23.

24.

25.

The crown portion for torispherical head (ID=40 inches) may be considered

as the portion lying entirely within a circle whose centre will be same as

head centre and diameter will be:

a.

36

b.

40

c.

32

d.

200

For 2:1 Ellip. Head (ID=75 inches), the crown portion would lie within similar

circle of diameter:

a.

60

b.

30

c.

54

d.

48

In liquid penetrant examination the maximum permitted rounded indication

size for circumferential welds with plate thickness up to 1 inch will be:

a.

1/8

b.

1/16

c.

3/16

d.

For a vertical process column with column ID. = 48'' and height (tan-tan) =98

ft., the hydrostatic head for bottom dished head (2:1 Ellip. type) will be:

a.

40.6 psi

b.

42.4 psi

c.

43.3 psi

d.

None of above

26. Leak tightness of the relief valves is tested by conducting:

a.

b.

c.

d.

Water Bubble test with water head = 0.5 at the set pressure

Water Bubble test with water head = 1.0 at set pressure

Water Bubble test with water head = 0.5 at 90% of the set

pressure

None of above

FINAL EXAM (OPEN)

27.

28.

29.

30.

Estimated rate of Sulphidation corrosion for a crude handing equipment due

to sulpher content of 0.5% (by weight) at 6000F is 10 mpy. What will be the

corrosion rate if sulpher content is 1.0% by weight?

a.

10 mpy approximately

b.

12 mpy approximately

c.

15 mpy approximately

d.

20 mpy approximately

Suggest suitable construction materials for caustic service having 40%

Na0H concentration (by weight) operating at 2400F

a.

Carbon steel with PWHT

b.

Carbon Steel, but PWHT is not required

c.

Carbon steels with quenched and tempering treatment

d.

Consider Use of Nickel alloys.

To avoid HTHA, suggest suitable materials of construction for hydrogen

service with partial pressure of hydrogen = 1500psi, and temperature =

8000F

a.

Carbon steel

b.

1.25 Cr 0.5 Mo

c.

2.25 Cr 1 Mo

d.

1 Cr 0.5 Mo

In typical refinery service, PWHT of 2.25 Cr 1 Mo steel is generally

required if hardness values in base metal and HAZ is

a.

b.

c.

d.

Higher than 241 Brinell

Lower than 241 Brinell

Higher than 225 Brinell

Lower than 225 Brinell

-------------------------------- End -----------------------------------

Anda mungkin juga menyukai

- Non-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingDari EverandNon-Destructive Evaluation of Corrosion and Corrosion-assisted CrackingRaman SinghBelum ada peringkat

- 510 IRS Pune Open Book Questions FinalDokumen6 halaman510 IRS Pune Open Book Questions Finaljaheer1Belum ada peringkat

- Daily Exam 2 (Open)Dokumen3 halamanDaily Exam 2 (Open)nikafiqBelum ada peringkat

- API 510 PC 20 31 Aug05 Bench MarkDokumen4 halamanAPI 510 PC 20 31 Aug05 Bench MarknikafiqBelum ada peringkat

- API 510 Closed 5Dokumen5 halamanAPI 510 Closed 5Einsteinw2Belum ada peringkat

- Api 577 Question-02Dokumen2 halamanApi 577 Question-02korichiBelum ada peringkat

- API 510 Data Sheet - AnswersDokumen11 halamanAPI 510 Data Sheet - Answersnikafiq100% (1)

- All You Need To Know About API 571 Corrosion and MaterialsDokumen13 halamanAll You Need To Know About API 571 Corrosion and MaterialsMasood KhanBelum ada peringkat

- API 510 Closed Exam PART IDokumen22 halamanAPI 510 Closed Exam PART ImaorealesBelum ada peringkat

- Sudhy+api+510 2Dokumen310 halamanSudhy+api+510 2sheikmoinBelum ada peringkat

- API 570 Questions 13Dokumen4 halamanAPI 570 Questions 13Ravindra S. JivaniBelum ada peringkat

- 10 MCQS API 510 Anees Ul HasnainDokumen126 halaman10 MCQS API 510 Anees Ul HasnaintayyabBelum ada peringkat

- Api 510 - Book 6Dokumen120 halamanApi 510 - Book 6Tauqeer SalimBelum ada peringkat

- 12) Api 510 Day 4Dokumen67 halaman12) Api 510 Day 4hamedBelum ada peringkat

- API 570 Questions 12Dokumen5 halamanAPI 570 Questions 12Ravindra S. JivaniBelum ada peringkat

- API 570 Questions 19Dokumen4 halamanAPI 570 Questions 19Ravindra S. Jivani100% (1)

- API 510 Data Sheets - QuizletDokumen1 halamanAPI 510 Data Sheets - Quizletads_1203Belum ada peringkat

- API-510 Pressure Vessel Inspector Preparatory Training Program Final Exam - (Close Book)Dokumen3 halamanAPI-510 Pressure Vessel Inspector Preparatory Training Program Final Exam - (Close Book)Ali AhmedBelum ada peringkat

- Sis Book1Dokumen99 halamanSis Book1Hamza AlamBelum ada peringkat

- API-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFDokumen23 halamanAPI-570-Exam-100-Q (계산문제 정리할수 있는 문제) PDFasBelum ada peringkat

- Api 510 Q&a-2Dokumen32 halamanApi 510 Q&a-2Mohammed ShakilBelum ada peringkat

- API 510 Data Sheet - AnswersDokumen6 halamanAPI 510 Data Sheet - Answersjithinjose86Belum ada peringkat

- API 570 Practice Questions and AnswersDokumen4 halamanAPI 570 Practice Questions and AnswersAshwani Dogra100% (1)

- 60 Multiple Choice Questions: No Answer GivenDokumen21 halaman60 Multiple Choice Questions: No Answer GivenAnonymous Q4YUvRBelum ada peringkat

- API 570 Exam QuastionsDokumen18 halamanAPI 570 Exam QuastionsBernathTurnipBelum ada peringkat

- API 570 DAY 2 BOOK (1 To 51)Dokumen66 halamanAPI 570 DAY 2 BOOK (1 To 51)Abdul Qhadeer AnsariBelum ada peringkat

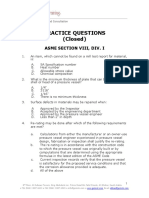

- Practice Questions (Closed) : Asme Section Viii, Div. IDokumen30 halamanPractice Questions (Closed) : Asme Section Viii, Div. Ihoussem khelilBelum ada peringkat

- API 570 Day 5 Book (1 To 130)Dokumen137 halamanAPI 570 Day 5 Book (1 To 130)melvinBelum ada peringkat

- Examination Question 510Dokumen12 halamanExamination Question 510ohengjkt100% (1)

- Api 510Dokumen7 halamanApi 510Ranaweera AriyamanjulaBelum ada peringkat

- API-510 Closed Book (Vérifié Lors Du Test) FLASH CARDSDokumen31 halamanAPI-510 Closed Book (Vérifié Lors Du Test) FLASH CARDSfathiBelum ada peringkat

- API-570 SAMPLE Closed Book ExamDokumen12 halamanAPI-570 SAMPLE Closed Book ExamuttamBelum ada peringkat

- API571 - NEW APP - Effective 2011 - CompletedDokumen12 halamanAPI571 - NEW APP - Effective 2011 - Completedtong2jeBelum ada peringkat

- API 510 Open Book Practice ExamDokumen48 halamanAPI 510 Open Book Practice Examcorey jacobsBelum ada peringkat

- Bay.t-510 Close Prac Exam #3Dokumen22 halamanBay.t-510 Close Prac Exam #3Karim Mamdouh50% (2)

- CKRC API 510 WORKBOOK MODULE 1 Rev 1Dokumen7 halamanCKRC API 510 WORKBOOK MODULE 1 Rev 1morneBelum ada peringkat

- 510 Closed Exam ADokumen24 halaman510 Closed Exam AAPIBelum ada peringkat

- Api 510 - 2015 PDFDokumen11 halamanApi 510 - 2015 PDFYasser Abd El FattahBelum ada peringkat

- Open Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedDokumen16 halamanOpen Book API 510 Practice Exam B Do Not Mark On Your Exam, Use The Answer Sheets ProvidedBeantickBelum ada peringkat

- API 510 QuestionDokumen2 halamanAPI 510 QuestionIsey MohdBelum ada peringkat

- MSTS Mark's API 510 STUDY GUIDE.Dokumen30 halamanMSTS Mark's API 510 STUDY GUIDE.Hares SlalBelum ada peringkat

- Api 510 MSTSDokumen1 halamanApi 510 MSTSAbu Huraira50% (2)

- Api 510, 2015Dokumen5 halamanApi 510, 2015Mohmed AllamBelum ada peringkat

- Api 510 Close Book - 14Dokumen6 halamanApi 510 Close Book - 14tayyabBelum ada peringkat

- API 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsDokumen6 halamanAPI 570 Calcs Summary Page 1 of 6: T Required (Minimum Required Thickness) CalcsIbtehaj ManiBelum ada peringkat

- API 570 Questions 09 API-571-577Dokumen5 halamanAPI 570 Questions 09 API-571-577Ravindra S. JivaniBelum ada peringkat

- API 570-Final Model Exam-Closed Book Without AnswersDokumen9 halamanAPI 570-Final Model Exam-Closed Book Without AnswersbananaBelum ada peringkat

- Api 578-Mock 1 - KeyDokumen28 halamanApi 578-Mock 1 - KeysheikmoinBelum ada peringkat

- LADWER API 510 - API RP 577 April 2017Dokumen7 halamanLADWER API 510 - API RP 577 April 2017Luthfi ArdiansyahBelum ada peringkat

- Typical QUESTIONS in May 2015 API 510 Exam (: # HthaDokumen5 halamanTypical QUESTIONS in May 2015 API 510 Exam (: # HthaabdoBelum ada peringkat

- ch6 - API 571 PDFDokumen20 halamanch6 - API 571 PDFRAMADOSSBelum ada peringkat

- API 577 Questions Scope and DefinitionsDokumen10 halamanAPI 577 Questions Scope and DefinitionsmaorealesBelum ada peringkat

- Closed Book Api 572-A (55-65) - 2Dokumen11 halamanClosed Book Api 572-A (55-65) - 2slxanto100% (1)

- API 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationDokumen8 halamanAPI 570 Authorized Piping Inspector Preparatory Program: Open Book Mockup ExaminationmelvinBelum ada peringkat

- API 571+à+ç+å+Dokumen7 halamanAPI 571+à+ç+å+Bilal Ghazanfar100% (1)

- API 510 Exam Q.bank-V VVV ImportantDokumen138 halamanAPI 510 Exam Q.bank-V VVV ImportantJeganeswaranBelum ada peringkat

- API 510 Open Book Q&ADokumen138 halamanAPI 510 Open Book Q&AMohammed Shakil25% (4)

- API 510 Mid-Session Exam (Open Book) : Instructions: Choose Only One Answer Which You Think Is Most AppropriateDokumen6 halamanAPI 510 Mid-Session Exam (Open Book) : Instructions: Choose Only One Answer Which You Think Is Most AppropriatesnamprogBelum ada peringkat

- 510 PC Oct04 Qar-Mid Open PSJDokumen7 halaman510 PC Oct04 Qar-Mid Open PSJCss SfaxienBelum ada peringkat

- WIS5 Consumables PDFDokumen29 halamanWIS5 Consumables PDFnikafiqBelum ada peringkat

- API 510 PC Final Exam ClosedDokumen12 halamanAPI 510 PC Final Exam ClosedAbdel-Rahman Taha Merdan100% (1)

- API 577 Closed Books Questions AnswersDokumen3 halamanAPI 577 Closed Books Questions Answersnikafiq100% (5)

- API 510 572 576 Questions AnswersDokumen33 halamanAPI 510 572 576 Questions Answersnikafiq100% (7)

- Arriving in Australia - Declare It!: Australian BiosecurityDokumen2 halamanArriving in Australia - Declare It!: Australian BiosecuritynikafiqBelum ada peringkat

- API 510 Data Sheet - AnswersDokumen11 halamanAPI 510 Data Sheet - Answersnikafiq100% (1)

- API 571 Study GuideDokumen8 halamanAPI 571 Study Guidenikafiq100% (5)

- HR Wallingford-009 - Wave - GaugeDokumen2 halamanHR Wallingford-009 - Wave - GaugeSutanto HadiBelum ada peringkat

- Reliability Analysis Center: Practical Considerations in Calculating Reliability of Fielded ProductsDokumen24 halamanReliability Analysis Center: Practical Considerations in Calculating Reliability of Fielded ProductsNg Wei LihBelum ada peringkat

- Calculation Sheet Boiler Control BuildingDokumen35 halamanCalculation Sheet Boiler Control BuildingKhamal Rachmanda AdamBelum ada peringkat

- Mechanics of MaterialsDokumen11 halamanMechanics of MaterialsMagesh KumarBelum ada peringkat

- Free Computer Fundamentals and Programming in C by Reema TharejaDokumen5 halamanFree Computer Fundamentals and Programming in C by Reema TharejaGopi S0% (1)

- Arthashastra: Citation NeededDokumen4 halamanArthashastra: Citation NeededtusharBelum ada peringkat

- MCAT Uhs Past Paper (2008-2016)Dokumen180 halamanMCAT Uhs Past Paper (2008-2016)Abdullah SheikhBelum ada peringkat

- Lab ReportDokumen5 halamanLab Reportivan glenn baldomerostBelum ada peringkat

- Circuits in MatlabDokumen38 halamanCircuits in MatlabRana UsmanBelum ada peringkat

- Hide Answer Notebook Notebook Discuss: Here Is The Answer and ExplanationDokumen16 halamanHide Answer Notebook Notebook Discuss: Here Is The Answer and ExplanationPayashwini KulkarniBelum ada peringkat

- 351 DatasheetDokumen14 halaman351 DatasheetRafael NavarroBelum ada peringkat

- Energy Audit Report by CPRIDokumen247 halamanEnergy Audit Report by CPRImag_ktps20021520100% (2)

- Vogue 201602 Japan PDFDokumen254 halamanVogue 201602 Japan PDFJack Douglas YooBelum ada peringkat

- Codigo Ficheros PHPDokumen33 halamanCodigo Ficheros PHPm_montielBelum ada peringkat

- Oracle Database 11g Transparent Data EncryptionDokumen40 halamanOracle Database 11g Transparent Data EncryptionYelena BytenskayaBelum ada peringkat

- Final Formula SheetDokumen1 halamanFinal Formula SheetFaryalBelum ada peringkat

- Summative Test in Grade 10 Science PDF FreeDokumen2 halamanSummative Test in Grade 10 Science PDF FreeMalyn ReyesBelum ada peringkat

- Electric Power Applications, Engine & Generator SizingDokumen120 halamanElectric Power Applications, Engine & Generator SizingDIPPOSBelum ada peringkat

- Penn State University Press Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To Philosophy & RhetoricDokumen16 halamanPenn State University Press Is Collaborating With JSTOR To Digitize, Preserve and Extend Access To Philosophy & RhetoricvanduongBelum ada peringkat

- MAJOR14Dokumen14 halamanMAJOR14swathi100% (1)

- Traulsen RLT - ALT Freezer DUTDokumen2 halamanTraulsen RLT - ALT Freezer DUTwsfc-ebayBelum ada peringkat

- SMO Senior 2017Dokumen6 halamanSMO Senior 2017Kanchit SaehoBelum ada peringkat

- Upcoming: Advisor Webcast: Oracle Database Resource ManagerDokumen41 halamanUpcoming: Advisor Webcast: Oracle Database Resource ManagerLayne MoránBelum ada peringkat

- Microsoft WordDokumen79 halamanMicrosoft Wordthamel_09Belum ada peringkat

- JAVA NotesDokumen12 halamanJAVA NotesVarun BawaBelum ada peringkat

- SAP QM Calibration MethodDokumen3 halamanSAP QM Calibration MethodvrkattulaBelum ada peringkat

- (John F. Moulder) PHI Handbook of XRay Photoelectron SpectrosDokumen192 halaman(John F. Moulder) PHI Handbook of XRay Photoelectron SpectrosCamilo CorredorBelum ada peringkat

- SOPRANO TIM SMTP Interface Developers GuideDokumen43 halamanSOPRANO TIM SMTP Interface Developers GuidenettellectBelum ada peringkat

- Ethernet Managed Phoenix Contact 2702331 enDokumen25 halamanEthernet Managed Phoenix Contact 2702331 enshankar kumarBelum ada peringkat

- Vector AlgebraDokumen7 halamanVector AlgebraDeeeBelum ada peringkat

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontDari EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontPenilaian: 4.5 dari 5 bintang4.5/5 (18)

- Slow Violence and the Environmentalism of the PoorDari EverandSlow Violence and the Environmentalism of the PoorPenilaian: 4 dari 5 bintang4/5 (5)

- The Cyanide Canary: A True Story of InjusticeDari EverandThe Cyanide Canary: A True Story of InjusticePenilaian: 4 dari 5 bintang4/5 (52)

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionDari EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionPenilaian: 3 dari 5 bintang3/5 (1)

- Desperate: An Epic Battle for Clean Water and Justice in AppalachiaDari EverandDesperate: An Epic Battle for Clean Water and Justice in AppalachiaPenilaian: 4 dari 5 bintang4/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretDari EverandWaste: One Woman’s Fight Against America’s Dirty SecretPenilaian: 5 dari 5 bintang5/5 (1)

- Principles of direct and superior responsibility in international humanitarian lawDari EverandPrinciples of direct and superior responsibility in international humanitarian lawBelum ada peringkat

- Did Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksDari EverandDid Your Can of Soda Kill A Whale? Water Pollution for Kids | Children's Environment BooksBelum ada peringkat

- Reduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksDari EverandReduce, Reuse and Recycle : The Secret to Environmental Sustainability : Environment Textbooks | Children's Environment BooksBelum ada peringkat

- Introduction to Ecology and Environmental Laws in IndiaDari EverandIntroduction to Ecology and Environmental Laws in IndiaBelum ada peringkat

- The Rights of Nature: A Legal Revolution That Could Save the WorldDari EverandThe Rights of Nature: A Legal Revolution That Could Save the WorldPenilaian: 5 dari 5 bintang5/5 (1)

- Busted!: Drug War Survival Skills and True Dope DDari EverandBusted!: Drug War Survival Skills and True Dope DPenilaian: 3.5 dari 5 bintang3.5/5 (7)

- 3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionDari Everand3rd Grade Science: Life Sciences in Eco Systems | Textbook EditionBelum ada peringkat

- Land Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Dari EverandLand Divided by Law: The Yakama Indian Nation as Environmental History, 1840-1933Belum ada peringkat

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontDari EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle against DuPontPenilaian: 4.5 dari 5 bintang4.5/5 (9)

- Environmental Education in Practice: Concepts and ApplicationsDari EverandEnvironmental Education in Practice: Concepts and ApplicationsBelum ada peringkat

- Dawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawDari EverandDawn at Mineral King Valley: The Sierra Club, the Disney Company, and the Rise of Environmental LawPenilaian: 4 dari 5 bintang4/5 (334)

- Ecosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksDari EverandEcosystem Facts That You Should Know - The Forests Edition - Nature Picture Books | Children's Nature BooksBelum ada peringkat

- Obstacles to Environmental Progress: A U.S. perspectiveDari EverandObstacles to Environmental Progress: A U.S. perspectiveBelum ada peringkat