WB 3 - Fireproofing Intumescent

Diunggah oleh

wafik.bassilyHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

WB 3 - Fireproofing Intumescent

Diunggah oleh

wafik.bassilyHak Cipta:

Format Tersedia

PRODUCT DATA SHEET

CAFCO SprayFilm WB 3 INTUMESCENT FIRE PROTECTION

INTERIOR

CAFCO SprayFilm WB 3 is a water-based, intumescent coating consisting of polyvinyl acetate resins and inorganic fillers designed for the

fire protection of interior structural steel.

CAFCO SprayFilm gives architects the ability to

design using steel that can be decorative and

aesthetically pleasing. It can be top coated to

match its surroundings and allows steel to be

left exposed to view while providing the fire resistance rating.

PHYSICAL PERFORMANCE

It is important for fire protection materials to be

able to withstand abuse. American Society for

Testing and Materials (ASTM) test methods are

used to evaluate the performance of intumescent

materials when subjected to these various physical forces. CAFCO SprayFilm WB 3 has been

evaluated to meet rigorous industry test standards.

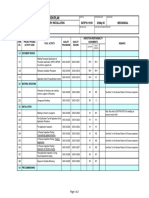

ASTM PHYSICAL CHARACTERISTICS

Test Method

PRODUCT ADVANTAGES

Water-Based intumescent coating with low

odor, low VOCs

Durable, smooth architectural finish

Quick, easy application and clean up

Can be finished with a wide variety of topcoat

types and colors

Contains no solvents or harmful compounds

Wide range of testing

Provides up to 4-hour fire resistance ratings in

accordance with UL 263 (ASTM E119), CAN /

ULC-S101 and ISO 834

ICC Approved (ICC ESR 1092)

APPLICATION

A primer must be applied to the steel substrate. Contact Isolatek Technical Services

Department for a complete list of approved

primers.

CAFCO SprayFilm WB 3 can be brushed or

sprayed, not rolled. It is available in a trowel

grade material.

The applied thickness of CAFCO SprayFilm

WB 3 will depend upon the specified fire rating and size / shape of the steel member to be

protected.

If desired, a finish coat may be applied in the

desired color and finish directly over CAFCO

SprayFilm WB 3 in accordance with the guidelines noted in our Finish Coat Materials data

sheet.

CAFCO SprayFilm WB 3*

Flame Spread - 5

Smoke Developed - 35

SURFACE BURNING

E84

DUROMETER HARDNESS

D2240

84 Shore D

IMPACT RESISTANCE

D2794

56 inch-lb (0.65 kg-m)

ABRASION RESISTANCE

D4060

0.2850 g/ 1000 cycles

BOND STRENGTH

D4541

280 psi (1931 k Pa)

Class A

* Values represent independent laboratory tests under controlled conditions.

TECHNICAL DATA

PACKAGING

5 U.S. gallon (19L) pail

DENSITY

12.0 lb/gal 0.5

COLOR

white

STORAGE TEMP.

Min. 50F (10 C), Max. 100F (38 C)

APPLICATION TEMP.

Min. 50F (10 C), Max. 100F (38 C)

pH VALUE

7.5 to 8.5

VOC COMPLIANCE

< 12 g/L

2

COVERAGE

1235 ft /gal @ 1 mil (DFT)

SHELF LIFE

12 months

Type SprayFilm WB 3 OR Type WB 3

File 16640

MASTIC COATING

FIRE RESISTANCE CLASSIFICATION

SEE UL FIRE RESISTANCE DIRECTORY

For more detailed information, visit our website at www.cafco.com

phone: 1-800-631-9600 email: technical@isolatek.com

CAFCO SprayFilm WB 3 Guide Specification

Section 07812Intumescent Fire Resistive Material

Following is an outline/short language specification. Complete specifications for the SprayFilm Systems are available on various media upon request.

PART 1 GENERAL

1.1 SCOPE

1.1.1 This specification covers labor, materials, equipment, and application necessary for,

and incidental to, the complete and proper installation of intumescent fire

protection for application to steel structures and supports in accordance with all

applicable requirements of contract documents.

1.1.2 This specification shall be supplemented by the applicable requirements of building

codes, insurance rating organizations and all other authorities having jurisdiction.

1.9.3 Relative humidity shall not exceed 85% throughout the total period of application

and drying for the intumescent fire resistive material, and must not exceed 85%

throughout the application and drying for the protective decorative topcoat.

1.2

1.2.1

1.2.2

SECTION INCLUDES

Intumescent fire protection material.

Topcoat protective decorative finish.

PART 2PRODUCTS

1.3

1.3.1

1.3.2

RELATED SECTIONS

Section 05100: Structural Steel.

Section 05120 - 05500: Structural steel and metal fabrications with reference to

primer receiving fire protection materials.

Section 07810: Spray-Applied Fire Resistive Material.

Section 07270: Firestopping and Smoke Seals.

Section 09900: Painting.

1.3.3

1.3.4

1.3.5

1.4

1.4.1

1.4.2

1.4.3

1.4.4

1.4.5

REFERENCES

Underwriters Laboratories Inc. (UL) Fire Resistance Directory.

Test Standards

A. UL 263 (ASTM E119) - Fire Tests of Building Construction and Materials.

B. ASTM E84 (UL723, CAN/ULC-S102) - Surface Burning Characteristics of

Building Materials. Class A Rating Required; Flame Spread Maximum: 5 and

Smoke Developed Maximum: 35.

C. ASTM D2240 Durometer Hardness (Shore D Only). Minimum: 84 Shore D.

D. ASTM D2794 Impact Resistance. 56 inch-lb (0.65 kg-m).

E. ASTM D4060 Abrasion Resistance. Maximum 0.2850 grams/1000 cycles.

F. ASTM D4541 Bond Strength. Minimum: 180 psi. (1931 k Pa.)

Steel Structures Painting Council (SSPC) Surface Preparation Standards.

Material manufacturer's current published information including, but not limited to,

application guide.

AWCI Technical Manual 12-B "Standard Practice for the Testing and Inspection of

Field Applied Thin-Film Intumescent Fire-Resistive Materials; an Annotated

Guide", Latest Edition.

1.5

1.5.1

SYSTEM DESCRIPTION

The intumescent fire protection materials shall be applied at the required thickness to provide the UL fire resistive ratings.

1.6

1.6.1

SUBMITTALS

Manufacturer's Data: Submit manufacturer's specifications, including certification

as may be required to show material compliance with contract documents.

1.7

1.7.1

1.7.2

QUALITY ASSURANCE

Manufacturer - Company specializing in manufacturing fire protection products.

The intumescent fire resistive material shall be manufactured under the FollowUp Service program of UL or ULC and bear the UL and/or ULC label (mark).

Applicator - A firm with expertise in the installation of fire resistive or similar

materials. This firm shall be licensed or otherwise approved by fire resistive

material supplier.

Product - The product shall be approved by the architect and applicable authorities

having jurisdiction.

1.7.3

1.7.4

1.8

1.8.1

1.9

1.9.1

1.9.2

DELIVERY, STORAGE AND HANDLING

Deliver materials to the project in manufacturer's unopened packages, fully

identified as to trade name, type and other identifying data. Packaged materials

shall bear the appropriate labels, seals and UL label (mark) for fire resistive

ratings and shall be stored at temperatures between 50 F (10 C) and 100 F

(38 C), in a dry interior location away from direct sunlight. DO NOT FREEZE.

PROJECT/SITE CONDITIONS

When the temperature at the job site is less than 50 F (10 C), a minimum

substrate and ambient temperature of 50 F (10 C) shall be maintained prior to,

during, and a minimum of 72 hours after application. If necessary for job

schedule, the General Contractor shall provide enclosures and heat to

maintain proper temperatures and humidity levels in the application areas.

In enclosed areas, ventilation shall not be less than 4 complete air exchanges per

hour until the material is dry.

1.10 SEQUENCING AND SCHEDULING

1.10.1 Applicator shall cooperate in the coordination and scheduling of fire protection work

to avoid delays in job progress.

1.10.2 The installation of piping, ducts, conduit or other suspended equipment shall not

commence until the application of the thin-film fire resistive material is complete

in that area.

2.1

COMPATIBLE METAL PRIMER

2.1.1 Primer shall be approved by manufacturer and applied in full accordance with the

primer manufacturer's written instructions.

2.2 INTUMESCENT FIRE PROTECTION SYSTEM

2.2.1 The intumescent fire resistive material shall be CAFCO SprayFilm -WB 3 as supplied

by Isolatek International or CAFCO Industries.

2.2.2 Intumescent fire resistive material shall be applied in accordance with drawings

and/or specifications, and shall have been tested in accordance with the procedures

of UL 263 or ASTM E119 or CAN/ULC-S101, and reported by Underwriters

Laboratories, Inc. or Underwriters Laboratories of Canada only.

2.3 DECORATIVE TOPCOATING

2.3.1 Topcoat materials shall be as required for color-coding, aesthetics or additional

surface protection, and approved by the thin-film fire resistive material manufacturer.

PART 3EXECUTION

3.1 PREPARATION

3.1.1 All surfaces to receive thin-film fire resistive material shall be clean, dry and free

of oil, grease, loose mill scale, dirt, dust or other materials which would impair

bond of the thin-film fire resistive material to the surface. Any cleaning of the

surfaces to receive fire resistive material shall be the responsibility of the

General Contractor or steel erector, as outlined in the structural steel section.

3.1.2 Confirm compatibility of surfaces to receive thin-film fire resistive material. Steel

surfaces shall be primed with a compatible primer approved by the thin-film

fire resistive material manufacturer.

3.1.3 Provide masking, drop cloths or other suitable coverings to prevent overspray onto

surfaces not intended to be coated with intumescent coating.

3.2

APPLICATION

3.2.1 The thin-film fire resistive material shall be applied at the required dry film thickness

per the appropriate UL design number.

3.3

MOCK UP

3.3.1 Before proceeding with the work, the applicator shall apply the thin-film fire

resistive material to a section witnessed by the architect's or owner's representative.

The application shall be subject to their approval and shall be used as a

guide for texture and thickness of the finished work.

3.4

CLEAN UP AND REPAIR

3.4.1 Upon completion of installation, all excess material, overspray and debris shall be

cleared and removed from the job site.

3.4.2 All patching of and repair to thin-film fire resistive material, due to damage by

other trades, shall be performed under this section and paid for by the trade

responsible for the damage. Patching shall be performed by applicators licensed or

otherwise approved by the manufacturer.

3.5

INSPECTION AND TESTING

3.5.1 In addition to continuous Wet Film Thickness checks performed by applicator during

application, the installed intumescent material shall be inspected by a qualified

independent testing laboratory for thickness in accordance with the AWCI

Technical Manual 12-B "Standard Practice For The Testing and Inspection Of Field

Applied Thin-Film Intumescent Fire-Resistive Materials; an Annotated Guide",

Second Edition, before application of the topcoat.

3.5.2 The results of the above tests shall be made available to all parties at the

completion of each area and approved prior to the application of topcoat.

For Further Information

In the United States: Isolatek International, Stanhope, New Jersey Tel: 800.631.9600 Fax: 973.347.9170

In Mxico & Central America: Cafco Mxico S.A. de C.V., Mxico D.F. Tel: 52.55.5254.6683 Fax: 52.55.5531.7826

In Andean Countries: Cafco Andina S.A., Santiago, Chile Tel: 562.719.0394

In Canada: Cafco Industries, Toronto (Ontario) Tel: 888.873.0003 Fax: 416.679.2933

In Asia: Tel: 60.3.5121.3886 Fax: 60.3.5212.4886

06/11

For more detailed product information, visit our website at www.cafco.com or contact us at technical@isolatek.com

ISOLATEK International All Rights Reserved

The performance data herein reflect our expectations based on tests conducted in accordance with recognized standard methods under controlled conditions. The applicator, general

contractor, property owner and/or user MUST read, understand and follow the directions, specifications and/or recommendations set forth in Isolatek International's publications concerning use and application of these products, and should not rely merely on the information contained in this product data sheet. Isolatek International is not responsible for property

damage, bodily injuries, consequential damages, or losses of any kind that arise from or are related to the applicator's, general contractor's, or property owner's failure to follow the

recommendations set forth in Isolatek International's publications. The sale of these products shall be subject to the Terms and Conditions of Sale set forth in the Company's invoices.

Total Passive

Fire Protection

Anda mungkin juga menyukai

- ISOLATEK Intumescent Interior Spec April 2015 2Dokumen6 halamanISOLATEK Intumescent Interior Spec April 2015 2FALwilliamsBelum ada peringkat

- 07270-Fire StoppingDokumen4 halaman07270-Fire StoppingEfz EfzBelum ada peringkat

- And Machine Rooms) (, That Are in Mechanical Rooms) (, That Are in Air-Handling Plenums)Dokumen13 halamanAnd Machine Rooms) (, That Are in Mechanical Rooms) (, That Are in Air-Handling Plenums)Emiliano Grados BarreraBelum ada peringkat

- XHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQDokumen4 halamanXHEZ.f-a-2043 - Through-Penetration Firestop Systems - UL Product IQMd. Atiqul IslamBelum ada peringkat

- NFCA2016InspectionTrainingProgramLinktowebsite032116WM PDFDokumen184 halamanNFCA2016InspectionTrainingProgramLinktowebsite032116WM PDFZaid Raslan AyoubBelum ada peringkat

- Technical Data Sheet Avikote Av 650 R PDFDokumen2 halamanTechnical Data Sheet Avikote Av 650 R PDFCIAKBelum ada peringkat

- Saudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 MechDokumen2 halamanSaudi Aramco Inspection Checklist: Receiving Inspection of Intumescent Fireproofing Mat'ls SAIC-B-2003 30-Apr-13 Mechpookkoya thangalBelum ada peringkat

- University of Houston Master Construction SpecificationsDokumen8 halamanUniversity of Houston Master Construction SpecificationsTaher AmmarBelum ada peringkat

- API936 Effective Sheet-2020 PDFDokumen2 halamanAPI936 Effective Sheet-2020 PDFmalleshBelum ada peringkat

- Rakic - Type of Fireproofing Materials PDFDokumen3 halamanRakic - Type of Fireproofing Materials PDFbehrouzbehnam100% (1)

- Y710Dokumen2 halamanY710RimBelum ada peringkat

- Section 07810 Applied FireproofingDokumen4 halamanSection 07810 Applied FireproofingMØhãmmed ØwięsBelum ada peringkat

- Steel Shot Grit SizingDokumen2 halamanSteel Shot Grit SizingSUBODHBelum ada peringkat

- Repairing Damaged Hot-Dip Galvanized Steel With Zinc-Rich Paint, Zinc MetallDokumen4 halamanRepairing Damaged Hot-Dip Galvanized Steel With Zinc-Rich Paint, Zinc MetallMJK008100% (1)

- FireproofingDokumen3 halamanFireproofingarki_emmanBelum ada peringkat

- Fireproofing Brochure (US)Dokumen8 halamanFireproofing Brochure (US)Ramesh PrabhakarBelum ada peringkat

- Design No. XR711: BYBU - XR711 Fire-Resistance Ratings - ANSI/UL 1709Dokumen2 halamanDesign No. XR711: BYBU - XR711 Fire-Resistance Ratings - ANSI/UL 1709EngTamerBelum ada peringkat

- UL Design D925Dokumen9 halamanUL Design D925RimBelum ada peringkat

- SSPC Pa 7 PDFDokumen10 halamanSSPC Pa 7 PDFkishorekumar.animuBelum ada peringkat

- SSPC-VIS Pictorial Surface Standards - TQC (EN) PDFDokumen7 halamanSSPC-VIS Pictorial Surface Standards - TQC (EN) PDFMuhammad Adnan Riaz ButtBelum ada peringkat

- Molded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForDokumen2 halamanMolded Glass Fiber Reinforced Gypsum Parts: Standard Specification ForJesús Luis Arce Guillermo100% (1)

- Concrete Protective CoatingDokumen10 halamanConcrete Protective CoatingShabbar Abbas MalikBelum ada peringkat

- Cafco Fendolite Mii Application Guidelines PDFDokumen23 halamanCafco Fendolite Mii Application Guidelines PDFTanmay GorBelum ada peringkat

- Acid Resistant Tiles BricksDokumen6 halamanAcid Resistant Tiles BricksDeboline MitraBelum ada peringkat

- BXUVDokumen23 halamanBXUVMd Farid AhmedBelum ada peringkat

- J718Dokumen4 halamanJ718Gatot KeceBelum ada peringkat

- Saes B-006 (2017)Dokumen21 halamanSaes B-006 (2017)Ralph Ian Malabanan100% (1)

- SP15 99Dokumen1 halamanSP15 99Orlando Manriquez LBelum ada peringkat

- Astm A572 1979 PDFDokumen5 halamanAstm A572 1979 PDFeko.kusgmail.comBelum ada peringkat

- Defining Mechanical Surface Preparation Standards With Power ToolsDokumen8 halamanDefining Mechanical Surface Preparation Standards With Power ToolsAryo Wicaksono100% (1)

- HANDOUTS - Fire Protection Coordination With HVAC DesignDokumen18 halamanHANDOUTS - Fire Protection Coordination With HVAC Designsolowe988Belum ada peringkat

- Fire Protective Coatings - An OverviewDokumen1 halamanFire Protective Coatings - An OverviewdantranzBelum ada peringkat

- NFPA 285 Fire Testing For Exterior Walls: Code Requirements and Design ChallengesDokumen1 halamanNFPA 285 Fire Testing For Exterior Walls: Code Requirements and Design ChallengesaialosangelesBelum ada peringkat

- Pl-Coat-1.0.0 (Fusion Bonded Epoxy Coating)Dokumen10 halamanPl-Coat-1.0.0 (Fusion Bonded Epoxy Coating)Hector MejiaBelum ada peringkat

- The Industrial Coatings MarketDokumen5 halamanThe Industrial Coatings MarketjagrititanuBelum ada peringkat

- Styrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber ReinforcementsDokumen3 halamanStyrene Butadiene Styrene (SBS) Modified Bituminous Sheet Materials Using Glass Fiber ReinforcementsLuigi HernándezBelum ada peringkat

- Clarifying Membrane Penetration RequirementsDokumen7 halamanClarifying Membrane Penetration Requirementsfire-1Belum ada peringkat

- PIP CTSE1000 (Application of External Coatings)Dokumen79 halamanPIP CTSE1000 (Application of External Coatings)이동욱Belum ada peringkat

- 1411 - Explanation To Product Data SheetsDokumen0 halaman1411 - Explanation To Product Data SheetseraswastaBelum ada peringkat

- Section 5.0 - Epoxy Coatin SystemsDokumen36 halamanSection 5.0 - Epoxy Coatin SystemsgemotorresBelum ada peringkat

- SECTION 09 96 00 High Performance Coatings GeneralDokumen8 halamanSECTION 09 96 00 High Performance Coatings Generalraja qammarBelum ada peringkat

- Immersion Testing of Industrial Protective Coatings: Standard Practice ForDokumen6 halamanImmersion Testing of Industrial Protective Coatings: Standard Practice ForJhon Jeiwer SantosBelum ada peringkat

- SSPC Paint System RecommendationsDokumen3 halamanSSPC Paint System RecommendationsJayesh2281Belum ada peringkat

- ASTM E761 - 92 Reapproved 2011Dokumen3 halamanASTM E761 - 92 Reapproved 2011Trà Trần SơnBelum ada peringkat

- Updated: 05/02/2007: IMO PSPC - IACS Interpretations IMO PSPC Topic Approved Clarification Items InterpretationsDokumen7 halamanUpdated: 05/02/2007: IMO PSPC - IACS Interpretations IMO PSPC Topic Approved Clarification Items InterpretationsLinnie McleodBelum ada peringkat

- 1 SATIP-N-110-01 Castable Refractory InstallationDokumen2 halaman1 SATIP-N-110-01 Castable Refractory Installationsonalisabir100% (1)

- Repair Application ProceduresDokumen6 halamanRepair Application ProceduresSatheesh Rama SamyBelum ada peringkat

- ASTM E1132-99aDokumen27 halamanASTM E1132-99aOmar Bellido ValenciaBelum ada peringkat

- BYBU - XR731 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq - GCP-AVICOTE Z-156PC PDFDokumen5 halamanBYBU - XR731 - Fire-Resistance Ratings - ANSI - UL 1709 - UL Product Iq - GCP-AVICOTE Z-156PC PDFCIAKBelum ada peringkat

- Chartek Range - UKDokumen2 halamanChartek Range - UKTung ThanhBelum ada peringkat

- Thermal Spray Aluminium CoatingDokumen5 halamanThermal Spray Aluminium CoatingMythri Metallizing Pvt Ltd Projects100% (2)

- SDI - 108 - Standard Steel Doors and FramesDokumen4 halamanSDI - 108 - Standard Steel Doors and FramesPangit BertBelum ada peringkat

- Internal Launch Presentation Version 01 - SingaporeDokumen100 halamanInternal Launch Presentation Version 01 - SingaporeEnrico Savira100% (1)

- ASTM A572 Grade 50 Plate: AnalysisDokumen2 halamanASTM A572 Grade 50 Plate: Analysisdaniel moreno jassoBelum ada peringkat

- Concrete Batch Plants CommentsDokumen2 halamanConcrete Batch Plants CommentsShoaib SafdarBelum ada peringkat

- Cafco 300Dokumen2 halamanCafco 300henrengBelum ada peringkat

- Monokote Z-146PC: High Density Cementitious Fireproofing - Petrochemical GradeDokumen6 halamanMonokote Z-146PC: High Density Cementitious Fireproofing - Petrochemical GradeMARIA CECILIA BANDA LOYDABelum ada peringkat

- FireproofingDokumen6 halamanFireproofingrobinhoss100% (1)

- Laboratory Testing of Hydrocarbon Fire Protection Coatings and Effect of Wet EnvironmentsDokumen16 halamanLaboratory Testing of Hydrocarbon Fire Protection Coatings and Effect of Wet EnvironmentsDinh Quoc HungBelum ada peringkat

- Iso 19232 2 2013Dokumen9 halamanIso 19232 2 2013NDT HITECHBelum ada peringkat

- Coating DFT-RulesDokumen2 halamanCoating DFT-RulesAnand100% (1)

- Customer Satisfaction Level of Maruti Four WheelerDokumen59 halamanCustomer Satisfaction Level of Maruti Four WheelerShobhit GoswamiBelum ada peringkat

- Cat 20 23 Minibloc6 Rom GBDokumen16 halamanCat 20 23 Minibloc6 Rom GBarteorBelum ada peringkat

- AI6Dokumen32 halamanAI6aissarapan_bBelum ada peringkat

- Brewer 2010Dokumen28 halamanBrewer 2010carlosdanskeBelum ada peringkat

- Dr. Tadisina Kishen Kumar ReddyDokumen2 halamanDr. Tadisina Kishen Kumar ReddyReeta DuttaBelum ada peringkat

- LOPAS SA Company Profile - ENDokumen63 halamanLOPAS SA Company Profile - ENCyril Jean-BaptisteBelum ada peringkat

- PSN Institute of Technology and ScienceDokumen1 halamanPSN Institute of Technology and ScienceS ArunBelum ada peringkat

- Marketingul MobileDokumen8 halamanMarketingul MobileIuliana DimaBelum ada peringkat

- A Project Report On Analysis of Financial Statement at Kirloskar Project Report Mba FinanceDokumen86 halamanA Project Report On Analysis of Financial Statement at Kirloskar Project Report Mba FinanceAmar Singh KushwahBelum ada peringkat

- Canam Purlins and Girts Catalogue CanadaDokumen0 halamanCanam Purlins and Girts Catalogue CanadasaivanvalendezBelum ada peringkat

- Charles BovillDokumen2 halamanCharles BovillGallg BaronBelum ada peringkat

- Walkway 1Dokumen5 halamanWalkway 1Bryan PittmanBelum ada peringkat

- Second Internal Assessment Test, August 2015Dokumen4 halamanSecond Internal Assessment Test, August 2015AnuShaBelum ada peringkat

- Arcati Mainframe Yearbook 2012Dokumen173 halamanArcati Mainframe Yearbook 2012Kavungal Abdul JaleelBelum ada peringkat

- Transportation in A Supply ChainDokumen18 halamanTransportation in A Supply ChainprateekBelum ada peringkat

- 9852 2171 01 Transport Instructions MT5020 6020Dokumen2 halaman9852 2171 01 Transport Instructions MT5020 6020tincho_0026Belum ada peringkat

- alashankri-Bangalore-3ST Road, Phase.: WXIN2106250004345 4th 7th Banashankn User Type: End UserDokumen2 halamanalashankri-Bangalore-3ST Road, Phase.: WXIN2106250004345 4th 7th Banashankn User Type: End UserKaushal RaghuBelum ada peringkat

- The Requirement For Effective Military Training: LT Col Nigel Gallier British Liaison Officer - STRICOMDokumen60 halamanThe Requirement For Effective Military Training: LT Col Nigel Gallier British Liaison Officer - STRICOMnigelgallierBelum ada peringkat

- QP 101Dokumen7 halamanQP 101mdd omanBelum ada peringkat

- Project Proposal On Project Management in Telecommunication FieldDokumen4 halamanProject Proposal On Project Management in Telecommunication Fieldsamaratul100% (1)

- MICHIGAN MOTORZ - New Engine Warranty InformationDokumen2 halamanMICHIGAN MOTORZ - New Engine Warranty InformationDaddyos Marine EnginesBelum ada peringkat

- NB-CPD SG04 10 075 - en 12899-1 - Fixed Vertical Road Traffic Signs - Fixed SignsDokumen10 halamanNB-CPD SG04 10 075 - en 12899-1 - Fixed Vertical Road Traffic Signs - Fixed SignsSebastian CiprianBelum ada peringkat

- Training Brochure v1.0Dokumen63 halamanTraining Brochure v1.0Steve ForsterBelum ada peringkat

- Escorts TractorsDokumen65 halamanEscorts TractorsAnonymous RQcJ8yM100% (2)

- Clean Steel Practices in The Melt ShopDokumen3 halamanClean Steel Practices in The Melt Shopmp87_ingBelum ada peringkat

- Sap Landscape TransformationDokumen24 halamanSap Landscape TransformationbhangaramBelum ada peringkat

- Senior Systems AdministratorDokumen5 halamanSenior Systems AdministratorBrijesh PatilBelum ada peringkat

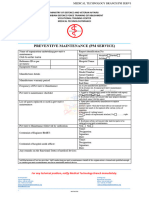

- Preventive Maintenance (PM Service)Dokumen2 halamanPreventive Maintenance (PM Service)jim tauBelum ada peringkat

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDari EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedPenilaian: 5 dari 5 bintang5/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesDari EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesBelum ada peringkat

- A Place of My Own: The Architecture of DaydreamsDari EverandA Place of My Own: The Architecture of DaydreamsPenilaian: 4 dari 5 bintang4/5 (242)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialDari EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialBelum ada peringkat

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionDari EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionPenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Building Construction Technology: A Useful Guide - Part 1Dari EverandBuilding Construction Technology: A Useful Guide - Part 1Penilaian: 4 dari 5 bintang4/5 (3)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationDari EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettPenilaian: 4 dari 5 bintang4/5 (1)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyDari EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyPenilaian: 4 dari 5 bintang4/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyDari EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyPenilaian: 4 dari 5 bintang4/5 (1)

- Estimating Construction Profitably: Developing a System for Residential EstimatingDari EverandEstimating Construction Profitably: Developing a System for Residential EstimatingBelum ada peringkat

- Civil Engineer's Handbook of Professional PracticeDari EverandCivil Engineer's Handbook of Professional PracticePenilaian: 4.5 dari 5 bintang4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADari EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ABelum ada peringkat

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseDari EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HousePenilaian: 5 dari 5 bintang5/5 (3)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsDari EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsPenilaian: 1 dari 5 bintang1/5 (4)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDari Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuidePenilaian: 3.5 dari 5 bintang3.5/5 (7)

- The Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishDari EverandThe Everything Woodworking Book: A Beginner's Guide To Creating Great Projects From Start To FinishPenilaian: 4 dari 5 bintang4/5 (3)

- History of Smart Textiles: A Comprehensive Guide To E-TextilesDari EverandHistory of Smart Textiles: A Comprehensive Guide To E-TextilesBelum ada peringkat

- Essential Building Science: Understanding Energy and Moisture in High Performance House DesignDari EverandEssential Building Science: Understanding Energy and Moisture in High Performance House DesignPenilaian: 5 dari 5 bintang5/5 (1)

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsDari EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsPenilaian: 3.5 dari 5 bintang3.5/5 (3)

- Field Guide for Construction Management: Management by Walking AroundDari EverandField Guide for Construction Management: Management by Walking AroundPenilaian: 4.5 dari 5 bintang4.5/5 (3)