CE-515: Design of Steel Structures: Course Outline

Diunggah oleh

ZiaullahJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

CE-515: Design of Steel Structures: Course Outline

Diunggah oleh

ZiaullahHak Cipta:

Format Tersedia

CE -515: Design of Steel Structures

CE-515: Design of Steel Structures

M. Engg. (Civil), Fall 2014

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Course Outline

Review of elastic-plastic concepts of structural

behaviour; plastic design of beams and frames;

design of plate girders; compression member

with large width-thickness ratio; stiffened plate;

composite design and behaviour; behaviour of

rigid and semi-rigid connections; design

considerations for fracture and fatigue; design of

rigid frames; behaviour of multi-storey frames

and second-order analysis.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Recommended Books

Englekirk, R. E. (1994). Steel Structures: Controlling

Behaviour Through Design. John Wiley & Sons

Segui, W. T. (2007). Steel Design, Fourth Edition.

Thomson

McCormac, J. C. (1995). Structural Steel Design, Second

Edition. Harper Collins Publishers

AISC Steel Construction Manual

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Evaluation & Assessment

Sessional evaluation

(40 marks)

Assignments (10)

Mid-term test (10)

Final test (10)

Presentation (10)

Final exam

(60 marks)

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Introduction

Structural design may be defined as a mixture of art

and science combining the intuitive feeling for the

behaviour of a structure with rational principles of

mechanics (statics, solid mechanics, dynamics, etc.)

and structural analysis to produce a safe and

economical structure to serve its intended purposes.

Steel is one of the most important building materials in

the modern era. It is used solely or in combination with

other materials such as concrete, timber, composites,

etc., for a variety of purposes.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Advantages of Steel

Economy

Durability

Design flexibility

Simplicity

All weather construction

Easy repair

Recyclable

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Benefits of Structural Steel

Steel allows for reduced frame construction time and the

ability to construct in all seasons.

Steel makes large spans and bay sizes possible, providing

more flexibility for owners.

Steel is easier to modify and reinforce if architectural

changes are made to a facility over its life.

Steel is lightweight and can reduce foundation costs.

Steel is durable, long-lasting and recyclable.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Unique Aspects of Steel Construction

Procurement and management

of structural steel is similar to

other materials, but there are

some unique aspects to steel

construction:

Steel is fabricated off-site.

On-site erection is a rapid

process.

This gives use of structural steel

some scheduling advantages.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

History

Wootz is a steel developed in India around

300 BC.

Damascus steel is a hot-forged steel used in

Middle Eastern sword making from about

1100 to 1700 A.D.

Japanese sword making from special steel

forging is legendary.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

History

Ancient Use

Beginning 5th Century B.C.,

Weaponry, Ornaments and

Bridge construction in Middle

East, China and India.

Early Use

1777-79 First Cast iron bridge

in England

1780-1820 Several bridges all

over Europe, preliminary

rolled shapes manufactured

1820 -Rails manufactured

1840 -advent of wrought iron

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

History

Bessemer Process invented in 1855.

Bessemer converter introduced in 1870.

Early Structures:

1870s Brooklyn Bridge

1880s Eiffel Tower (330 m), steel bridges in Pittsburgh,

several steel buildings in Chicago (rebuilt after the

great fire)

1890sSeveral steel buildings in NY and Europe

1907 Quebec Bridge followed by several bridges

in North America

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

History

Modern structures

1930s Golden Gate bridge,

Empire State Building, etc.

1960s Sears Tower

Extensive use of steel for

medium to high rise buildings

and long span bridges.

Equally extensive use of steel in

industrial structures, airports,

etc.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Steel Design

Structures or structural components

primarily made of steel members attached

to each other appropriately.

Steel is excellent in both tension and

compression.

Since steel is primarily made of thin plate

like elements, they are susceptible to

buckling (local and overall).

Connections in steel are considerably

different from those in concrete. In steel,

the members are discrete or rolled

(fabricated) separately and are attached to

each other using appropriate connections.

CE -515: Design of Steel Structures

Shanghai world

finance centre

2014

CE -515: Design of Steel Fall

Structures

Steel: The Material Facts

Modern steel was first produced in 1738 in Sheffield England known

as Crucible steel. It was very pure, but difficult and expensive to

produce.

British Inventor Henry Bessemer produced the first economical

steel in 1856.

Today steel is produced in over 50 countries all across the world.

To every ton of Portland Cement produced, 3 tons of wood and 10

tons of steel are produced.

In 2003, China was the first country to produce more than 200

million tons of crude steel in a year (more than 20% of the worlds

steel is produced in China).

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Steel: The Material Facts

China is the worlds largest consumer of steel (cars, general

industry, construction).

The United States and China are the largest importers of steel.

Japan is the largest exporter of steel.

Steel is the worlds most recycled material.

More than 60% of the steel produced annually is from recycled

steel.

Properties of steel are not altered by how many times it is recycled.

Per pound of material, steel is the most efficient of all building

materials.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Steel: The Material Facts

A small amount of steel can do load-carrying tasks with a

fraction of the material needed from other materials such as

concrete or wood.

Steel is the densest of structural materials and therefore

handles longer spans, and produces lighter structures with

the greatest economy.

Steel can be found in fasteners (nails), structural

components, rebar, sheet-metal, appliances, cars, ships,

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Types of Steel

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Steel making

Basic shapes in relative

proportion

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Steel rolling

Cast steel is a relatively weak mass of coarse, uneven metal crystals, or

'grains'. Rolling causes this coarse grain structure to re-crystallize into a

much finer grain structure, giving greater toughness, shock resistance and

tensile (stress) strength.

Rolling is the main method used to shape steel into different products

after it has been cast. There are two types of rolling - hot and cold.

The rolling process (for both hot and cold) consists of passing the steel

between two rolls revolving at the same speed but in opposite directions.

The gap between the rolls is smaller than the steel being rolled, so that

the steel is reduced in thickness and at the same time lengthened.

One set of rollers is called a stand, and in any one mill there can be a

number of stands. One length of steel can pass through a stand a number

of times so that it is gradually reduced in size and progressively rolled to

the desired shape. A slab 230mm thick can end up only 1.5mm thick, but

many times longer, after the hot rolling process.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Material Behaviour

10

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Material Behaviour

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Material Behaviour

11

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Material Behaviour

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Material Behaviour

12

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Typical Steel Use

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Typical Steel Use

13

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

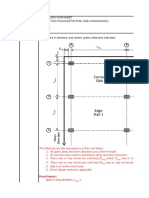

Steel Frame Structure

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Structures

14

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Bridges

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Bridges

15

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Bridges

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Bridges

16

CE -515: Design of Steel Structures

Architecturally Exposed Structural Steel AESS

Exposed steel will

require special

processing that will

impact the cost and

schedule.

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Typical Applications

The entire structure or key portions may use

AESS

Popular applications include

Hanging walkways

Framing in atriums and lobbies

Office interiors

Canopies

Airport terminals

17

CE -515: Design of Steel Structures

2014

CE -515: Design of Steel Fall

Structures

Typical Applications

18

Anda mungkin juga menyukai

- Steel Structures - Design Behaviour by Salmon JohnsonDokumen1.044 halamanSteel Structures - Design Behaviour by Salmon JohnsonRen Bautista92% (12)

- ST4091 - Design of Bridge StructuresDokumen19 halamanST4091 - Design of Bridge Structurescharvi shinyBelum ada peringkat

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesDari EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesPenilaian: 4.5 dari 5 bintang4.5/5 (16)

- Mineralogy 100A Syllabus 2016-EditDokumen4 halamanMineralogy 100A Syllabus 2016-Editnot realBelum ada peringkat

- CE 4219 Design of Steel Structure: Introductory LectureDokumen21 halamanCE 4219 Design of Steel Structure: Introductory LectureMARUFBelum ada peringkat

- Unit 1Dokumen11 halamanUnit 1Himal AryalBelum ada peringkat

- Chapter 1 Introduction To Steel DesignDokumen33 halamanChapter 1 Introduction To Steel DesignRami Demachki100% (1)

- BJTC 2023 Construction Technology: Chapter 5 - Steel and Other MetalsDokumen50 halamanBJTC 2023 Construction Technology: Chapter 5 - Steel and Other MetalsHermioneBelum ada peringkat

- Safi SS1 L1 Intoduction 2 11 2020 - 231226 - 100052Dokumen96 halamanSafi SS1 L1 Intoduction 2 11 2020 - 231226 - 100052AL-YEMENI al-yemeniBelum ada peringkat

- Steel DesignDokumen131 halamanSteel DesignAndrea RamirezBelum ada peringkat

- ReinforcementDokumen6 halamanReinforcementakinyemioaBelum ada peringkat

- Introduction To Steel StructuresDokumen71 halamanIntroduction To Steel StructuresJay-r MiñozaBelum ada peringkat

- Types of Steel Connections and Their SignificanceDokumen22 halamanTypes of Steel Connections and Their SignificanceAryan KhanBelum ada peringkat

- Lecture 01 - Introduction To Steel StructuresDokumen20 halamanLecture 01 - Introduction To Steel StructuresVai re Vai100% (1)

- Module 1 - Intro To Design of Steel StructuresDokumen10 halamanModule 1 - Intro To Design of Steel StructuresJuan Paulo DiazBelum ada peringkat

- Materials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CDokumen25 halamanMaterials and Methods in Building Construction-Iv: Presented By: Puneet B Rani P Ratan R Ritika B Sachin CNidhi MehtaBelum ada peringkat

- Lecture 1Dokumen72 halamanLecture 1feysalBelum ada peringkat

- Steel Trusses PDFDokumen73 halamanSteel Trusses PDFmayuresh barbarwar100% (1)

- Bhemba Re SteelDokumen26 halamanBhemba Re SteelAshley ChikodziBelum ada peringkat

- RSW 05 - Introduction To Steel ConstructionDokumen8 halamanRSW 05 - Introduction To Steel ConstructionarpigaoBelum ada peringkat

- Avani and RitijaDokumen17 halamanAvani and RitijaDevyaniAgrawalBelum ada peringkat

- DSR Unit 1Dokumen69 halamanDSR Unit 1hujefaBelum ada peringkat

- Safi Ss1 l2 Stee Section Load Design Methods 09-11-2020Dokumen71 halamanSafi Ss1 l2 Stee Section Load Design Methods 09-11-2020esamalnhari77Belum ada peringkat

- Steel Member: Types and UsesDokumen8 halamanSteel Member: Types and Usesgunjan kandariBelum ada peringkat

- Structural Design: Jejomar Duque, CeDokumen174 halamanStructural Design: Jejomar Duque, CeSoro SorotBelum ada peringkat

- Payra, Jimwell L, AR 4C ES433, Research Work 2 (Finals)Dokumen23 halamanPayra, Jimwell L, AR 4C ES433, Research Work 2 (Finals)Jimwell Linsangan PayraBelum ada peringkat

- ST4091 - Design of Bridge StructuresDokumen20 halamanST4091 - Design of Bridge Structurescharvi shinyBelum ada peringkat

- LECTURE 1.1 - Introduction To Steel DesignDokumen44 halamanLECTURE 1.1 - Introduction To Steel DesignAnn loraine BanzonBelum ada peringkat

- Lec1 & Lec2 Intro and LoadsDokumen115 halamanLec1 & Lec2 Intro and Loadsjaffer talhaBelum ada peringkat

- Steel StructureDokumen6 halamanSteel StructureONG VBelum ada peringkat

- Lect 01-02Dokumen18 halamanLect 01-02thorkhan42Belum ada peringkat

- Steel Structures Design and Behavior 4Th Edition Solution Manual Salmon Johnson MalhasDokumen7 halamanSteel Structures Design and Behavior 4Th Edition Solution Manual Salmon Johnson MalhasGreen MyanmarBelum ada peringkat

- Construction Engineering and Building Information Modelling: Dr. Nasir JavedDokumen73 halamanConstruction Engineering and Building Information Modelling: Dr. Nasir JavedBilal JamilBelum ada peringkat

- Module 1 - Introduction To Structural Steel DesignDokumen13 halamanModule 1 - Introduction To Structural Steel DesignNiña Criselle PasiaBelum ada peringkat

- Steel Truss, Girder, BridgeDokumen55 halamanSteel Truss, Girder, BridgeShai AranasBelum ada peringkat

- Composite Structure (31-38)Dokumen48 halamanComposite Structure (31-38)Badri DadiBelum ada peringkat

- Benz StadiumDokumen18 halamanBenz StadiumHARI NIVETHAN K G 20BAR0026Belum ada peringkat

- Lecture 01Dokumen49 halamanLecture 01shalukaBelum ada peringkat

- III Civil Vi Sem Question BankDokumen281 halamanIII Civil Vi Sem Question BankDr Kaarthik MBelum ada peringkat

- Steel StaircaseDokumen17 halamanSteel StaircaseKarthick CrazeiBelum ada peringkat

- 1 - Structural Steel Properties and Steel ProductsDokumen12 halaman1 - Structural Steel Properties and Steel ProductsfostbarrBelum ada peringkat

- CE 5001 Structural Steel Design Lecture 01Dokumen49 halamanCE 5001 Structural Steel Design Lecture 01Oshada Attygalle100% (1)

- Chapter One - Introduction To Steel StructuresDokumen8 halamanChapter One - Introduction To Steel StructuresJohn Philip Molina NuñezBelum ada peringkat

- Steel As A Structural MaterialDokumen3 halamanSteel As A Structural MaterialsisayBelum ada peringkat

- Design of Steel Structures 2Dokumen3.379 halamanDesign of Steel Structures 2Structural SpreadsheetsBelum ada peringkat

- Ilovepdf Merged PDFDokumen784 halamanIlovepdf Merged PDFRe DesignBelum ada peringkat

- TOS III Chapter V Design of Steel Structures. A.PropertiesDokumen4 halamanTOS III Chapter V Design of Steel Structures. A.PropertiesShyam WanaskarBelum ada peringkat

- Design of Steel StructuresDokumen2.529 halamanDesign of Steel StructuresStructural Spreadsheets75% (8)

- Steel 1Dokumen25 halamanSteel 1basanthi noorbashaBelum ada peringkat

- Iare SSDD LN PDFDokumen94 halamanIare SSDD LN PDFNi MeshBelum ada peringkat

- Lecture 19Dokumen35 halamanLecture 19RaviBelum ada peringkat

- Structural SteelworkDokumen15 halamanStructural SteelworkkgatoBelum ada peringkat

- Steel + Wood StructuresDokumen129 halamanSteel + Wood StructuresYigezu YehombaworkBelum ada peringkat

- Steel As A Structural MaterialDokumen10 halamanSteel As A Structural MaterialFaisal ShahzadBelum ada peringkat

- III Design of Steel Structures Unit 1Dokumen76 halamanIII Design of Steel Structures Unit 1laiju p bBelum ada peringkat

- Optimum Unbraced Length Ratios of Slender Steel Sections: Saleem M. Umair, Q. Hisham, and Zahid A. SiddiqiDokumen5 halamanOptimum Unbraced Length Ratios of Slender Steel Sections: Saleem M. Umair, Q. Hisham, and Zahid A. SiddiqimargitorsiBelum ada peringkat

- Steel Structures - (Introduction) - 1Dokumen6 halamanSteel Structures - (Introduction) - 1Ceren ŞirinBelum ada peringkat

- Design of Steel StructuresDokumen10 halamanDesign of Steel Structuresviveksp99Belum ada peringkat

- Structural Detailing of Steel Connection XstructuresDokumen340 halamanStructural Detailing of Steel Connection XstructuresAl Hassan Jr.100% (2)

- Steel and Steel Making: Fact: Carbon Steels Make Up About 90% of All Steel ProductionDokumen6 halamanSteel and Steel Making: Fact: Carbon Steels Make Up About 90% of All Steel ProductionSAMANTHA SARAH PURBABelum ada peringkat

- American Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingDari EverandAmerican Blacksmithing, Toolsmiths' and Steelworkers' Manual - It Comprises Particulars and Details Regarding:: the Anvil, Tool Table, Sledge, Tongs, Hammers, How to use Them, Correct Position at an Anvil, Welding, Tube Expanding, the Horse, Anatomy of the Foot, Horseshoes, Horseshoeing, Hardening a Plowshare and BabbitingBelum ada peringkat

- BM Products QC ProcedureDokumen6 halamanBM Products QC ProcedureZiaullahBelum ada peringkat

- BMP - Brochure (Latest)Dokumen11 halamanBMP - Brochure (Latest)ZiaullahBelum ada peringkat

- Combined Footings FPS SystemDokumen13 halamanCombined Footings FPS SystemZiaullahBelum ada peringkat

- CE-515: Design of Steel Structures: Shear StrengthDokumen12 halamanCE-515: Design of Steel Structures: Shear StrengthZiaullahBelum ada peringkat

- CE-515: Design of Steel StructuresDokumen15 halamanCE-515: Design of Steel StructuresZiaullahBelum ada peringkat

- Soil Lab Report Format 1Dokumen10 halamanSoil Lab Report Format 1ZiaullahBelum ada peringkat

- Mangla Dam Raising ProjectDokumen41 halamanMangla Dam Raising ProjectZiaullah100% (1)

- Highway Material ManualDokumen59 halamanHighway Material ManualHany Seif-Aldien NasserBelum ada peringkat

- Manufacturing Technology II - Notes PDFDokumen17 halamanManufacturing Technology II - Notes PDFSenthil Kumar Subramanian100% (1)

- Non-Catalytic and Heterogeneous Acid/base-Catalyzed Biodiesel Production: Recent and Future DevelopmentsDokumen34 halamanNon-Catalytic and Heterogeneous Acid/base-Catalyzed Biodiesel Production: Recent and Future DevelopmentsJelian GraceBelum ada peringkat

- Hedenquist 2018 - Epithermal Features at Shallow DepthDokumen26 halamanHedenquist 2018 - Epithermal Features at Shallow Depthcarlos arroyo huaracaBelum ada peringkat

- Dievar D20140715 PDFDokumen16 halamanDievar D20140715 PDFRizal IephoBelum ada peringkat

- Case Study On Operational Inspection of A Fluidised Bed Combustion BoilerDokumen31 halamanCase Study On Operational Inspection of A Fluidised Bed Combustion Boilerparthi20065768Belum ada peringkat

- Pencetan Slide 4aDokumen59 halamanPencetan Slide 4aFaradita RahmaBelum ada peringkat

- Salient Features of LHB CoachesDokumen3 halamanSalient Features of LHB CoachesVijay AnandBelum ada peringkat

- Samsung 25R MSDSDokumen8 halamanSamsung 25R MSDSRais Ovadeyyanusasey AliemBelum ada peringkat

- Materialqualitaeten EDokumen2 halamanMaterialqualitaeten EjvilamaiorBelum ada peringkat

- Poly Aluminum Chloride ProductionDokumen7 halamanPoly Aluminum Chloride ProductionTermodynamicsBelum ada peringkat

- DOICT - Technical SpecificationsDokumen6 halamanDOICT - Technical Specificationsahmadmukit0Belum ada peringkat

- Topic 7Dokumen39 halamanTopic 7deema dmdBelum ada peringkat

- Sika® Latex R: Acrylic Latex, Bonding Agent and Admixture For Cement Mortar and ConcreteDokumen2 halamanSika® Latex R: Acrylic Latex, Bonding Agent and Admixture For Cement Mortar and ConcretepouyaBelum ada peringkat

- ROAD TO MY LEWIS ActivityDokumen1 halamanROAD TO MY LEWIS ActivityCristy SevillaBelum ada peringkat

- Foaming Capacity of SoapsDokumen5 halamanFoaming Capacity of SoapsGurbaaz GillBelum ada peringkat

- Weld Metal CertificateDokumen1 halamanWeld Metal CertificatePhương Do QuangBelum ada peringkat

- Traffic Analysis and Design of Flexible Pavement With Cemented Base and SubbaseDokumen7 halamanTraffic Analysis and Design of Flexible Pavement With Cemented Base and Subbasemspark futuristicBelum ada peringkat

- Boq Proposed 3 Storey With Penthouse Edited As of 12062018Dokumen27 halamanBoq Proposed 3 Storey With Penthouse Edited As of 12062018John CedricBelum ada peringkat

- Lecture-Unit 7 Chemical EnergeticsDokumen5 halamanLecture-Unit 7 Chemical EnergeticsKemoy FrancisBelum ada peringkat

- PVC Butterfly Valve (Lever)Dokumen4 halamanPVC Butterfly Valve (Lever)Elias SusantoBelum ada peringkat

- Ra6969 MH - Mavic BDokumen68 halamanRa6969 MH - Mavic BVinz SelabeBelum ada peringkat

- Effect of Pasture Improvement Managements On Physical Properties and Water Content Dynamics of A Volcanic Ash Soil in Southern ChileDokumen10 halamanEffect of Pasture Improvement Managements On Physical Properties and Water Content Dynamics of A Volcanic Ash Soil in Southern ChileJose CuevasBelum ada peringkat

- 8 AdsorptionDokumen85 halaman8 AdsorptionRush WahabBelum ada peringkat

- AAC Panel Is The Shortened Form of Autoclaved Aerated Concrete PanelDokumen8 halamanAAC Panel Is The Shortened Form of Autoclaved Aerated Concrete PanelcesareBelum ada peringkat

- S355G10 GBDokumen4 halamanS355G10 GBH41GAMINGBelum ada peringkat

- Cool - Ex MSDS - CompressedDokumen4 halamanCool - Ex MSDS - CompressedSofyanBelum ada peringkat

- Advanced Energy Materials - 2019 - Sultan - Single Atoms and Clusters Based Nanomaterials For Hydrogen Evolution OxygenDokumen48 halamanAdvanced Energy Materials - 2019 - Sultan - Single Atoms and Clusters Based Nanomaterials For Hydrogen Evolution Oxygenkangwei MaoBelum ada peringkat

- Flat SlabDokumen69 halamanFlat Slabmukhlesh100% (1)