103 Solution EC Msds 5-08

Diunggah oleh

Brian HernandezHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

103 Solution EC Msds 5-08

Diunggah oleh

Brian HernandezHak Cipta:

Format Tersedia

May 2008

Page 1 of 3

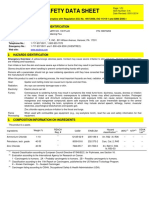

MATERIAL SAFETY DATA SHEET

MAY BE USED TO COMPLY WITH OSHA'S HAZARD COMMUNICATION STANDARD, 29 CFR 1910.1200 AND SUPERFUND AMENDMENTS

AND REAUTHORIZATION ACT (SARA) OF 1986 PUBLIC LAW 99-499. STANDARD

SHOULD BE CONSULTED FOR SPECIFIC REQUIREMENTS.

SECTION I (IDENTIFICATION)

MANUFACTURER/

SUPPLIERS NAME:

EUTECTIC CORPORATION

N94 W14355 Garwin Mace Drive

Menomonee Falls, WI 53051 USA

PRODUCT NAME:

Solution 103

PRODUCT CLASSIFICATION:

Chemical Aid

TELEPHONE NUMBER:

1-800-558-8524

SECTION II (HAZARDOUS INGREDIENTS/IDENTITY INFORMATION)

IMPORTANT: This section covers the materials from which these products are manufactured. The fumes and gases produced during normal use of these

products are covered in Section V. The term "Hazardous" in "Hazardous Ingredients" should not only be interpreted as a term required and defined in OSHA

Hazard Communication Standard (29 CFR Part 1910.1200), but also as defined by other regulatory agencies. The chemicals or compounds subject to

reporting under Title III, in Section 313, of the Superfund Amendments and Reauthorization Act (SARA) are marked by the symbol #.

WARNING: This product contains or produces a chemical known to the State of California to cause birth defects (or other reproductive harm) and cancer.

(California Health & Safety Code 25249.5 et seq.)

INGREDIENTS

Titanium Dioxide

Water

Calcium Carbonate

Silicon Dioxide

Talc

Ethylene Glycol #

CAS

NUMBER

13463-67-7

7732-18-5

1317-65-3

14808-60-7

14807-96-6

107-21-1

Exposure Limit (mg/m3)

OSHA PEL

ACGIH-TLV

15

10

Not Listed

Not Listed

5

10

**

0.05

20 mppcf

2

Not Listed

100 (ceiling)

Percent Ingredients (by weight)

10 30

15 40

15 40

37

37

15

** 10 mg/m / (% SiO2 + 2)

mppcf = millions of particles per cubic foot of air

SECTION III (PHYSICAL DATA/USE)

Chemical Aid - a compound that can be brushed on and used as a stop-off during brazing and/or soldering or as a barrier when thermal spraying.

SECTION IV (FIRE AND EXPLOSION HAZARD DATA)

Non-Flammable: Brazing and thermal spraying can ignite combustibles. Refer to American National Standard Z49.1 for fire prevention during welding.

These products as shipped are non-hazardous, nonflammable, non-explosive, and non-reactive. Flash Point: not applicable

Rating under National Fire Protection 704: Health, 2: Flammability, 0: Reactivity, 0.

SECTION V (REACTIVITY DATA)

Welding / spraying fumes cannot be classified simply. The composition and quantity of both are dependent upon the metal being worked on, the process,

procedure, and the products used. Other conditions which also influence the composition and quantity of the fumes and gases to which workers may be

exposed include: coatings on the metal being worked on (such as paint, plating, or galvanizing), the number of workers and the volume of the work area, the

quality and the amount of ventilation, position of the worker's head with respect to the fume plume, as well as the presence of contaminants in the atmosphere

(such as chlorinated hydrocarbon vapors from cleaning and degreasing activities).

When used as intended, as the alloy or powder is consumed, fume and gas decomposition products generated are different in percent and form from the

ingredients listed in Section II. Fume and decomposition products, not the ingredients in the product, are important. Decomposition products include those

originating from the volatilization, reaction, or oxidation of materials in Section II, plus those from the base metal and coating, etc., as noted above. These

components are virtually always present as complex oxides and not as metals (Characterization of Arc Welding Fume: American Welding Society). See the

Material Safety Data Sheet for the product that is being used in conjunction with the Solution 103.

MSDS: Solution 103

Page 2 of 3

When brazing or flame spraying, the gaseous reaction products may include carbon monoxide and carbon dioxide. Monitor fume levels. One recommended

way to determine the composition and quantity of fumes and gas to which workers are exposed is to take an air sample in the worker's breathing zone (see

ANSI/AWS F1.1, F1.2, F1.3, F1.4, and F1.5, available from the "American Welding Society," 550 N.W. LeJeune Road, Miami, FL 33126).

SECTION VI (HEALTH HAZARD DATA)

Threshold Limit Value: The ACGIH recommended general limit for welding fume NOS (not otherwise specified) is 5 mg/m. The ACGIH 1999 preface

states: "The TLV-TWA should be used as guides in the control of health hazards and should not be used as firm lines between safe and dangerous

concentrations." See Section V for specific fume constituents that may modify the TLV.

EFFECTS OF OVEREXPOSURE - Thermal spraying, soldering, and brazing may create one or more of the following health hazards:

FUMES AND GASES can be dangerous to your health.

PRIMARY ROUTES OF ENTRY are the respiratory system. Other possible routes are eyes, ingestion, and/or skin contact.

PREEXISTING respiratory or allergic conditions may be aggravated in some individuals (i.e. asthma, emphysema).

SHORT TERM (ACUTE) OVEREXPOSURE to welding / brazing / spraying fumes may result in discomfort such as metal fume fever, dizziness, nausea,

or dryness or irritation of nose, throat, or eyes. Symptoms to overexposure to ethylene glycol include irritation to eyes, skin, nose, throat, nausea vomiting,

abdominal pain, lassitude (weakness, exhaustion), dizziness, stupor, convulsions, central nervous system, depression, and skin sensitization. Renal failure

and brain injury may result. PRIMARY ROUTES OF ENTRY are the respiratory system. Other possible routes are eyes, ingestion, and/or skin contact.

LONG TERM (CHRONIC) OVEREXPOSURE to ethylene glycol may effect the central nervous system and eyes. PRIMARY ROUTES OF ENTRY

are the respiratory system. Other possible routes are eyes, ingestion, and/or skin contact.

See Section VII for precautions.

EMERGENCY & FIRST AID PROCEDURES: Call for medical aid. Employ first aid techniques recommended by The American Red Cross.

INHALATION: Remove to fresh air. If breathing is difficult, administer oxygen. If not breathing, begin artificial respiration.

If no detectable pulse, begin Cardiopulmonary Resuscitation. (CPR). Call for medical aid.

SKIN: Wash affected area with soap and water. If rash develops, see a physician.

EYES: Flush with a large amount of fresh water for at least 15 minutes. Get medical attention.

INGESTION: Seek medical attention.

CARCINOGENICITY

SILICON DIOXIDE - is listed as being carcinogenic to humans on IARC and NTP lists, and is listed by NIOSH as being a potential occupational

carcinogen (with no further categorization).

TITANIUM DIOXIDE is listed as being unclassifiable as to Carcinogenicity in humans by IARC and is listed by NIOSH as being a potential occupational

carcinogen (with no further categorization).

WELDING FUMES (not otherwise specified) are considered to be carcinogenic defined with no further categorization by NIOSH and IARC.

SECTION VII (PRECAUTION FOR SAFE HANDLING AND USE/APPLICABLE CONTROL MEASURES)

Read and understand the manufacturer's instructions and precautionary label on this product.

See American National Standard Z49.1, Safety in Welding and Cutting, published by the "American Welding Society," 550 N.W. LeJeune Road, Miami, FL

33126 and OSHA Publication 2206 (29CFR 1910), U.S. Government Printing Office, Superintendent of Documents, P.O. Box 371954, Pittsburgh, PA

15250-7954 for more detail on the following:

Ventilation: Use enough ventilation, local exhaust at the work area, or both, to keep the fumes and gases below the TLV's in the workers breathing

zone and the general area. Train the worker to keep his head out of the fumes. Monitor fume levels and do not exceed permissible exposure limits or values.

Respiratory Protection: Use respirable fume respirator or air supplied respirator when welding in a confined space or where local exhaust or ventilation

does not keep exposure below the TLV's.

Eye Protection: Wear appropriate eye protection for process being done. Wear appropriate chemical safety goggles and face shield when handling fluxes

and chemical aids.

Protective Clothing: Wear appropriate head, hand, and body protection for process being done. Wear protective gloves when handling Solution 103.

Waste: Dispose of waste residues in accordance with EPA or local regulations. Plastic containers and cardboard packaging can be

recycled.

Storage: Keep material sealed before use. After use, keep container closed and sealed. Store at ambient temperature. Keep from freezing and keep this

product away from children.

MSDS: Solution 103

Page 3 of 3

SUPPLEMENTAL INFORMATION

IARC: International Agency for the Research on Cancer

ACGIH: American Conference of Governmental Industrial Hygienists

NIOSH: National Institute for Occupational Safety and Health

NTP: National Toxicology Program

PEL: Permissible Exposure Limit

OSHA: U.S. Occupational Safety and Health Administration

TLV: Threshold Limit Value

CAS: Chemical Abstracts Service Registry Number

Exposure limits are subject to change. Contact ACGIH, OSHA, NIOSH, and IARC for current values.

The information in this MSDS was obtained from sources we believe are reliable. However, this information is provided without any representation or

warranty, expressed or implied, regarding accuracy or correctness. The conditions or methods of handling, storage, use, and disposal of the product are

beyond our control and may be beyond our knowledge. For this and other reasons we do not assume responsibility and expressly disclaim liability of loss,

damage, or expense arising from it or any way connected with the handling, storage, use, or disposal of the product.

Anda mungkin juga menyukai

- Handbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesDari EverandHandbook of Fire and Explosion Protection Engineering Principles: for Oil, Gas, Chemical and Related FacilitiesPenilaian: 5 dari 5 bintang5/5 (2)

- 360, 370, 380 Brazing Rod MG MSDS 6-09Dokumen3 halaman360, 370, 380 Brazing Rod MG MSDS 6-09orcbane27Belum ada peringkat

- Dust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesDari EverandDust Explosion and Fire Prevention Handbook: A Guide to Good Industry PracticesBelum ada peringkat

- ZULFI E6013 Welding ElectrodesDokumen1 halamanZULFI E6013 Welding ElectrodesJunard M. Lu HapBelum ada peringkat

- Handbook of Air Pollution Prevention and ControlDari EverandHandbook of Air Pollution Prevention and ControlPenilaian: 5 dari 5 bintang5/5 (2)

- Material Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Dokumen2 halamanMaterial Safety Data Sheet (MSDS) : Msds No: Aluminum Electrode REVISED 12-2009Rama Krishna Reddy DonthireddyBelum ada peringkat

- Nic-L-Weld 99 59Dokumen9 halamanNic-L-Weld 99 59CezaryCezasBelum ada peringkat

- Aluminum Wires and Rods 1Dokumen2 halamanAluminum Wires and Rods 1OteranmoralesBelum ada peringkat

- Material Safety Data Sheet: Emergency Phone Number: 1-866-272-4378Dokumen1 halamanMaterial Safety Data Sheet: Emergency Phone Number: 1-866-272-4378So MayeBelum ada peringkat

- Aluminum Msds 8-05Dokumen3 halamanAluminum Msds 8-05mohamed AdelBelum ada peringkat

- MSDS Tungsten Electrode Safety DataDokumen2 halamanMSDS Tungsten Electrode Safety DataSerkan ApayBelum ada peringkat

- Heat Fence Inorganic MineralsDokumen3 halamanHeat Fence Inorganic MineralsmeBelum ada peringkat

- Understanding MSDS'sDokumen7 halamanUnderstanding MSDS'sDominic EmerencianaBelum ada peringkat

- Nepheline Syenite MSDSDokumen5 halamanNepheline Syenite MSDSLynne MarrBelum ada peringkat

- Find MSDS onlineDokumen4 halamanFind MSDS onlineHoài ThươngBelum ada peringkat

- MSDS Er70s 6Dokumen1 halamanMSDS Er70s 6RosyidiMuhammadMahfudzBelum ada peringkat

- S 800wtxm 12k Msds EngDokumen2 halamanS 800wtxm 12k Msds Eng이상훈Belum ada peringkat

- 62super Ti Se en 0Dokumen4 halaman62super Ti Se en 0Jhony MedranoBelum ada peringkat

- MSDS NiCrDokumen2 halamanMSDS NiCrBety FajriaBelum ada peringkat

- Product Name: Galvalume Sheet Severstal Sparrows Point LLCDokumen4 halamanProduct Name: Galvalume Sheet Severstal Sparrows Point LLCT Bagus Tri LusmonoBelum ada peringkat

- La 71 MSDSDokumen2 halamanLa 71 MSDSdeepak2803Belum ada peringkat

- Material Safety Data Sheet (MSDS)Dokumen2 halamanMaterial Safety Data Sheet (MSDS)Heri SusantoBelum ada peringkat

- M - ENG - MSDS v1.2Dokumen157 halamanM - ENG - MSDS v1.2sunthron somchaiBelum ada peringkat

- Material Safety Data SheetsDokumen5 halamanMaterial Safety Data SheetsSuryanarayanan VenkataramananBelum ada peringkat

- Flexovit Abrasives - Cartridge Rolls Spiral Bands PadsDokumen2 halamanFlexovit Abrasives - Cartridge Rolls Spiral Bands PadsFlexovit AbrasivesBelum ada peringkat

- Safety Data Sheet for All-State AquaSafe No. 100 FluxDokumen5 halamanSafety Data Sheet for All-State AquaSafe No. 100 Fluxmohamed AdelBelum ada peringkat

- MsdsDokumen3 halamanMsdsTobi MazzoccaBelum ada peringkat

- 088 Oxygen Pressurized GasDokumen8 halaman088 Oxygen Pressurized Gaseng20072007Belum ada peringkat

- MSDS Molykote G-N Metal Assembly PasteDokumen9 halamanMSDS Molykote G-N Metal Assembly PasteNikola PolimenovBelum ada peringkat

- Material Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?Dokumen9 halamanMaterial Safety Data Sheet: What Is The Material and What Do I Need To Know in An Emergency?haharameshBelum ada peringkat

- MSDS Nitrogen GasDokumen6 halamanMSDS Nitrogen GasShafakut AliBelum ada peringkat

- Activated Aluminum Oxide Desicant MSDSDokumen2 halamanActivated Aluminum Oxide Desicant MSDSgeverett2765Belum ada peringkat

- COM KOIL MSDS Material Safety Data SheetDokumen4 halamanCOM KOIL MSDS Material Safety Data SheetOana-Maria OlingherBelum ada peringkat

- Seachem Laboratories, Inc. Safety Data Sheet Cover Multitest: IronDokumen19 halamanSeachem Laboratories, Inc. Safety Data Sheet Cover Multitest: IronJorge Restrepo HernandezBelum ada peringkat

- Fact 01Dokumen3 halamanFact 01cuervohijoguachoBelum ada peringkat

- CHEMICALnHAZARDSnn1n 12627b00e1e8638Dokumen13 halamanCHEMICALnHAZARDSnn1n 12627b00e1e8638Cristian RomeroBelum ada peringkat

- Vermiculite Strong Lite ProductsDokumen4 halamanVermiculite Strong Lite ProductsZohra BukhuthBelum ada peringkat

- Novec1230 MSDSDokumen6 halamanNovec1230 MSDSoscarninanBelum ada peringkat

- Tabular Alumina Support Desiccant SDSDokumen5 halamanTabular Alumina Support Desiccant SDSClaudio TurlherBelum ada peringkat

- MSDS for #112NZ-ISO46 Lubricating OilDokumen2 halamanMSDS for #112NZ-ISO46 Lubricating OilDavide BoreanezeBelum ada peringkat

- Accrolube MSDS EuropeanDokumen5 halamanAccrolube MSDS EuropeanCarlos LoresBelum ada peringkat

- Seachem Laboratories, Inc. Safety Data Sheet Cover Multitest: CopperDokumen28 halamanSeachem Laboratories, Inc. Safety Data Sheet Cover Multitest: CopperJorge Restrepo HernandezBelum ada peringkat

- MSDS N-5000 Anti-SeizeDokumen5 halamanMSDS N-5000 Anti-SeizemarciofelipessantosBelum ada peringkat

- Material Safety Data Sheet (MSDS) : Activated Carbon AdsorbentDokumen5 halamanMaterial Safety Data Sheet (MSDS) : Activated Carbon AdsorbentLalu RifqyBelum ada peringkat

- MSDS AlloysDokumen15 halamanMSDS AlloysMaryam EradewiBelum ada peringkat

- MSDS Liquide MSDSDokumen4 halamanMSDS Liquide MSDSShaikhRizwanBelum ada peringkat

- 3430indoor Air Quality SMDokumen28 halaman3430indoor Air Quality SMAbubacker SiddiqueBelum ada peringkat

- Material Safety Data Sheet: MarkalDokumen5 halamanMaterial Safety Data Sheet: MarkalPaulino MoranBelum ada peringkat

- Material Safety Data Sheet: Section 1 - Product and Company IdentificationDokumen5 halamanMaterial Safety Data Sheet: Section 1 - Product and Company IdentificationMicheal MattheyBelum ada peringkat

- SB-930 MSDSDokumen4 halamanSB-930 MSDSOana-Maria OlingherBelum ada peringkat

- 51 EX Msds 9-07Dokumen3 halaman51 EX Msds 9-07Mohamed AdelBelum ada peringkat

- MSDS Alseal 518 CoatingsDokumen5 halamanMSDS Alseal 518 CoatingsHernan GirautBelum ada peringkat

- CarbonFoam PU/PIR Foam MSDSDokumen5 halamanCarbonFoam PU/PIR Foam MSDSAnonymous voA5Tb0Belum ada peringkat

- Understanding OSHA Regulations for Chemical SafetyDokumen4 halamanUnderstanding OSHA Regulations for Chemical SafetyAhmad Danial OmarBelum ada peringkat

- Reactivity Data and Health Hazards of Welding ElectrodeDokumen1 halamanReactivity Data and Health Hazards of Welding ElectrodeSona MahardhikaBelum ada peringkat

- Material Safety Data Sheet for IronDokumen7 halamanMaterial Safety Data Sheet for IronIlham NugrahaBelum ada peringkat

- Material Safety Data Sheet for IronDokumen7 halamanMaterial Safety Data Sheet for IronRiza ApreliaBelum ada peringkat

- MSDS Polyken 955Dokumen5 halamanMSDS Polyken 955raditia2205Belum ada peringkat

- Material Safety Data SheetDokumen15 halamanMaterial Safety Data Sheethomam Salim Khalaf100% (1)

- Safety Hazards Associated With Oil and Gas Extraction ActivitiesDokumen5 halamanSafety Hazards Associated With Oil and Gas Extraction ActivitiesNaiduSatyanarayanaNaiduBelum ada peringkat

- Antorchas BINZEL AlphaDokumen20 halamanAntorchas BINZEL AlphaBrian HernandezBelum ada peringkat

- E6HSSDokumen2 halamanE6HSSBrian HernandezBelum ada peringkat

- Xuper 2109Dokumen2 halamanXuper 2109Brian HernandezBelum ada peringkat

- Manual de GymDokumen28 halamanManual de GymBrian HernandezBelum ada peringkat

- Tero Dyn 3000Dokumen4 halamanTero Dyn 3000Brian HernandezBelum ada peringkat

- Kali Linux For BeginnersDokumen13 halamanKali Linux For Beginnersnihal0% (1)

- Grade CalculatorDokumen1 halamanGrade CalculatorKHENN ALDIANOBelum ada peringkat

- Partition WallDokumen24 halamanPartition WallSHRADDHA GHUGEBelum ada peringkat

- S Parameter Theory of Lossless BlockDokumen14 halamanS Parameter Theory of Lossless BlockthgnguyenBelum ada peringkat

- Engineering Drawing Solution All Year First Part Ioe NotesDokumen31 halamanEngineering Drawing Solution All Year First Part Ioe Notesई. सन्तोष शर्माBelum ada peringkat

- ASTMDokumen4 halamanASTMSupriyo PBelum ada peringkat

- Engineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzDokumen1 halamanEngineering Data Sheet: 49187073 E 1145842 1 of 1 October 21, 2016 60HzGustavo VillarrealBelum ada peringkat

- 4 LoopsDokumen30 halaman4 LoopsThirukkuralkaniBelum ada peringkat

- Curriculum Vitae: Vivek PatilDokumen3 halamanCurriculum Vitae: Vivek PatilVivek PatilBelum ada peringkat

- TNK500P Taneko Industrial Generator (TNK JKT)Dokumen2 halamanTNK500P Taneko Industrial Generator (TNK JKT)Rizki Heru HermawanBelum ada peringkat

- Conversion Factors GuideDokumen2 halamanConversion Factors GuideAndri MPBelum ada peringkat

- BPC BW HierarchyDokumen8 halamanBPC BW HierarchyJulio RafaelBelum ada peringkat

- History of JS: From Netscape to Modern WebDokumen2 halamanHistory of JS: From Netscape to Modern WebJerraldBelum ada peringkat

- HSP Power Point PresentationDokumen10 halamanHSP Power Point PresentationocintezaBelum ada peringkat

- United States Air Force: Next Generation Ejection SeatDokumen2 halamanUnited States Air Force: Next Generation Ejection SeatChris EfstathiouBelum ada peringkat

- Xlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundDokumen3 halamanXlpe - Ls243Nta: - 1 Technical Data Sheet Crosslinkable Polyethylene CompoundLe MinhBelum ada peringkat

- Maintenance & Trouble Shooting of Voith CouplingDokumen20 halamanMaintenance & Trouble Shooting of Voith Couplingsen_subhasis_58100% (1)

- Data Acquisition Systems (DAS) in GeneralDokumen3 halamanData Acquisition Systems (DAS) in GeneralArjun SinghBelum ada peringkat

- TUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILDokumen4 halamanTUGAS BAHASA INGGRIS Cahaya Karisma Wilani Faturrachman Rengga Wisnu Resza Bunga Nisa POLITEKNIK NEGERI JAKARTA JURUSAN KONSTRUKSI BANGUNAN SIPILFaturrachman Nanu Rengga WisnuBelum ada peringkat

- Presentation - Slides Holmes Lever 221215Dokumen33 halamanPresentation - Slides Holmes Lever 221215Ralitsa OlevaBelum ada peringkat

- Premiertrak 1100x650 Parts ENGDokumen276 halamanPremiertrak 1100x650 Parts ENGarttv44100% (1)

- Colorado Passenger Tramway Safety Board Adam Lee Accident ReportDokumen28 halamanColorado Passenger Tramway Safety Board Adam Lee Accident ReportMichael_Lee_RobertsBelum ada peringkat

- 4 General Types of Polymers Molecular StructureDokumen3 halaman4 General Types of Polymers Molecular StructureArgel Linard Francisco MabagaBelum ada peringkat

- MCP HistoryDokumen18 halamanMCP HistoryStanciu VladBelum ada peringkat

- Hollow Metallic and Dielectric Wave-Guides For Long Distance Optical Transmission and LasersDokumen28 halamanHollow Metallic and Dielectric Wave-Guides For Long Distance Optical Transmission and LasersClaudia Lopez ZubietaBelum ada peringkat

- Çimsa Eco White TDS (EN)Dokumen1 halamanÇimsa Eco White TDS (EN)Babu NysemereBelum ada peringkat

- Furuno GMDSS Installation Manual PDFDokumen64 halamanFuruno GMDSS Installation Manual PDFEric PskdBelum ada peringkat

- BFT 40503 A T E: Ntersection OntrolDokumen12 halamanBFT 40503 A T E: Ntersection OntrolghajiniiBelum ada peringkat

- What Is Physical GeologyDokumen25 halamanWhat Is Physical GeologyMelanyBelum ada peringkat

- AMMONIUM SULPHATE, TECHNICAL SpecificationDokumen10 halamanAMMONIUM SULPHATE, TECHNICAL Specificationbabji dudekulaBelum ada peringkat

- Transformed: Moving to the Product Operating ModelDari EverandTransformed: Moving to the Product Operating ModelPenilaian: 4 dari 5 bintang4/5 (1)

- Design for How People Think: Using Brain Science to Build Better ProductsDari EverandDesign for How People Think: Using Brain Science to Build Better ProductsPenilaian: 4 dari 5 bintang4/5 (8)

- Understanding Automotive Electronics: An Engineering PerspectiveDari EverandUnderstanding Automotive Electronics: An Engineering PerspectivePenilaian: 3.5 dari 5 bintang3.5/5 (16)

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsDari EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsBelum ada peringkat

- The Maker's Field Guide: The Art & Science of Making Anything ImaginableDari EverandThe Maker's Field Guide: The Art & Science of Making Anything ImaginableBelum ada peringkat

- 507 Mechanical Movements: Mechanisms and DevicesDari Everand507 Mechanical Movements: Mechanisms and DevicesPenilaian: 4 dari 5 bintang4/5 (28)

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureDari EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CulturePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Nir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryDari EverandNir Eyal's Hooked: Proven Strategies for Getting Up to Speed Faster and Smarter SummaryPenilaian: 4 dari 5 bintang4/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsDari EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsBelum ada peringkat

- The User's Journey: Storymapping Products That People LoveDari EverandThe User's Journey: Storymapping Products That People LovePenilaian: 3.5 dari 5 bintang3.5/5 (8)

- Electrical Principles and Technology for EngineeringDari EverandElectrical Principles and Technology for EngineeringPenilaian: 4 dari 5 bintang4/5 (4)

- Operational Amplifier Circuits: Analysis and DesignDari EverandOperational Amplifier Circuits: Analysis and DesignPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Design Is The Problem: The Future of Design Must Be SustainableDari EverandDesign Is The Problem: The Future of Design Must Be SustainablePenilaian: 1.5 dari 5 bintang1.5/5 (2)

- The Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorDari EverandThe Box: How the Shipping Container Made the World Smaller and the World Economy Bigger - Second Edition with a new chapter by the authorPenilaian: 4 dari 5 bintang4/5 (7)

- Iconic Advantage: Don’t Chase the New, Innovate the OldDari EverandIconic Advantage: Don’t Chase the New, Innovate the OldPenilaian: 4 dari 5 bintang4/5 (1)

- Top-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsDari EverandTop-Down Digital VLSI Design: From Architectures to Gate-Level Circuits and FPGAsBelum ada peringkat

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceDari EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperiencePenilaian: 4 dari 5 bintang4/5 (19)

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerDari EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerPenilaian: 5 dari 5 bintang5/5 (1)

- What to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationDari EverandWhat to Expect When You're Expecting Robots: The Future of Human-Robot CollaborationPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Microwave Active Circuit Analysis and DesignDari EverandMicrowave Active Circuit Analysis and DesignPenilaian: 5 dari 5 bintang5/5 (4)