Drive Report

Diunggah oleh

lisahunHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Drive Report

Diunggah oleh

lisahunHak Cipta:

Format Tersedia

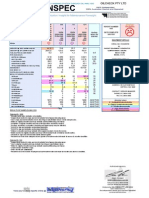

Report Number:

K Number Ref:

Sample Number:

Cust Sample ID/Job No:

Schedule Class:

Date Sampled:

Date Received:

Hrs On Oil:

Hrs On Equipment:

Status

999

899

714

3DRV

31/05/1999

31/05/1999

1284

8284

3DRV

26/04/1999

27/04/1999

1037

8037

3DRV

10/03/1999

15/03/1999

764

7764

3DRV

10/07/1998

22/07/1998

512

7512

STATUS

673

REPORT NUMBER

999

Caution

values for

DRIVE

Take Action

DATE COMPLETE

1/06/1999

EQUIPMENT DETAILS

SERIAL NO: H12345678B

ID: 1234

PARENT EQUIPMENT: EXCAVATOR

METALS (ASTM D5185) ppm

ALUMINIUM ppm

ANTIMONY ppm

BARIUM ppm

BORON ppm

CADMIUM ppm

CHROMIUM ppm

CALCIUM ppm

COPPER ppm

IRON ppm

LEAD ppm

MOLYBDENUM ppm

NICKEL ppm

PHOSPHORUS ppm

SILICON ppm

97 C

0

8

0

2

0

18

6

1262 C

0

18

8

1036

301 D

SILVER ppm

SODIUM ppm

TIN ppm

TITANIUM ppm

ZINC ppm

VANADIUM

16

0

0

11

0

16

0

8

0

0

0

8

4

359 A

0

15

2

1051

35 A

0

18

0

0

4

0

12

0

8

0

0

1

27

0

335 B

1

15

17

0.101

30 A

0

11

0

0

30

0

18 A

11

0

0

0

0

0

21

30

ADDITIVE

8

51

59

150

0

51

3

ADDITIVE

7

599

29

30

0

0

51

0

51

0

5

0

NITRATION (OL1100)

WATER (OL1100) ppm

PARTICLE QUALITY INDEX (OL1028)

VISCOSITY @ 40C (ASTM D445) cSt

RETAINED SOLIDS @ 8.0m w/w (OL1003) %w/w

MAKE: ACME

MODEL: BIG DIG

OPERATION DETAILS

OIL TYPE: ALPHA SP

OIL GRADE: ISO 460

TOP UP (L):

LUBE CAPACITY (L):

OIL CHANGED: N

BRANCH: SYDNEY

SITE: MINE SITE

CUSTOMER DETAILS

CUSTOMER CODE: 123456

NAME: SMART PTY LTD

ADDRESS: 95 CLAPHAM ROAD

SEFTON 2162 NSW

CONTACT: SERVICE MANAGER

PHONE: 61 2 9644 9100

FTIR SCAN (JOAP)

OXIDATION (OL1100)

COMPARTMENT: FINAL DRIVE

11.4

5.5

0.627

188

449.49

1430

14.8

6.7

0.024

92

443.51

493

10.0

5.0

0.077

77

440.45

220

11.6

5.6

0.072

22

331.47 X

29

RESULTS OF SAMPLE ANALYSIS

FAX: 61 2 9644 5865

0.100

200

300

Abnormal values

X = Uncategorised abnormal value

A = Slightly elevated abnormal value

B = Elevated abnormal value

C = High abnormal value

D = Critical abnormal value

Filtergram at 60 times actual size

Comments: 999

* Iron content is high and could indicate gear/bearing wear.

* Retained solids is critical and consistent with dirt/wear debris. Check seals.

* Silicon/aluminium content is critical and may reflect dirt entry. Check seals.

* Water content is critical . Check for source of moisture ingress. Check seals.

* Silicon increase at >500% is critical.

* Aluminium increase at 389% is critical.

* Iron increase at 184% is elevated.

* Other results are satisfactory.

* Recommend oil be drained and new oil be sampled at half recommended intervals to monitor condition

Comments: 899

* Iron is slightly elevated and may indicate gear tooth/bearing wear.

* Retained solids is elevated and consistent with dirt/wear debris. Check seals.

* Silicon is slightly elevated and may indicate dirt or gasket sealant.

* Other results are satisfactory.

* Recommend current oil be resampled at half recommended intervals to monitor and assess condition.

Comments: 714

* Iron content is elevated and could indicate gear tooth/bearing wear.

* Silicon is slightly elevated and may indicate dirt or gasket sealant.

* Iron increase at 280% is high.

* Other results are satisfactory.

* Recommend current oil be resampled at half recommended intervals to monitor and assess condition.

SMART PTY LTD

95 CLAPHAM ROAD

SEFTON 2162 NSW

9

8

7

6

5

4

3

2

1

0

600

500

400

300

200

100

Normalised Iron ppm

Normalised ppm

Wear metals

Chromium Cr

Copper as Cu

Lead as Pb

Tin as Sn

Iron as Fe

0

6

Sample

Water

Contamination elements

350

0.7

300

0.6

0.5

Sodium as Na

200

Aluminium Al

150

Silicon as Si

ppm

ppm

250

0.4

100

0.2

50

0.1

Water

0.3

0

6

Sample

Sample

Did you know: The information that you would normally find

on the back of the report has moved. Weve made it easier to

read and understand on the web along with other interesting

information. For more information visit us on the web at

www.oilcheck.com.au/questions

Did you know: Graphed metal results are normalised, this

means we are only comparing results at standard intervals i.e.

200 hours for engines, 500 hours for non-engines. This is only for

trending purposes so you can compare the current results with

past results. For more information visit us on the web at

www.oilcheck.com.au/questions

Did you know: It is important to fill out the sample description

forms correctly. The information that you provide us with will help

us to know more about your sample, and help us help you for

when you get the report back. For more information visit us on

the web at

www.oilcheck.com.au/questions

Did you know: If you take the sample when the oil is cold it

will reduce the accuracy of the sample. The majority of the

particles we are looking for fall to the bottom and may not be

tested. So make sure the samples are taken at operating

temperatures to get the maximum benefit out of your PROBE oil

analysis

www.oilcheck.com.au/questions

This analysis is to aid scheduled maintenance only. NO GUARANTEE expressed or implied is made against failure of this equipment

Anda mungkin juga menyukai

- How to Rebuild & Modify Rochester Quadrajet CarburetorsDari EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsPenilaian: 5 dari 5 bintang5/5 (2)

- Chrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildDari EverandChrysler TorqueFlite A-904 and A-727 Transmissions: How to RebuildPenilaian: 5 dari 5 bintang5/5 (1)

- Gel Electrophoresis Lab ReportDokumen10 halamanGel Electrophoresis Lab Reportapi-31150900783% (6)

- Manual Servicio Case 580 Super K Construction KingDokumen1.312 halamanManual Servicio Case 580 Super K Construction KingSergio Ramos98% (46)

- 63 Fuller RTF 11608 Transmission Service ManualDokumen106 halaman63 Fuller RTF 11608 Transmission Service ManualEmanuel SepulvedaBelum ada peringkat

- Tribocare Cylinder Oil Drain AnalysisDokumen10 halamanTribocare Cylinder Oil Drain AnalysisSwaminathan KbBelum ada peringkat

- Concrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateDokumen2 halamanConcrete Mix Design: Strength (Psi) 4000 Slump (In) : 3 To 4 Max. Aggregate (In) : 0.750 Cement: Coarse AggregateAnonymous PeFQLw19Belum ada peringkat

- Machine Profiles: 789, 789B and 789C Construction and Mining TrucksDokumen8 halamanMachine Profiles: 789, 789B and 789C Construction and Mining TrucksJavier Pagan TorresBelum ada peringkat

- Oil Analysis Report ExplanationDokumen2 halamanOil Analysis Report Explanationzrcjsyll100% (1)

- Customer Cat ET OverviewDokumen36 halamanCustomer Cat ET Overviewlisahun100% (5)

- 250 Service Manual PDFDokumen47 halaman250 Service Manual PDFSnejana Stoianov100% (2)

- Wheel Motor Inspection GuidelinesDokumen29 halamanWheel Motor Inspection GuidelinesRimbertBelum ada peringkat

- Baroque MusicDokumen15 halamanBaroque Musicthot777100% (2)

- F2970.1558734-1 Trampoline CourtDokumen22 halamanF2970.1558734-1 Trampoline CourtKannan LakshmananBelum ada peringkat

- Analisis Motor de Traccion (Ingles) PDFDokumen28 halamanAnalisis Motor de Traccion (Ingles) PDFVictorDjChiqueCastillo100% (1)

- Instruction Manual for Capacitor Voltage TransformersDokumen22 halamanInstruction Manual for Capacitor Voltage Transformerst.o.i.n.gBelum ada peringkat

- Komatsu HD785-7 Shop Manual PDFDokumen1.491 halamanKomatsu HD785-7 Shop Manual PDFIB EldinBelum ada peringkat

- Automatic Retarder Control (ARC)Dokumen5 halamanAutomatic Retarder Control (ARC)lisahun100% (1)

- API 676 Datasheet PDFDokumen6 halamanAPI 676 Datasheet PDFPierre Norris0% (1)

- 773E ToolingListDokumen12 halaman773E ToolingListlisahunBelum ada peringkat

- Afton Lube Specification HandbookDokumen425 halamanAfton Lube Specification HandbookvsssarmaBelum ada peringkat

- GX Audit Internal Audit Risk and Opportunities For 2022Dokumen26 halamanGX Audit Internal Audit Risk and Opportunities For 2022Muhammad SamiBelum ada peringkat

- Wearcheck Oil Analysis ReportDokumen2 halamanWearcheck Oil Analysis Reportapi-105696388100% (1)

- Cummins Used Oil Analysis For HHP EnginesDokumen38 halamanCummins Used Oil Analysis For HHP EnginesRushikesh Sawant100% (2)

- DG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsDokumen11 halamanDG Maintenance Work List and Maintenance Track Record:-Ht DG Name Plate DetailsMugeshBelum ada peringkat

- Oli Cat Fluid Info - Part NumberDokumen46 halamanOli Cat Fluid Info - Part NumberHvbry100% (1)

- Oil Analysis Techniques For High Horsepower Diesel EnginesDokumen31 halamanOil Analysis Techniques For High Horsepower Diesel EnginesAli ArdinBelum ada peringkat

- 992G HYD TroubleshootingDokumen9 halaman992G HYD TroubleshootinglisahunBelum ada peringkat

- Manpower Calculator Introduction V1.5Dokumen18 halamanManpower Calculator Introduction V1.5lisahunBelum ada peringkat

- Understanding Oil Analysis TestsDokumen4 halamanUnderstanding Oil Analysis TestseigersumarlyBelum ada peringkat

- Gps Positioning and SurveyingDokumen62 halamanGps Positioning and SurveyinglisahunBelum ada peringkat

- Origen de Metales para CaterpillarDokumen16 halamanOrigen de Metales para CaterpillarHunab379Belum ada peringkat

- 793 793b 793cDokumen8 halaman793 793b 793cJulio Elias Mayta RamosBelum ada peringkat

- McBride Music Company - Woodwind and Brass Instrument RepairDokumen2 halamanMcBride Music Company - Woodwind and Brass Instrument Repairlisahun0% (1)

- Approved Lubricants for Cone Drive Worm Gear Speed ReducersDokumen2 halamanApproved Lubricants for Cone Drive Worm Gear Speed ReducersJustin HendrixBelum ada peringkat

- Tabela de Motores ScaniaDokumen9 halamanTabela de Motores Scaniaamd.cross.over over.cross.amd100% (1)

- Fuel Dilution of Engine OilDokumen2 halamanFuel Dilution of Engine Oillisahun100% (3)

- API 676 Pump Rotary DatasheetDokumen6 halamanAPI 676 Pump Rotary DatasheetvuongBelum ada peringkat

- Global Crude Assay Report 15-4019 Doba Crude Rev2Dokumen16 halamanGlobal Crude Assay Report 15-4019 Doba Crude Rev2hbates100% (1)

- Dri (Operation) : IntroductionDokumen33 halamanDri (Operation) : Introductionsourajpatel100% (6)

- YavorskyDokumen544 halamanYavorskyFilipe PadilhaBelum ada peringkat

- PECJ0003-05 July2014Dokumen448 halamanPECJ0003-05 July2014lisahunBelum ada peringkat

- LPG Cylinder Specifications, Testing and SegregationDokumen34 halamanLPG Cylinder Specifications, Testing and SegregationShubhamBelum ada peringkat

- 11249-Ispat Indo-500 Mill Rolling Mill BDokumen1 halaman11249-Ispat Indo-500 Mill Rolling Mill BBahtiar YudhistiraBelum ada peringkat

- Eastman 2197 Turbo-Oil TDS - SkySupplyUSADokumen2 halamanEastman 2197 Turbo-Oil TDS - SkySupplyUSASkySupplyUSABelum ada peringkat

- 07468-Ispatindo-Cellar 1 Rolling MillDokumen1 halaman07468-Ispatindo-Cellar 1 Rolling MillBahtiar YudhistiraBelum ada peringkat

- Pt. Corelab Indonesia: Oil Analysis ResultDokumen1 halamanPt. Corelab Indonesia: Oil Analysis ResultBahtiar Yudhistira100% (1)

- Engine Oil Analysis: Home Sales/Installations Parts Service Vessel Services ContactDokumen3 halamanEngine Oil Analysis: Home Sales/Installations Parts Service Vessel Services Contactmehdi kamaliBelum ada peringkat

- Oring ManualDokumen39 halamanOring ManualbewnigolBelum ada peringkat

- ASTM D 6593 - 00 Rdy1otmtmdaDokumen85 halamanASTM D 6593 - 00 Rdy1otmtmdaEnrique Alejandro OvandoBelum ada peringkat

- Approved Lubrication DDokumen2 halamanApproved Lubrication DMostafa MohamedBelum ada peringkat

- Damaged by Fuel SulfurDokumen4 halamanDamaged by Fuel Sulfurbambang eengBelum ada peringkat

- PDS - BearingCheck 894 and BearingCheck 824Dokumen1 halamanPDS - BearingCheck 894 and BearingCheck 824ratninp9368Belum ada peringkat

- 2012 Noa Catalog For PC ScreenDokumen0 halaman2012 Noa Catalog For PC ScreenJuan Manuel Gomez HernandezBelum ada peringkat

- Marine Fuel Specification and Test Methods Day 1Dokumen82 halamanMarine Fuel Specification and Test Methods Day 1riveraalvinBelum ada peringkat

- Re: (Panduan) Setting Carb V13: Posts: 903 WakakakaaaaDokumen9 halamanRe: (Panduan) Setting Carb V13: Posts: 903 WakakakaaaaHil MellBelum ada peringkat

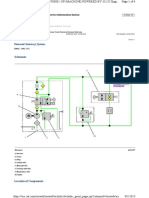

- 231,241,271 SchematicDokumen4 halaman231,241,271 Schematicab5951Belum ada peringkat

- 605 DatasheetDokumen1 halaman605 DatasheetDiego NetoBelum ada peringkat

- ASTM D 445 Viscosity Standard for Petroleum ProductsDokumen3 halamanASTM D 445 Viscosity Standard for Petroleum ProductsIan JoeBelum ada peringkat

- SHPbrochure (Rev-01,2014 2 16)Dokumen8 halamanSHPbrochure (Rev-01,2014 2 16)Epure GabrielBelum ada peringkat

- Cummins SB 4022060-Oil Analysis Techniques For High Horsepower Diesel Engines-UpdateDokumen34 halamanCummins SB 4022060-Oil Analysis Techniques For High Horsepower Diesel Engines-Updategilar herliana putraBelum ada peringkat

- Caterpillar Elevated Copper Levels in Used Oil SamplesDokumen3 halamanCaterpillar Elevated Copper Levels in Used Oil SamplesAnonymous Xi0dqd2Belum ada peringkat

- C12200Dokumen3 halamanC12200xgiorg100% (1)

- Understanding Elevated Copper Levels in Used Oil SamplesDokumen3 halamanUnderstanding Elevated Copper Levels in Used Oil SampleszuhdisulaemanBelum ada peringkat

- FS Lubricants. Oil Analysis ProgramDokumen8 halamanFS Lubricants. Oil Analysis ProgramManoj Kumar SinghBelum ada peringkat

- Mecanic AsDokumen6 halamanMecanic AsAnderson SantosBelum ada peringkat

- Premium Hydraulic Oil for Construction EquipmentDokumen2 halamanPremium Hydraulic Oil for Construction EquipmentWasimraja NanjwaniBelum ada peringkat

- O RigDokumen9 halamanO Rigavabhyankar9393Belum ada peringkat

- File 6Dokumen51 halamanFile 6Rinh Lai BaBelum ada peringkat

- Date: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17KDokumen2 halamanDate: Purchase Order No: Subject: Type: Batch No. SKD - S2 Spotcheck Developer 08D17Kisraelita77671Belum ada peringkat

- Brake Fluids Article R5 Bob Owen 230109Dokumen6 halamanBrake Fluids Article R5 Bob Owen 230109Kkbhuvan Kk100% (1)

- Pegasus 805 PdsDokumen2 halamanPegasus 805 PdsBudi NaisBelum ada peringkat

- QuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioDokumen4 halamanQuickServe en Línea - (4310736) ISX15 CM2250 SN Manual de ServicioHamilton miranda100% (1)

- Gas Engine Oil Analysis (Wear Check)Dokumen2 halamanGas Engine Oil Analysis (Wear Check)anibal_rios_rivasBelum ada peringkat

- S.O.S - Mining ForumDokumen32 halamanS.O.S - Mining ForumTC BengalonBelum ada peringkat

- Des para El Diesel AstmDokumen1 halamanDes para El Diesel AstmLuis Guardia MatosBelum ada peringkat

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceDari EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceBelum ada peringkat

- Beyond Mine Dispatch - Optimizing The Mining Value Chain - Wenco Mining SystemsDokumen5 halamanBeyond Mine Dispatch - Optimizing The Mining Value Chain - Wenco Mining Systemslisahun100% (1)

- Coda Training31Dokumen5 halamanCoda Training31lisahunBelum ada peringkat

- Geosat 8 UpdDokumen19 halamanGeosat 8 UpdlisahunBelum ada peringkat

- AMMJ Knowledge Centre Past Issue SummariesDokumen4 halamanAMMJ Knowledge Centre Past Issue SummarieslisahunBelum ada peringkat

- DT-94 EventDokumen6 halamanDT-94 EventlisahunBelum ada peringkat

- DT 102 EventDokumen17 halamanDT 102 EventlisahunBelum ada peringkat

- Dealer Stocking ListDokumen6 halamanDealer Stocking ListlisahunBelum ada peringkat

- Fuel Filter RestrictionDokumen2 halamanFuel Filter RestrictionlisahunBelum ada peringkat

- ORS Hardware and SchematicsDokumen11 halamanORS Hardware and Schematicslisahun100% (1)

- DT 101 HydraulicDokumen2 halamanDT 101 HydrauliclisahunBelum ada peringkat

- Lowongan Kerja Husky-CNOOC Madura Limited Februari 2015Dokumen4 halamanLowongan Kerja Husky-CNOOC Madura Limited Februari 2015lisahunBelum ada peringkat

- Engine ReportDokumen2 halamanEngine ReportlisahunBelum ada peringkat

- Lowongan Kerja MRT Jakarta Februari 2015Dokumen5 halamanLowongan Kerja MRT Jakarta Februari 2015lisahunBelum ada peringkat

- Maintenance ORSDokumen4 halamanMaintenance ORSlisahun100% (1)

- Welding PrecautionDokumen2 halamanWelding Precautionlisahun100% (1)

- Powered Stairway SystemDokumen4 halamanPowered Stairway Systemlisahun0% (1)

- Powered Stairway SystemDokumen4 halamanPowered Stairway Systemlisahun0% (1)

- EM SystemDokumen11 halamanEM SystemlisahunBelum ada peringkat

- Marketing BulletinDokumen7 halamanMarketing BulletinlisahunBelum ada peringkat

- Certified Marine AnalystDokumen1 halamanCertified Marine AnalystlisahunBelum ada peringkat

- Current Electricity O LevelDokumen59 halamanCurrent Electricity O LevelNoah OkitoiBelum ada peringkat

- MARS Motor Cross Reference InformationDokumen60 halamanMARS Motor Cross Reference InformationLee MausBelum ada peringkat

- Calculation of Moments and Shear: Input DataDokumen3 halamanCalculation of Moments and Shear: Input DataARSEBelum ada peringkat

- The 5th Edition of The World Health Organization Classification - of Haematolymphoid Tumours Myeloid and Histiocytic - Dendritic NeoplasmsDokumen17 halamanThe 5th Edition of The World Health Organization Classification - of Haematolymphoid Tumours Myeloid and Histiocytic - Dendritic NeoplasmsADMINISTRACION LABORATORIO INTERMEDICABelum ada peringkat

- How Ventilators Deliver BreathsDokumen51 halamanHow Ventilators Deliver BreathsArnaldo SantizoBelum ada peringkat

- QF-16 Security ProceduresDokumen55 halamanQF-16 Security Proceduresmaruka33Belum ada peringkat

- Handouts For Semantics GradDokumen8 halamanHandouts For Semantics GradPhuong Thao DangBelum ada peringkat

- Key-Words: - Techniques, Reflection, Corporal Punishment, EffectiveDokumen7 halamanKey-Words: - Techniques, Reflection, Corporal Punishment, EffectiveManawBelum ada peringkat

- Socsci 032 Midterm Compilation NotesDokumen12 halamanSocsci 032 Midterm Compilation NotesCarla AbalaBelum ada peringkat

- Totally New Term Dates 2013.20Dokumen9 halamanTotally New Term Dates 2013.20nabub8Belum ada peringkat

- AirLocker PresentationDokumen11 halamanAirLocker PresentationjzuckertBelum ada peringkat

- The Photoconductive CellDokumen4 halamanThe Photoconductive Cellfasdasd123Belum ada peringkat

- Excel File - Business Computing - End Term (To Be Shared Vide Email)Dokumen301 halamanExcel File - Business Computing - End Term (To Be Shared Vide Email)Aman SankrityayanBelum ada peringkat

- CHAPTER 8 SULLIVAN MyReviewerDokumen7 halamanCHAPTER 8 SULLIVAN MyReviewerFrances LouiseBelum ada peringkat

- Bill Porter Updated PDFDokumen3 halamanBill Porter Updated PDFapi-362500677Belum ada peringkat

- Pamantasan NG Lungsod NG Maynila - Freshmen AdmissionDokumen6 halamanPamantasan NG Lungsod NG Maynila - Freshmen AdmissionPoppy HowellBelum ada peringkat

- Shrub - Wikipedia, The Free EncyclopediaDokumen5 halamanShrub - Wikipedia, The Free EncyclopediabmxengineeringBelum ada peringkat

- Laplace Transform solved problems explainedDokumen41 halamanLaplace Transform solved problems explainedduchesschloeBelum ada peringkat

- Parameter Pengelasan SMAW: No Bahan Diameter Ampere Polaritas Penetrasi Rekomendasi Posisi PengguanaanDokumen2 halamanParameter Pengelasan SMAW: No Bahan Diameter Ampere Polaritas Penetrasi Rekomendasi Posisi PengguanaanKhamdi AfandiBelum ada peringkat

- Jurnal Aceh MedikaDokumen10 halamanJurnal Aceh MedikaJessica SiraitBelum ada peringkat

- SDH PDFDokumen370 halamanSDH PDFClaudia GafencuBelum ada peringkat

- Big Bang TheoryDokumen9 halamanBig Bang TheoryLoo DrBradBelum ada peringkat