Road Detailed Estimate

Diunggah oleh

nageshwarraobandiDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Road Detailed Estimate

Diunggah oleh

nageshwarraobandiHak Cipta:

Format Tersedia

N.

W :-

Construction of HLB @ 12/0-2 of Bothalapalem - Ragada Road in Nalgonda District

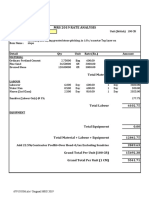

BRIDGE DETAILED ESTIMATE(HLB @ Km 12/0-2

S.No

Description

No

Length

Bredth

Depth

Quantity

unit

Earthwork excavation in soils upto SDR by mechanical means for foundations of structures as per

drawing and technical specification including setting out, construction of shoring and bracing,

removal of stumps and other deleterious matter, dressing sides of bottom, back filling the

excavation earth to the extent required etc., complete including seignioarge charges for finished

item of work as per MoRT&H specification 304(4th Revision)

a)

In ordinary soils upto SDR soils using Machinery

excluding dewatering charges up to 3.0m depth

Abutments

Piers

wing walls

Toe walls

Avg depth

or say

b)

In ordinary soils upto SDR soils using Machinery

including dewatering charges up to 3.0m depth

Abutments

Piers

Avg depth

or say

c)

In ordinary Rock (Lime stone) soils using Machinery

including dewatering charges from 3.0m depth

Abutments

Piers

2

2

2

8.450 4.300

4.500 4.500

3.500 3.800

0.150

0.150

0.150

or say

``

10.90

6.08

3.99

20.97

21.00 cum

Vibrated cement concrete M 15 Grade Concrete using 40mm , 20mm and 10mm size HBG crushed

stone aggregate (Coarse aggregate conforming to table 1000-1 and fine aggregate conforming to

table 1000-2) including cost,seignorage and conveyance of all materials to site and all labour

charges for machine mixing,laying in position, Compacting , Vibrating and curing including all other

incidental and all other operational charges of T&P required etc., complete as per MoRT&H

Specification 1500,1700, 2100 (4th Revision) for footings of Aburments and Wing walls.

Abutments (A1 & A2) 1st footing

Abutments trep.footing (2.30+3.30)/2

wing walls W1 footing

wing walls W1 trep.footing (1.9+2.8)/2

2

2

2

2

8.450

8.450

3.500

3.500

4.300

2.800

3.800

2.350

0.500

1.000

0.500

1.500

or say

0.00

0.00

0.00

0.00 cum

PCC(1:3:6) Nominal mix in foundation with crushed stone aggregate 40 mm nominal size

mechanically mixed placed in foundation and compacted by vibration including curing complete

asper Morth Spn no.2100.

Abutments ( A1 & A2)

Piers (P1 & P2)

Wing walls W1

0.00

0.00

0.00

0.00 cum

Avg depth

or say

2

0.00

0.00

0.00

0.00

0.00

0.00 cum

36.34

47.32

13.30

24.68

121.63

122.00 cum

Vibrated reinforced cement concrete M 20 grade using 20mm & 10mm HBG crushed stone

aggregate (Coarse aggregate conforming to table 1000-1 and fine aggregate conforming to

table 1000-2) including cost, seigniorage conveyance of all materials to site and labour

charges, centering, machine mixing, laying, vibrating, curing etc., including other incidental

hire and operational charges of all T&P as per approved drawings and as directed during

execution but excluding cost of steel and its fabrication charges for finished item as per

MoRT&H specification 1500,1600,1700 & 2200 (4th revision ) and as directed by the

Engineer-in-Charge for Pier footings

Piers (P1 & P2)

Pedestal

2

2

4.500

2.800

4.500

2.800

0.700

0.760

or say

28.35

11.92

40.27

41.00 cum

S.No

Description

No

Length

Bredth

Depth

Abutments (A1 & A2) (2.3+1.0)/2

Wing walls W1 (1.9+0.45)/2

2

2

8.450 1.650

3.500 1.175

4.039

4.625

or say

Quantity

unit

Vibrated cement concrete M 15 Grade Concrete using 40mm , 20mm and 10mm size HBG crushed

stone aggregate (Coarse aggregate conforming to table 1000-1 and fine aggregate conforming to

table 1000-2) including cost,seignorage and conveyance of all materials to site and all labour

charges for machine mixing, laying in position,Compacting, Vibrating and curing including all other

incidental and all other operational charges of T&P required etc., complete as per MoRT&H

Specification 1500,1700, 2200 (4th Revision) for Sub structure for abutments and wingwalls

112.63

38.04

150.67

151.00 cum

Vibrated reinforced cement concrete M 20 grade using 20mm & 10mm HBG crushed stone

aggregate (Coarse aggregate conforming to table 1000-1 and fine aggregate conforming to table

1000-2) including cost, seigniorage conveyance of all materials to site and labour charges,

centering, machine mixing, laying, vibrating, curing etc., including other incidental hire and

operational charges of all T&P as per approved drawings and as directed during execution but

excluding cost of steel and its fabrication charges for finished item as per MoRT&H specification

1500,1600,1700 & 2200 (4th revision ) and as directed by the Engineer-in-Charge for Bed blocks

& Backing walls

a Bed blocks and backing walls

S.No

Description

Abutments (A1 & A2)

Backing wall

Over Abutments

No

Length

Bredth

Depth

8.450 1.050

0.300

2

-2

8.450 0.350

7.500 0.350

1.886

0.300

or say

a) Hammer Head Bed blocks (0-5m)

Hammer Head Bed blocks (7+1.8)/2

2

2

7.000

4.400

1.800

1.800

0.800

0.700

b) Piers (P1 & P2) 3.14/4 (1.8*1.8)

2.543

1.000

or say

2.879

or say

18

0.930

0.520

0.150

or say

20.16

11.09

31.25

32.00 cum

14.64

15.00 cum

1.31

2.00 cum

Vibrated reinforced cement concrete M 20 grade using 20mm & 10mm HT crushed stone

aggregate (Coarse aggregate conforming to table 1000-1 and fine aggregate conforming to

table 1000-2) including cost, seigniorage conveyance of all materials to site and labour

charges, centering, machine mixing, laying, vibrating, curing etc., including other incidental

hire and operational charges of all T&P etc., complete as per approved drawings and as

directed during execution but excluding cost of steel and its fabrication charges for finished

item as per MoRT&H specification 1500,1600,1700 and as per M.O.S.T DRG No No.BD/1476A, & BD/15-76A for T-Beam Girder Slab

1

61.200

or say

61.20

62.00 cum

Providing HYSD bars (Fe-415) of different diameters, wrought and put up bars of all diameters

including cost and conveyance of steel to site and all labour charges for fabrication of reinforcement

including cutting, bending, binding rods, tying grills, placing them in position etc., complete including

cost and conveyance of binding wire and all handling charges and operational charges etc., and

including over lapping welding if required etc., complete for all R.C.C items for finished item of work

as per standard drawings, as per the directions of the Engineer-in-Charge and as per MoRT&H

specification 1600 &2200 (4th revision) and as per I.S.1786 of 1985 for Super structure of R.C.C

items.

Super structure A1 to P1

Approach slab

Wearing coat

Hand Rails

1

1

1

1

1.00

10373 Kgs/span

85

Kgs/cum

35

Kgs/cum

9

Kgs/Rm

or say

11

11.16

-1.58

14.90

15.00 cum

Vibrated reinforced cement concrete M 30 grade using 20mm & 10mm HT crushed stone

aggregate (Coarse aggregate conforming to table 1000-1 and fine aggregate conforming to

table 1000-2) including cost, seigniorage conveyance of all materials to site and labour

charges, centering, machine mixing, laying, vibrating, curing etc., including other incidental

hire and operational charges of all T&P etc., complete as per approved drawings and as

directed during execution but excluding cost of steel and its fabrication charges for finished

item as per MoRT&H specification 1500,1600,1700. for Bearing Pedestals

Super structure A1 to P1 (0-5m)

10

unit

5.32

Vibrated reinforced cement concrete M 20 grade using 20mm & 10mm HBG crushed stone

aggregate (Coarse aggregate conforming to table 1000-1 and fine aggregate conforming to table

1000-2) including cost, seigniorage conveyance of all materials to site and labour charges,

centering, machine mixing, laying, vibrating, curing etc., including other incidental hire and

operational charges of all T&P as per approved drawings and as directed during execution but

excluding cost of steel and its fabrication charges for finished item as per MoRT&H specification

1500,1600,1700 & 2200 (4th revision ) and as directed by the Engineer-in-Charge for Hammer

Head Bed blocks

Bearing Pedestals (2*3+2*6)

Quantity

10.37

0.00

0.00

0.00

10.37

11.00 MT

Providing HYSD bars (Fe-415) of different diameters, wrought and put up bars of all diameters

including cost and conveyance of steel to site and all labour charges for fabrication of reinforcement

including cutting, bending, binding rods, tying grills, placing them in position etc., complete including

cost and conveyance of binding wire and all handling charges and operational charges etc., and

including over lapping welding if required etc., complete for all R.C.C items for finished item of work

as per standard drawings, as per the directions of the Engineer-in-Charge and as per MoRT&H

specification 1600 &2200 (4th revision) and as per I.S.1786 of 1985 for Sub structure of R.C.C

items.

Bed blocks,backing walls,kerbs&pedestals

Hammer Head Bed blocks

Piers (P1 & P2)

1

1

1

18.01

31.25

14.64

100.00 Kgs/cum

125.00 Kgs/cum

80.00 Kgs/cum

1.80

3.91

1.17

S.No

Description

Skin reinforcement for abutment (A1 & A2)

(2*8.45*4.039+4.039*(2.3+1.0))

Skin reinforcement for wing walls (W1)

(2*4*4.625+4.625*(1.9+0.45))

No

Length

Bredth

Depth

2 81.59

5.00

Kgs/sqm

0.82

2 47.87

5.00

Kgs/sqm

0.48

8.17

9.00 MT

Say

Quantity

unit

S.No

12

Description

No

Length

Bredth

Depth

Quantity

unit

Providing HYSD bars (Fe-415) of different diameters, wrought and put up bars of all diameters

including cost and conveyance of steel to site and all labour charges for fabrication of reinforcement

including cutting, bending, binding rods, tying grills, placing them in position etc., complete including

cost and conveyance of binding wire and all handling charges and operational charges etc., and

including over lapping welding if required etc., complete for all R.C.C items for finished item of work

as per standard drawings, as per the directions of the Engineer-in-Charge and as per MoRT&H

specification 1600 &2200 (4th revision) and as per I.S.1786 of 1985 for foundations of R.C.C

items.

Skin reinforcement for abutments (A1 & A2)

2 83.53

(8.45(1.0+1.0*1.414+1.0+1.0+4.30)+4.3*2*0.5+1.0(3.30+2.30))

Skin reinforcement for Pier Footings P1 & P2

1

40.27

Skin reinforcement for wing walls (W1)

2

40.02

(3.5*(1.0+1.0+3.8+1.5+1.5*1.414)+1.5*(2.8+1.9))

5.00 Kgs/sqm

60.00 Kgs/cum

5.00 Kgs/sqm

Say

0.84

2.42

0.40

3.65

4.00 MT

S.No

13

Description

No

Length

Bredth

Depth

Quantity

behind abutments A1 & A2

6.950

3.334

5.775

Say

14

15

unit

Back filling behind Abutments with gravel including cost ,conveyance and seigniorage of all

materials to site etc., complete as per Clause 710.1.4 of IRC : 78and as per MoRT&H

Specification No. 2200 and as per Cl 710.1.4 of IRC :78

267.63

267.63

268.00 cum

Providing and laying of filter media using 50% of 150 mm IRC soling stone and 50 % of 40 mm

HBG metal satisfying the requirements laid down in clause 2504.2.2 of MoRT&H specifications to

athickness of not less than 600mm with smaller size towards the soil and bigger size towards the

wall and provided over the entire surface behind the abutment, wing wall and return wall to the full

height compacted to a firm condition including cost and conveyance of all metal seignorage charges

,and all labour charges as directed by the departmental officers as per drawing and Technical

specifications as per clause 710.1.1 of IRC:78 and Clause 2200 of MoRT&H (4th Revision) for

finished item of work.

behind abutments A1 & A2

behind Wing walls W1

2

2

7.550

2.900

0.600

0.600

6.775

6.125

61.38

21.32

82.70

Say

83.00 cum

Providing weep holes in VCC Abutments, Return walls and wing walls with 100mm Diameter AC

pipe extending through the full width of the structure at 1.00m C/C in both horizontal and vertical

direction so that the weep holes in each horizontal direction is staggered from the weep holes laying

above and below lines as shown in drawing including cost and conveyance of the A.C pipes and

labour charges for cutting to required length, placing the pipe with a slope of about 1V : 20H towards

stream side face etc., complete for finished item of work for weep holes as per MoRT&H

specification 2706 & 2200 (4th Revision)

Wing walls W1 (0.45+1.9)/2

Abutments A1 & A2 (2.30+1.0)/2

2

2

3.000

7.000

4.00

4.00

1.175

1.650

Say

28.20

92.40

120.60

121.00 Rm

16

Supplying and fixing of CI drainage spouts complete as per MoRT&H Specification No.2705 and as

per drawing No.BD / 1-69

Drainage spouts ( A1 to P1)

1

4.00

4.00 no

17

Supplying and fitting and fixing in postion true to line and level elastomeric neoprene bearings

of size 630*220*61mm conforming toIRC : 83 (part-II) section IX and clause 2005 of MoRTH

specifications complete including all accessories as per drawing and Technical Specifications

and as per MoRTH Specifications No. 2000 & 2200

over Abutments A1

over Piers P1

1

1

3.00

3.00

Say

18

19

20

21

Provision for soil investigation and soil exploration

Provision for Pylon construction

Provision for variation in foundation levels

Provision for Painting to railing

Asst..Exe.Engineer (R&B)

R&B Section Miryalaguda

Exe.Engineer (R&B)

(R&B) .Division Miryalaguda

3.00

3.00

6.00 no

6.00 no

LS

LS

LS

LS

Deputy Exe.Engineer (R&B)

R&B Sub Division Miryalaguda

Superintending Engineer (R&B)

(R&B) Circle, Nalgonda

N.W :-

Construction of HLB @ 12/0-2 of Bothalapalem - Ragada Road in Nalgonda District

BRIDGE DETAILED ESTIMATE(HLB @ Km 12/0-2

S.No

Description

No

Length

Bredth

Depth

Forming embanking with borrowed usefull earth from outside roadboundary by mechanical means up

to SDR with all leads and lifts including pre-watering of soil at borrow area, removal of top soil,

excavation of soils at borrow area, conveyance of soil, depositing the soil on the embankment,

spreading soil, breaking clods, sectioning, grading and consolidation with 8 to 10 tonnes vibratory

road roller @ OMC to meet reuirement of table 300-2 of MoRT&H, including all hire and oprational

charges of T&P and seigniorage charges, complate for finished item of work as per MoRT&H

specification 305 (4th revision) (payment will be made based on level for finished item of work)

a)

Bothalapalem side level portion (4.49+2.70)/2

(12+12+2*1.5*3.595)/2

Bothalapalem side Gradient portion(2.7+0.5)/2

11.50

95.00

17.39

3.595

Avg depth

15.20

1.600

or say

2

3

Add for VAT @ 5%

Provision for Caution boards, guide posts & caution boards etc..,

nda District

Quantity

unit

dary by mechanical means up

w area, removal of top soil,

he soil on the embankment,

with 8 to 10 tonnes vibratory

luding all hire and oprational

m of work as per MoRT&H

finished item of work)

718.95

2310.40

3029.35

3030.00 cum

LS

LS

Anda mungkin juga menyukai

- Cost-Based Pricing: A Guide for Government ContractorsDari EverandCost-Based Pricing: A Guide for Government ContractorsBelum ada peringkat

- Lot 80, Block 27, Maria Clara Corner Craig ST., Sampaloc, Manila August 09,2014Dokumen1 halamanLot 80, Block 27, Maria Clara Corner Craig ST., Sampaloc, Manila August 09,2014gia guallarBelum ada peringkat

- 07 Building Up Rates For The BoQ UIPE ApprovedDokumen24 halaman07 Building Up Rates For The BoQ UIPE Approvedjoz lapBelum ada peringkat

- Academic Lecture Theatre Vol IV BoqDokumen102 halamanAcademic Lecture Theatre Vol IV Boqdrjonesg19585102Belum ada peringkat

- BoQ For Water TankDokumen10 halamanBoQ For Water TankMenaka GurusingheBelum ada peringkat

- Steel QuantityDokumen21 halamanSteel QuantityAshish Jain100% (1)

- BOQ DescriptionsDokumen8 halamanBOQ Descriptionsnayanahari100% (1)

- Quantity Estimation ReportDokumen9 halamanQuantity Estimation ReportSandip BudhathokiBelum ada peringkat

- IGC Project Budget Template SampleDokumen2 halamanIGC Project Budget Template SampleAddiBelum ada peringkat

- Picket Fence RM BOQDokumen5 halamanPicket Fence RM BOQAndrew ArahaBelum ada peringkat

- EstimateDokumen14 halamanEstimateAnonymous fQLEF2tQpqBelum ada peringkat

- Estimate of SBTWDokumen17 halamanEstimate of SBTWSaral MajumderBelum ada peringkat

- Ledge Design HCSDokumen3 halamanLedge Design HCSsidiq7Belum ada peringkat

- Estimation of A RCCslab CulvertDokumen5 halamanEstimation of A RCCslab CulvertShah Mohammad IqbalBelum ada peringkat

- Civil Works: 1,331,433.12 Earth WorkDokumen7 halamanCivil Works: 1,331,433.12 Earth WorkhafizBelum ada peringkat

- Elemental Cost Analysis-Form 1: Job Title: Client: Location: Tender DateDokumen1 halamanElemental Cost Analysis-Form 1: Job Title: Client: Location: Tender DateninaamirahmBelum ada peringkat

- Boq Proposed Single Vintlation Improved Pit Latrine: General Preliminary Item Description QTY Unit Rate AmountDokumen6 halamanBoq Proposed Single Vintlation Improved Pit Latrine: General Preliminary Item Description QTY Unit Rate AmountEng Hinji RudgeBelum ada peringkat

- Loadings PoultryDokumen6 halamanLoadings PoultryJems MansuetoBelum ada peringkat

- Estimating - Quantity Take OffDokumen11 halamanEstimating - Quantity Take OffpierorrosazzaBelum ada peringkat

- Building Estimate DurganagarDokumen8 halamanBuilding Estimate DurganagarMriganka GhoshBelum ada peringkat

- WBLFF To ListDokumen7 halamanWBLFF To ListWong LippingBelum ada peringkat

- Course Syllabus Second Semester FubkDokumen6 halamanCourse Syllabus Second Semester FubkAliyu Shehu0% (1)

- Ddrcs TheoryDokumen10 halamanDdrcs TheoryhpkBelum ada peringkat

- Grouted Stone Pitching in 1.8 CSMDokumen3 halamanGrouted Stone Pitching in 1.8 CSMusama buttBelum ada peringkat

- Reinforcement in Column Below Plinth Level Is Less Than That Above. 6 Nos. It Needs To Be ConfirmedDokumen3 halamanReinforcement in Column Below Plinth Level Is Less Than That Above. 6 Nos. It Needs To Be ConfirmedSaroj AcharyaBelum ada peringkat

- Beam DesignDokumen6 halamanBeam DesignSHEETHALBelum ada peringkat

- Estimate For IISDokumen14 halamanEstimate For IISNavam NanthanBelum ada peringkat

- Boq 2Dokumen34 halamanBoq 2Muhammad Auwal TahirBelum ada peringkat

- Boq For RCC BuildingDokumen35 halamanBoq For RCC Buildingjatin kalraBelum ada peringkat

- Total Summery of Composite Factory (40Mx26M)Dokumen8 halamanTotal Summery of Composite Factory (40Mx26M)FITIWIBelum ada peringkat

- Summary of Approved Budget For The Contract: Department of Public Works and HighwaysDokumen31 halamanSummary of Approved Budget For The Contract: Department of Public Works and HighwaysBunny HopperBelum ada peringkat

- Ministry of Physical Infrastructure DevelopmentDokumen25 halamanMinistry of Physical Infrastructure DevelopmentrahulBelum ada peringkat

- Estimate Od Compound WallDokumen79 halamanEstimate Od Compound WallAliasgar LokhandwalaBelum ada peringkat

- Project Budget TemplateDokumen2 halamanProject Budget Templateapi-271276668Belum ada peringkat

- Bill of Quantities Site - Xls FinalDokumen39 halamanBill of Quantities Site - Xls FinalTariq MahmoodBelum ada peringkat

- Taking Off List Example WBLFFDokumen1 halamanTaking Off List Example WBLFFNor Nadhirah NadzreyBelum ada peringkat

- Schedule - A: (See Clause 10.1)Dokumen78 halamanSchedule - A: (See Clause 10.1)rupanta74100% (1)

- West Bengal Schedule Rates of Building Works 2015Dokumen399 halamanWest Bengal Schedule Rates of Building Works 2015Arunashish Mazumdar75% (8)

- BoqDokumen22 halamanBoqDheeraj ThakurBelum ada peringkat

- Series 2000 - DrainageDokumen36 halamanSeries 2000 - DrainageBatenda FelixBelum ada peringkat

- Unit Rates Build UpDokumen6 halamanUnit Rates Build UpBernard KagumeBelum ada peringkat

- Quantity Take OffDokumen1 halamanQuantity Take OffSadiq_Hammad_5394Belum ada peringkat

- ECA Form 2Dokumen2 halamanECA Form 2ninaamirahmBelum ada peringkat

- Rebar Cutting ListDokumen31 halamanRebar Cutting ListJona PajilaBelum ada peringkat

- Steelwork Quantity Take-Off For BATU 3 Advertisement Board Item Description Unit Qty KG/M KG LDokumen4 halamanSteelwork Quantity Take-Off For BATU 3 Advertisement Board Item Description Unit Qty KG/M KG LlaurenjiaBelum ada peringkat

- Boq 6-14-2022Dokumen5 halamanBoq 6-14-2022kiran NeedleweaveBelum ada peringkat

- Topic 2 RoofDokumen20 halamanTopic 2 RoofChee HernBelum ada peringkat

- Taking Off SewerageDokumen4 halamanTaking Off SewerageMrJanji JohnyBelum ada peringkat

- Plan Take OffDokumen44 halamanPlan Take OfftinBelum ada peringkat

- COST ANALYSIS - Foundation of Gantry TowerDokumen9 halamanCOST ANALYSIS - Foundation of Gantry TowerDesign explorer olomizanaBelum ada peringkat

- Item Rate Boq: Validate Print HelpDokumen7 halamanItem Rate Boq: Validate Print HelpNaveen NagisettiBelum ada peringkat

- Standard Method of Measurement For Building Works, Ghana GHANA Library Authority International Standard Book Number (Isbn)Dokumen57 halamanStandard Method of Measurement For Building Works, Ghana GHANA Library Authority International Standard Book Number (Isbn)Nnanyelu OnyekwulujeBelum ada peringkat

- Old Estimate For Mr. Annadurai, Erode.: Rate in Rs. in Rs. Plinth Area Measurement:-Total AmountDokumen35 halamanOld Estimate For Mr. Annadurai, Erode.: Rate in Rs. in Rs. Plinth Area Measurement:-Total AmountsivabuvanaBelum ada peringkat

- Rate Analysis 15-09 Final Road LATESTDokumen18 halamanRate Analysis 15-09 Final Road LATESTKotoju Rajitha SaisindhujaBelum ada peringkat

- Deflection Egyptian CodeDokumen3 halamanDeflection Egyptian CodeMagdy BakryBelum ada peringkat

- Bill No. 10 - Construction of Office and StoreDokumen25 halamanBill No. 10 - Construction of Office and StorePn EkanayakaBelum ada peringkat

- Construction of Drainage System & DevelopmeDokumen6 halamanConstruction of Drainage System & DevelopmeYashika Bhathiya JayasingheBelum ada peringkat

- Quantity Take Off Bored Pile and King PostDokumen4 halamanQuantity Take Off Bored Pile and King PostSANJAY SBBelum ada peringkat

- Bar Bending Schedule RCC SlabDokumen8 halamanBar Bending Schedule RCC SlabRajendra BadjatyaBelum ada peringkat

- Rate Analysis 074-75 TerhathumDokumen569 halamanRate Analysis 074-75 TerhathumBinod Raj GiriBelum ada peringkat

- Specifications: Project: Proposed Two-Storey Residential BuildingDokumen9 halamanSpecifications: Project: Proposed Two-Storey Residential BuildingRey Gabriel Advincula Granada100% (1)

- Welding Electrode ChartDokumen2 halamanWelding Electrode ChartZaheed Manoo50% (2)

- AcousticsDokumen47 halamanAcousticsnidhimagoonBelum ada peringkat

- Technical Catalogue - XLPE Insulated HT CablesDokumen30 halamanTechnical Catalogue - XLPE Insulated HT Cablesoadipphone7031100% (1)

- oscarUK05 07Dokumen4 halamanoscarUK05 07nikolatnBelum ada peringkat

- Outokumpu - Steel Grade 01Dokumen2 halamanOutokumpu - Steel Grade 01royalfabioBelum ada peringkat

- Russia Standard PDFDokumen2 halamanRussia Standard PDFHakan CetinkayaBelum ada peringkat

- ITP AllDokumen1 halamanITP AllMuhammadIqbalMughalBelum ada peringkat

- ESDEP Vol0302Dokumen124 halamanESDEP Vol0302aladinmf1Belum ada peringkat

- Kaolin For Paint Overview PDFDokumen2 halamanKaolin For Paint Overview PDFAmir FadzilBelum ada peringkat

- Price Bid PDFDokumen5 halamanPrice Bid PDFKrunal BhanderiBelum ada peringkat

- 5.10.1 e HoloribDokumen8 halaman5.10.1 e HoloribÔzØnè BęržëŕkBelum ada peringkat

- Anchor BoltsDokumen24 halamanAnchor BoltsJose Jesus Chagolla LopezBelum ada peringkat

- Super Nippon Weather BondDokumen6 halamanSuper Nippon Weather BondKazumi MySarahBelum ada peringkat

- GFRC PanelsDokumen8 halamanGFRC PanelsramluramanaBelum ada peringkat

- PW Consumables en 2013Dokumen8 halamanPW Consumables en 2013Vicente Elías Venegas LunaBelum ada peringkat

- 0 B4 GU13 C 4 Z Cu 1 VUx Ed 2 X 1 Un ZP TK UDokumen16 halaman0 B4 GU13 C 4 Z Cu 1 VUx Ed 2 X 1 Un ZP TK ULarizza Delos SantosBelum ada peringkat

- MoldaviteDokumen3 halamanMoldavitenight hawkBelum ada peringkat

- NORSOK M-501: Frequently Asked QuestionsDokumen7 halamanNORSOK M-501: Frequently Asked QuestionsSam JoseBelum ada peringkat

- Fisa Tehnica Beton Clasa C25-30 TORCRETDokumen1 halamanFisa Tehnica Beton Clasa C25-30 TORCRETryyssoBelum ada peringkat

- Phosphorus/Copper Brazing Alloys: Harris O Stay-Silv 5 and Stay-Silv 6 Dynaflow Stay-Silv 15Dokumen6 halamanPhosphorus/Copper Brazing Alloys: Harris O Stay-Silv 5 and Stay-Silv 6 Dynaflow Stay-Silv 15HassanSobohBelum ada peringkat

- DurraWallSystem 050606Dokumen1 halamanDurraWallSystem 050606tallerautorepBelum ada peringkat

- IBS Seminar Notes Yeap 1.0 - QS Perspective On HKL SCACC 10dec13Dokumen18 halamanIBS Seminar Notes Yeap 1.0 - QS Perspective On HKL SCACC 10dec13mrlobboBelum ada peringkat

- Cement SaminarDokumen11 halamanCement SaminarGayathri ShastryBelum ada peringkat

- Organic CoatingDokumen29 halamanOrganic CoatingThanh Nguyen100% (1)

- PROJ-DOC-PRsoft Copy of Project Report PDFDokumen42 halamanPROJ-DOC-PRsoft Copy of Project Report PDFjethwa999_62474255Belum ada peringkat

- Roof CoveringDokumen20 halamanRoof CoveringDiky AfriantoBelum ada peringkat

- What Is Framing?Dokumen6 halamanWhat Is Framing?Mark Custodio AquinoBelum ada peringkat