Alignment For A Reciprocating Compressor

Diunggah oleh

MVSEETARAMANDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Alignment For A Reciprocating Compressor

Diunggah oleh

MVSEETARAMANHak Cipta:

Format Tersedia

ENGINEERING REFERENCE

The contents of this document are proprietary and confidential. They are the

property of Ariel Corporation and may not be disclosed, reproduced, or used for

manufacture in part or in whole without written permission from Ariel Corporation.

Soft Foot and Top Plane Flatness Checks for

Proper Main Bearing Bore Alignment in

Reciprocating Compressors

Main bearing bore alignment is critical to main bearing and crankshaft life. Ariel manufactures the top

cover mounting surface of a compressor frame in close tolerance to a flat plane, to the main bearing

bores, and to the bottom of the compressor feet. The main bearing bores align when frame feet are

supported so the top cover mounting surface is flat and "in plane". Perform a soft foot check and top

plane flatness measurement at these times:

Setting of a new compressor (pre and post grouting).

Commission of a compressor in the field.

Reinstallation of a compressor.

Relocation of a package.

Discovery of loose hold down fasteners.

Performance of recommended scheduled maintenance inspection every 6 months or 4000 hours.

With new unit installations, Ariel recommends checking and recording initial top plane flatness before

shimming the guide feet and after initial rough coupling alignment. On compressors shipped

disassembled, perform the initial check before guide and cylinder assembly installation. Shim or

otherwise adjust the height to bring the top cover mounting surface within the specified plane

tolerance. Record subsequent readings after complete guide and cylinder installation, and again

after any vessel installation and shimming. Re-adjust height if guide, cylinder, and/or vessel

installation results in frame top rail measurements out of Table 1 tolerances.

JGB:V:Z:U and KBB:V:Z:U 4 and 6-throw frames require both a top plane flatness and soft foot

checks. For all other frames, the soft foot check is required; the top plane flatness measurement is

optional, except for the JGI, which requires none.

Use the procedure below to properly install and periodically inspect compressor frames.

1. To check soft foot, properly install and torque compressor frame hold down bolting. Loosen each

hold down bolt individually while checking the frame foot to skid deflection with a calibrated dial

indicator. Correct any hold down position that deflects more than 0.002 inches (0.05 mm) when

released. Re-torque the hold down bolt and repeat on each frame-to-skid bolt. See ER-26 for

proper frame foot and crosshead guide bolt size and torques.

2. Remove or reposition the top cover(s) and gasket(s) to expose the frame top cover mounting surface. Verify it is clean.

NOTE: For KBZ:U frames only, the frame top rail has been coated with a light coat of Cortec VPCI 369 corrosion inhibitor or equivalent to protect the aluminum to cast iron joint. If

the top cover is removed, clean both the top rail and the top cover and re-coat the frame

top rail with a light coat of the same compound. If VPCI 369 or equivalent is not available,

use marine grade grease. Apply only a light coat of the corrosion inhibitor; do not allow

excess material to flow into the frame when the top cover is installed.

REV

DESCRIPTION

Primary changes: Document reformatted to new ER

format. Old Figure 1 replaced by new figures 1 and 2.

Writing re-organized and edited for clarity and style.

PAGE 1 OF 2

REV 7

REV

EC

DATE

016003

5-19-09

REV

EC

DATE

4-28-11

015114

6-13-08

014434

10-30-07

015759

014236

3-19-07

016770

6-9-10

010374

11-13-06

015718

6-17-09

ER-82

ENGINEERING REFERENCE

The contents of this document are proprietary and confidential. They are the

property of Ariel Corporation and may not be disclosed, reproduced, or used for

manufacture in part or in whole without written permission from Ariel Corporation.

3. To check top plane flatness, use measurement equipment with a published accuracy

of +0.001 inches (0.025 mm) over the distance required to measure the entire length

of both frame rails. Measure the top surface of both sides of the frame rails at each

anchor bolt (see Figure 1), or between

each pair of anchor bolts for frames with

pairs of anchor bolts (see Figure 2). Readings between any two adjacent points must

be within 0.002 in. (0.05 mm). For proper

alignment, total accumulated out of plane

flatness must be within Table 1 tolerances.

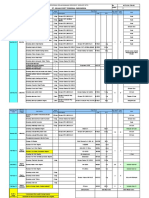

TABLE 1 Top Plane Flatness Tolerances

Compressor Frame

Tolerance

Inches (mm)

JGM:N:P:Q/1/2, JG:A/2/4, JGR:J/2

0.004 (0.10)

JGA/6, JGR/4, JGJ/4/6,

JGH:E:K:T:C:D:Z:U/2/4, JGB:V/4a,

KBZ:U/2/4, KBB:V/4

0.006 (0.15)

JGE:K:T/6, JGC:D/6, JGU:Z/6,

JGB:V/6, KBB:V:Z:U/6

0.008 (0.20)

a. Underlined frames require both soft foot and top plane

flatness checks.

NOTE: If the unit will not be restarted immmediately, re-preserve the unit in a manner

appropriate to the time duration until restart.

Measure Here

FIGURE 1 Flatness Check Locations for Frames with Single Anchor Bolts

Measure Here

FIGURE 2 Flatness Check Locations for Frames with Pairs of Anchor Bolts

PAGE 2 OF 2

REV 7

ER-82

Anda mungkin juga menyukai

- Coupling John CraneDokumen15 halamanCoupling John Cranelubricacion100% (2)

- Alignment Procedure PDokumen8 halamanAlignment Procedure PvinothenergyBelum ada peringkat

- Instruction Manual For Single Stage 350, 500, and 700 Frame Steam TurbinesDokumen295 halamanInstruction Manual For Single Stage 350, 500, and 700 Frame Steam Turbines213ekno100% (1)

- NUOVO PIGNONE Compressor Spares (2010-37)Dokumen4 halamanNUOVO PIGNONE Compressor Spares (2010-37)sianas1706Belum ada peringkat

- Field Service Manual: Title: Tightening Torque For Cap ScrewsDokumen3 halamanField Service Manual: Title: Tightening Torque For Cap ScrewsPuchit Spk100% (1)

- Is Rod Drop Measurement Right For My CompressorDokumen4 halamanIs Rod Drop Measurement Right For My CompressorMadhana GopalBelum ada peringkat

- TG 611 GovernorDokumen4 halamanTG 611 Governorveer_sBelum ada peringkat

- 30 - 200 Amarillo Gear Repair Manual PDFDokumen32 halaman30 - 200 Amarillo Gear Repair Manual PDFCesar Fabián Padilla GarzónBelum ada peringkat

- Unloader Selection For Recip CompressorsDokumen10 halamanUnloader Selection For Recip CompressorsAnonymous KpVxNXsBelum ada peringkat

- Microsoft Word - WET GAS COMPRESSOR OVERHAULING REPORTDokumen8 halamanMicrosoft Word - WET GAS COMPRESSOR OVERHAULING REPORTAbhi SharmaBelum ada peringkat

- Effect of Viscosity On PumpsDokumen4 halamanEffect of Viscosity On PumpsChemkhiBelum ada peringkat

- Shaft Alignment MathDokumen8 halamanShaft Alignment MathJose RattiaBelum ada peringkat

- Pages From API Standard 610 Centrifugal PumpsDokumen1 halamanPages From API Standard 610 Centrifugal PumpsAgustin A.100% (1)

- Elliott CompressorsDokumen7 halamanElliott CompressorsQuarkantBelum ada peringkat

- Recommended Radial Clearance For Cast Bronze BearingDokumen1 halamanRecommended Radial Clearance For Cast Bronze BearingMachineryengBelum ada peringkat

- Presentation: Reliability of Hydrogen Area Diaphragm CompressorDokumen43 halamanPresentation: Reliability of Hydrogen Area Diaphragm CompressorBiju_Pottayil100% (1)

- API 618 Compressors1 PDFDokumen0 halamanAPI 618 Compressors1 PDFAnonymous ffje1rpaBelum ada peringkat

- Axial Float Motor Rotor SettingDokumen2 halamanAxial Float Motor Rotor SettingMuhammed SulfeekBelum ada peringkat

- Flowserve VS6-installation PDFDokumen68 halamanFlowserve VS6-installation PDFAnonymous YWS7ndsiBelum ada peringkat

- Appendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Dokumen17 halamanAppendix 6a - Technical Specifiction Spare Rotor Repair T10 and T20Dino AndrianBelum ada peringkat

- Profile of the International Pump Industry: Market Prospects to 2010Dari EverandProfile of the International Pump Industry: Market Prospects to 2010Penilaian: 1 dari 5 bintang1/5 (1)

- Steam Turbine TheoryDokumen58 halamanSteam Turbine TheorySaleem QureshiBelum ada peringkat

- Troubleshooting VTP Vertical Turbine PumpDokumen20 halamanTroubleshooting VTP Vertical Turbine PumpKrrish100% (1)

- SP-P-001 - Specification For StrainerDokumen30 halamanSP-P-001 - Specification For Strainervishal bhamreBelum ada peringkat

- Fan Calculation MooreDokumen8 halamanFan Calculation MooreArjun GirishBelum ada peringkat

- API 613 Fifth Edition Special Purpose Gear Units For Petroleum, Chemical and Gas Industry Services - Overview PresentationDokumen8 halamanAPI 613 Fifth Edition Special Purpose Gear Units For Petroleum, Chemical and Gas Industry Services - Overview PresentationLymePark100% (1)

- InstallationOperationMaintenance 3600 enDokumen110 halamanInstallationOperationMaintenance 3600 enStaman1988Belum ada peringkat

- HPRT - PresentationDokumen19 halamanHPRT - PresentationMehrzad AlizadehBelum ada peringkat

- Gas Turbine - Compressor AlignmentDokumen2 halamanGas Turbine - Compressor AlignmentNazmiBelum ada peringkat

- Centrifugal Pump - Horizontal End Suction - Asme B73.1Dokumen3 halamanCentrifugal Pump - Horizontal End Suction - Asme B73.1wado11Belum ada peringkat

- Optalign Plus ManualDokumen172 halamanOptalign Plus Manualpower_generator1338100% (2)

- Hot Alignment CalculationDokumen2 halamanHot Alignment CalculationBv RaoBelum ada peringkat

- Dry Screw Compressor General Arangement Drawings - RedactedDokumen1 halamanDry Screw Compressor General Arangement Drawings - Redactedvomawew647Belum ada peringkat

- Type 28 Gas Seals System Presentation PDFDokumen108 halamanType 28 Gas Seals System Presentation PDFlogicloverBelum ada peringkat

- Mechanical Seal Replacement InstructionsDokumen1 halamanMechanical Seal Replacement InstructionsGiorgio FerBelum ada peringkat

- Pump Alignment.Dokumen3 halamanPump Alignment.sen_subhasis_58100% (1)

- KCDokumen3 halamanKCSandheepKumarBelum ada peringkat

- Maintenance of BCHDokumen44 halamanMaintenance of BCHdoanducbaoBelum ada peringkat

- Parker Hydraulic Accumulator Products HY10-1630Dokumen203 halamanParker Hydraulic Accumulator Products HY10-1630Yusuf Sukma IndrianaBelum ada peringkat

- 05rotary Shaft Seals PDFDokumen13 halaman05rotary Shaft Seals PDFKhanh Pham DangBelum ada peringkat

- Centrifugal Pump Axial ThrustDokumen4 halamanCentrifugal Pump Axial Thrustfawmer61100% (1)

- Solar Turbines - Centifugal Gas Compressor BookletDokumen48 halamanSolar Turbines - Centifugal Gas Compressor Bookletsetyo ardi100% (1)

- Goulds API 3600 i-FRAME: API BB3 Between-Bearing, Axially Split, Multistage PumpDokumen12 halamanGoulds API 3600 i-FRAME: API BB3 Between-Bearing, Axially Split, Multistage PumpJean Peak100% (1)

- SIHI Multistage Brochure NA - RGBDokumen7 halamanSIHI Multistage Brochure NA - RGBMaria Gabriela BusteloBelum ada peringkat

- Pump Baseplate Design and InstallationDokumen4 halamanPump Baseplate Design and InstallationSeungmin Paek100% (1)

- ES9-414 Leveling Install - CDokumen29 halamanES9-414 Leveling Install - CIfran Sierra100% (1)

- Introduction To Gate Valves and Gate Valve TypesDokumen16 halamanIntroduction To Gate Valves and Gate Valve TypesVinay Sharma100% (1)

- EBARA TEM Brochure - March 02Dokumen6 halamanEBARA TEM Brochure - March 02xsi666Belum ada peringkat

- Your Gas Compression ApplicationDokumen26 halamanYour Gas Compression Applicationdhanu_aqua100% (1)

- Hydro Life Extension Modernization Guide: Volume 6 - Civil and Other Plant ComponentsDokumen152 halamanHydro Life Extension Modernization Guide: Volume 6 - Civil and Other Plant ComponentsMauricio GonzálezBelum ada peringkat

- Rotor RepairsDokumen26 halamanRotor Repairsramnadh803181100% (1)

- Flanges General - Bolting Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud BoltsDokumen3 halamanFlanges General - Bolting Torque Tables - Table 2 - ASTM 193 Grade B7 and ASTM 193 Grade B16 Stud BoltsHakan ŞahinoğluBelum ada peringkat

- Divider Block - Operation and MaintenanceDokumen51 halamanDivider Block - Operation and MaintenanceMahfuz50% (2)

- Gas Turbine Tripping On Exhaust Pressure High - Need SolutionDokumen7 halamanGas Turbine Tripping On Exhaust Pressure High - Need SolutionAbdulyunus Amir100% (1)

- Gear Drive Manual No. 702Dokumen38 halamanGear Drive Manual No. 702MaintenanceBelum ada peringkat

- Gas Engine - MountingDokumen22 halamanGas Engine - MountingMauro DiazBelum ada peringkat

- Asset Integrity Management A Complete Guide - 2020 EditionDari EverandAsset Integrity Management A Complete Guide - 2020 EditionBelum ada peringkat

- Er 82Dokumen2 halamanEr 82michaelxiaoBelum ada peringkat

- Er 82Dokumen2 halamanEr 82Dibyendu ChakrabortyBelum ada peringkat

- ER-82 EN Soft Foot and Top Plane Flatness Checks PDFDokumen3 halamanER-82 EN Soft Foot and Top Plane Flatness Checks PDFCamilo Andres Cardozo FajardoBelum ada peringkat

- CBM Basics - Condition Based MaintenanceDokumen13 halamanCBM Basics - Condition Based MaintenanceMVSEETARAMANBelum ada peringkat

- Basic Plumbing PDFDokumen8 halamanBasic Plumbing PDFSamuel YudelzonBelum ada peringkat

- OTIS LIFT PM ChecklistDokumen2 halamanOTIS LIFT PM ChecklistMVSEETARAMAN70% (10)

- Introduction To Material HandlingDokumen244 halamanIntroduction To Material HandlingAreda100% (3)

- Brihat Stotra Ratnakar - TOC PDFDokumen34 halamanBrihat Stotra Ratnakar - TOC PDFRakesh Tandon100% (2)

- Spare Parts Manual-Radial Drilling MCDokumen41 halamanSpare Parts Manual-Radial Drilling MCMVSEETARAMAN0% (1)

- O & M Manual-Radial Drilling MachineDokumen45 halamanO & M Manual-Radial Drilling MachineMVSEETARAMAN57% (7)

- Sri Jagadguru Abhinava Vidyathirtha Maha - Arya PDFDokumen8 halamanSri Jagadguru Abhinava Vidyathirtha Maha - Arya PDFMVSEETARAMANBelum ada peringkat

- Tirupugaz 23 Songs by Sudha RaghunathanDokumen1 halamanTirupugaz 23 Songs by Sudha RaghunathanMVSEETARAMANBelum ada peringkat

- Hydraulic Press 50T ManualDokumen36 halamanHydraulic Press 50T ManualMVSEETARAMAN100% (2)

- 2009 Madras Music Season - Manda Sudharani - Carnatic Music - Arunn's NotebookDokumen5 halaman2009 Madras Music Season - Manda Sudharani - Carnatic Music - Arunn's NotebookMVSEETARAMAN100% (1)

- Tharpana ManthramDokumen7 halamanTharpana ManthramMVSEETARAMANBelum ada peringkat

- Pines EcuDokumen7 halamanPines EcuWladimir AmaguañaBelum ada peringkat

- Rotary Blasthole Drill-MD6240Dokumen8 halamanRotary Blasthole Drill-MD6240GARIBelum ada peringkat

- Servicing Multitronic 0AWDokumen100 halamanServicing Multitronic 0AWAlanGaoBelum ada peringkat

- Gt650 Parts CatalogueDokumen114 halamanGt650 Parts CatalogueGustavo MurrayBelum ada peringkat

- Manual Quemador 100 HP HurtsDokumen118 halamanManual Quemador 100 HP Hurtssthefany whiteBelum ada peringkat

- Design of Electromagnetic Engine, No Fuel ConsumptionDokumen11 halamanDesign of Electromagnetic Engine, No Fuel ConsumptionKaran SaharBelum ada peringkat

- Ceccato Compressor Industrial Air Multibrand BusinessDokumen29 halamanCeccato Compressor Industrial Air Multibrand BusinessFati ZoraBelum ada peringkat

- Hyundai Catalogue - 2-87Dokumen86 halamanHyundai Catalogue - 2-87Ahmed RagabBelum ada peringkat

- BW-LL125 Winch Ops Manual 2005 PDFDokumen10 halamanBW-LL125 Winch Ops Manual 2005 PDFconcha42Belum ada peringkat

- Service Bulletin: Fuel Injection PumpDokumen6 halamanService Bulletin: Fuel Injection PumpAnonymous wpUyixsj100% (2)

- Vlvna SB 284 069 01Dokumen6 halamanVlvna SB 284 069 01Jonah RagleBelum ada peringkat

- Golf SupliersDokumen1 halamanGolf SupliersFrederico Rad FernandezBelum ada peringkat

- Roof HoodsDokumen3 halamanRoof Hoodsapara_jitBelum ada peringkat

- Global Davit GMBH Catalogue 2016Dokumen40 halamanGlobal Davit GMBH Catalogue 2016Anonymous wBv8isOBelum ada peringkat

- Listado Baterias PDFDokumen9 halamanListado Baterias PDFMiguel PazBelum ada peringkat

- Catalogo de Partes ORBIT-125Dokumen63 halamanCatalogo de Partes ORBIT-125lainer chauxBelum ada peringkat

- ATA 36 PneumaticsDokumen58 halamanATA 36 PneumaticsBao HuynhBelum ada peringkat

- GM Passlock II SystemDokumen14 halamanGM Passlock II Systemalmia tronicsBelum ada peringkat

- Baldor Motor MaintenanceDokumen4 halamanBaldor Motor Maintenanceessjrs1Belum ada peringkat

- Process Pump Technical OfferDokumen53 halamanProcess Pump Technical OfferHisham ElsayedBelum ada peringkat

- Pedoman Service RTG + Truck - TraillerDokumen5 halamanPedoman Service RTG + Truck - TraillerLeman Yudhi Bin RosyidBelum ada peringkat

- 国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Dokumen30 halaman国际39M混凝土泵车卖点介绍Specification & Advantages of SYG39Alex MazaBelum ada peringkat

- Pareto CAT777E Januari-Maret 2019Dokumen518 halamanPareto CAT777E Januari-Maret 2019SARTONO INDO FRANSBelum ada peringkat

- Consumer Lighting: List PriceDokumen50 halamanConsumer Lighting: List PriceYOUTH FUTUREBelum ada peringkat

- MM DFR 912 Rev0 2017redDokumen199 halamanMM DFR 912 Rev0 2017rednicolas arevaloBelum ada peringkat

- Transmissao CVT - Jf010e - Jf011eDokumen56 halamanTransmissao CVT - Jf010e - Jf011eautomaticosbrasil100% (1)

- Honda Civic 2002Dokumen102 halamanHonda Civic 2002Mac PirxBelum ada peringkat

- Hyundai Santa Fe 2001Dokumen54 halamanHyundai Santa Fe 2001Mac Pirx100% (1)

- 2021 Honda SH Mode 125 8 PDFDokumen148 halaman2021 Honda SH Mode 125 8 PDFbezawada sailakshmiBelum ada peringkat

- P5000 (At3502064) 98725-45100 Cat Engine (1) (K21 and K25) (Upto March 2018) Engine Mechanical 102-01 Engine Gasket KitDokumen243 halamanP5000 (At3502064) 98725-45100 Cat Engine (1) (K21 and K25) (Upto March 2018) Engine Mechanical 102-01 Engine Gasket Kit2119100146Belum ada peringkat