Method of Statement For Pressure Test PDF

Diunggah oleh

Ben LimDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Method of Statement For Pressure Test PDF

Diunggah oleh

Ben LimHak Cipta:

Format Tersedia

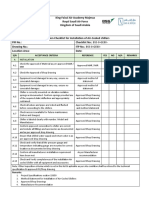

Method of Statement for Pressure Testing Procedures

Purpose

This procedure outlines the necessary actions and safety practises for pressure testing all

new sprinkler piping Wafer Test 2B- Level 2

Responsibility

Plumbing Work Foreman, Pipe Fitters, Construction Co-ordinator, Project Engineer, Site

Supervisor, Project Manager & Safety Officer

Discussion

In order to ensure the integrity of the new pipeline in and around the area, the contractor

will perform a pressure testing. The pressure testing procedures adopted the

recommended standards and practises. The procedures also outline proper safety practises

that must be followed in order to minimize risks.

Requirements

Tools and Equipment

All personnel within test area shall be required to wear eye and hearing Personnel

Protection Equipment (PPE). Hard Hat, safety shoe and dust mask.

Quick Couplings, Hydraulic Pressure Portable Pump set, Pressure Gauge and Non-return

Check Valve.

Ensuring Safety of Work Site

Hydraulic testing can be dangerous and should be performed with caution and careful

attention to all safety procedures. To ensure the safety of all workers, the following safety

precaution must be completed prior to conducting the pressure testing:

1. Notify system owner or personnel of the area to be avoided due to risks during

pressure testing.

2. Ensure that no high pressure testing occur in the work place.

3. Ensure personnel conducting the test stand behind a barrier during pressurization.

4. Mark-off and barricade the work area.

Results: After following the above procedures, the necessary steps to ensure safety will be

complete.

Conducting the Pressure Test

To conduct a pressure test of new pipelines at Clean Room Level 3-Support A, complete the

following steps:

HYDRAULIC TEST

1. Identify the maximum test pressure to be used (200 PSI), which is enough for the

system as the maximum pressure of the system range around 175 PSI.

2. Identify the steel pipe to be tested.

3. When possible, identify the maximum area tested.

4. Examine all connections prior to the test to ensure proper tightness.

5. Determine the pressure rating for all connected fittings and devices to ensure they

are rated for the maximum test pressure.

6. Place a Blind Flange / Plug or other suitable cover on all openings at pipelines that

are not closed off by valves.

7. Plug all test, drain and vent ports that are not required for the test.

8. If the section of pipe being tested is isolated from other sections by in-line valves,

ensure the portion not being tested is open to the atmosphere.

9. Apply a preliminary test pressure of 25 psi by using a portable Hydraulic Pressure

Portable Pump set, or as directed by the Project Engineer.

NOTE: this pressure should be held for a minimum of 10 minutes to allow for the

location of any major leaks. If leaks are detected during this step, or at any time

during the test, relieve the pressure and consult the Project Engineer for instruction.

10. Apply the test pressure in increments of 25 psi until the maximum test pressure is

reached (200 PSI). While filling pressure at the pipeline, release the air lock at the

end drain valve. Slowly flushed the pipe and released the air bubble until the water

has a clear flow. Closed the Drain Valve and built up the pressure until 200 PSI. Hold

pressure for 5 minutes at each 25 psi increment before adding more pressure.

11. Hold the maximum test pressure for 4 Hours.

12. Obtain confirmation of a successful test by the System Owner/ Caverion Personnel

after 4 hours time period.

13. Remove the pressure, with caution to avoid escaping air stream, debris and high

decibel noise level.

14. Complete the appropriate following forms Pressure/Leak Testing Sheet and

recorded the test data and place them in the appropriate engineering files as

specified by the Project Engineer.

Results After completing these steps, pressure testing is completed. Once the test is

successfully completed, then the new pipeline is ready for connection.

Anda mungkin juga menyukai

- Pressure Testing ProcedureDokumen4 halamanPressure Testing Proceduredavideristix100% (1)

- Method Statement - HVAC Duct Leakage Testing ProcedureDokumen7 halamanMethod Statement - HVAC Duct Leakage Testing ProcedureSyed TouqeerBelum ada peringkat

- Method of Statement For Pressure Testing ProceduresDokumen3 halamanMethod of Statement For Pressure Testing ProceduresBen Lim82% (11)

- Method Statement For Refrigerant Piping Installation and Pressure TestingDokumen4 halamanMethod Statement For Refrigerant Piping Installation and Pressure TestingRyan WongBelum ada peringkat

- Method Statement For Underground PVC Pipe InstallationDokumen44 halamanMethod Statement For Underground PVC Pipe InstallationSaad Amer100% (1)

- Method Statement For Leakage Testing of Gravity Sewer LineDokumen3 halamanMethod Statement For Leakage Testing of Gravity Sewer LinePrem Kumar100% (2)

- Method Fan Coil UnitDokumen4 halamanMethod Fan Coil UnitMohd HaroonBelum ada peringkat

- CPVC Method StatementDokumen2 halamanCPVC Method StatementPrashanth A67% (3)

- Ms-Black Steel PipeDokumen4 halamanMs-Black Steel PipeYusufBelum ada peringkat

- Fire Hose Rack & Reel Testing ProcedureDokumen2 halamanFire Hose Rack & Reel Testing ProcedureDong VanraBelum ada peringkat

- Air Terminal Device Installation MethodDokumen13 halamanAir Terminal Device Installation MethodAnish Kumar100% (1)

- Method Statement For HVAC Ductwork Insulation and Acoustic LiningDokumen4 halamanMethod Statement For HVAC Ductwork Insulation and Acoustic Liningrakeshamech100% (1)

- MS For Tank Installation - R1Dokumen6 halamanMS For Tank Installation - R1alvinchuan100% (1)

- MEP Snagging ChecklistDokumen15 halamanMEP Snagging ChecklistAnil Radheshwar100% (2)

- Method for Removing Fire Fighting Pipes from Existing NetworkDokumen1 halamanMethod for Removing Fire Fighting Pipes from Existing NetworkAamer Abdul MajeedBelum ada peringkat

- Method Statement For Gi Puddle Flanges InstallationDokumen1 halamanMethod Statement For Gi Puddle Flanges InstallationSanto E0% (1)

- Underground Pipe Installation Method StatementDokumen9 halamanUnderground Pipe Installation Method StatementAmirudin Rosli100% (2)

- Method Statement Installation of PPR Water SupplyFINALDokumen5 halamanMethod Statement Installation of PPR Water SupplyFINALmengineering75% (4)

- METHOD of STATEMENT Pressure Testing of PipeworkDokumen9 halamanMETHOD of STATEMENT Pressure Testing of Pipeworkyusuf ergulBelum ada peringkat

- Installation Of Ductile Iron Flange Type Joint MethodDokumen10 halamanInstallation Of Ductile Iron Flange Type Joint MethodshahidBelum ada peringkat

- Method Statement Installation of UPVC Drainage FINALDokumen4 halamanMethod Statement Installation of UPVC Drainage FINALanon_31671419450% (6)

- DSM-xxx-0xxx-xx, Checklist For HDPE Piping InstallationDokumen1 halamanDSM-xxx-0xxx-xx, Checklist For HDPE Piping Installationkadir tanzaniaBelum ada peringkat

- Method Statement HDPE PDFDokumen1 halamanMethod Statement HDPE PDFshameemBelum ada peringkat

- Inspection Report-Hdpec BlankDokumen2 halamanInspection Report-Hdpec BlankJoseph Perez100% (1)

- Vindair Sop For Duct Smoke TestDokumen2 halamanVindair Sop For Duct Smoke TestRamakrishna Ar A R88% (8)

- HDPE Electrofusion JointDokumen2 halamanHDPE Electrofusion JointBala Krishna GallaBelum ada peringkat

- Testing & Commissioning Method Statement For Fire Fighting PumpsDokumen2 halamanTesting & Commissioning Method Statement For Fire Fighting PumpsHumaid ShaikhBelum ada peringkat

- MOS For Underground Pipe Water InstallationDokumen2 halamanMOS For Underground Pipe Water InstallationMukhlish AkhatarBelum ada peringkat

- Method Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Dokumen9 halamanMethod Statement For CPFII Pipe Cleaning&Flushing With Air Works Rev1Delil OzanBelum ada peringkat

- Testing Procedure SprinklerDokumen2 halamanTesting Procedure SprinklerBea RullanBelum ada peringkat

- Method Statement For Hydrant As Per PVN CommentsDokumen23 halamanMethod Statement For Hydrant As Per PVN CommentsAbcd efgh100% (1)

- Installation of Plumbing and Sanitary System at Bunut SubstationDokumen4 halamanInstallation of Plumbing and Sanitary System at Bunut SubstationKAKABelum ada peringkat

- Method Statement For Installation of FansDokumen5 halamanMethod Statement For Installation of FansBinod Davis50% (2)

- Checklist For T&C of Chemical Fire Suppression SystemDokumen2 halamanChecklist For T&C of Chemical Fire Suppression Systembeho2000Belum ada peringkat

- Yanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationDokumen5 halamanYanbu Industrial City, KSA: Itp For Hvac (Heating Ventilation and Air Conditioning) System InstallationHARSHAL100% (2)

- Recommended Cold Cutting Procedure PDFDokumen3 halamanRecommended Cold Cutting Procedure PDFtahatekri83% (6)

- Method Statement Ductile Iron Flange Type Joint Pipe LTESTDokumen8 halamanMethod Statement Ductile Iron Flange Type Joint Pipe LTESTmuhammad syauqi shaidanBelum ada peringkat

- Method of Statement For Installation of Domestic Hot & Cold Water Supply Cop PDFDokumen4 halamanMethod of Statement For Installation of Domestic Hot & Cold Water Supply Cop PDFCool SharyBelum ada peringkat

- 0734 Refrigerant Installation ChecklistDokumen1 halaman0734 Refrigerant Installation ChecklistMubashir KhanBelum ada peringkat

- Method of Statement For Testing of Hot Water & Cold Water Supply and Return PipingDokumen10 halamanMethod of Statement For Testing of Hot Water & Cold Water Supply and Return PipingZin Ko NaingBelum ada peringkat

- PIPELINE HYDROSTATIC TEST REPORTDokumen6 halamanPIPELINE HYDROSTATIC TEST REPORTHalil GüneyBelum ada peringkat

- Method Statement For PCW Piping (Tool Install)Dokumen4 halamanMethod Statement For PCW Piping (Tool Install)amg007Belum ada peringkat

- 001 MEP - Method Floor&Wall PenetrationDokumen7 halaman001 MEP - Method Floor&Wall PenetrationHa Bao An100% (1)

- 04 Inspection Checklist - Installation of Air-Cooled ChillersDokumen2 halaman04 Inspection Checklist - Installation of Air-Cooled ChillersBabar Shehzad100% (3)

- Method of Statement For Installation of Compressed AirDokumen9 halamanMethod of Statement For Installation of Compressed AirrkssBelum ada peringkat

- Method Work Statement Pipe Welding WorksDokumen17 halamanMethod Work Statement Pipe Welding WorksSanjana AhujaBelum ada peringkat

- Kruger Fan InstalltionDokumen10 halamanKruger Fan Installtionjames_chan2178100% (1)

- Method Statement For Drainage & Vent PipingDokumen6 halamanMethod Statement For Drainage & Vent Pipingsujan19800% (1)

- Pneumatic Testing Procedure For PipelinesDokumen3 halamanPneumatic Testing Procedure For PipelinesKu Masayu Ku HusinBelum ada peringkat

- Hydrostatic Pressure Test Safety ChecklistDokumen3 halamanHydrostatic Pressure Test Safety ChecklistJerry Faria60% (5)

- Leak Test Procedure For SubDokumen5 halamanLeak Test Procedure For Subpallav chatterjeeBelum ada peringkat

- Hydrotest, Dewatering, DryingDokumen9 halamanHydrotest, Dewatering, DryingMikiRoniWijayaBelum ada peringkat

- Method of Statement Testing of PipeDokumen5 halamanMethod of Statement Testing of PipevpamatyaBelum ada peringkat

- Piping Hydrotest ProcedureDokumen9 halamanPiping Hydrotest Procedurewendypost73100% (1)

- Pressure Testing Fire Water LineDokumen9 halamanPressure Testing Fire Water Linesharif339Belum ada peringkat

- Method Statement For Hydrostatic Pressure Testing of Chilled Water PipeworkDokumen3 halamanMethod Statement For Hydrostatic Pressure Testing of Chilled Water Pipeworkamg007100% (3)

- Pneumatic Test - Write UpDokumen7 halamanPneumatic Test - Write UpDilip0% (1)

- Annex1 - Technical Specifications PDFDokumen64 halamanAnnex1 - Technical Specifications PDFabdelkader benabdallahBelum ada peringkat

- Pressure Equipment Hydro-Testing GuideDokumen10 halamanPressure Equipment Hydro-Testing GuideJamalAhmedBelum ada peringkat

- Inside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryDari EverandInside the Pill Bottle: A Comprehensive Guide to the Pharmaceutical IndustryBelum ada peringkat

- Fricton Loss in Valves & FittingsDokumen3 halamanFricton Loss in Valves & FittingsBen LimBelum ada peringkat

- Effective Fire Protection For Transformers PDFDokumen43 halamanEffective Fire Protection For Transformers PDFANDRESBelum ada peringkat

- Addressable Fireman Intercom System Write UpDokumen3 halamanAddressable Fireman Intercom System Write UpBen LimBelum ada peringkat

- The Benefits On Analogue Addressable Fire Alarm System Over Any Conventional Fire Alarm SystemsDokumen4 halamanThe Benefits On Analogue Addressable Fire Alarm System Over Any Conventional Fire Alarm SystemsBen LimBelum ada peringkat

- Portable Fire Extinguisher GuidelinesDokumen8 halamanPortable Fire Extinguisher GuidelinesidiayBelum ada peringkat

- Portable Fire Extinguisher GuidelinesDokumen8 halamanPortable Fire Extinguisher GuidelinesidiayBelum ada peringkat

- Carbon Dioxide Fire Suppression SystemDokumen9 halamanCarbon Dioxide Fire Suppression SystemBen Lim100% (1)

- Fire Emergency Lights Requirement in Malaysia Write-UpDokumen13 halamanFire Emergency Lights Requirement in Malaysia Write-UpBen LimBelum ada peringkat

- Fire Emergency Lights Requirement in Malaysia Write-UpDokumen13 halamanFire Emergency Lights Requirement in Malaysia Write-UpBen LimBelum ada peringkat

- Budget Cost For Fire Protection SystemDokumen1 halamanBudget Cost For Fire Protection SystemBen LimBelum ada peringkat

- Join Hydrant Pipes Safely with Collar JointsDokumen5 halamanJoin Hydrant Pipes Safely with Collar JointsBen LimBelum ada peringkat

- Servicing Portable Fire ExtinguishersDokumen1 halamanServicing Portable Fire ExtinguishersBen LimBelum ada peringkat

- Wet Riser Pump-Sets CalculationDokumen3 halamanWet Riser Pump-Sets CalculationBen LimBelum ada peringkat

- 1.1.0 General Description of VESDA Aspirating Smoke Detection SystemDokumen9 halaman1.1.0 General Description of VESDA Aspirating Smoke Detection SystemBen Lim100% (1)

- Fire Smoke DampersDokumen2 halamanFire Smoke Dampersfabieduarte440Belum ada peringkat

- Portable Fire Extinguisher GuidelinesDokumen8 halamanPortable Fire Extinguisher GuidelinesidiayBelum ada peringkat

- VesdaDokumen6 halamanVesdaBen LimBelum ada peringkat

- Downcomer System for Low-Rise BuildingsDokumen1 halamanDowncomer System for Low-Rise BuildingsBen Lim100% (1)

- Method of Statement For Addressable Fire Alarm SystemDokumen3 halamanMethod of Statement For Addressable Fire Alarm SystemBen Lim80% (5)

- Pyrogen - Design, Operation & Maintenance ManualDokumen82 halamanPyrogen - Design, Operation & Maintenance ManualBen Lim100% (1)

- 1.1.0 General Description of VESDA Aspirating Smoke Detection SystemDokumen9 halaman1.1.0 General Description of VESDA Aspirating Smoke Detection SystemBen Lim100% (1)

- Dry Risers Write-UpDokumen6 halamanDry Risers Write-UpBen LimBelum ada peringkat

- Fire Protection System Testing & Commissioning ProcedureDokumen268 halamanFire Protection System Testing & Commissioning ProcedureBen LimBelum ada peringkat

- PIPE TAPPING SAFETYDokumen2 halamanPIPE TAPPING SAFETYBen Lim100% (1)

- Work Method Statement For Coring Works (A)Dokumen3 halamanWork Method Statement For Coring Works (A)Ben Lim50% (6)

- RecycleDokumen1 halamanRecycleBen LimBelum ada peringkat

- Finesse Service ManualDokumen34 halamanFinesse Service ManualLuis Sivira100% (1)

- Journal of Petroleum Science and Engineering: Bin Yuan, David A. WoodDokumen13 halamanJournal of Petroleum Science and Engineering: Bin Yuan, David A. Woodarash7495Belum ada peringkat

- 2019-03-30 New Scientist PDFDokumen60 halaman2019-03-30 New Scientist PDFthoma leongBelum ada peringkat

- Habawel V Court of Tax AppealsDokumen1 halamanHabawel V Court of Tax AppealsPerry RubioBelum ada peringkat

- Rochester MN Unified Development Code (Draft)Dokumen442 halamanRochester MN Unified Development Code (Draft)randyBelum ada peringkat

- Fifeville Plan: Building A Connected CommunityDokumen92 halamanFifeville Plan: Building A Connected CommunityAl DiBelum ada peringkat

- S650 Service - 6987168 enUS SMDokumen1.311 halamanS650 Service - 6987168 enUS SMcarlos andres salazar sanchez75% (4)

- KCC Strategic Plan 2020-2023Dokumen103 halamanKCC Strategic Plan 2020-2023Kellogg Community CollegeBelum ada peringkat

- Best Practices For SAP-PM History DocumentationDokumen8 halamanBest Practices For SAP-PM History DocumentationLaammeem Noon100% (1)

- 1Z0-062 Exam Dumps With PDF and VCE Download (1-30)Dokumen6 halaman1Z0-062 Exam Dumps With PDF and VCE Download (1-30)Humberto Cordova GallegosBelum ada peringkat

- Table of Forces For TrussDokumen7 halamanTable of Forces For TrussSohail KakarBelum ada peringkat

- Black Box Components and FunctionsDokumen9 halamanBlack Box Components and FunctionsSaifBelum ada peringkat

- Fayol's Principles in McDonald's ManagementDokumen21 halamanFayol's Principles in McDonald's Managementpoo lolBelum ada peringkat

- Gustilo Vs Gustilo IIIDokumen1 halamanGustilo Vs Gustilo IIIMoon BeamsBelum ada peringkat

- Math30.CA U1l1 PolynomialFunctionsDokumen20 halamanMath30.CA U1l1 PolynomialFunctionsUnozxcv Doszxc100% (1)

- Feedback Mechanism InstrumentDokumen2 halamanFeedback Mechanism InstrumentKing RickBelum ada peringkat

- Ab Initio Interview Questions - HTML PDFDokumen131 halamanAb Initio Interview Questions - HTML PDFdigvijay singhBelum ada peringkat

- Superelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDokumen7 halamanSuperelement Modeling-Based Dynamic Analysis of Vehicle Body StructuresDavid C HouserBelum ada peringkat

- FFTW Installation On WindowsDokumen6 halamanFFTW Installation On WindowsDebora SchwarzBelum ada peringkat

- Audit Report of CompaniesDokumen7 halamanAudit Report of CompaniesPontuChowdhuryBelum ada peringkat

- Business Plan - Docx 3-Star Hospitality and Tourism Devt Centre in Mbarara - UgandaDokumen49 halamanBusiness Plan - Docx 3-Star Hospitality and Tourism Devt Centre in Mbarara - UgandaInfiniteKnowledge100% (9)

- FINC 301 MQsDokumen40 halamanFINC 301 MQsMichael KutiBelum ada peringkat

- Agro Chems MrRGAgarwalDokumen17 halamanAgro Chems MrRGAgarwalapi-3833893Belum ada peringkat

- $$TR Sas 114 AllDokumen384 halaman$$TR Sas 114 Allctudose4282Belum ada peringkat

- 02 - AbapDokumen139 halaman02 - Abapdina cordovaBelum ada peringkat

- University of Cebu-Main Campus Entrepreneurship 100 Chapter 11 QuizDokumen3 halamanUniversity of Cebu-Main Campus Entrepreneurship 100 Chapter 11 QuizAnmer Layaog BatiancilaBelum ada peringkat

- Desarmado y Armado de Transmision 950BDokumen26 halamanDesarmado y Armado de Transmision 950Bedilberto chableBelum ada peringkat

- 2.1 Elements of Computational ThinkingDokumen25 halaman2.1 Elements of Computational ThinkingHamdi QasimBelum ada peringkat

- Make $50 A Day Autopilot MethodDokumen4 halamanMake $50 A Day Autopilot MethodJadon BoytonBelum ada peringkat

- Payment Solutions For Travel Platform: SabreDokumen2 halamanPayment Solutions For Travel Platform: Sabrehell nahBelum ada peringkat