33A Front Suspension

Diunggah oleh

takedashindenHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

33A Front Suspension

Diunggah oleh

takedashindenHak Cipta:

Format Tersedia

33A-1

FRONT

SUSPENSION

CONTENTS

..................2

LOWER ARM ..............................

9

ON-VEHICLE SERVICE .....................

4

GENERAL INFORMATION

Front Wheel Alignment Check and

Adjustment ..................................

SERVICE SPECIFICATIONS

33209000073

SPECIAL TOOLS ...........................

STABILIZER BAR

.........................

STRUT ASSEMBLY

12

........................

TROUBLESHOOTlNG

....................... 4

................. 3

I'

33A-2

FRONT SUSPENSION

General Information

GENERAL INFORMATION

332ooo10099

The front suspension is a Mcpherson strut with coil spring. The shock absorber is hydraulic double-acting

type.

COIL SPRING

2-door models

Item

Wire diameter x free length mm (in.)

Item

Wire diameter x free length mm (in.)

CONSTRUCTION DIAGRAM

1.5L M/T

1.8L M/T

1.5L AIT

1.8L A/T

12 x 138 x 340

(.47 x 5.43 x 13.39)

12 x 138 x 350

(.47 x 5.43 x 13.78)

1.5L

1.8L without ABS

1.8L with ABS

12 x 138 x 350

(.47 x 5.43 x 13.78)

12 x 138 x 360

(.47 x 5.43 x 14.17)

FRONT SUSPENSION

- Service Specifications/SpeciaI TOOIS

SERVICE SPECIFICATIONS

33A-3

33200030071

Specifications

I tems

Toe-in mm(in.)

0 .+ 3 (0 f .12)

Steering angle

Inner wheel

37'30' -c 2"OO

Outer wheel

31"40'

Camber

0"OO .e 30' (LeWright deviation within 30')

Caster

2'51'

Lower arm ball joint breakaway torque Nm (in.lbs.)

1.O - 6.4 (9 - 56)

Protruding length of stabilizer bar mounting bolt mm (in.)

22 (.87)

f 30'

(LefVright deviation within 30')

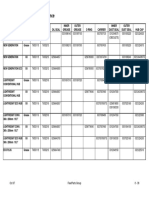

SPECIAL TOOLS

33200060063

I Application

Tool number and name

Supersession

MB991004

Wheel alignment gauge

attachment

MB991004-01 or

General service tool

Wheel alignment

measurement

MB990278 or MB990775

Special spanner

MB990775-01

Strut assembly

disassembly/assembly

8991004

6990278

A: MB991237

Spring compressor body

B: MB991238

Arm set

MIT 62220

Front coil spring

compression

00003796

MB991113

Steering linkage puller

8991113

MB990800-01

1 Dust cover installation

Ball joint remover and

installer

8990800

MB990326

Preload socket

breakaway torque

measurement

33A-4

FRONT SUSPENSION

- Troubleshooting/On-vehicle Service

TROUBLESHOOTING

Symptom

Probable cause

Remedy

Steering wheel is heavy, vibrates

or pulls to one side

Suspension malfunction

Ball joint

Coil spring

Wheel alignment

Adjust or replace

1 Adjust or replace

~~

Unbalanced or worn tires

~~~

________

Excessive vehicle rolling

Broken or deteriorated stabilizer

Shock absorber malfunction

Poor riding

Improper tire inflation pressure

Replace

I Adjust

Broken or deteriorated coil spring

Shock absorber malfunction

~

Inclinationof vehicle

Broken or deteriorated coil spring

Noise

Lack of lubrication

Replace

Looseness and wear of each part

Broken coil spring

Shock absorber malfunction

I Replace

1 Lubricate

I

I

1 Replace

Replace

ON-VEHICLE SERVlCE

33100090106

FRONT WHEEL ALIGNMENT CHECK AND

ADJUSTMENT

Measure wheel alignment with alignment equipment on a

level surface.

The front suspension, steering system, and wheels should

be serviced to normal condition before measuring of wheel

alignment.

TOE-IN

Standard value: 0

3 mm (0 -c . I 2 in.)

FRONT SUSPENSION

- On-vehicle

Service

33A-5

NOTE

1. If the toe-in is not within the standard value, adjust the

toe-in by undoing the clips and turning the left and right

tie rod turnbuckles by the same amount (in opposite

directions).

2. The toe will move out as the left turnbuckle is turned

toward the front of the vehicle and the right turnbuckle

is turned toward the rear of the vehicle.

For each one turn of the left and right tie rods, the toe-in

will be adjusted by approx. 105 (per wheel).

s

A1 2 0 000

STEERING ANGLE

Standard value:

Inner wheel 37O30 2 O O O

Outer wheel 31040

CAMBER AND CASTER

Standard value:

Camber OoOO f 30 (LeWright deviation within 30)

Caster 2O51 I30 (LeWright deviation within 30)

A12S0057

NOTE

1. Camber and caster are preset at the factory and cannot

be adjusted.

2. If camber is not within the standard value, check and

replace bent or damaged parts.

3. For vehicles with aluminum type wheels, attach the camber/caster/kingpin gauge to the drive shaft by using the

special tool. Tighten the special tool to the same torque

177-275 Nm (130-203 ft.lbs.) as the drive shaft nut.

Caution

Never subject the wheel bearings to the vehicle load

when the drive shaft nuts are loosened.

33A-6

FRONT SUSPENSION

- Strut Assembly

STRUT ASSEMBLY

33200110058

REMOVAL AND INSTALLATION

Post-Installation Operation

Front Wheel Alignment Adjustment

(Refer to P.33A-4.)

44 Nm

Nm

ftlbs.

A12MO054

80

4Ab

- 94 ft.lbS.

Removal steps

1. Brake hose clamp

2. Front speed sensor

<Vehicles with ABS>

3. Bolts

4. Self-locking nut

5. Strut assembly

Caution

For vehicles with ABS, be careful when handling

the pole piece at the tip of the speed sensor so

as not to damage it by striking against other parts.

REMOVAL SERVICE POINT

4-

BOLTS REMOVAL

(1) Suspend the lower arm from the vehicle with wire.

(2) Remove the strut and knuckle connection.

INSPECTION

0

0

33200120020

Check for oil leaks from the strut assembly.

Check the strut assembly for damage or deformation.

- Strut Assembly

FRONT SUSPENSION

33A-7

DISASSEMBLY AND REASSEMBLY

33200130078

/-

/I

-59

Nm

43 ft.lbs.

12M0053

00004904

4+

.A4

Disassembly steps

1. Dust cover

2. Self-locking nut

3. Strut insulator

4. Spring seat, upper

5.

6.

7.

8.

Bump rubber

Coil spring

Spring pad, lower

Strut assembly

DISASSEMBLY SERVICE POINTS

++

991237

B 12S0007

SELF-LOCKIING NUT REMOVAL

(1) Use the special tools to compress the coil spring.

Caution

1. Install the special tools evenly, and so that the

maximum length will be attained within the

installation range.

2. Do not use an impact wrench to tighten the special

tool bolt.

(2) Use the special tools to remove the self-locking nut.

Caution

Do not use an impact wrench.

81220003

33A-8

FRONT SUSPENSION

Strut Assembly

+ B F STRUT ASSEMBLY REMOVAL

To discard the strut assembly, place the assembly horizontally

with its piston rod extended. Then drill a hole of approx.

3 mm (.12 in.) in diameter at the location shown in the

illustration and discharge the gas.

Caution

The gas itself i s harmless but it may issue out of the

hole together with chips generated by the drill. Therefore,

be sure to wear goggles.

12U0014

REASSEMBLY SERVICE POINT

FA( SELF-LOCKING NUT INSTALLATION

(1) With the coil spring held compressed by the special tools

(MB991237 and MB991238), provisionally tighten the

self-locking nut.

Caution

Do not use an impact wrench to tighten the special

tool bolt.

(2) Line up the holes in the strut assembly spring lower seat

with the hole in the spring upper seat.

NOTE

The alignment is easily accomplished with a rod.

(3) Correctlyalign both ends of the coil spring with the grooves

in the spring seat, and then loosen the special tools

(MB991237 and MB991238).

Rod

A12M00.55

(4) Using the special tool, tighten the self-locking nut to the

specified torque.

Caution

Do not use an impact wrench.

B 1220004

INSPECTION

0

0

0

0

33200140057

Check the bearing for wear or rust.

Check the rubber parts for damage or deterioration.

Check the spring for deformation, deteriorationor damage.

Check the shock absorber for deformation.

FRONT SUSPENSION

- Lower Arm

33A-9

LOWER ARM

33200160053

REMOVAL AND INSTALLATION

Post-installationOperation

0

Press the ball joint dust cover with a finger to check

whether the dust cover is cracked or damaged.

Front Wheel Alignment Adjustment

(Refer to P.33A-4.)

3

4

3

5

59

43

Removal steps

1. Lower arm ball joint connection

F A 4 2. Self-locking nut

3. Stabilizer rubber

4. Stabilizer bar

5. Collar

6. Lower arm front bushing

connection

MB99;1113

4iF

B12Z0001

7. Support bracket

8. Lower arm assembly

Caution

Indicates parts which should be temporarily

tightened, and then fully tightened with the

vehicle on the ground in the unladen condition.

*:

REMOVAL SERVICE POINT

++

LOWER ARM BALL JOINT DISCONNECTION

Use the special tool to disconnect the lower arm ball joint

from the knuckle.

Caution

1. Using the special tool, loosen the tie rod end mounting

nut. Only loosen the nut; do not remove it from the

ball joint.

2. Support the special tool with a cord, etc. to prevent

it from coming off.

33A-10

FRONT SUSPENSION

Lower Arm

INSTALLATION SERVICE POINT

.A+

SELF-LOCKING NUT INSTALLATION

Tighten the self-locking nut so that the amount of protrusion

of the end of the stabilizer bar mounting bolt is at the standard

value.

Standard value (A): 22 mm (.87 in.)

-----4

hr/ /

01M0007

INSPECTION

0

0

0

0

0

Check

Check

Check

Check

Check

33200170070

the bushing for wear and deterioration.

the lower arm for bend or breakage.

the support bracket for deterioration or damage.

the ball joint dust cover for cracks.

all bolts for condition and straightness.

BALL JOINT BREAKAWAY TORQUE CHECK

(1) After shaking the ball joint stud several times, install the

nut to the stud and use the special tool to measure the

breakaway torque of the ball joint.

Standard value:

1.0 - 6.4 Nm (9 56 in.lbs.)

(2) When the measured value exceeds the standard value,

replace the ball joint.

(3) When the measured value is lower than the standard

value, check that the ball joint turns smoothly without

excessive play. If so, it is possible to use that ball joint.

BALL JOINT DUST COVER CHECK

(1) Press the dust cover with a finger to check whether the

dust cover is cracked or damaged.

NOTE

If the dust cover is cracked, the ball joint could be

damaged, so if the dust cover is damaged during

maintenance work, replace it.

(2) When dust cover is cracked or damaged, replace the

lower arm ball boint assembly.

A1220007

FRONT SUSPENSION

- Lower Arm

33A-11

BALL JOINT DUST COVER REPLACEMENT

33200820029

612s0003

Replace the dust cover only when it has been cracked or

damaged by mistake during the maintenance work.

(1) Remove the dust cover.

(2) Apply multipurpose grease to the lip and inside of the

dust cover.

(3) Drive in the dust cover with special tool until it is fully

seated.

(4) Press the dust cover with a finger to check whether the

dust cover is cracked or damaged.

LOWER ARM REAR BUSHING REPLACEMENT

33200810033

(1) Apply soapy water between the shaft and old bushing,

and pry up bushing using a flat-tipped screwdriver.

(2) Apply soapy water to the shaft and new bushing and

install new bushing into the shaft at the angle shown

in the illustration.

(3) Press in the bushing as illustrated.

33A-12

FRONT SUSPENSION

- Stabilizer Bar

STABILIZER BAR

33200190052

REMOVAL AND INSTALLATION

Pre-removal and Post-installation Operation

Crossmember Removal and Installation

(Refer to GROUP 32 - Crossmember.)

Nm

ft.lbs.

L

,

~12M0013

Removal steps

b B 4 1. Self-locking nut

2. Stabilizer rubber

.

3. Collar

Approx. lOmm (.4 in.)

-v-

F A 4 4. Fixture

.A4

5. Bushing

6. Stabilizer bar

INSTALLATION SERVICE POINT

,A+

BUSHING/FIXTUR E INSTALLATION

Place the identification mark of the stabilizer bar to the left,

and installthe bushing so that the identificationmark protrudes

approximately 10 rnrn (.4 in.) from the edge of the inside

of the bushing.

1210027

w

FRONT SUSPENSION

- Stabilizer

Bar

33A-13

FBISELF-LOCKING NUT INSTALLATION

Tighten the self-locking nut so that the amount of protrusion

of the end of the stabilizer bar mounting bolt is at the standard

value.

Standard value (A): 22 mm (.87 in.)

INSPECTION

0

33200200021

Check the bushing for wear and deterioration.

Check the stabilizer bar for deterioration or damage.

Anda mungkin juga menyukai

- P EcommerceDokumen1.467 halamanP EcommercetakedashindenBelum ada peringkat

- USB-Parallel Cable User ManualDokumen6 halamanUSB-Parallel Cable User ManualtakedashindenBelum ada peringkat

- Fujita Seiko NinjutsuDokumen22 halamanFujita Seiko NinjutsuДориян Александров0% (1)

- 32 Power Plant MountDokumen9 halaman32 Power Plant MounttakedashindenBelum ada peringkat

- 99 Mirage Tach HookupDokumen2 halaman99 Mirage Tach HookuptakedashindenBelum ada peringkat

- 忍 び 六 具 Shinobi RokuguDokumen4 halaman忍 び 六 具 Shinobi RokugutakedashindenBelum ada peringkat

- Japanese CountingDokumen1 halamanJapanese CountingtakedashindenBelum ada peringkat

- 99 Mirage Splice LocationsDokumen11 halaman99 Mirage Splice LocationstakedashindenBelum ada peringkat

- 15 Intake and ExhaustDokumen9 halaman15 Intake and ExhausttakedashindenBelum ada peringkat

- 27 Rear AxleDokumen6 halaman27 Rear AxletakedashindenBelum ada peringkat

- 54 Chassis ElectricalDokumen70 halaman54 Chassis ElectricaltakedashindenBelum ada peringkat

- 35A Basic Brake SystemDokumen32 halaman35A Basic Brake SystemtakedashindenBelum ada peringkat

- 23B Auto Trans OverhaulDokumen75 halaman23B Auto Trans OverhaultakedashindenBelum ada peringkat

- 70 Component LocationsDokumen18 halaman70 Component LocationstakedashindenBelum ada peringkat

- 31 Wheels and TiresDokumen5 halaman31 Wheels and TirestakedashindenBelum ada peringkat

- 23A Automatic TransaxleDokumen81 halaman23A Automatic Transaxletakedashinden100% (1)

- 11A 1.5L Engine MirageDokumen34 halaman11A 1.5L Engine MiragetakedashindenBelum ada peringkat

- EkyogetsushogeiDokumen2 halamanEkyogetsushogeiSergiy MatvyeyevBelum ada peringkat

- 21B Clutch OverhaulDokumen8 halaman21B Clutch OverhaultakedashindenBelum ada peringkat

- 99 Mirage Fuel SupplyDokumen5 halaman99 Mirage Fuel SupplytakedashindenBelum ada peringkat

- Bansenshukai Ninjutsu Manual PDFDokumen27 halamanBansenshukai Ninjutsu Manual PDFtakedashindenBelum ada peringkat

- 12 Engine Lubrication 99 MirageDokumen4 halaman12 Engine Lubrication 99 MiragetakedashindenBelum ada peringkat

- 11D 1.8L Overhaul MirageDokumen55 halaman11D 1.8L Overhaul Miragetakedashinden50% (2)

- 22A Manual TransaxleDokumen14 halaman22A Manual TransaxletakedashindenBelum ada peringkat

- 13a Mfi 1.5LDokumen164 halaman13a Mfi 1.5LDian Zahari Zainal AbidinBelum ada peringkat

- 11B 1.5L OverhaulDokumen51 halaman11B 1.5L OverhaultakedashindenBelum ada peringkat

- Bansenshukai 01Dokumen0 halamanBansenshukai 01Rafael Afonso100% (1)

- Okuma 3 PubDokumen13 halamanOkuma 3 PubtakedashindenBelum ada peringkat

- General: General General OOEDokumen53 halamanGeneral: General General OOEBenedict SalidoBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Cat Comex Fuel InjectorDokumen12 halamanCat Comex Fuel InjectorGehovanny RíosBelum ada peringkat

- 740 and 750 e 38 Bmws Trannys Installed Real Oem - Com ReferenceDokumen2 halaman740 and 750 e 38 Bmws Trannys Installed Real Oem - Com ReferencegoogleheadBelum ada peringkat

- 2010 Chevrolet HHR ManualDokumen480 halaman2010 Chevrolet HHR ManualFernando Peña RodríguezBelum ada peringkat

- Fusion PDFDokumen25 halamanFusion PDFMadalina CameliaBelum ada peringkat

- TMS9000 2 SM CTRL649 01 SPANISH With Alignment Supp Light PDFDokumen414 halamanTMS9000 2 SM CTRL649 01 SPANISH With Alignment Supp Light PDFJhonnatan Alexis roaBelum ada peringkat

- Electrical & Power Control System OverviewDokumen199 halamanElectrical & Power Control System OverviewJose espinosaBelum ada peringkat

- Data Sheet - Volvo 9900 Eu6 - enDokumen3 halamanData Sheet - Volvo 9900 Eu6 - enAaron Hevia MirandaBelum ada peringkat

- Section 8 - BPW Quick ReferenceDokumen43 halamanSection 8 - BPW Quick ReferenceSanhory Abd AlgaderBelum ada peringkat

- Wiring Schematic: OptionsDokumen2 halamanWiring Schematic: OptionsAlexandrBelum ada peringkat

- Kia Sportage ANCAP PDFDokumen3 halamanKia Sportage ANCAP PDFcarbasemyBelum ada peringkat

- Lifan X60 Manual de ServicioDokumen878 halamanLifan X60 Manual de ServicioYURI JAVIER SIERRA JIMENEZ80% (5)

- Data Book: Automotive TechnicalDokumen1 halamanData Book: Automotive TechnicalDavidGuzmanBelum ada peringkat

- w638 Fuse Box and Relay Diagram 1996 2003Dokumen5 halamanw638 Fuse Box and Relay Diagram 1996 2003Radek Caver Johánek50% (2)

- Body Electrical SystemDokumen2 halamanBody Electrical Systempavel35Belum ada peringkat

- Peugeot 206 FusesDokumen2 halamanPeugeot 206 FusesThomas Gunawan100% (3)

- 206 09A Anti Lock ControlDokumen11 halaman206 09A Anti Lock ControlMiguel AngelBelum ada peringkat

- Hunter wheel alignment software update titleDokumen3 halamanHunter wheel alignment software update titleOscar Daniel ManzottiBelum ada peringkat

- Toyota Corolla Altis (2014)Dokumen10 halamanToyota Corolla Altis (2014)alvinhaw98Belum ada peringkat

- AT2512C Eng 01 953804Dokumen2 halamanAT2512C Eng 01 953804Victor Hugo Benitez PaezBelum ada peringkat

- Chery A15 Inner Lining ManualDokumen7 halamanChery A15 Inner Lining ManualCarlos TecnicBelum ada peringkat

- New Holland Tractor Tj425 Parts CatalogDokumen20 halamanNew Holland Tractor Tj425 Parts Catalogandrew100% (49)

- Mercedes-Benz GLC Coupé 2016 5d Hybrid EN 253.35v2.0Dokumen2 halamanMercedes-Benz GLC Coupé 2016 5d Hybrid EN 253.35v2.0Ricardo Santo AntonioBelum ada peringkat

- General Information: Workshop ManualDokumen39 halamanGeneral Information: Workshop ManualAlexander Neyra90% (10)

- Fiat 124 1975 Coupe-Spider Specs and DataDokumen93 halamanFiat 124 1975 Coupe-Spider Specs and Datafiat12486% (7)

- U301l - 1 - Cover & Disc Clutch (Fitting Parts) .Dokumen6 halamanU301l - 1 - Cover & Disc Clutch (Fitting Parts) .bennieBelum ada peringkat

- Scania j1939 FMSDokumen80 halamanScania j1939 FMSzibetto67% (3)

- Volvo XC70 (08-) - 2013 Structure Week 12w46 VOLVO S60 (11-), V60, XC60, S80 (07-), V70 (08-) & XC70 WIRING DIAGRAMDokumen4 halamanVolvo XC70 (08-) - 2013 Structure Week 12w46 VOLVO S60 (11-), V60, XC60, S80 (07-), V70 (08-) & XC70 WIRING DIAGRAMsen tilBelum ada peringkat

- Circle Track Car Setup GuideDokumen8 halamanCircle Track Car Setup GuideHitesh Vashist100% (1)

- Braking System Suggested For The AtvDokumen9 halamanBraking System Suggested For The AtvAkash SaxenaBelum ada peringkat

- 40-074-XT 60 Oil in Transmission-922Dokumen1 halaman40-074-XT 60 Oil in Transmission-922Fer EmilBelum ada peringkat