AP113L - 0301 - 1 GM8 Plessey Ignition Harness

Diunggah oleh

dsgaviation0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

365 tayangan7 halamanGipsy Major Mk 8 Ignition Harness

Judul Asli

AP113L_0301_1 GM8 Plessey Ignition Harness

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniGipsy Major Mk 8 Ignition Harness

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

365 tayangan7 halamanAP113L - 0301 - 1 GM8 Plessey Ignition Harness

Diunggah oleh

dsgaviationGipsy Major Mk 8 Ignition Harness

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 7

AIR PUBLICATION

113L-0301-1

PLESSEY IGNITION HARNESS

FOR GIPSY MAJOR

| MK. 8 ENGINE

| GENERAL AND TECHNICAL INFORMATION

DSGAviation

vor dsgviation co.uk

mail@dsgavitoneoule

BY COMMAND OF THE DEFENCE COUNCIL

Zi [Bunn

Ministry of Defence

FOR USE IN THE

ROYAL NAVY

ROYAL AIR FORCE

(Prepared by the Ministry of Technology

Pret

Insued July 68 eet

RESTRICTED

AMENDMENT RECORD SHEET

‘To record the incorporation of an Amendment List

fn this publication, sign against the appropriate

ALL. No. and insert the date of incorporation,

Prelim

Page 2

RESTRICTED

[AL.No. AMENDED BY DATE AL. No] AMENDED BY | DATE

a z F

2 | Ea |

3 | x6 |

| | ”

| i |e

‘ I »

7 | «|

8 | 7 “

2 a

» | : ° : |

a “ | -

a | oo”

w | i | i

“ | «| |

is |

6 ” DSGAviati

" so | Miksewatonca

ie | a |

» 2 | |

» =| |

2 “| mo

2 | | s |

al | 0 r

uw | 7

a i =| t

26 | * Tt

w | oO

2 a |

2. © |

i | eo) |

a | el |

2 ~| ‘5 |

3 I wo |

ADANSL-0301-1

LIST OF CHAPTERS

1 Plessey ignition harness for Gipsy Major Mk. 8 engine

Chapter 1

PLESSEY IGNITION HARNESS FOR GIPSY MAJOR Mk. 8 ENGINE

‘CONTENTS

Page Page

1 Painting. 2

- ~ 1 Special ols... 2

“ 1 Make-up of fitings 2

. 1 Replacement of conductor 2

1 Testing 3

2

TABLES

No. Page

1 Lengo of conductors 2

2 Provisioning schedule right-hand 3

DSGAviation

pene 3 Provisioning schedule left-hand 3

mai@éegaratoncouk

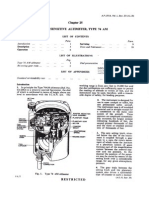

ILLUSTRATIONS

Fi Page

1 Ignition harness, righthand 4

2 Ieniton harness, lefthand 5

3 Special tol. - 6

Introduction SERVICING

1. The Plessey ignition harnesses Ref, No. 37B 3009 Prestesting

Kighs Hand and 378 3010 Left Hand ate ted © Comma op

the De-Havilland Gipsy Major Mk. § engine

DESCRIPTION

General

2. Bach harness, fg. 1 ot fig. 2, comprises a mani-

fi ‘ely magne cand ‘see yan ts

spark. plug conduit assemblies. The left-hand har

‘ess incorporates four spark piug elbow assemblies

and the righthand harness one, Details of these

assemblies are given in Para, 8 10 11.

awed July 68

3. Test each complete cable for continuity, using a

Multimeter Type 12889 from plug terminal to

‘magneto terminal

Inada resistance tes

4, Using Tester Ignition Type HT. Mk. 2 (Ref:

No, 56/39) te intron eer ce eae Re

the contact stud of eac conductor must be hotles

than 2 megohms,

1

Page 1

Cleaning

3. _Allparts should be cleaned with Trichlorethylene

Ref, No. 330547.

Painting

6 Paint used is Grey Cellulose to D-T-D. 7724.

Special Tools

7. The only sperial tool is C spanner see fg. 3.

‘TABLE 1

Length of Conductors

Cable cutting length

Length

Make-up of Fittings

‘Spark plug elbows assembly

8. A spark plag elbow is silver soldered at one end

1 a threaded union. A coupling unit is slid on to

the other end of the elbow and is retained by the

shoul er of a ferrule silver soldered to the end of the

elbow. A spring and washer located in the ferrule

are retained by an insert swaged into the ferrule

reves.

Spark ing conduit asiembly

9, Each end of the spark plug conduit assembly is

‘identical. The flexible conduit has a cap ferrule

‘waged to cach end. A coupling nat is retained by

the shoulder of a spring ferrule assembly fitted over

the end of the conduit and soft soldered. A spring

‘and washer located in the ferule are retained by an

insert swaged into the ferrule recess. On the left-

‘hand harness the four spak plag elbow assemblies

fir on to the spark plug conduit ends. To make up

‘the plug terminal a ceramic insulator fits over the

‘end of the cable on to the copper washer and the

end is sealed by a cup washer and contact stud. The

length of the conduit is covered by a neoprene sleeve

secured by rwo clamp rings

Magneto conduit assembly

10. The 0 magneto conduit assemblies are ident

cal except that the right-hand assembly is} in longer,

‘The flexible conduit has a cap ferrule swaged to each

nd. A flange and ferrule assembly is fied over one

end of the conduit and is soft soldered. At che other

end, 8 coupling nut is retained by the shoulder of

ferrule fired over the end of the conduit and soft

soldered. The length of the conduit is covered by a

neoprene sleeve secured by two clamp rings

Page 2

Manifoid Assembly

11, Manufactured from brass tube the manifold

has four screwed lugs silver soldered to three extrit-

sions and to the end of the tube on the right-hand

hharness, and to four extrusions on the left-hand

harness. These lugs connect the spark plug conduit

assemblies to the manifold. On the right-hand har-

ness cylinder No. 1 connection at the end of the

tube is through a spark plug elbow assembly. A

screwed coupling silver soldered to the other end of

the tube connects the magneto conduit assembly t0

the manifold through a copper washer. Two brackets

‘wrapped around the tube are drilled for attachment

bolts

Replacement of Conductor

12, Remove old conductor

(1). Strip off cap washer, contact stud and

Insulator from spark plug conduit assembly.

(2) Remove spark plug conduit assembly by

coupling mut at manifold tube

screwed lug.

sing seca wolf. inconet

‘coupling nut securing ‘conduit assembly

to manifold tube sewed coupling

(4), Remove tag and cable marker from end of

cable.

(5), Withdraw conducts freeman

end

‘oe degniaton tk

13. Fit new conductor. ete erdacoice

(1) Cut cable wo length given in Table 1

2) Smear cable with grene MS.4 (DTD.

00 42985

3) Feed cable through manifold assembly

the screwed lug, and feed through magneto

conduit assembly,

Note...

Gradual rotate cable asi fedit condi.

The cable must not be pulled through.

(4) Treat all threads with an approved anti-

seize compound,

(3) Fit spark plug conduit assembly.

(6)_ Fit insulator, contact stud and cap washer

to cable end.

(D_Using special tool connect and tighten

rupling ut at magneto conduit fo manifold

tube joint.

(8) Fit cable marker

(9) Refer to fig. 1 or fig. 2 as appropriate and

stop ack cable an lig bi ened

length from magneto adapter. a

AP.usL-001-1

TABLE 2

Provisioning schedule, right-hand

TT Feetty

Ref. No, Description Per Set Requirement

378 /3069 ‘Manifold Assembly

378 3059 Lug

378 3070 Bracket

378 3890 Serial No. Plate

378 3889 Nameplate

3784353 Screwed coupling

378 3887 Label

‘NIV Lae ‘Screwed lug

No. Z5

37B 3025 ‘Magneto Conduit 1 General Assembly

378 3022 Spark Plug Conduit 4 > om

378 3028 Spark Plug Elbow 1 ae

37B 3072 Protective Cap 4 soe

37B 2376 Cup Washer 4 5

378 565 Contact Stud 4

37B 3091 Tasulator 4 z

37B 4310 ‘Markers 1 7

378 3029 Washer 1 :

SK Id Tag 4 = @

Uniplagsheath Cable No. + 15 > om

DSGAviation

TABLE 3 ‘mail@ssgaviation co.uk

Provisioning Schedule, left-hand

Ref, No, Description $e'se Requirement

378 3026 ‘Manifold Assembly 1 “Manifold Repair

378 3059 Lug 1 > on

37B 3067, Lug 3 > om

37B 3018 Bracket 2 > om

2338 3850 Label i 7

37B 3889 Nameplate 1 »

37B 4353 Screwed Coupling 1 a

37B 3887 Label i a

378 3024 ‘Magneto Conduit 1 General Assembly

378 3020 Spark Plug Conduit 3 _

378 3021 Spark Plug Conduit 1 x a

378 3028 Spark Plug Elbow 4 SS

37B 3844 Protective Cap 4 :

37B 2376 Cup Washer 4 yon

378 565 Contact Stud 4 soe

378 3091 Insulator 4 a

37B 4310 ‘Markers 1 » OR

378 3029 Washer 1 sos

3K Ia ag 4 ae

Uniplugsheath Cable No. 4 1S ft

Testing

Conti tt

14, Test each complete cable for continuity, sng

4 Multimeter ‘Type 12888, fom pg eral

dragnet ternina

Issued July 68

Insulation resistance test

45. Using Tester Ignition Type H.T. Mk. 2 (Ret,

‘No. 5/399) the insulation berween the conduit and

the contact stud of each conductor must be not less

Fig. 1. Ignition harness, right-hand

APIISL-0301-1

Fig. 2, Ignition harness, left-hand

1

Iesced July 68

Anda mungkin juga menyukai

- Ads Ts20 Ags SpecsDokumen120 halamanAds Ts20 Ags Specsdsgaviation100% (1)

- AP1086 Vocab of SectionsDokumen49 halamanAP1086 Vocab of Sectionsdsgaviation100% (2)

- BSX29 Paint InfoDokumen6 halamanBSX29 Paint InfodsgaviationBelum ada peringkat

- AP1275A Vol1 Sec15 Ch9 Brake Pressure GaugesDokumen3 halamanAP1275A Vol1 Sec15 Ch9 Brake Pressure GaugesdsgaviationBelum ada peringkat

- SDM A15 Sec 4 Cable ReplacementsDokumen2 halamanSDM A15 Sec 4 Cable ReplacementsdsgaviationBelum ada peringkat

- Hunting Percival DB14-03 SprocketsDokumen2 halamanHunting Percival DB14-03 SprocketsdsgaviationBelum ada peringkat

- Cancelled AGS StandardsDokumen1 halamanCancelled AGS StandardsdsgaviationBelum ada peringkat

- KCA1501 P12 Compass Overhaul ManualDokumen63 halamanKCA1501 P12 Compass Overhaul Manualdsgaviation100% (1)

- AP2850A Sec 3 General InformationDokumen22 halamanAP2850A Sec 3 General InformationdsgaviationBelum ada peringkat

- Hunting Percival Design Standard DS Chains PDFDokumen4 halamanHunting Percival Design Standard DS Chains PDFdsgaviationBelum ada peringkat

- MoS SDM 12 SwitchesDokumen27 halamanMoS SDM 12 SwitchesdsgaviationBelum ada peringkat

- MoS SDM IntroductionDokumen3 halamanMoS SDM IntroductiondsgaviationBelum ada peringkat

- Hunting Percival DB14-01 ChainsDokumen6 halamanHunting Percival DB14-01 ChainsdsgaviationBelum ada peringkat

- MoS SDM 36 StiffnutsDokumen3 halamanMoS SDM 36 StiffnutsdsgaviationBelum ada peringkat

- MoS SDM 136 Bolts and NutsDokumen5 halamanMoS SDM 136 Bolts and NutsdsgaviationBelum ada peringkat

- Dunlop Aircraft Wheels ApplicationsDokumen11 halamanDunlop Aircraft Wheels Applicationsdsgaviation0% (1)

- AP1275A Vol1 Sec21 Ch13 Smiths As Type ASIDokumen4 halamanAP1275A Vol1 Sec21 Ch13 Smiths As Type ASIdsgaviationBelum ada peringkat

- AP2850A Morris TypeDokumen20 halamanAP2850A Morris TypedsgaviationBelum ada peringkat

- AP2850A Sec5 General InstructionsDokumen13 halamanAP2850A Sec5 General InstructionsdsgaviationBelum ada peringkat

- AP2850A Section 2Dokumen22 halamanAP2850A Section 2dsgaviationBelum ada peringkat

- AP2850A Marston TypeDokumen9 halamanAP2850A Marston TypedsgaviationBelum ada peringkat

- AP2850A Serck TypeDokumen27 halamanAP2850A Serck Typedsgaviation100% (1)

- AP2580A Gallay TypeDokumen18 halamanAP2580A Gallay TypedsgaviationBelum ada peringkat

- AP1275A Vol1 Sec22 74AM AltimeterDokumen3 halamanAP1275A Vol1 Sec22 74AM Altimeterdsgaviation100% (1)

- Ap1275a Vol1 Sec13 Ch30 Mk1b AhDokumen10 halamanAp1275a Vol1 Sec13 Ch30 Mk1b AhdsgaviationBelum ada peringkat

- AP1275A Vol1 Sec26 CH 3 Flexible DrivesDokumen2 halamanAP1275A Vol1 Sec26 CH 3 Flexible DrivesdsgaviationBelum ada peringkat

- AP2850A Gen InfoDokumen9 halamanAP2850A Gen InfodsgaviationBelum ada peringkat

- AP1275A Vol1 Sec26 Ch4 Tacho IndicatorsDokumen3 halamanAP1275A Vol1 Sec26 Ch4 Tacho Indicatorsdsgaviation100% (2)

- AP1275A Vol1 Sec22 Ch4 RoC IndicatorsDokumen6 halamanAP1275A Vol1 Sec22 Ch4 RoC IndicatorsdsgaviationBelum ada peringkat

- AP1275 Vol1 Sec26 Ch5 Tacho GeneratorDokumen2 halamanAP1275 Vol1 Sec26 Ch5 Tacho GeneratordsgaviationBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)