P 3 3 e 12 150dpi19 5774

Diunggah oleh

dianistefyJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

P 3 3 e 12 150dpi19 5774

Diunggah oleh

dianistefyHak Cipta:

Format Tersedia

Cryogenic

Standard Tanks

LITS 2

Contents.

3 Introduction

4 Standard vacuum-insulated tanks

5 Quality standards for cryogenic tanks

6 Technical data - tanks for air gases LIN, LOX, LAR

7 Technical data - tanks for carbon dioxide

8 Features

Highly effective operation

Safety

Easy operation

Ergonomical position of controls and instruments

Non-corroding transport and lifting devices

10 Flow diagram - tanks for nitrogen, oxygen, argon

11 Flow diagram - tanks for carbon dioxide

12 Clip-on standard design

Title-page: The Linde standard tanks

Optional standards for enhanced quality

Special VAP - Quality for specific use

14 SHEQ - safety, health, environment and quality police

15 Service and guarantee

16 Contact

Introduction.

To an increasing extent, industrial gases such as

oxygen, nitrogen and argon are delivered to customers in liquid form at cryogenic temperatures and

stored by the customer in tanks before further use.

The pressure ratings and sizes of these tanks have

been standardised in accordance with the requirements of distribution logistics and economical series

production.

Standard vacuum insulated tanks.

The vacuum-insulated double wall tanks consist

of two concentric vessels, an austenitic steel

inner tank and an outer jacket in carbon steel

with an anti-corrosion primer and a special environmentally friendly top coat. The interspace

between inner and outer tank is evacuated and

filled with insulating powder (perlite). An adsorbent is also added to maintain the vacuum

in the insulation interspace.

The standard tanks come in gross nominal water

capacities from 3,160 litre to 61,620 litre. The

maximum allowable working pressure for the

inner vessels is 18, 22 or 36 bar gauge for design

temperatures ranking from -196C up to 20C.

All standard tanks have vertical configuration,

requiring little space for installation.

The pressure vessels are manufactured and tested in accordance with the Pressure Equipment Directive EU 97/23/EC and EN 13458. These codes

are internationally accepted. Consequently, it will

be much easier than before to install and use

these tanks in and outside of the European Union.

The Linde quality management system satisfies

all elements of the ISO 9001 program. All produced tanks are subjected to inspection and

quality control under supervision of independent inspection bodies.

The operating pressure may be set up to 90 % of

the maximum allowable working pressure and is

automatically maintained constant by the regulator and pressure building coil fitted to the tank.

Each tank can also be equipped with a tank

mounted (clip-on) air-heated vaporiser to

supply product in gaseous form at ambient

temperatures and flow rates up to 120 Nm3/h.

Standard tank features are various fittings for

transportation and installation. Vaporisers up

to 1,000 Nm3/h are installed separately.

Based on the standard design, Linde offers additional features depending on clients requirements.

Standard carbon dioxide tanks are very similar

to the tanks for air gases. As a function of the

application and customers request you have

here the choice between an inner vessel either

manufactured from a low temperature resistant

austenitic steel or a fine grain carbon steel. The

insulation system is equal to the system which

is used for the air gas tanks.

CO2-tanks, equipped with an inner vessel made

out of a low temperature resistant austenitic

steel can therefore also be used as multi-purpose storage for other industrial gases.

Linde owns long standing experience in handling other liquefied gases such as for example

LNG and hydrogen. Tanks for these gases are

engineered and manufactured according to customers specifications, therefore quotations will

be elaborated from case to case.

Arrangements of valves, pipes and instrumentation

Quality standards for cryogenic tanks.

Quality management and inspection is based

on the following guiding principles:

Quality management and inspection is an indispensable part of our corporate strategy and

therefore a managerial responsibility carried

out at all levels of the company. We consider the

improvement of our product quality and the continued development of our quality management

system as a permanent challenge.

The Schalchen Plant is certified according to:

EN ISO 9001/2000

ASME (U, U2, R-Stamp)

Manufacture license of special equipment

Peoples Republic of China and others

Acceptance inspection is carried out by the

experts of the Notified Body acc. to the valid

(international) laws and further by Lindes

own specialists.

Optional standards for enhanced quality

Depending on customer requirements the tanks are

available in two enhanced quality degrees:

Quality degree

Technical detail

HQ

Degree for media

with purity >5.0

Applications

Inner vessel stainless steel

High demands in semiconductor

Inner vessel and pipes pickled

industry and research

Stainless steel cryogenic valves

below sealed

IQ

Degree for corrosive

Inner vessel stainless steel

industrial environment

Stainless steel cryogenic valves

with stuffing box

Corrosive environment

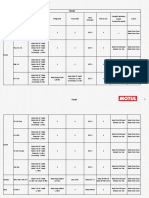

Technical data - tanks for air gases LIN, LOX, LAR.

Size

30

Max. allowable working pressure

air gases: 18 bar, 36 bar

Gross capacity

Net capacity

approx. litre

approx. litre

Pressure stage

18 bar,

filling ratio 95 %, 1 bar

36 bar,

filling ratio 90 %, 1 bar

Boil-off rate

1 bar, 15C A.T.

referred to total capacity

vacuum < 2 x 10-2 mbar

60

110

200

300

490

610

800

for LIN only

3,160

3,000

2,840

6,365

6,050

5,730

11,535

10,960

10,380

20,355

19,340

18,320

30,205

28,700

27,180

49,020

46,570

44,120

61,620

58,540

55,460

80,360

76,340

kg LIN

kg LOX

kg LAR

kg LIN

kg LOX

kg LAR

2,425

3,425

4,185

2,300

3,250

3,970

4,890

6,910

8,440

4,630

6,540

7,990

8,855

12,530

15,290

8,390

11,850

14,480

15,630

22,090

26,980

14,800

20,920

25,560

23,190

32,885

40,040

21,970

31,050

37,920

37,630

53,180

64,965

35,650

50,390

61,550

47,300

66,850

81,660

44,810

63,340

77,370

61,680

%/d LIN

%/d LOX

%/d LAR

0.67

0.42

0.46

0.58

0.37

0.40

0.44

0.29

0.32

0.31

0.20

0.21

0.30

0.19

0.21

0.21

0.13

0.15

0.20

0.12

0.14

300

380

380

140

180

180

300

380

380

140

180

180

600

750

750

280

360

360

18 bar

36 bar

Discharge capacity with standard pressure building

coil at 0,7 x MAWP and 8 hours operating time

pressure stage

18 bar

m3/h (1 bar, 15C) LIN

m3/h (1 bar, 15C) LOX

m3/h (1 bar, 15C) LAR

36 bar

m3/h (1 bar, 15C) LIN

m3/h (1 bar, 15C) LOX

m3/h (1 bar, 15C) LAR

150

190

190

140

180

180

Capacity of one safety valve at 1.1 x MAWP/cold condition

pressure stage

18 bar

kg/h LIN

kg/h LOX

kg/h LAR

36 bar

kg/h LIN

kg/h LOX

kg/h LAR

600

750

750

280

360

360

1,090

1,010

1,240

5,610

2,260

2,850

0.19

600

1,070

Insulation

insulating powder (perlite), vacuum < 5 x 10-2 mbar (tank in operation), status of delivery: 5 mbar

Main material

inner vessel: low temperature resistant austenitic steel

outer vessel: carbon steel

Main dimensions

overall diameter

overall hight

1,600

4,150

1,600

7,150

2,000

7,350

2,400

8,350

2,400

11,550

3,000

11,550

3,000 3,000

14,150

18,050

Weight empty, kg

18 bar

36 bar

2,510

2,600

4,910

5,220

5,940

7,180

9,840

12,310

13,920

17,090

19,300

24,570

23,370

30,260

type

type

LIN = liquid nitrogen; LOX = liquid oxygen; LAR = liquid argon

29,650

Technical data - tanks for carbon dioxide.

Size

30

60

110

200

300

490

610

Max. allowable

working pressure

CO2 : 22 bar

Gross capacity

Net capacity

approx. litre

approx. litre

3,160

2,940

6,365

5,920

11,535

10,730

20,355

18,930

30,205

28,090

49,020

45,590

61,620

57,310

Filling ratio 93 %, 1 bar

kg CO2

3,120

6,280

11,370

20,065

29,780

48,330

60,740

0.22

0.19

0.14

0.10

0.10

0.07

0.06

140

140

280

Boil-off rate

1 bar, 15C A.T.

referred to total capacity

vacuum < 2 x 10-2 mbar

%/d CO2

Discharge capacity with standard

pressure building coil at 0.7 x MAWP

and 8 hours operating time

pressure stage

22 bar

kg/h (1 bar, 15C) CO2

70

280

Capacity of one safety valve

at 1.1 x MAWP/cold condition

pressure stage

22 bar

kg/h, CO2

975

Insulation

insulating powder (perlite),

vacuum < 5 x 10-2 mbar (tank in operation)

status of delivery: 5 mbar

Main material

inner vessel: low temp. resistant austenitic steel

outer vessel: carbon steel

Main dimensions

overall diameter

overall hight

1,600

4,150

1,600

7,150

2,000

7,350

2,400

8,350

2,400

11,550

3,000

11,550

3,000

14,150

Weight empty, kg

22 bar

2,510

4,910

6,300

10,250

14,500

20,500

24,800

Type

Features.

Highly effective operation

Two service valves provide an exchange possibility for the filling valves even if the tank is

filled.

Integrated pressure building coil for standard

discharge capacities (service valves see flow

diagrams: valve 2 pressure building and valve

13 gas shut-off). The tank also has an optimized

design to reduce ice formation.

Safety

In case that the safety valves will release product,

the medium will be blown off to a safe place.

Easy operation

All valves required for operation are set in one line

Ergonomical position of controls

and instruments

The tank controls and instruments are set

in two lines.

Operation line:

Operation controls and instruments

Service line:

Service controls and instruments

Weather protection for instruments

The operation controls and instruments can be

operated by the user. A white handwheel is

fixed on top of this instruments and will be used

for filling or extraction.

The service controls and instruments will be

used by trained employees of the gas supplier

only. These valves are marked with a green

handwheel.

Non-corroding transport and lifting devices

Stainless steel transport legs

Additional vent valve (for T.. V110 - T.. V610)

Lifting lugs with stainless steel inlay

10

Flow diagram - tanks for nitrogen, oxygen, argon.

Instrumentation and equipment, standard

Valves, standard

C/1

C/4, C/6

C/PI

D

I

IN

LI

L/11-1

L/11-2

L/11-3

NRV

O

PC

PI

RV/O

SV1, SV2

Fill coupling

Connection add. transmitter

Test connection pressure indicator

Pressure building coil

Inner vessel

Insulation

Level indicator

Pipeline discharge

Pipeline discharge (plugged)

Pipeline discharge (plugged)

Non return valve

Outer vessel

Pressure controller

Pressure indicator

Relief valve-outer vessel

Safety valve

1

2

3

4

5

6

9-1

11

12

13

18

21

(1)

(2)

only T ... V110 - T ... V800

only T18 V200 - T18 V800

Filling

Pressure building valve

Vent valve

Bottom gauge (+)

Gauge bypass

Top gauge (-)

Evacuation connection

Discharge

Top filling

Gas shut-off

Change over

Trycock

Options

SAA

LI(T)

LI(T)

Safety shut-off valve,

control line for SAA

Level indicator Samson Media 6

incl. instrument panel and standard

programming,

extra programming of Samson Media 6

acc. to customer requirements

Level indicator WIKA with transmitter

output 4 - 20 mA

11

Flow diagramm - tanks for carbon dioxide.

Instrumentation and equipment, standard

Valves, standard

C/3

C/4, C/6

C/PI

D

I

IN

LI(T)

L/11-1

L/11-2

NRV

O

PC

PI

RV/O

SV1, SV2

1

2

3

4

5

6

9-1

11

12

13

18

21

26

Vent coupling

Connection add. transmitter

Test connection pressure indicator

Pressure building coil

Inner vessel

Insulation

Level indicator

Pipeline discharge

Pipeline discharge (plugged)

Non return valve

Outer vessel

Pressure controller

Pressure indicator

Relief valve-outer vessel

Safety valve

Filling

Pressure building valve

Vent

Bottom gauge (+)

Gauge bypass

Top gauge (-)

Evacuation connection

Discharge

Top filling

Gas shut-off

Change over

Trycock

Pressuring

Options

SAA

LI(T)

LI(T)

Safety shut-off valve,

control line for SAA

Level indicator Samson Media 6

incl. instrument panel and standard

programming,

extra programming of Samson Media 6

acc. to customer requirements

Level indicator WIKA with transmitter

output 4 - 20 mA

12

Clip-on standard design.

Special VAP - Quality for specific use.

The vaporisers are suitable for a design overpressure = max. allowable working pressure (PS)

of 40 bar and an allowable operating temperature

range (TS) of -269C/+50C.

Design and testing was carried out in accordance with the directive 97/23/EC concerning

pressure equipment, AD 2000-Merkbltter and

DIN EN.

Explanation of type designation:

L = air heated

40 = max. permissible working overpressure:

40 bar

8 F = number of Finned tubes: 8

2,5 = length of single finned tube: 2,5 m

The Linde finned tubes and connecting flanges

are made of aluminium alloy and the seals are

formed according to Linde Standards.

Clip-on standard design means the vaporiser

without frame. Upon customer request, a mounting kit for installation on a cryo-tank is available.

Type L 40 - 4 F 2,5

Mounting kit

Type L 40 - 2 F 2,5

vaporiser type dimensions approx.

depth [m] widht [m] height[m]

connections

nominal

weight empty

(inlet/outlet)

capacity*)

[kg]

L 40 - 8 F 2,5

1,67

0,516

2,733

140

L 40 - 4 F 2,5

1,67

0,276

2,733

74

L 40 - 2 F 2,5

0,69

0,276

2,709

37

N2 [Nm/h]

Linde ident-no.

[mm]

120

screwed: M40 x 2

pipe: DN 15 (21,3 x 1,5)

60

socket welding end: 18,2

material: stainless steel

30

J34895

I32740

I32631

*) The capacity is based on an ambient temperature of 20C, 70 % rel. humidity, 15C temperature difference between ambient and gas outlet temperature at a continuous 8-hours-operation

13

14

SHEQ - safety, health, environment

and quality police.

At the Engineering Division, we do not want to

harm people or the environment. We will comply with all applicable legal, regulatory, internal

and industry requirements.

We strive to be leading in SHEQ to meet safe,

secure and healthy working conditions and

supplying safe, compliant and environmentally

responsible products and services for our

customers.

SHEQ is a key part of The Linde Groups overall

strategy and we will also require our contractors

and partners to manage in line with this policy.

To achieve this vision,

SHEQ is 100 % of our

behaviour,

100 % of the time.

15

Service and guarantee.

Welcome to the Engineering Division

The Linde Schalchen Plant is located 100 km

east of Munich, Germany. 700 engineers and

skilled workers design and manufacture components and complete modules for the application in process plants.

Backed up by more than 100 years of production

know-how, highly developed plant modules are

manufactured. Our innovative technologies and

our competitiveness open the door to participation in prestigious plant projects worldwide.

Linde AG

Engineering Division

Schalchen Plant

Carl-von-Linde-Strasse 15

83342 Tacherting/Germany

Phone: +49.8621.85-6434

Fax:

+49.8621.85-6622

E-Mail: plantcomponents@linde-le.com

Internet: www.linde.de

Linde provides complete services on field installation and operation. A specialised service crew

is available for immediate and professional

repair services.

Production area

of standardised equipment:

Advice and sale

Phone: +49.8621.85-6777

After sales service, guarantee, spare parts

Phone: +49.8621.85-6279

Do you need further and more

detailed information?

Just ask us we will be pleased to help you.

Other products by production area

of standardised equipment:

Static vacuum insulated cryogenic vessels

Spiral welded pipes

Designing processes constructing plants.

Lindes Engineering Division continuously develops extensive process engineering know-how in the planning,

project management and construction of turnkey industrial plants.

The range of products comprises:

Petrochemical plants

LNG and natural gas processing plants

Synthesis gas plants

Hydrogen plants

Gas processing plants

Adsorption plants

Air separation plants

Cryogenic plants

Biotechnology plants

Furnaces for petrochemical plants and refineries

More than 4,000 plants worldwide document the leading position of the Engineering Division in international

plant construction.

Production facilities.

Product range.

At Linde Engineering Schalchen Plant over 700

skilled engineers and workers design and manufacture components and complete modules for

numerous applications in process plants such as

ethylene plants, hydrogen and synthesis gas

plants, LNG plants and air separation plants. Production capacity totals approx. 1.3 million hours

per year.

In addition, the plant offers services for field installation and advice on operation. A specialised

service crew is available for immediate and professional repair services.

Aluminium plate-fin heat exchangers as

single units or as manifolded assemblies

Cold boxes with aluminium plate-fin heat

exchangers, columns and vessels

Coil-wound heat exchangers and isothermal reactors for chemical and petro-

chemical plants

Columns and pressure vessels in aluminium

for cryogenic plants

Spiral-welded pipes in aluminium

Storage tanks for liquefied gases

Steam-heated waterbath vaporisers as well

as air-heated vaporisers for liquefied gases

Linde AG

Engineering Division, Schalchen Plant

Carl-von-Linde-Strasse 15, 83342 Tacherting, Germany

Phone +49.8621.85-6434, Fax +49.8621.85-6622

E-Mail: plantcomponents@linde-le.com, www.linde-plantcomponents.com

P/3.3.e/12

For further informations please contact:

Anda mungkin juga menyukai

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (119)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- PG M-Ii L1624Dokumen408 halamanPG M-Ii L1624sridharBelum ada peringkat

- 1440207759wpdm - Brochure API 653 - InHouse (150821) PDFDokumen3 halaman1440207759wpdm - Brochure API 653 - InHouse (150821) PDFcilacapBelum ada peringkat

- Blow-Out Contingency PlanDokumen61 halamanBlow-Out Contingency PlanShanying PengBelum ada peringkat

- Writing PieDokumen20 halamanWriting PieBishal PunksBelum ada peringkat

- Europa Valve Non Slam Check ValvesDokumen16 halamanEuropa Valve Non Slam Check ValvesBryan KellyBelum ada peringkat

- EE153 Notes No. 1 - The Electric Distribution SystemDokumen129 halamanEE153 Notes No. 1 - The Electric Distribution SystemAnonymous EnggrUsm100% (3)

- Hoja de Datos Bomba Sumergible Amarex KRTDokumen8 halamanHoja de Datos Bomba Sumergible Amarex KRTRicardo BarrosBelum ada peringkat

- Talesun Technology and Product Roadmap SummaryDokumen49 halamanTalesun Technology and Product Roadmap SummaryMohamed SomaiBelum ada peringkat

- EDS 01-0045 Overhead Line Ratings PDFDokumen10 halamanEDS 01-0045 Overhead Line Ratings PDFRajendra Prasad ShuklaBelum ada peringkat

- Financing of Steel Projects: in Private SectorDokumen56 halamanFinancing of Steel Projects: in Private SectorSanket AdvilkarBelum ada peringkat

- Industrial Engeeniring DictionaryDokumen42 halamanIndustrial Engeeniring DictionaryFabian Gaviria Vergara100% (1)

- AHRIDokumen3 halamanAHRISithuBelum ada peringkat

- Scribd 2 July-Low PDFDokumen136 halamanScribd 2 July-Low PDFBurcu UcaBelum ada peringkat

- BrahmaDokumen4 halamanBrahmamegaciclonBelum ada peringkat

- AIR-X Circuit Replacement InstructionsDokumen9 halamanAIR-X Circuit Replacement InstructionsscabdBelum ada peringkat

- 1 Is The Austin Energy Project A Failure Explain YourDokumen1 halaman1 Is The Austin Energy Project A Failure Explain YourAmit PandeyBelum ada peringkat

- Design of A Separation ProcessDokumen8 halamanDesign of A Separation Processdario delmoralBelum ada peringkat

- Combined Heat and Power For Electricity GenerationDokumen20 halamanCombined Heat and Power For Electricity GenerationbteamenergyBelum ada peringkat

- Raycap - Transient Voltage Surge Suppressor - 4006895 - 02Dokumen20 halamanRaycap - Transient Voltage Surge Suppressor - 4006895 - 02Andi PermanaBelum ada peringkat

- Say No To Corruption IESCO GST Bill DetailsDokumen2 halamanSay No To Corruption IESCO GST Bill DetailsQamar AbbasBelum ada peringkat

- Annual Report Electricity of Vietnam 2012-2013Dokumen41 halamanAnnual Report Electricity of Vietnam 2012-2013Nguyen Quang VinhBelum ada peringkat

- NSL Textile BrochureDokumen24 halamanNSL Textile BrochureAbhisek AgarwalBelum ada peringkat

- FM EXDust HazardPosterDokumen1 halamanFM EXDust HazardPosterTasawwur TahirBelum ada peringkat

- Design and Fabrication of Safety Stand For Two WheelersDokumen4 halamanDesign and Fabrication of Safety Stand For Two WheelersVishwas ShettyBelum ada peringkat

- GEA Ecoflex China Co., LTD PDFDokumen49 halamanGEA Ecoflex China Co., LTD PDFdebu1985100% (1)

- Nexa BrochureDokumen12 halamanNexa BrochureSuDoku100% (1)

- Lanway BrochureDokumen4 halamanLanway BrochuregugiBelum ada peringkat

- TEC Reports NewDokumen54 halamanTEC Reports NewLakmal JayashanthaBelum ada peringkat

- Guía de Lubricación de Motos Honda PDFDokumen3 halamanGuía de Lubricación de Motos Honda PDFMartin LabatBelum ada peringkat