Lecture4 - Characterization of Solid Surfaces - SPM - AFM Etc

Diunggah oleh

Ayyanna HabalJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Lecture4 - Characterization of Solid Surfaces - SPM - AFM Etc

Diunggah oleh

Ayyanna HabalHak Cipta:

Format Tersedia

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

Characterization of Solid Surfaces

Dr. Pallab Ghosh

Associate Professor

Department of Chemical Engineering

IIT Guwahati, Guwahati781039

India

Joint Initiative of IITs and IISc Funded by MHRD

1/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

Table of Contents

Section/Subsection

2.4.1 Introduction

2.4.2 Microscopy of surfaces

Page No.

3

313

2.4.2.1 Fluorescence microscopy

2.4.2.2 Confocal microscopy

2.4.2.3 Electron microscopy

2.4.2.4 Scanning probe microscopy

713

2.4.2.4.1 Scanning tunneling microscopy (STM)

2.4.2.4.2 Atomic force microscopy (AFM)

10

2.4.3 Spectroscopy of surfaces

1318

2.4.3.1 Auger electron spectroscopy (AES)

14

2.4.3.2 X-ray photoelectron spectroscopy (XPS)

15

2.4.3.3 Secondary ion mass spectrometry (SIMS)

16

2.4.3.4 Attenuated total reflectance spectroscopy (ATR)

17

2.4.3.5 Total internal reflectance fluoroscopy (TIRF)

18

Exercise

19

Suggested reading

20

Joint Initiative of IITs and IISc Funded by MHRD

2/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

2.4.1 Introduction

A number of microscopic and spectroscopic methods are available which provide

information about the structure of a solid surface and its composition. In this lecture, we

will discuss some of these methods.

2.4.2 Microscopy of surfaces

The optical data are usually in the form of an instantaneously obtained twodimensional map of a patch of the surface. Conventional optical microscopy can

resolve feature down to about 0.5 m.

When light from various feature points in the object are reconstituted in the image,

the image points are not new points, but small disks called Airy disks which contain

diffraction patterns. When the diffraction patterns surrounding the neighboring image

feature points start to overlap, these points are not resolvable.

The minimum object distance d between resolvable points depends on the size of

the Airy disks, which depends on the wavelength of light in the medium between the

object and the objective lens , and the fraction of the light emanating from an

object point captured by the objective lens of the microscope.

This depends on the ratio of the lens diameter to the distance between the object and

the lens. The resolution d for the case of reflected light (non-luminous objects) is

given by,

2n sin

(2.4.1)

where 0 is the wavelength of light in vacuo, n is the refractive index of the medium

and is the polar angle subtended by the lens (see Fig. 2.4.1).

Fig. 2.4.1 Optical microscopy.

Joint Initiative of IITs and IISc Funded by MHRD

3/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

The quantity n sin is called numerical aperture. Since the maximum possible value

of is 2 , sin 1 . For air n 1 , the upper limit of numerical aperture for a dry

objective is practically less than unity.

If the gap between the object and the lens is filled with oil which has n 1 , the

aperture can be increased. The usual oil for oil immersion objective has n 1.515 ,

which renders an upper limit for the aperture of about 1.4.

The resolution (minimum value of d ) of an optical microscope is thus roughly half

the wavelength of the light for a dry objective, and one-third the wavelength of the

light for an oil immersion objective.

2.4.2.1 Fluorescence microscopy

Various methods of surface staining or marking may be used to enhance contrast

between the features of the surface. One of the most powerful methods is the use of

fluorescent markers.

Fluorescence microscopy is very powerful for the examination of biological surface

since fluorophors can be designed to attach to certain surface chemical

functionalities. The fluorophor absorbs photon energy of a particular wavelength and

very quickly (in nanoseconds) re-emits light of a slightly longer wavelength.

The difference between the excitation and the re-emission wavelengths is called

Stokes shift. It is the basis for spectrally separating the incoming and outgoing

radiation.

A strong illumination source is required because the number of fluorophors present is

small, and their quantum efficieny is low. The fluorescence microscopy of a

patterened surface is shown in Fig. 2.4.2.

Joint Initiative of IITs and IISc Funded by MHRD

4/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

Fig. 2.4.2 Fluorescence microscope image of a patterned biosurface.

2.4.2.2 Confocal microscopy

Confocal microscopy is a variation of the fluorescence microscopy. The present-day

technique is known as laser scanning confocal microscopy. It permits high-resolution

optical sectioning through thick specimens.

This method is extensively used to make three-dimensional scans in solutions, and at

biological interfaces.

The light source is a high-intensity laser point source. The light is reflected off the

dichroic mirror. Then, by means of the objective lens, it is brought to focus on a

sharp diffraction limited spot in the specimen.

The spot then emits fluorescence that passes back up through the objective lens and

an emission filter. It is brought to focus at a particular location where an image of the

original laser point source is formed. This is the confocal plane.

It then moves on to the photodetector, where an image of the illuminated spot is

formed. The image will be formed by fluorescent light emanating not only from the

focal plane of the specimen, but also by the light emanating from planes above and

below it, causing a blurring of the image even when the depth of field is very small.

This problem can be solved by placing a pin-hole aperture in the confocal plane. It

blocks essentially all light coming from above or below the focal place of the

specimen spot.

Since only a single spot is observed, a photomultier tube can be used in synchrony

with the laser to record the photon count from the illuminated spot. Then the spot can

be scanned horizontally to build up the image of the focal plane of the specimen.

Joint Initiative of IITs and IISc Funded by MHRD

5/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

Thereafter, the vertical location of the specimen may be changed, and the scanning

process is repeated to obtain the image of another specimen plane.

Hundreds of vertical sections may be scanned in this way to build up a highresolution three dimensional image of the specimen.

2.4.2.3 Electron microscopy

Electrons have wave-like properties under certain conditions with effective

wavelengths in the nanometer range. This is the motivation for using electron

microscopy to study the topography of a surface.

In transmission electron microscopy (TEM), the image is produced by focusing a

beam of electrons which have passed through and been scattered by a thin specimen.

TEM can resolve features down to ~1 nm. Since the electrons must pass through the

sample, this technique is limited to thin films.

TEM has found wide use in characterizing nanomaterials and in semiconductor

industries.

Fig. 2.4.3 illustrates how TEM can distinguish each metal layer so that the detailed

structure can be known during the processing steps.

Fig. 2.4.3 TEM image of a tungsten via, showing detailed structure of metal

Stack. The sample contains Al, SiO2, Ti, TiN and W (source: H. Zhang, Thin

Solid Films, 320, 77, 1998; reproduced by permission from Elsevier, 1998).

Scanning electron microscopy (SEM) analyzes electrons scattered back from the

surface of the specimen as the impinging beam of electrons is moved across the

surface in a raster pattern. The images produced by a beam hitting the surface at

Joint Initiative of IITs and IISc Funded by MHRD

6/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

oblique angles produce a three-dimensional image. SEM can produce a resolution

of ~10 nm. The SEM image of nanocrystalline palladium supported on

mesoporous carbon is illustrated in Fig. 2.4.4.

Fig. 2.4.4 SEM image of nanocrystalline palladium (< 3 nm) supported on ordered

mesoporous carbon (source: X. Ji, K. T. Lee, R. Holden, L. Zhang, J. Zhang, G. A.

Botton, M. Couillard, and L. F. Nazar, Nature Chemistry, DOI: 10.1038/NCHEM.553;

reproduced by permission from Macmillan Publishers, 2010).

Both TEM and SEM require conductive samples and high-vacuum conditions.

Sometimes, it is difficult to separate the artifacts from true sample features.

Recently, water vapor has been used as gas-ionization detector in environmental

SEM (called E-SEM). Wet and non-conducting samples may be examined under

moderate vacuum.

2.4.2.4 Scanning probe microscopy

One of the most important new developments for probing surface structure is

scanning probe microscopy (SPM). It has found extensive use in nanoscience and

technology.

In this method, a sharp-tipped probe is moved with atomic precision over or near

to a surface allowing surface topography and/or surface forces to be mapped.

The first scanning probe method developed was scanning tunneling microsccopy

(STM). In this method, the basis for measurement is a tunneling electron current

passing between a conducting tip and a conducting or a semi-conducting solid

surface.

Joint Initiative of IITs and IISc Funded by MHRD

7/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

The second method is the atomic force microscopy (AFM). In this method, the

force exerted on or by a cantilever to which a sharp tip is attached is measured

when the probe is in contact, or in the proximity of the surface which is to be

studied.

2.4.2.4.1 Scanning tunneling microscopy (STM)

The idea initially used for STM was based on the concept of field emission

microscopy. It used piezo-electric translators to position a sharp-tipped probe

with precise position (within a few nanometers) over the surface of the

conductive specimen in vacuo. Two such translators were used to position the xy

coordinates of the probe, and a third was used to adjust the vertical position of the

specimen to a position 50 nm away from the probe tip.

The probe was connected to a source of electricity creating a potential difference

great enough (~109 V/cm) to establish a field emission across the gap. As the

emitting probe was rastered across the surface of the specimen, a servo

mechanism adjusted its vertical position to keep the current constant. The

variations in the vertical position were recorded.

In 1981, a variation of this method was developed by Binnig and Rohrer (Nobel

Prize for Physics, 1986). In their method, the device moved an automatically

sharp metal probe tip to within 1 nm of a hard conducting or semi-conducting

specimen surface, and took advantage of the spontaneous tunneling of electrons

across this gap with the imposition of a small bias potential (~13 V).

The tunneling current (~0.0110 nA) occurs when the highest occupied molecular

orbital of the material on one side of the gap overlaps with the lowest unoccupied

orbital of the material on the other side of the gap. The tunneling current for a

given system decreases exponentially with the gap. The STM is schematically

shown in Fig. 2.4.5.

Joint Initiative of IITs and IISc Funded by MHRD

8/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

2.4.5 Schematic of scanning tunneling microscopy.

Tips for STM scanning are typically made of tungsten wire electrochemically

etched into a sharp uniforrm shape. Often a subsequent chemical etching with

hydrofluoric acid is employed to remove or clean up oxide layers that quickly

form.

STM is limited to conducting or semi-conducting samples. For such samples, its

extraordinary resolution has permitted the investigation of the atomic structure of

the surfaces of such materials, and the manner in which such structure differs

from that in the bulk as a result of the asymmetry of inter-atomic forces acting

upon them. Therefore, this method has limited applications in biology.

STM has been used to analyze LangmuirBlodgett layers. STM can also be used

to manipulate atoms on surfaces. STM is generally applied in ambient air, but it

can be applied in vacuo or under liquids as well. An application is illustrated in

Fig. 2.4.6.

1.6 nm

1.6 nm

1.6 nm

1.6 nm

Fig. 2.4.6 A time-lapsed series of STM images of a disordered glassy set of

terphenyltetracarboxylic acid molecules on graphite. The sequence shows the

movement of a tiling defect across the surface (highlighted in blue) (source: L.

Bartels, Nature Chemistry, DOI: 10.1038/nchem.517; reproduced by permission

from Macmillan Publishers, 2010).

Joint Initiative of IITs and IISc Funded by MHRD

9/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

2.4.2.4.2 Atomic force microscopy (AFM)

Atomic force microscopy is another form of scanning probe microscopy. It is a

very versatile method of characterization of solid surfaces and biointerfaces.

This method was developed in 1986. The microscope has three main parts:

cantilever, sample stage and optical deflection system consisting of a laser diode

and photodetector. The laser beam is reflected off the back side of the cantilever.

A four quadrant photodetector gives the opportunity to measure both normal

bending (ab) and torsion (cd) of the cantilever, corresponding to normal and

lateral forces (see Fig. 2.4.7).

The cantilever is usually microfabricated from silicon or silicon nitride. The

typical dimensions are 100300 m in length, 1030 m in width and 0.53 m

in thickness. The spring constant lies between 0.01 and 100 N/m.

The position of the sample is usually controlled by piezoelectric ceramics, which

move the sample relative to the cantilever in three dimensions. Alternatively, the

cantilever may be mounted on a piezoelectric actuator in order to scan the tip

instead of the sample. The bending of the cantilever, which is a measure of the

tipsample interaction, or loading force, is often determined by an optical

deflection system.

Fig. 2.4.7 Schematic of atomic force microscope.

Forces between 107 and 1015 N can be measured with the AFM.

Joint Initiative of IITs and IISc Funded by MHRD

10/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

In the contact mode of operation, the tip and sample are placed in contact, and

the tip is simply dragged across the surface resulting in a topographical image of

the surface. The scanning is usually done under feedback control where the

sample is moved toward or away from the cantilever during the scan so that the

bending of the cantilever, normal to the surface, remains constant in order to

maintain constant force.

The up and down motion of the sample is therefore a record of the sample

topography. However, the dragging motion of the tip, combined with adhesive

and lateral forces, can cause substantial damage to both the tip and the sample. To

alleviate this problem, a tapping or intermittent-contact mode of operation is

used.

This is accomplished by first oscillating the cantilever at or near its resonant

frequency using a piezoelectric actuator. The oscillation amplitude of the

cantilever in air can be greater than 20 nm when the tip is not in contact with the

surface. Moving the oscillating tip toward the surface until it begins to lightly

touch or tap the surface reduces the oscillation amplitude. The reduction in

oscillation amplitude now becomes the feedback control signal which can be used

to measure the surface topography.

The AFM differs from other forms of microscopes in that a controlled force is

applied to the specimen while imaging. On the one hand, the imaging force can

be a limitation if one is seeking to image weakly bound adsorbates or soft

materials.

On the other hand, if the magnitude of the force is measured as a function of the

tipsurface separation, the chemical and physical properties of the surface (e.g.,

surface forces, stiffness/elasticity, and adhesion) can be measured.

The unique capabilities that the AFM brings to the biological community are:

imaging the structure of biomolecules and biosurfaces with (sub)molecular

resolution, imaging under physiological conditions, including in situ dynamic

events of native biomolecules and living cells in real-time, measuring local

charge densities, mechanical properties and intermolecular forces with

Joint Initiative of IITs and IISc Funded by MHRD

11/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

nanometer-scale spatial resolution, and manipulating individual biomolecules on

the nanometer scale. An application is illustrated in Fig. 2.4.8.

Fig. 2.4.8 Comparison of surface roughness for graphene on SiO2 (a), and on

mica (b) by three-dimensional AFM topographic data (source: C. H. Lui, L. Liu,

K. F. Mak, G. W. Flynn, and T. F. Heinz, Nature, 462, 339, 2009; reproduced by

permission from Macmillan Publishers, 2009).

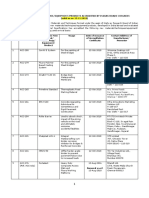

The various modes of atomic force microscopy and their applications are

illustrated in Table 2.4.1.

Table 2.4.1 Various modes of AFM

Mode

Name

Quantity measured

Contact AFM imaging

AFM/C-AFM

Nanoscale profilometry

LFM/FFM

In-plane lubricity/friction

KPM

Contact potential difference

TIM

Thermal property mapping

Micro thermomechanical analysis

TMA

Thermal expansions/softening

Scanning force microscopy

FS/SFS

Forcedistance profile

Chemical force microscopy

CFM

Bond force mapping

Pulsed-force mode

PFM

Topography, adhesion, stiffness,

Lateral or friction force

microscopy

Kelvin probe force microscopy

Micro thermal imaging

microscopy

mapping

Tapping or intermittent contact

mode

IC-AFM

Joint Initiative of IITs and IISc Funded by MHRD

Topography of soft materials

12/20

NPTEL Chemical Engineering Interfacial Engineering

Phase detection imaging

Scanning electrochemical

PDI

Module 2: Lecture 4

Material properties by phase

lagging

ECM/SECM

Current cyclic voltammograms

Non-contact mode

NCM

Near field van der Waals forces

Magnetic force microscopy

MFM

Magnetic domain mapping

Electric force microscopy

EFM

Scanning near-field acoustic

SNAM

Dynamic fluid damping

SNTM

Heated thermocouple tip, thermal

microscopy

Coulombic charge domain

mapping

microscopy

Scanning near-field thermal

microscopy

Ultrasonic force microscopy

property mapping

UFM

Material properties by MHz to subGHz sample vibration

2.4.3 Spectroscopy of surfaces

If a surface (typically a metal surface) is irradiated with a probe beam of photons,

electrons, or ions (usually positive ions), one generally finds that photons,

electrons, and ions are produced in various combinations.

In a spectroscopic method, the intensity or efficiency is studied as a function of

the energy of the produced species at constant probe beam energy.

The spectroscopic methods can be divided into two categories: vacuum and nonvacuum techniques.

Examples of the vacuum techniques are Auger electron spectroscopy (AES), Xray photoelectron spectroscopy (XPS), and secondary ion mass spectrometry

(SIMS).

Examples of the non-vacuum techniques are attenuated total reflectance

spectroscopy (ATR), and total internal reflectance fluoroscopy (TIRF).

Many colloidal solid materials change structure irreversibly under high vacuum

(e.g., the hydrocolloids). Therefore, the high-vacuum methods are of little

Joint Initiative of IITs and IISc Funded by MHRD

13/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

importance for such materials, because of the overwhelming influence of water

on the structure of the solidwater interface.

2.4.3.1 Auger electron spectroscopy (AES)

This method is based on the Auger effect (discovered in 1925 by Pierre Auger),

which is based on the analysis of energetic electrons emitted from an excited

atom after a series of internal relaxation events. AES was developed in the 1960s,

when ultra-high vacuum (UHV) technology became commercially available.

In this technique, probe electrons of energy 23 keV are fired at the surface.

When a primary electon displaces an electron from one of the inner shells of a

surface atom, an electron from an outer shell drops down to take its place. When

this happens, all of the excess energy is taken up by another outer shell electron,

which is then emitted from the atom with an energy which is characteristic of the

atom and independent of the energy of the incident beam. This electron is the

Auger electron, and its energy can be used to identify the surface atom.

Suppose that the incident electron with sufficient primary energy, E p , ionizes the

core level, such as a K level. The vacancy thus produced is immediately filled by

another electron from L1 . The energy EK EL1 released from this transition

can be transferred to another electron, as in the L2 level. The Auger electron will

have energy given by,

E EK EL1 EL 2

(2.4.2)

The excitation process is denoted as a KL1L2 Auger transition.

It is obvious that at least two energy states and three electrons must take part in an

Auger process. Therefore, hydrogen and helium atoms cannot give rise to Auger

electrons. Isolated Li atoms having a single electron in the outermost level cannot

give rise to Auger electrons. However, in a solid, the valence electrons are shared

and the Auger transitions of the type KVV occur involving the valence electrons

of the solid.

Joint Initiative of IITs and IISc Funded by MHRD

14/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

Several transitions (e.g., KL1L1, KL1L2 , LM1M 2 ) can occur with various transition

probabilities. The Auger electron energies are characteristic of the target material

and independent of the incident beam energy.

The general uses of AES are identification of elements on surfaces of materials,

quantitative determination of elements on surfaces, studies on adsorption,

desorption and surface aggregation, and chemical reactivity at a surface.

The main advantages of this technique are its high sensitivity for chemical

analysis in the 0.520 nm region near the surface, a rapid data acquisition speed,

ability to detect all elements above helium, and capability of high-spatial

resolution. The high-spatial resolution is achieved because the specimen is

excited by an electron beam that can be focused into a fine probe.

2.4.3.2 X-ray photoelectron spectroscopy (XPS)

The X-ray photoelectron spectroscopy is closely related to Auger electron

spectroscopy. It is also called electronic spectroscopy for chemical analysis

(ESCA).

This method uses a monochromatic beam of X-rays to dislodge electrons from the

inner shells (K and L) of the surface atoms, and then analyzes the energy of the

emitted electrons (which includes Auger electrons) directly.

It is much more precise than AES, and can be used to detect changes in the

valence states of the adsorbed species. To illustrate, for 1s sulfur electrons, there

is a chemical shift of over 5 V, and the ionization energy increases as the valence

state of sulfur varies from 2 to +6.

It is possible to analyze oxidation and reduction at the surface of solids using

XPS.

The kinetic energy of the emitted photo-electron is determined in the

spectrometer. It is given by,

E h binding energy of electron

(2.4.3)

where is the frequency of the initial X-ray and is the work function of the

spectrometer.

Joint Initiative of IITs and IISc Funded by MHRD

15/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

The binding energy is influenced principally by the nature of the atom from

which it originated, but it is affected also by the valence state of the atom and, to

some extent, by the disposition and polarity of the bonds from the adjacent atoms.

These chemical shifts can also be used to identify more subtle effects in the

adsorbate molecules.

The kinetic energies of the emitted photo-electrons are normally very low.

Therefore, only electrons from the upper 15 nm are able to escape. Thus, this

method is very sensitive to the surface structure.

XPS has been used to characterize polymer surfaces and to determine the

thickness of polymer layers on metals.

Since X-rays are very penetrating, a grazing angle is often used to emphasize the

contribution from the surface atoms.

2.4.3.3 Secondary ion mass spectrometry (SIMS)

The secondary ion mass spectrometry is used for identifying atomic surface

constituents. A primary beam of ions is aimed at the surface and the secondary

particles (which comprise of a different composition and charge) are collected

and focussed in a mass spectrometer. It is identified in the usual way by their

charge/mass ratio.

The primary beam species are ions such as Cs+, O+2, O+, Ar+ and Ga+ with

energies in the range of 130 keV. Therefore, this process is usually much more

energetic than electron bombardment. This results in the sputtering of the surface.

Atoms are gouged out of the surface and some primary ions are incorporated in

the solid. The implantation of primary ions can occur to depths of up to 10 nm.

The secondary beam consists of monoatomic and polyatomic particles of sample

material and resputtered primary ions along with primary electrons and photons

with kinetic energies in the range of zero to several hundred electron volts.

The primary beam can be focussed to less than 1 m in diameter. It can be

scanned across the surface to yield a microanalysis of the surface structure. The

beam can also be trained on a certain area of the sample and will gradually gouge

Joint Initiative of IITs and IISc Funded by MHRD

16/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

out the surface and generate a depth profile of the material in the surface layers.

This process is known as dynamic SIMS.

At the lowest energy level of scanning and microanalysis, the method is called

static SIMS. As little as one millionth of a monolayer can be detected by this

method, which is among the the most sensitive techniques available for analyzing

the surface.

An important drawback of this method is that it destroys the surface it analyzes.

2.4.3.4 Attenuated total reflectance spectroscopy (ATR)

Only a few spectroscopic techniques can be applied directly to the study of the

solidliquid interfaces.

Due to the small volume of the interfacial region, very few methods have

sufficient sensitivity to provide information about any interface involving

aqueous solutions.

One of the most promising spectroscopic methods is ATR, because it can be

concentrated on the interfacial region alone, and can be arranged to sample that

region several times in a single measurement.

Using a thin glass block, the ATR beam can be bounced several times off the

interface during a single pass. At each encounter, the reflection/penetration

depends on the properties of the interfacial region.

The final beam has a signature which contains information on the adsorbed

material in the interface. The visibile/ultraviolet method has been used to the

study of surfactant, polymer, and protein adsorption at the glassaqueous solution

interface. An application is shown in Fig. 2.4.9.

In the case of visible/UV radiation, the aim is to get the bulk of light absorption

process occurring in the interface. Therefore, most studies have been carried out

at the interface between the glass (or quartz) and the adjoining aqueous solution.

With FTIR, the ATR mode can be used to study the surface near where the

reflection is occurring.

Since water has a strong absorption in the IR region, the IR spectra of aqueous

systems are normally studied in extremely short path-length cells. The ATR

Joint Initiative of IITs and IISc Funded by MHRD

17/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

method is a way of circumventing that problem, especially for suspensions, since

such cells cannot be easily filled or cleaned and would be easily plugged with the

solid.

Fig. 2.4.9 ATR-FTIR spectra of adsorbed mussel adhesive protein on polystyrene

(PS) and poly(octadecyl methacrylate) (POMA) surfaces using ATR-FTIR

spectrometry (source: A. M. Baty, P. A. Suci, B. J. Tyler, and G. G. Geesey, J.

Colloid Interface Sci., 177, 307, 1996; adapted by permission from Elsevier Ltd.,

1996).

2.4.3.5 Total internal reflectance fluoroscopy (TIRF)

This technique is closely related to ATR. However, instead of studying the

absorption due to the evanescent wave, the excitation due to that wave produces a

fluorescent emission which is collected in a monochromator and passed on to a

photomultiplier tube for analysis.

The exciting laser beam is chopped at a characteristic frequency so that the

fluorescent emission is modulated at that frequency. This aids in the detection

process.

After suitable calibration, the TIRF signal can be used to measure the adsorption

of the substrate at the solidliquid interface.

Joint Initiative of IITs and IISc Funded by MHRD

18/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

Exercise

Exercise 2.4.1: Calculate the resolution of an optical microscope if the wavelength of

(reflected) light in vacuo is 600 nm, refractive index of the medium is 1.43 and the

numerical aperture is 0.9. Assume that the object is non-luminous.

Exercise 2.4.2: Answer the following questions clearly.

a. What size range of objects is measurable by optical microscopy?

b. Define resolution. How does it depend on the wavelength of light and numerical

aperture?

c. What are the main advantages of fluoroscence microscopy?

d. What is Stokes shift?

e. What are the advantages of confocal microscopy?

f. Discuss the advantages and disadvantages of SEM and TEM?

g. What is scanning probe microscopy? Give two examples.

h. Explain the principle of scanning tunneling microscopy. Discuss its applications.

i. Explain how atomic force microscopy works. What magnitude of force can it

measure? Mention five modes of operation of atomic force microscopy, and

explain their applications.

j. Mention two examples of vacuum-based and non-vacuum spectroscopic

techniques for characterizing a fluidsolid interface.

k. Explain how Auger electron spectroscopy works. Mention three uses of Auger

electron spectroscopy.

l. What is X-ray photoelectron spectroscopy? What is its difference with Auger

electron spectroscopy?

m. Mention two important applications each of secondary ion mass spectrometry and

attenuated total reflectance spectrometry.

Joint Initiative of IITs and IISc Funded by MHRD

19/20

NPTEL Chemical Engineering Interfacial Engineering

Module 2: Lecture 4

Suggested reading

Textbooks

A. W. Adamson and A. P. Gast, Physical Chemistry of Surfaces, John Wiley,

New York, 1997, Chapter 8.

J. C. Berg, An Introduction to Interfaces and Colloids: The Bridge to

Nanoscience, World Scientific, Singapore, 2010, Chapter 4.

R. J. Hunter, Foundations of Colloid Science, Oxford University Press, New

York, 2005, Chapter 6.

Reference books

L. L. Schramm, Dictionary of Nanotechnology, Colloid and Interface Science,

Wiley-VCH, Weinheim, 2008 (find the topic by following the alphabetical

arrangement in the book).

Journal articles

A. M. Baty, P. A. Suci, B. J. Tyler, and G. G. Geesey, J. Colloid Interface Sci.,

177, 307 (1996).

C. H. Lui, L. Liu, K. F. Mak, G. W. Flynn, and T. F. Heinz, Nature, 462, 339

(2009).

H. Zhang, Thin Solid Films, 320, 77 (1998).

L. Bartels, Nature Chemistry, DOI: 10.1038/NCHEM.517 (2010).

X. Ji, K. T. Lee, R. Holden, L. Zhang, J. Zhang, G. A. Botton, M. Couillard, and

L. F. Nazar, Nature Chemistry, DOI: 10.1038/NCHEM.553 (2010).

Joint Initiative of IITs and IISc Funded by MHRD

20/20

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Semi-Mechanical Pulping of Napier GrassDokumen98 halamanSemi-Mechanical Pulping of Napier GrassAmelyate NamatBelum ada peringkat

- Performance of SMA With Different FibersDokumen29 halamanPerformance of SMA With Different FibersAyyanna HabalBelum ada peringkat

- Materials As Per IRCDokumen7 halamanMaterials As Per IRCAyyanna HabalBelum ada peringkat

- Materials As Per IRCDokumen7 halamanMaterials As Per IRCAyyanna HabalBelum ada peringkat

- Highway Research Journal Vol 5 - No 2 PDFDokumen48 halamanHighway Research Journal Vol 5 - No 2 PDFAyyanna HabalBelum ada peringkat

- JournalApr Jun12Dokumen168 halamanJournalApr Jun12Anonymous YHcvra8Xw6Belum ada peringkat

- TRR PaperDokumen13 halamanTRR PaperAyyanna HabalBelum ada peringkat

- Evolution of Coefficient of Friction Between Tire and Pavement Under Wet Conditions Using Surface Free Energy TechniqueDokumen8 halamanEvolution of Coefficient of Friction Between Tire and Pavement Under Wet Conditions Using Surface Free Energy TechniqueAyyanna HabalBelum ada peringkat

- IJRET - 110213031 - Published Paper PDFDokumen7 halamanIJRET - 110213031 - Published Paper PDFAyyanna HabalBelum ada peringkat

- Kwok Et Al-1999-Journal of Polymer Science Part B Polymer PhysicsDokumen13 halamanKwok Et Al-1999-Journal of Polymer Science Part B Polymer PhysicsAyyanna HabalBelum ada peringkat

- Precipitation TitrationDokumen7 halamanPrecipitation Titrationadnan nuravifBelum ada peringkat

- Solvent Sbps 1425 - HPCLDokumen2 halamanSolvent Sbps 1425 - HPCLBharat ChatrathBelum ada peringkat

- Pharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)Dokumen13 halamanPharmacon Kandungan Flavonoid Dan Aktivitas Antioksidan Total Ekstrak Etanol Daun Kayu Kapur (Melanolepsis Multiglandulosa Reinch F)wangzahBelum ada peringkat

- State Wise Distribution of Units Registered Under Factories Act, 1948Dokumen6 halamanState Wise Distribution of Units Registered Under Factories Act, 1948api-19850688Belum ada peringkat

- Calculation of Liquid Heat Capacity of Petroleum Distillate FuelsDokumen3 halamanCalculation of Liquid Heat Capacity of Petroleum Distillate Fuelsdennise8Belum ada peringkat

- Unconfined CompressionDokumen3 halamanUnconfined CompressionAhmadGhanemBelum ada peringkat

- Lignocellulosic Biomass A Sustainable Platform For Production of Bio-Based - Isikgor2015 PDFDokumen62 halamanLignocellulosic Biomass A Sustainable Platform For Production of Bio-Based - Isikgor2015 PDFNatasha Mgt JoharBelum ada peringkat

- FLUORESCENCE - Clinical and Drug Applications: A Go Mez-Hens, University of Cordoba, Cordoba, SpainDokumen9 halamanFLUORESCENCE - Clinical and Drug Applications: A Go Mez-Hens, University of Cordoba, Cordoba, SpainAzad Hama AliBelum ada peringkat

- PFD of ETPDokumen2 halamanPFD of ETPJahanzeb KhanBelum ada peringkat

- Metallic Implant Materials: 5.1. Stainless SteelsDokumen36 halamanMetallic Implant Materials: 5.1. Stainless SteelsK.KRITHIKA HICET STAFF BMEBelum ada peringkat

- Aade 11 Ntce 23Dokumen10 halamanAade 11 Ntce 23Kinni ShenoldBelum ada peringkat

- Spin Atomic Model: Role of Electron Spin in Forming Atoms and MoleculesDokumen8 halamanSpin Atomic Model: Role of Electron Spin in Forming Atoms and MoleculesGhanshyam JadhavBelum ada peringkat

- Dulux Firepro Epoxy Intumescent Application GuideDokumen10 halamanDulux Firepro Epoxy Intumescent Application GuideAlpha DekoBelum ada peringkat

- Science10 Q4 M3 W5 6 1Dokumen10 halamanScience10 Q4 M3 W5 6 1Reyydell DelimaBelum ada peringkat

- Combustion Lecture Midterm ExamDokumen3 halamanCombustion Lecture Midterm ExamNazareno Religioso MateoBelum ada peringkat

- Chelidonium Majus PDFDokumen40 halamanChelidonium Majus PDFbhaskarsgBelum ada peringkat

- PS1Dokumen4 halamanPS1cptudorBelum ada peringkat

- Acetone Production ReportDokumen83 halamanAcetone Production Reportpravalchauha89% (9)

- Finalreport PDFDokumen47 halamanFinalreport PDFNelCamHerBelum ada peringkat

- H2SDokumen21 halamanH2SBeatrizCamposBelum ada peringkat

- Solutions NumericalsDokumen3 halamanSolutions Numericalsdevesh saiBelum ada peringkat

- PH - Wikipedia, The Free EncyclopediaDokumen11 halamanPH - Wikipedia, The Free EncyclopediaShikhar MahajanBelum ada peringkat

- Benzop 092020 TRDokumen89 halamanBenzop 092020 TRAnakaya IRABelum ada peringkat

- Wet Type Electrostatic Precipitator Technology For Industrial and Power ApplicationsDokumen8 halamanWet Type Electrostatic Precipitator Technology For Industrial and Power Applicationssrajl94Belum ada peringkat

- EXPERIMENT 1 Introduction To Chemistry LabDokumen6 halamanEXPERIMENT 1 Introduction To Chemistry LabDulce DeBelum ada peringkat

- Quantum Dot Poster 4Dokumen1 halamanQuantum Dot Poster 4api-253695787Belum ada peringkat

- STUDY GUIDE - Lipid and Carbohydrate CombinedDokumen5 halamanSTUDY GUIDE - Lipid and Carbohydrate CombinedMaya Abou MradBelum ada peringkat

- CH 8 Handouts (All) PDFDokumen34 halamanCH 8 Handouts (All) PDFSandipan SahaBelum ada peringkat

- Design of Formwork For Column R0 - 3.7 MTRDokumen5 halamanDesign of Formwork For Column R0 - 3.7 MTRrahul1433Belum ada peringkat