Effect of Nitrite To Sulfide Ratios On The Performance of Anoxic Sulfide Oxidizing Reactor

Diunggah oleh

Muhammad ArslanJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Effect of Nitrite To Sulfide Ratios On The Performance of Anoxic Sulfide Oxidizing Reactor

Diunggah oleh

Muhammad ArslanHak Cipta:

Format Tersedia

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E.

Islam, and Munir Ahmed

EFFECT OF NITRITE TO SULFIDE RATIOS ON THE

PERFORMANCE OF ANOXIC SULFIDE OXIDIZING

REACTOR

Qaisar Mahmood*

Department of Environmental Sciences COMSATS Institute of Information Technology, Abbottabad 22060, Pakistan

Ping Zheng

Department of Environmental Engineering, Zhejiang University, Hangzhou 310029, China

Yousaf Hayat

Institute of Statistical Genetics and Bioinformatics, Zhejiang University, Hangzhou 310029, China,

Department of Mathematics, Statistics and Computer Sciences, North Western Frontier Province Agricultural University

Peshawar Pakistan

Jin Ren-cun

Department of Environmental Sciences, Hangzhou Normal University, Hangzhou, China

Muhammad Rashid Azim

Department of Botany, Federal Government Post Graduate College Sector H-8 Islamabad, Pakistan

Ghulam Jilani

Department of Soil Science and Soil & Water Conservation, PMAS Arid Agriculture University, Rawalpindi 46300, Pakistan

Ejazul Islam

Nuclear Institute of Agriculture, Tandojam, Hyderabad, Pakistan

Munir Ahmed

Department of Mathematics, Federal Government Post Graduate College Sector H-8 Islamabad, Pakistan

:

( ASO)

%99 .

.

0.58 .

( 1400mg S/l)

. .(ASO) 71.89-86.86

. 1.75

*Corresponding Author

E-mail: pzheng@zju.edu.cn, mahmoodzju@gmail.com

Tel: +86-571-86971709

Paper Received: 1 September 2006; Accepted 4 June 2008

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

January 2009

45

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

ABSTRACT

The present study reports the operation of a laboratory-scale anoxic sulfide oxidizing (ASO) reactor to

investigate the effects of influent nitrite to bisulfide molar ratios of 0.58, 1.45, and 1.75 upon the simultaneous

bisulfide and nitrite removal rates from the synthetic wastewater. For all tested ratios, very high bisulfide removal

percentages (above 99 %) were observed. The mass balance analysis suggested that the bisulfide oxidation was

incomplete. The sulfate formation decreased with the increasing influent sulfide concentrations. An influent bisulfide

concentration above 1400 mg S / l accompanied by high effluent nitrite might have some inhibitory effect on the

complete sulfide oxidation to sulfate. Nitrite removal percentage for the 0.58 ratio was in the range of 71.8986.86

%, showing some fluctuations in the working performance of the ASO reactor. Nitrite removal at the 1.45 ratio

ranged from 72.7087.30 %. Comparatively higher nitrogen removal (7894 %) was observed for the 1.75 ratio. The

application of an influent nitrite to sulfide molar ratio of 1.75 would be a better choice for higher nitrite and bisulfide

removal efficiencies in an ASO reactor.

Key words: anoxic bisulfide oxidation, anoxic sulfide oxidizing reactor, sulfide to nitrite ratio, anoxic nitrite

removal, lithoautotrophic denitrification

46

January 2009

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

EFFECT OF NITRITE TO SULFIDE RATIOS ON THE PERFORMANCE OF ANOXIC

SULFIDE OXIDIZING REACTOR

1. INTRODUCTION

Hydrogen sulfide is a toxic and corrosive gas that causes environmental and economic problems in a variety of

sectors such as sewerage, oil field, the petrochemical industry, etc. [1]. Among other strategies to control and remove

the sulfide is the use of nitrate, which has proved very effective, as shown by some researchers [24]. However,

nitrite was also found to be efficient to oxidize bisulfides in synthetic wastewater [5].

Anoxic sulfide oxidation (ASO) based lithoautotrophic denitrification requires an efficient supply of electron

donor for successful operation of tertiary treatment of wastewater. Such efficient supply of external electron donor is

desirable because most of the electron donors are depleted during secondary treatment of wastewater. Heterotrophic

denitrification is efficient for nitrate reduction when adequate amounts of organic carbon are available [6, 7].

However, when the organic carbon content in the wastewater is low compared to nitrogen, expensive chemicals such

as methanol must be added. The use of such compounds makes the application in full-scale reactors quite expensive.

For this reason, sulfur-based autotrophic denitrification has received more attention recently due to its two

advantages [710]: (a) no need for an external organic carbon source, thereby lowering the cost and risk of the

process; and (b) less amount of sludge produced, thereby minimizing the handling of sludge.

Lab-scale studies on simultaneous removal of bisulfide and nitrite from synthetic wastewaters as conducted by

our research group have shown promising results. The ASO reactor utilized bisulfide as electron donor and nitrite as

electron acceptor. The previous experiments achieved more than 95 % sulfide removal and 75 % nitrite removal

from synthetic wastewater [5]. Different molar ratios of nitrite to sulfide in the influent (Equations 1 and 2) show

that the nature of end products is dissimilar based on influent ratios [5].

3HS + 8NO2 + 5H+ 3 SO42 + 4N2 + 4H2O

Gm = 2944 KJ / mol

3HS + 2NO2 + 5H 3S + N2 + 4H2O

Gm = 917 KJ / mol

2

During ASO process reduced bisulfide was oxidized to SO4

dinitrogen.

(1)

(2)

or S while nitrite was converted into gaseous

1.1. Aim of the Study

The earlier studies on anoxic bisulfide biooxidation in our lab using nitrite as electron acceptor dealt with testing

the potential of an ASO reactor at influent molar ratio of 1.17 [5]. The present experiment was conducted to

investigate the behavior of bisulfide oxidation under different influent electron donor and acceptor molar ratios in an

ASO reactor to accomplish simultaneous bisulfide and nitrite removal from synthetic wastewater.

2. EXPERIMENTAL

2.1. Anoxic Sulfide Oxidizing Reactor

The anoxic sulfide oxidizing (ASO) reactor is an upflow reactor with biomass retention. The reactor is made of

perspex with a working volume of 1.3 liter. The synthetic influent was pumped with a peristaltic pump from the

influent vessel into the reactor. The flow rate can vary from 0.6 to 12.5 liters per day, which gives the possibility of

operating at HRTs between 2 and 0.1 days. For present study, HRT was kept constant (1 day). A recycling pump was

used in order to mix the influent (substrate) and sludge (biocatalyst) well and hence to enhance mass transfer and

decrease possible substrate inhibition. The ratio of recycling flow to the influent flow was set about 2.53. The

temperature of the reactor can be controlled between 20 C and 70 C with a thermostat, although the normal

operational temperature is 30 C, as is usual for the ASO process.

2.2. Inoculum

Inoculum was taken from the anaerobic methanogenic reactor in Sibao wastewater treatment plant located in

Hang Zhou city, China. Its total solids (TS) and volatile solids (VS) were 154.10 g/l and 50.89 g /l, respectively, with

VS/TS ratio of 0.322.

2.3. Synthetic Wastewater

The reactor was fed on daily basis with freshly prepared synthetic influent containing NaHCO3 (as a source of

inorganic carbon for the growth of bacteria), MgCl2, KH2PO4, (1 g/l each), (NH4)2SO4 (0.24 g/l) and trace element

solution (1 ml/l). The trace element solution contained Na2EDTA (5 g/l), NaOH (11g/l), CaCl2.2H2O (11 g/l),

FeCl24H2O (3.58 g/l), MnCl2.2H2O (2.5 g/l), ZnCl2 (1.06 g/l), CoCl2.6H2O (0.5 g/l), (NH+4)6 Mo7O24.4H2O (0.5 g/l)

and CuCl2.2H2O (0.14 g/l). The nitrite-nitrogen and sulfide-sulfur concentrations varied according to the type of

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

January 2009

47

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

experiment conducted. The influent concentrations used for ratios tests are shown in Table 1. The nitrite was used in

the form of NaNO2 while bisulfide as Na2S.9H2O. The influent pH was maintained in the range of 77.5 by 1 mol/l

HCl or 1 mol/l NaOH. The influent was flushed with argon gas for five minutes to create anoxic conditions. The

ASO reactor was operated at 30C operating at a HRT (hydraulic retention time) of 1 d because this was found to be

a suitable HRT for the operation of ASO reactor during its optimization. For a detailed account of the process

performance parameters, our previous work [5] may be consulted.

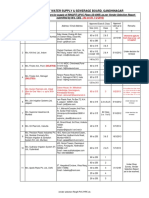

Table 1. The Nitrite and Sulfide Concentrations at Various Molar Ratios used During Experiments

Nitrite/Sulfide Ratio = 0.58

Nitrite/Sulfide Ratio = 1.45

Nitrite/Sulfide Ratio = 1.75

Sulfide

Nitrite

Sulfide

Nitrite

Sulfide

Nitrite

(mg S/l)

(mg N/l)

(mg S/l)

(mg N/l)

(mg S/l)

(mg N/l)

480

184

240

230

240

276

720

276

480

460

480

552

960

368

720

690

720

828

1200

460

960

920

960

1104

1440

552

1200

1150

1200

1380

1660

644

1440

1380

1440

1656

1900

736

1680

1610

1680

1932

1920

1840

1920

2208

2.4. Chemical Analyses

Ammonium nitrogen (NH4+-N), nitrite nitrogen (NO2-N) and nitrate nitrogen (NO3-N) were analyzed on a daily

basis using spectrophotometric methods (Unico UV-2102 PC and 722S, China). NO3-N was determined by

ultraviolet absorption spectroscopy. NO2-N was determined by N-(1-naphthyl)-1, 2-diaminoethane dihydrochloride

spectrophotometry. NH4+-N was determined by phenol-hypochlorites spectrophotometry. The S2 was determined by

ultraviolet absorption spectroscopy. SO42 was determined by barium chromate spectroscopy. The pH value was

measured by using a pH-meter. TS (Total Solids) concentrations were determined according to Standard Methods

[11].

2.5. Graphical Work

The computer program Sigma Plot version10 was use for graphical work.

3. RESULTS

3.1. ASO Process Performance at Influent Nitrite to Sulfide Molar Ratio Of 0.58

The sulfide oxidation in ASO reactor for influent sulfide to nitrite molar ratio of 0.58 has been presented in

Figure 1. The sulfide loading rates for nitrite to sulfide molar ratio of 0.58 were in the range of 0.51.9 kg S / m3 / d.

The sulfide removal efficiency was higher than 99 % for the applied range of influent sulfide concentration. The

results indicated that sulfide was oxidized to sulfate upon complete oxidation while nitrite might have reduced to

gaseous nitrogen as there was no dissimilatory ammonium formation. Sulfide oxidation resulted in almost constant

amounts of sulfate formation for tested sulfide and nitrite ratio of 0.58. As it is evident from Figure 1, the sulfate

production decreased with the increasing influent sulfide concentration.

48

January 2009

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

100.00

Influent sulfide

Sulfate formed

Removal Efficiency

99.95

1500

99.90

99.85

1000

99.80

99.75

500

99.70

Removal Efficiency

Influent sulfide (mgS/L) and

sulfate formed (mgN/L)

2000

99.65

0

99.60

0

10

15

20

25

30

Time (days)

Figure 1. Relation between influent sulfide, removal efficiency, and sulfate formed at influent molar ratio of 0.58

800

160

Nitrite Effluent

Removal efficiency

Influent Nitrite

140

700

120

600

100

500

80

400

60

300

40

Influent Nitrite (mg N/L)

Effluent Nitrite (mgN/L) and Removal Efficiency

An the sulfate produced at nitrite to sulfide molar ratio of 0.58 ranged between 49130 mg S / l . The influent

nitrite concentration ranged from 184 mg N / l to 736 mg N / l at influent ratio of 0.58 (Figure 1). At this ratio the

nitrite loading rates were in the range of 0.16-0.6 kg N / m3 / d. With the increasing influent nitrite concentration,

nitrite gradually built up in the ASO reactor (Figure 2). Its initial concentration was 26.6 mg N / l at the start of the

experiment that gradually increased to 136.98 mg N / l towards the end of the experiment (Figure 2). Overall nitrite

removal efficiency in ASO reactor remained in the range of 71.9 86.8 %, showing some fluctuations in the working

performance of the ASO reactor. The nitrite removal efficiency increased during the middle stages of the experiment

when it reached to %, but then dropped to 80 % as the influent nitrite concentration was increased above 736 mg N /

l resulting in the build up of effluent nitrite (Figure 2).

200

20

0

100

0

10

15

20

25

30

Time (days)

Figure 2. Relation between influent nitrite, effluent nitrite, and nitrite removal efficiency for influent molar ratio of 0.58

3.2. ASO Process Performance at Influent Nitrite to Sulfide Molar Ratio Of 1.45

At a nitrite to sulfide molar ratio of 1.45, the sulfide loading rates were in the range of 0.251.9 kg S / m3 / d with

the sulfide removal percentage more than 99 %. Like other nitrite to sulfide ratios, sulfide oxidation into sulfate was

incomplete as shown in Figure 3. The sulfate formation was in the range of 122281 mg / l at various influent sulfide

concentrations. The amount of sulfate decreased with the increasing influent sulfide concentrations (Figure 3).

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

January 2009

49

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

100.0

Influent Sulfide

Sulfate formed

Removal Efficiency

2000

99.9

1500

99.8

1000

99.7

500

Removal Efficiency

Influent Sulfide and sulfate formed (mg S/L)

2500

99.6

99.5

0

10

Time (Days)

15

20

25

Figure 3. Relation between influent sulfide, removal efficiency, and sulfate formed at influent molar ratio of 1.45

260

2000

Effluent Nitrite

Removal Efficiency

Influent Nitrite

240

220

1800

1600

200

1400

180

1200

160

1000

140

800

120

600

100

80

400

60

200

40

Influent nitrite (mgN/L)

Effluent nitrite (mgN/L) and Removal Efficiency

The nitrite loading rates for nitrite to sulfide molar ratio of 1.45 ranged 0.16-1.6 kg N / m3 / d. As far as nitrite

removal percentage is concerned, it ranged from 72.7 % to 87.3 % for nitrite to sulfide molar ratio of 1.45. The

relation between influent and effluent nitrite along with its removal percentage has been shown in Figure 4. The

effluent nitrite amount ranged from 62.8 to 240.3 mg N / l with nitrite-nitrogen removal efficiency in the range of

7187 % (Figure 4). There was a little amount of ammonium nitrogen at lower influent pH while later there was

absolutely no formation of ammonium in the reactor for the tested range of influent nitrite (data not shown).

0

0

10

15

Time (days)

20

25

Figure 4. Relation between influent nitrite, effluent nitrite, and nitrite removal efficiency at influent molar ratio of 1.45

3.3. ASO Process Performance at Influent Nitrite to Sulfide Molar Ratio Of 1.75

Sulfide removal for this ratio observed was also pretty high i.e. more than 99%. At various applied influent

sulfide amounts i.e. 2401900 mg S/l, the effluent sulfide always remained less than 2 mg/l (Figure 5). The sulfide

loading rates for nitrite to sulfide molar ratio of 1.75 were in range of 0.2-1.9 KgS/m3.d.The amounts of sulfate

formed were in the range of 24256 mgS/l, almost similar to those formed at influent molar ratio of 1.45. However,

the amount of sulfate formed decreased with the increasing influent sulfidesulfur content. The amount of sulfate

formed (above 250 mg/l) above influent sulfide concentration of 1440 mg S/l which was accompanied by increase in

the effluent sulfide and nitrite concentrations (Figure 5 and 6).

50

January 2009

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

Comparatively higher nitrogen removal percentages were observed for present ratio i.e. 7894%, these nitrogen

removal percentages are highest among the all tested nitrite to sulfide molar ratios (0.58, 1.45, and 1.75). The nitrite

loadings for influent ratio 1.75 were in the range of 0.22.0 kgN/m3.d. Figure 6 presents the relation between influent

nitrite, effluent nitrite and nitrite removal efficiency for influent molar ratio of 1.75. No ammonium appeared in the

reactor during testing of present molar nitrite to sulfide ratios.

Influent Sulfide

SulfateFormed

Removal Efficiency

2500

100.0

99.9

2000

99.8

1500

99.7

99.6

1000

99.5

500

99.4

0

Removal Efficiency

Influent Sulfide and Sulfate Formed (mgS/L)

The results showed that the effluent sulfide concentration was less than 2% in all tested cases, while the

maximum nitrite removal percentage was observed for influent nitrite to sulfide molar ratio of 1.75 which was

statistically significant (p<0.05). In addition, relatively greater and statistically significant (p<0.05) amounts of

sulfate were formed due to complete oxidation of sulfide in the presence of abundant supply of electron acceptor

(nitrite) at higher nitrite to sulfide molar ratios viz .1.45 and 1.75.

99.3

99.2

0

10

15

Time (Days)

20

25

200

2500

Effluent Nitrite

Removal Efficiency

Influent Nitrite

180

2000

160

140

1500

120

1000

100

80

Influent Nitrite (mgN/L)

Effluent Nitrite (mgN/L) and Removal Efficiency

Figure 5. Relation between influent sulfide, removal efficiency, and sulfate formed at influent molar ratio of 1.75

500

60

40

0

0

10

15

Time (days)

20

25

Figure 6. Relation between Influent, Effluent Nitrite and Nitrite removal efficiency at influent ratios of 1.75

3.4. Influence of Sulfide Oxidation Upon pH

The effluent pH is an important parameter used to judge stability of a reactor. Increase in pH results from the

OH ions produced from sulfide oxidation under anoxic conditions. The effluent pH was monitored throughout the

experiment and was presented in Figure 7. The results showed that the effluent pH was in the range of 89.5

(Figure 7).

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

January 2009

51

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

Influent and Effluent pH values

10.0

Influent pH

Effluent pH at 0.58

Effluent pH at 1.45

Effluent pH at 1.75

9.5

9.0

8.5

8.0

7.5

7.0

0

10

15

Time(days)

20

25

30

Figure 7. Relation between influent and effluent pH values at various molar ratios

4. DISCUSSION

For assessing the potential of a process, volumetric loading rate, removal percentage and the effluent

concentration are important performance indices. For all the tested ratios in the ASO reactor, very high sulfide

removal efficiency (above 99 %) was recorded. Very high sulfide removal (> 96 %) was also achieved in our

previous experiments with a ASO reactor at a nitrite to sulfide molar ratio of 1.17 [5]. Other workers [1215] also

obtained such higher sulfide removal efficiencies using different bioreactors from a variety of waste streams.

Mass balance showed that the sulfide oxidation for tested ratios seemed to be incomplete. Generally, the amount

of sulfate formed as a result of complete sulfide oxidation increased up to an influent sulfide concentration of 1440

mg S / l , and then decreased (Figures 1, 3, and 5). Actually, the sulfate formation did not correspond to the reaction

stoichiometry. Sulfides might have been oxidized to elemental sulfur [1617]. Stoichiometric analysis of data for

present study showed that around 1525 % of the fed sulfide was converted to sulfate for sulfide to nitrite ratio of

0.58. The sulfate formation was 30100 % and 40100 % for the ratios of 1.45 and 1.75, respectively. It was

assumed that rest of sulfide had been converted to elemental sulfur (not determined).

Incomplete oxidation of bisulfides can be explained in terms of substrate and product toxicity which can present

one of the technical barriers in the application of this technology to the treatment of sour wastes on a commercially

useful scale [18]. Bisulfide is toxic to the biotic communities present in the ASO reactor and, therefore, an inhibitory

substrate. Increasing bisulfides and nitrites in the influent, high effluent nitrites may have inhibited the complete

sulfide oxidation into sulfate. Some intermediates of bisulfide oxidation might have arisen in the reactor, which need

to be characterized through further research. The practical implication is that reactor systems employed to treat any

bisulfide laden wastes must be operated on a bisulfide-limited basis so that the steady-state concentration of bisulfide

in the bulk liquid is below inhibitory levels. Further, reactor systems must be well-mixed to avoid high gradients in

bisulfide concentrations and, therefore, isolated pockets of inhibitory bisulfide concentrations [18].

Sulfate is the end product of the aerobic or anoxic (with nitrate) oxidation of sulfides by Thiobacillus

denitrificans whose activity has been shown to be inhibited by sulfate concentrations in excess of 250 mg [19]. This

is likely not an inherent inhibition by sulfate but an effect of increasing ionic strength. In any regard, this product

inhibition places an operating restriction on both batch and continuous reactors. In batch systems, the accumulation

of sulfate can determine the cycle time between batches. In a continuous system the sulfate concentration at the

steady state is determined by the dilution rate; therefore, at any given sulfide feed rate, the reactor volume or

hydraulic throughput is controlled by the sulfate concentration to be maintained in the culture [18].

Our previous studies on simultaneous sulfide and nitrite removal at an influent molar ratio of 1.17 showed that

sulfide oxidation was incomplete and about 1011 % sulfide removal was due to auto-oxidation resulting from the

presence of small quantities of dissolved oxygen in the influent wastewater [5]. It may be logical to suppose that

most of the bisulfide oxidation was due to biotic action, and the possibility of autooxidation of bisulfide was the

minimum as the influent wastewater was flushed with argon gas to avoid oxygen. As far as the toxicity of sulfide

52

January 2009

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

and nitrite to bacterial communities present in the reactor is concerned, the effects of various nitrite and sulfide

concentrations were tested on the growth and physiology of two isolates from ASO reactor in batch cultures (data

not shown). The results showed that the isolates were more sensitive to sulfide compared with nitrite as IC 50 values

for sulfide were lower than those of nitrite.

Stability is an essential parameter to assess the usefulness of a process. The effluent pH is an important parameter

used to the judge stability of a reactor. Under all the tested influent nitrite to sulfide ratios, the effluent pH was in the

range of 89.5 (Figure 7). Increase in pH results from the OH ions produced from bisulfide oxidation under anoxic

conditions [20]. Clause and Kutzner [9] in their study on the kinetics of autotrophic denitrification with Thiobacillus

denitrificans have reported that a pH around 7.58.0 was optimum for denitrification. Further experiments on testing

different influent pH to investigate the performance of ASO reactor are required. We characterized the effects of

various influent pH values on the performance of anoxic sulfide oxidizing reactor [21]. It was found that the

bacterial communities in ASO reactors were more sensitive to acidic pH compared with alkaline pH, as nitrite and

sulfide removal rates dropped significantly when exposed to acidic pH 3.0. High dissolved bisulfide ions, nitrite and

excess of sulfate (> 300 mg / l) inhibited the sulfide oxidation under highly acidic and alkaline conditions in the ASO

reactor [21].

Judged by the results, a higher nitrite to sulfide molar ratio (1.75) was handy for simultaneous removal of sulfide

and nitrite from wastewater as shown by higher sulfide and nitrite removal efficiencies. Though the amount of

effluent nitrite was higher at higher sulfide to nitrite ratio, further aerobic treatment of the effluent may reduce the

nitrite concentration.

5. CONCLUSIONS

For all the tested sulfide to nitrite ratios in the ASO process, very high sulfide removal percentages (above 99 %)

were recorded. The sulfide and nitrite mass balance analysis suggested that the sulfide oxidation was incomplete.

The sulfate formation decreased with the increasing influent sulfide concentrations. An influent sulfide concentration

above 1400 mg S / l, accompanied by high effluent nitrite, may have an inhibitory effect on the complete sulfide

oxidation to sulfate. A higher ratio, viz. 1.75, may be a suitable ratio for better results to eliminate sulfide and nitrite

from the wastewater, simultaneously.

REFERENCES

[1]

E. Vaiopoulou, P. Melidis, and A. Aivasidis, Sulfide Removal in Wastewater from Petrochemical Industries by

Autotrophic Denitrification, Water Res., 39(2005), pp. 41014109.

[2]

A. J. Telang, S. Ebert, J. M. Foght, D. W. S. Westlake, G. E. Jenneman, D. Gevertz, and G. Voordouw, Effect of

Nitrate Injection on the Microbial Community in an Oil Field Monitored by a Reverse Sample Genome Probing,

Appl. Environ. Microbiol., 63(1997), pp. 17831793.

[3]

G. E. Jenneman, P. D. Moffitt, G. A. Bala, and R. H. Webb, Sulfide Removal in Reservoir Brine by Indigenous

Bacteria, SPE 57422. SPE Production and Facilities, 14(1999), pp. 219225.

[4]

V.L. Mathioudakis, E. Vaiopoulou, and A. Aivasidis, Addition of Nitrate for Odour Control in Sewer Networks:

Laboratory and Field Experiments, Proc. Nineth International Conference on Environmental Science and

Technology, Rhodes, Greece, 2005.

[5]

M. Qaisar, Z. Ping, C. Jing, W. Donglei, H. Baolan, and L. Jinye, Anoxic Sulfide Biooxidation Using Nitrite as

Electron Acceptor, J. Hazard. Mat., 147(2007), pp. 249256.

[6]

J. M. Flere and T. C. Zhang, Nitrate Removal with Sulfur-Limestone Autotrophic Denitrification Processes, J.

Environ. Eng., 8(1999), pp. 721729.

[7]

T. C. Zhang and D. G. Lampe, Sulfur: Limestone Autotrophic Denitrification Processes for Treatment of NitrateContaminated Water: Batch Experiments, Water Res., 33(1999), pp. 599608.

[8]

B. Batchelor and A. W. Lawrence, Autotrophic Denitrification Using Elemental Sulfur, J. WPCF, 50(1978), pp.

19862001.

[9]

G. Claus and H. J. Kutzner, Autotrophic Denitrification by Thiobacillus Denitrificans in a Packed Bed Reactor,

Appl. Microbiol. Biotechnol., 22(1985), pp. 289296.

[10]

A. Koenig and L. H. Liu, Autotrophic Denitrification of Landfill Leachate Using Elemental Sulphur, Wat. Sci.

Tech., 34(1996), pp. 469476.

[11]

American Public Health Association, Inc., (APHA), Standard Methods for the Examination of Water and

Wastewater, 20th edn. Washington DC: APHA, USA.

[12]

J. S. Devinny, D. E. Chitwood, and A.M. Deshusses, Co-Treatment of VOC's in Low-Sulfide Biofilters, Abst. Air

and Waste Management Associations 92nd Annual Meeting and Exhibition, St. Louis, Missouri, 1999 p. 9.

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

January 2009

53

Q. Mahmood, Ping Zheng, Y. Hayat, Jin Ren-cun, M. R. Azim, G. Jilani, E. Islam, and Munir Ahmed

54

[13]

Y. C. Chung, C. Huang, and C. P. Tseng, Biotreatment of Hydrogen Sulfide- and Ammonia- Containing Waste

Gases by Fluidized Bed Bioreactor, J. Air & Waste Manage. Assoc., 51(2001), pp. 163172.

[14]

C. McComas and L.K. Sublette, Characterization of a Novel Biocatalyst System for Sulphide Oxidation, Biotech.

Prog., 17(2001), pp. 439446.

[15]

R. Kleerebezem and R. Mendez, Autotrophic Denitrification for Combined Hydrogen Sulfide Removal From

Biogas and Post-Denitrification, Water Sci. Tech., 45(2002), pp. 349356.

[16]

D. D. Schulte and R. K. Koelsch, Improving Odor Control in Swine Lagoons by Better Understanding and

Management of Purple Sulfur Bacteria, Trans. ASAE, 48(2000), pp. 18531859.

[17]

J. L. Sund, C. J. Evenson, K. A. Strevett, R. W. Nairn, D. Athay, and E. Trawinski, Nutrient Conversion by

Photosynthetic Bacteria in a Concentrated Animal Feeding Operation Lagoon System, J. Environ. Qual.,

30(2001), pp. 648655.

[18]

K. L. Sublette, R. Kolhatkar, and K. Raterman, Technological Aspects of the Microbial Treatment of Sulfide-Rich

Wastewaters: A Case Study, Biodegrad., 9(1998), pp. 259271.

[19]

K. L. Sublette, Microbial Treatment of Sour Gases for the Removal and Oxidation of Hydrogen Sulfide, Gas

Separ. & Purif., 4(1990), pp. 9196.

[20]

B. Krishnakumar and V. B. Manilal, Bacterial Oxidation of Sulphide Under Denitrifying Conditions, Biotech.

Lett., 21(1999), pp. 437440.

[21]

M. Qaisar, Z. Ping, H. Yousaf, I. Ejazul, W. Donglei, and R. C. Jin, Effect of pH on Anoxic Sulfide Oxidizing

Reactor Performance, Bioresour. Technol., 99(2008), pp. 32913296.

January 2009

The Arabian Journal for Science and Engineering, Volume 34, Number 1A

Anda mungkin juga menyukai

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Quality Assurance Plan (1) ..Dokumen5 halamanQuality Assurance Plan (1) ..ARUNKUMARANNANBHEDABelum ada peringkat

- J.M. Hurst Cyclic AnalysisDokumen45 halamanJ.M. Hurst Cyclic AnalysisChristian Robinson80% (10)

- Esquema Elétrico NGD 9.3Dokumen2 halamanEsquema Elétrico NGD 9.3LuisCarlosKovalchuk100% (1)

- Water QuizDokumen11 halamanWater QuizMuhammad ArslanBelum ada peringkat

- Eramus Bridge PDFDokumen10 halamanEramus Bridge PDFBabaO.Riley100% (1)

- Bs en 00378 3 2016Dokumen30 halamanBs en 00378 3 2016Darius VinBelum ada peringkat

- Sustaining Soil Productivity by Integrated Plant Nutrient Management in Wheat Based Cropping System Under Rainfed ConditionsDokumen9 halamanSustaining Soil Productivity by Integrated Plant Nutrient Management in Wheat Based Cropping System Under Rainfed ConditionsMuhammad ArslanBelum ada peringkat

- Blood Mercury Levels of Dental Students and Dentists at A Dental SchoolDokumen4 halamanBlood Mercury Levels of Dental Students and Dentists at A Dental SchoolMuhammad ArslanBelum ada peringkat

- Mood - Introduction To The Theory of StatisticsDokumen577 halamanMood - Introduction To The Theory of StatisticsFelipe Ortiz81% (21)

- Environmental MonitoringDokumen267 halamanEnvironmental MonitoringMuhammad ArslanBelum ada peringkat

- New Theoretical Approaches For Human-Computer Interaction.Dokumen58 halamanNew Theoretical Approaches For Human-Computer Interaction.Muhammad ArslanBelum ada peringkat

- Aliphatic HydrocarbonsDokumen1 halamanAliphatic HydrocarbonsMuhammad ArslanBelum ada peringkat

- Wastewater Treatment ReportDokumen2 halamanWastewater Treatment ReportMuhammad ArslanBelum ada peringkat

- Hazard Identification ReportDokumen2 halamanHazard Identification ReportMuhammad ArslanBelum ada peringkat

- The Right Stuff PDFDokumen4 halamanThe Right Stuff PDFNeelank Tiwari100% (1)

- JDE ApplicationDokumen642 halamanJDE ApplicationAnonymous cputyzBelum ada peringkat

- PORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairDokumen34 halamanPORTFOLIO: OFFICE WORK (20/06/2022-20/12/2022) Harleen KlairHarleen KlairBelum ada peringkat

- GWSSB Vendor List 19.11.2013Dokumen18 halamanGWSSB Vendor List 19.11.2013sivesh_rathiBelum ada peringkat

- TDS Sadechaf UVACRYL 2151 - v9Dokumen5 halamanTDS Sadechaf UVACRYL 2151 - v9Alex MacabuBelum ada peringkat

- Pioneer XDP - 30R ManualDokumen213 halamanPioneer XDP - 30R Manualmugurel_stanescuBelum ada peringkat

- UMTS AircomDokumen20 halamanUMTS AircomDũng PhạmBelum ada peringkat

- Report On Automatic Phase Changer: Submitted ByDokumen32 halamanReport On Automatic Phase Changer: Submitted ByAndrea JohnsonBelum ada peringkat

- E 7016 Product-SheetDokumen1 halamanE 7016 Product-SheetAlireza TakrimiBelum ada peringkat

- G270han01 V0Dokumen26 halamanG270han01 V0NemkoBelum ada peringkat

- Formulas To RememberDokumen6 halamanFormulas To Rememberuygurzeren100% (3)

- Experiment 5 DACDokumen3 halamanExperiment 5 DACABHISHEK SHARMABelum ada peringkat

- WEISER Locks and HardwareDokumen24 halamanWEISER Locks and HardwareMaritime Door & WindowBelum ada peringkat

- Panel 01-Eldora-Grand-1500V-2021-R01 - G1Dokumen2 halamanPanel 01-Eldora-Grand-1500V-2021-R01 - G1DHAVAL SHAHBelum ada peringkat

- How Is Electrical Energy MeasuredDokumen4 halamanHow Is Electrical Energy MeasuredSonya ReddyBelum ada peringkat

- Circuiting Explained-Water Coils PDFDokumen2 halamanCircuiting Explained-Water Coils PDFFrancisBelum ada peringkat

- Kinematics-03-Subjective SolvedDokumen11 halamanKinematics-03-Subjective SolvedRaju SinghBelum ada peringkat

- Mech 3-Module 1Dokumen41 halamanMech 3-Module 1melkisidick angloanBelum ada peringkat

- 2019 All PDFDokumen27 halaman2019 All PDFvishesh bhatiaBelum ada peringkat

- 8th ICCIT - 2005 - 564Dokumen5 halaman8th ICCIT - 2005 - 564Amit BiswasBelum ada peringkat

- 25252525Dokumen38 halaman25252525Ivan GonzalezBelum ada peringkat

- Doing Hot Work On Gas ShipDokumen5 halamanDoing Hot Work On Gas ShipAnonymous icnhaNsFBelum ada peringkat

- Pro TrekDokumen4 halamanPro TrekTri WidodoBelum ada peringkat

- Supplier GPO Q TM 0001 02 SPDCR TemplateDokumen6 halamanSupplier GPO Q TM 0001 02 SPDCR TemplateMahe RonaldoBelum ada peringkat