Final Report

Diunggah oleh

shaista khanHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Final Report

Diunggah oleh

shaista khanHak Cipta:

Format Tersedia

Designing of Retaining Wall and Box Portion of Underpass 2014

Chapter - 1

INTRODUCTION

SET -JU

Page 1

Designing of Retaining Wall and Box Portion of Underpass 2014

Chapter 1

INTRODUCTION

1.1 General

The transformation of Sri Kempegowdas 16th Century Garden City

Bangalore to todays Silicon Valley has been rapid. The city has grown from 21

Sqkm. in 1897 to 800 Sqkm. in 2013. The capital of Karnataka, Bangalore, is the

fifth largest city in the country, is the perfect blend of natural beauty man made

marvels of architecture and technology. The city is the second fastest growing in

the world after Mexico City.

The city which was originally developed as a garden city subsequently

became an administrative, industrial center and lately transformed itself into the

software hub of India. Bangalore city, which had an area of 28.85 sq. km in 1901,

had grown to 174.7 Sq. km in 1971 and presently it has expanded to nearly 800

Sq. km. The last three decades have witnessed rapid growth in the population of

Bangalore city. The city, which had a population of 29.14 lakh in 1981, has

currently reached a level of nearly 8.426 million in 2011. It is expected that the

population will be about 110 lakh by 2015. Traffic and other infrastructure has

become one of the key problems due to the rapid growth of the city. There were

hardly any high rise buildings. The population of the city exploded during the last

three decades. From a population of about 2.9 million in 1981, it is going to

surpass 12 million by 2022. Figure 1.1 shows the growth of population projected

as on 2022 in Bangalore. The value as on 2020 will be of the order of 121 lakhs

SET -JU

Page 2

Designing of Retaining Wall and Box Portion of Underpass 2014

Fig 1.1

1.2 Key Map

The proposed grade separator is located in the western part of Bangalore City,

acts as a link between Magadi road and Basaveshwara nagar and is one of the

busiest stretches in the city. This junction attracts a lot of traffic throughout the

day as either side of the corridor is populated with establishments like Adyar

Anand Bhavan, Government Homeopathy College, A D Halli Park, and also welldeveloped Residential Areas like Vijaynagar, Govindrajnagar, Priyadarshini Layout,

K H B Layout , etc. fig 1.2 shows the key map of the proposed grade separator.

SET -JU

Page 3

Designing of Retaining Wall and Box Portion of Underpass 2014

Fig 1.2

SET -JU

Page 4

Designing of Retaining Wall and Box Portion of Underpass 2014

Chapter - 2

Objectives and scope of study

SET -JU

Page 5

Designing of Retaining Wall and Box Portion of Underpass 2014

Chapter - 2

Objectives and scope of study

2.1 General

Junctions located in the Western Part of the City. The Project Junction along

Magadi Road connects with Outer Ring Road in the west at a distance of

about 2.2km away and with Chord Road in the east at a distance of about

1.5km away. The Junction is surrounded by Residential Layouts such as

Vijay Nagar, K. H. B. Colony, Govindaraja Nagar, Kamakshipalya, Prashant

Nagar Colony, Basaveshwara Nagar, etc. and Industrial Establishments like

Rajaji Nagar Industrial Town, Kamakshipalya Industrial Estate, etc.

The Primary Objectives of the Study are

To effectively and optimally manage Traffic at the Project Junction.

To conduct necessary Surveys and Investigations to arrive at Alignment

Alternatives for Traffic Improvement at the Project Junction.

To suggest Optimal and Feasible Junction Improvement Measures to

reduce travel time.

To improve the existing Junction to streamline Traffic Flow at Grade

Level.

To improve the Environmental Conditions near the Project Junction by

reducing Idle Time.

To reduce the Vehicle Operation Cost of the Road Users commuting

through this Junction.

To reduce Traffic Accidents at the Junction.

SET -JU

Page 6

Designing of Retaining Wall and Box Portion of Underpass 2014

To summarise, the Main Objective of the Study of this Junction is to offer to

the Road Users commuting through this Junction Comprehensive

Connectivity, Convenience, Comfort, Affordability, Safety and Aesthetics.

2.2 Project Scope

The Scope of the Study to be carried out involves the following.

Review of Available Data and Reports.

Topographical Survey of the Project Junction.

Necessary Traffic Survey to obtain Data and its Analysis for the Concept

Proposal.

Geotechnical Investigation.

Study of Alternative Solutions and Evaluation of the same.

Selection of Feasible Alternative.

Work out Traffic Management / Diversion and Traffic Engineering

Schemes.

2.3 Approach Methodology

The Activities that are involved in the Preparation of Detailed Project Report

for Construction of Underpass at the Junction of Magadi Road and

Basaveshwara Nagar Road, Bangalore are briefed below.

2.3.1 Stage 1

To define the Objectives and Scope of Work.

To plan Approach and Methodology, Data Collection.

Carry out Field Reconnaissance Survey that includes Site Appreciation,

Identification of Survey Locations and Site Constraints.

SET -JU

Page 7

Designing of Retaining Wall and Box Portion of Underpass 2014

2.3.2 Stage 2

Data Collection

Engineering Surveys and Investigations

1. Classified Turning Traffic Volume Survey.

2. Topographic Survey.

3. Geotechnical Investigation.

Secondary Data

1. Economic Indicators affecting Traffic Growth.

2. Details of any on going Road Improvements, Junction

Improvements, Grade Separator Schemes; Footpath Improvement

Scheme.

Analysis of Traffic Volume Count in deciding the Alignment of Grade

Separation Scheme.

Analysis of Surface Level Improvements based on the Traffic Data and

Proposed Grade Separation Scheme.

Analysis of Traffic Circulation at Surface Level based on Proposed

Scheme.

Design suitable Traffic Improvement Measures to reduce Conflicting

Traffic Stream.

Preparation of Layout Drawings and Longitudinal Sections of the

Proposals conceptualized.

2.3.3 Stage 3

Basic Engineering Designs, Drawings and Longitudinal

Sections of the Approved Concept.

Geometrical design.

Designing of Retaining wall of Underpass

SET -JU

Page 8

Designing of Retaining Wall and Box Portion of Underpass 2014

Designing of Box Portion of Underpass

2.4 Design Philosophy

The Technical Proposal given in this Detailed Project Report

consists of four lanes divided bi directional Underpass along

Magadi Road, its Basic Engineering Designs and Drawings and all

relevant Technical Data / Details based on the Studies and

Investigations stated in Section 2.2.

The Design Standards that will be adopted in the Design of

Proposed Underpass at the Junction of Magadi Road and

Basaveshwara Nagar Road, Bangalore shall be in accordance with

the Codal Provisions of India as stipulated by the Indian Road

Congress (IRC), the Ministry of Road Transport & Highways

(MoRT&H) and the Bureau of Indian Standard Specifications

(BIS). Deviations may be considered in Planning Parameters, if

absolutely necessary, considering the Dense Urban Conditions

from the present Codal Provisions. These Modifications in the

Design shall be adopted based on Sound Engineering Practices.

The Basic Engineering Designs and Drawings presented as part of

this Detailed Project Report are based on the Studies and

Investigations carried

SET -JU

Page 9

Designing of Retaining Wall and Box Portion of Underpass 2014

2.5 Approach Methodology

SET -JU

Traffic Survey

Designing of

Retaining wall

Geometrical

Design

Designing of

Box portion

Page 10

Designing of Retaining Wall and Box Portion of Underpass 2014

Chapter - 3

Site Characteristics

SET -JU

Page 11

Designing of Retaining Wall and Box Portion of Underpass 2014

Chapter 3

Site Characteristics

3.1 Junction Details Physical

The Junction of Magadi Road Basaveshwara Nagar Road is one of the

most important and busiest Junctions located on Magadi Road (SH 17E) in

the Western Part of the City. The Project Junction along Magadi Road

connects with Outer Ring Road in the west at a distance of about 2.2km

away and with Chord Road in the east at a distance of about 1.5km away.

The Junction is surrounded by Residential Layouts such as Vijay Nagar, K.

H. B. Colony, Govindaraja Nagar, Kamakshipalya, Prashant Nagar Colony,

Basaveshwara Nagar, etc. and Industrial Establishments like Rajaji Nagar

Industrial Town, Kamakshipalya Industrial Estate, etc. This is a typical three

legged (T Shaped) Intersection in which Magadi Road forms the East

West Axis and Road towards Basaveshwara Nagar forms the North Axis.

The Details of the Arms forming this Intersection are as follows.

SET -JU

Page 12

Designing of Retaining Wall and Box Portion of Underpass 2014

3.1.1 Arm (Magadi Road) towards Chord Road Side of the

Intersection

This part of the Road is divided bi directional with 0.3m wide Central

Median. The Carriageway Width of this Stretch varies between 20m and

21m whereas the ROW of this Road varies between 39m and 40m near the

Junction. Slip Road of average width of 9m is present on southern side of

this Stretch of Road. The Gradient is slopping away from the Junction.

Thickly Developed Commercial and Residential Establishments are present

on either side of this Stretch of Road.

3.1.2 Arm (Magadi Road) towards Outer Ring Road Side of the

Intersection

This Part of the Road is divided bi directional with 0.9m wide Central Median. The

Width of Carriageway varies between 21m and 22m whereas the ROW of this

Road varies between 35m and 36m near the Junction. Slip Road of average width

of 7m is present on southern side of this Stretch of Road. The Gradient is slopping

towards the Junction. Well Developed Commercial and Residential

Establishments, Public Service Buildings are present along this Stretch of Road.

Bus Stop is located on either side of this Stretch of Road at about 100m away from

the Junction.

SET -JU

Page 13

Designing of Retaining Wall and Box Portion of Underpass 2014

3.1.3 Arm towards Basaveshwara Nagar Side of the Intersection

This part of the Road is divided bi directional with 0.4m wide Central

Median. The Width of Carriageway varies between 15m and 16m whereas

the ROW of this Road is 24m near the Junction. The Gradient is slopping

towards the Junction. Either side of this Stretch is populated with thickly

developed Residential and Commercial Establishments.

3.2 Existing Traffic Regulations

Two directional movements are present along all the three arms of the

Junction. It is permitted to move from one arm to other two arms of the

Junction. There are Signals present at the Junction. At present the Traffic

Flow at the Junction is being controlled by Automated Traffic Signal

manned with Traffic Police Personnel.

3.3 Street Lighting Pattern

Road Side Street Lighting Arrangement along the Project Stretch is not

adequate. Hence, Provision of adequate Nos. of Street Lights along all the

Approach Arms to the Project Junction shall be incorporated in the Project

Proposal for the effective illumination.

3.4 Bus Stops

The presence of Bus Stops on the Intersecting Arm of the Junctions, four on

the Arm towards Outer Ring Road Side of the Intersection inside the

Carriageway hinders the smooth traffic movement along the Corridor near

the Junction.

3.5 Pedestrian Movement

The presence of Bus Stops, Educational Institutions, Hospital Building,

Commercial Establishments and their related activities in the vicinity of the

SET -JU

Page 14

Designing of Retaining Wall and Box Portion of Underpass 2014

Junction leads to hazardous movement pattern of the Pedestrians across the

Road, thus reducing the Safety Aspects. Further, presence of Trees, other

Utilities and Hawkers Activities on the Footpath has reduced the Effective

Width of the Footpath and in turn is obstructing the Pedestrian Movement.

Chapter - 4

Field studies and Analysis

SET -JU

Page 15

Designing of Retaining Wall and Box Portion of Underpass 2014

Chapter - 4

Field studies and Analysis

4.1 General

This Chapter presents the various Studies (Reconnaissance Survey, Traffic

Survey, Topographical Survey, etc.) and thereafter the Data, obtained as a Result

of these Studies, Analysis carried out. The Results of Analysis form Inputs for

Planning and Design of Proposed Junction Improvement Scheme, Traffic Forecast

and Economic Analysis.

4.2 Reconnaissance Survey

Reconnaissance Survey has been carried out at and around the Project

Junction and the Physical Characteristics of the Junction such as Road Geometrics,

Pavement Structure, Traffic Controls (Signs, Signals, Road Markings and Parking

Restrictions), Side Walks, Shoulders, Adjacent Land Use, Service Lines (for

example Water, Electricity, Telephone), Storm Water Drains and the Intensity of

Non Traffic Activities, which encroach upon Road Space (such as Hawkers,

Builders Materials, Market Stalls, etc.) have been studied. The Data recorded have

SET -JU

Page 16

Designing of Retaining Wall and Box Portion of Underpass 2014

been detailed out in Chapter 3 Site Characteristics. At present no Improvement

Scheme has been taken up in and around Basaveshwara Nagar Road Junction.

4.3 Traffic Surveys

To establish the Vehicular Traffic Flow Characteristics such as Hourly Variation,

Composition, Peak Hour Flows at the Junction, Turning Movement Survey of

Vehicles at the Project Junction has been conducted on first week of April.

4.3.1 Methodology for Traffic Surveys

4.3.1.1 Turning Movement Survey of Vehicles at the Junction

24 hours Manual Traffic Counts have been conducted to cover all the Vehicular

Movements at the Junction. The Vehicle Classification System adopted for the

Study is given in Table 4.1.

Table 4.1

Vehicle Classification System

Motorised Traffic

Non Motorised Traffic

2 Wheelers, Auto Rickshaw,

Passenger Car: Car, Taxi and Jeep

Bicycle, Cycle Rickshaw, Animal

Drawn Vehicle, Hand Drawn Cart

Utility Vehicle: Van and Tempo

Bus

Truck

Mini Bus

Standard Bus

Light

Commercial

Vehicle (LCV)

Heavy

Commercial

Vehicle (HCV)

SET -JU

Page 17

Designing of Retaining Wall and Box Portion of Underpass 2014

The Turning Movement Survey has been conducted to obtain Information on Mode

wise and Direction wise Turning Movement of Traffic at the Intersection. The

Survey has been conducted for 24 hours (0600 hrs. to 0600 hrs.) covering Morning

and Evening Peak Hours.

Traffic Counting has been carried out manually in two twelve hour shifts by

trained enumerators, using Hand Tally. The Count Data have been recorded at 15

minute intervals using Hand Tallies and total per hour for each vehicle category

has been computed. The Traffic Volume Count Data has been processed using the

commonly used Spreadsheet Package. The processed Hourly Traffic Volume Data

has been compiled Direction wise.

The Peak Hourly Directional Vehicular Movement Data has been used to plan and

design the Improvement Scheme such as Grade Separation and At Grade

Intersection with Traffic Signals.

4.4 Analysis of Traffic Study Data

The Data and Pertinent Information collected from the Traffic Survey have been

analysed using the Utility Software Packages (MS Excel) to obtain the required

Information concerning Traffic Characteristics at the Intersection. Findings and the

brief Discussions thereon are presented in this Section.

4.4.1 Analysis of Turning Movement Count Data

Data have been processed on quarter hourly basis to establish the most appropriate

Peak Hours. Data collected from Survey have been computerised and analysed to

study Hourly Variation of Traffic, Peak Hour Flows, Traffic Composition, etc. and

are presented below. The Counts have been classified by Category of Vehicles and

by Direction of Movement. The various Vehicle Types having different Sizes and

Characteristics have been converted into Equivalent Passenger Car Units. The

SET -JU

Page 18

Designing of Retaining Wall and Box Portion of Underpass 2014

Passenger Car Unit (PCU) Factors recommended by Indian Road Congress in

Guidelines for Capacity of Urban Roads in Plain Areas (IRC: 106 1990) have

been used. The same are detailed in Table 4.2

Table 4.2

Recommended PCU Factors for Various Types of Vehicles in Urban Roads

Sl. No.

Vehicle Type

Equivalent PCU Factors

% Composition of Vehicle

Type

Up to 10%

10%

above

Fast Vehicles

Two wheelers, Motorcycle or Scooter, etc.

0.5

0.75

Passenger car, Pick up Van

1.0

1.0

Auto Rickshaw

1.2

2.0

Light Commercial Vehicle

1.4

2.0

Truck or Bus

2.2

3.7

6

B

Agricultural Tractor Trailer

Slow Vehicles

4.0

5.0

Cycle

0.4

0.5

Cycle Rickshaw

1.5

2.0

Tonga (Horse drawn vehicle)

1.5

2.0

Hand Cart

2.0

3.0

and

4.4.2 Hourly Variation of Traffic

Hourly Variation of Vehicular Traffic Flow is presented in Fig. 4.1. The Hourly

Traffic Volume observed at the Junction varied in the range of 527 8243 PCUPH

SET -JU

Page 19

Designing of Retaining Wall and Box Portion of Underpass 2014

(Passenger Car Unit per Hour). Peak Hour Flows are observed during 0900 1000

hrs. in the morning (8243 PCU) and 1800 1900 hrs. in the evening (7876 PCU).

This Junction handles more than 5500 PCU / hr. for most part of the day (0700

2200 hrs.)

Fig.4.4.2

4.4.3 Direction wise Traffic

Peak Hour Direction wise Vehicular Traffic Flow is presented in Fig. 4.2 for the

Junction of Magadi Road and Basaveshwara Nagar Road. The Major Flow is along

Magadi Road in which Current Peak Hour Flow is 4301 PCU, which amounts to

52.18% of Junction Volume.

4.4.4 Traffic Composition

Composition of Traffic (on 24 hour basis) has been observed at the Junction and is

shown in Fig. 4.3. Share of Two Wheelers is high (32.44%). The Analysis of

Composition of Vehicles in the Traffic Stream at the Junction brings out the

following.

Passenger Vehicle Category: Two Wheelers along with Car / Jeep / Taxi and

Auto constitute 68.01% while Buses account for 7.74%.

SET -JU

Page 20

Designing of Retaining Wall and Box Portion of Underpass 2014

4.5 Topographic Survey

A Comprehensive Topographic Survey has been conducted using Total Station

Equipment to accurately map the Area and obtain the Present Information on Road

Width, Adjoining Land Use, Building Offsets and Levelling Data using Auto

Level. The GTS Bench Mark has been transferred to the Site by carrying out Fly

Levelling and the Bench Marks have been established at Site. The entire Levelling

has been carried out using GTS Bench Mark. The Profiles and Levels of the Road

Network within the Study Area have been also captured by taking Longitudinal

and Cross Section Levels. The Extent of Survey has been limited to 300m on all

the Approach Arms of the Junction and the Details have been captured adequately

for Planning and Designing of Grade Separation Scheme. The Data captured are in

3D Format, which could be directly downloaded to computers and compatible for

Modern Design Softwares. The Existing Site Features collected during

Topographical Survey are enumerated in Chapter 3 Site Characteristics.

SET -JU

Page 21

Designing of Retaining Wall and Box Portion of Underpass 2014

4.6. Traffic volume survey

Table 4.6.1

Traffic Volume at the Junction of Magadi Road and Basaveshwara Nagar Road,

Bangalore(MONDAY)

Fast Moving Vehicles

Ti

m

e

Pe

rio

d

08

00

09

00

Trucks

Dire

ctio

n

Auto

Car /

Jeep

/

Taxi

Van

/

Tem

po

Min

i

Bus

377

255

159

183

174

138

106

80

Two

Whe

eler

1-2

1-3

SET -JU

Slow Moving

Vehicles

Ani

ma

O

Total

l/

t

Vehicl

Ha Cycl h

es

nd

es

e

Dr

r

aw

s

n

Total

PCU

Bus

L

C

V

HC

V

117

193

1289

1822

85

584

782

Page 22

Designing of Retaining Wall and Box Portion of Underpass 2014

09

00

10

00

10

00

11

00

11

00

12

00

12

00

13

00

2-1

2-3

3-1

3-2

Tot

al

1-2

394

298

155

373

1771

228

185

115

179

1100

249

129

93

166

902

176

98

89

174

800

147

74

61

53

537

234

0

0

1

429

3

0

1

1

8

3

1

0

0

4

0

0

0

0

0

1

0

0

0

3

0

0

0

0

0

1435

785

514

947

5554

2026

986

664

1098

7377

427

282

177

204

131

215

1447

2039

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

192

470

332

189

414

2024

154

259

196

124

202

1217

110

278

143

112

183

1003

89

196

110

99

194

892

97

150

82

68

59

587

4

261

2

0

1

483

0

4

2

2

1

14

0

3

3

0

0

8

0

0

0

0

0

0

1

2

3

2

0

12

0

0

0

0

0

0

647

1623

873

596

1054

6240

874

2262

1089

754

1225

8243

384

259

161

186

119

196

1310

1854

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

177

401

303

158

380

1803

140

232

188

117

182

1118

108

253

131

94

169

916

81

179

100

91

177

814

87

150

75

62

54

547

2

238

0

2

1

439

0

3

1

0

1

7

0

2

0

1

0

5

0

0

0

0

0

0

0

2

1

0

0

4

0

0

0

0

0

0

595

1460

799

525

964

5653

798

2060

1001

681

1117

7510

323

219

136

157

101

165

1108

1568

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

149

338

256

133

320

1519

118

196

159

99

154

945

91

214

110

80

143

774

68

151

84

76

149

685

73

126

63

52

46

461

3

201

0

0

0

369

0

2

1

0

0

6

0

1

0

0

0

3

0

0

0

0

0

0

1

2

0

0

2

7

0

0

0

0

0

0

503

1231

673

440

814

4769

674

1736

844

568

942

6332

271

183

114

132

85

139

928

1313

1-3

125

99

76

132

61

494

636

SET -JU

Page 23

Designing of Retaining Wall and Box Portion of Underpass 2014

13

00

14

00

14

00

15

00

15

00

16

00

16

00

17

00

2-1

2-3

3-1

3-2

Tot

al

1-2

284

215

112

269

1276

164

133

83

129

791

179

93

67

120

649

57

127

71

64

583

106

53

44

38

387

169

1

0

0

310

1

0

0

0

3

0

0

0

0

1

0

0

0

0

0

0

1

0

0

2

0

0

0

0

0

960

623

377

620

4002

1383

766

485

727

5312

240

162

101

117

78

128

831

1181

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

111

251

190

99

238

1129

88

146

118

74

114

702

68

159

82

59

106

575

51

112

63

57

111

511

57

98

49

40

35

357

2

155

0

1

1

287

0

1

1

0

0

4

0

1

0

0

0

2

0

0

0

0

0

0

0

1

0

0

0

3

0

0

0

0

0

0

377

924

503

330

605

3570

508

1312

633

428

703

4765

245

126

138

113

92

151

870

1227

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

111

126

249

159

289

1179

51

106

120

103

234

740

45

125

79

82

156

625

26

80

85

67

143

514

69

106

58

48

42

415

2

184

1

0

1

339

0

0

0

0

0

2

0

0

0

0

0

1

0

0

0

0

0

0

0

2

0

0

0

4

0

0

0

0

0

0

304

729

592

459

865

3819

412

1150

721

580

1078

5169

261

135

147

121

98

162

929

1312

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

119

135

266

170

309

1260

54

113

128

110

250

790

48

133

84

87

166

665

27

86

91

72

152

549

73

113

62

51

45

442

2

196

0

0

1

361

1

1

0

0

0

4

0

1

0

1

0

3

0

0

0

0

0

0

0

0

0

0

0

2

0

0

0

0

0

0

324

778

631

491

923

4076

439

1230

767

621

1151

5519

307

158

173

141

116

190

1089

1539

1-3

140

64

56

32

86

379

512

SET -JU

Page 24

Designing of Retaining Wall and Box Portion of Underpass 2014

17

00

18

00

18

00

19

00

2-1

2-3

3-1

3-2

Tot

al

1-2

158

312

199

362

1478

132

151

128

294

927

156

99

103

195

782

101

106

84

179

643

132

73

60

52

519

231

1

0

0

423

2

1

1

0

6

2

0

1

0

4

0

0

0

0

0

2

1

0

0

4

0

0

0

0

0

916

744

576

1082

4786

1446

906

728

1348

6479

352

182

199

162

133

218

1253

1769

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

160

182

358

228

416

1696

73

152

173

147

337

1064

64

179

113

118

224

897

37

116

122

96

205

738

98

152

84

69

60

596

3

265

0

0

1

487

1

1

0

2

0

7

1

2

0

1

1

6

0

0

0

0

0

0

0

0

0

2

1

6

0

0

0

0

0

0

437

1049

850

663

1245

5497

593

1659

1034

837

1552

7443

371

192

210

171

140

230

1325

1872

1-3

2-1

2-3

3-1

3-2

Tot

al

169

191

378

241

439

1789

77

160

183

156

356

1124

68

189

120

124

237

948

39

122

129

102

216

779

104

160

88

72

63

627

3

279

1

3

1

517

2

4

1

2

0

12

0

3

2

0

1

10

0

0

0

0

0

0

1

2

2

1

0

10

0

0

0

0

0

0

463

1110

904

701

1313

5816

626

1753

1101

887

1637

7876

Table 4.6.2

Traffic Volume at the Junction of Magadi Road and Basaveshwara Nagar Road,

Bangalore(TUESDAY)

Ti

m

e

Pe

rio

d

08

00

09

00

Fast Moving Vehicles

Dire

ctio

n

1-2

SET -JU

Two

Whe

eler

Auto

345

277

Car

/

Jee

p/

Tax

i

165

Trucks

Van

/

Tem

po

Min

i

Bus

170

120

Bus

L

C

V

H

C

V

180

Slow Moving

Vehicles

Ani

mal /

Cy

Ot

Han

cle her

d

s

s

Dra

wn

0

2

0

Total

Vehi

cles

Total

PCU

1264

1816

Page 25

Designing of Retaining Wall and Box Portion of Underpass 2014

09

00

10

00

10

00

11

00

11

00

12

00

12

00

13

00

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

143

401

323

143

398

1753

140

266

156

170

192

1201

111

232

135

92

150

885

78

150

104

77

192

771

88

153

82

59

59

561

3

220

0

0

2

405

0

2

0

3

0

10

0

2

2

0

0

4

0

0

0

0

0

0

0

1

0

3

0

6

0

0

0

0

0

0

563

1427

802

547

993

5596

776

2043

978

751

1159

7523

420

288

155

210

123

221

1428

2027

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

186

501

320

193

420

2040

164

268

188

136

213

1257

127

234

153

127

176

972

77

201

123

85

176

872

103

142

92

53

63

576

6

271

2

0

2

502

0

5

1

3

2

17

0

2

1

0

0

5

0

0

0

0

0

0

1

1

2

2

3

12

0

0

0

0

0

0

664

1625

882

599

1055

6253

912

2267

1103

750

1240

8299

365

244

146

186

123

178

1247

1764

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

189

378

299

168

365

1764

165

232

156

112

189

1098

123

233

165

76

134

877

101

154

123

98

176

838

88

154

88

76

70

599

2

245

0

4

2

431

0

3

0

0

2

7

0

1

0

2

0

5

0

0

0

0

0

0

1

3

2

0

2

9

0

0

0

0

0

0

669

1403

833

536

940

5628

894

2020

1019

704

1124

7524

343

222

145

143

121

176

1158

1652

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

133

354

256

144

329

1559

133

202

144

111

143

955

86

222

98

92

154

797

77

145

77

82

143

667

68

132

55

65

49

490

5

193

0

0

0

374

0

3

2

0

0

9

0

2

0

0

0

3

0

0

0

0

0

0

1

3

0

1

1

9

0

0

0

0

0

0

503

1256

632

495

819

4863

690

1761

779

647

938

6467

266

176

122

138

90

123

917

1284

SET -JU

Page 26

Designing of Retaining Wall and Box Portion of Underpass 2014

13

00

14

00

14

00

15

00

15

00

16

00

16

00

17

00

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

132

298

198

121

154

1169

101

172

142

65

132

788

64

187

99

72

111

655

143

51

132

66

72

602

56

109

54

54

43

406

2

176

1

0

0

302

0

1

0

2

0

4

0

1

0

0

0

2

0

0

0

0

0

0

0

2

1

0

1

4

0

0

0

0

0

0

498

997

627

380

513

3932

636

1437

785

480

658

5279

254

171

99

109

85

122

843

1199

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

121

234

187

109

243

1148

76

156

121

76

123

723

54

165

89

70

111

588

61

109

54

64

101

498

63

85

54

33

29

349

2

158

0

1

1

284

1

1

0

0

1

5

0

1

0

0

1

2

0

0

0

0

0

0

1

1

0

2

0

5

0

0

0

0

0

0

379

910

505

355

610

3602

503

1300

644

443

710

4799

254

133

143

121

102

143

899

1265

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

119

133

239

145

291

1181

45

98

132

98

154

660

56

112

85

91

139

626

31

76

72

75

151

526

76

111

55

54

32

430

3

179

1

0

2

328

0

0

0

0

0

2

0

0

0

0

0

1

0

0

0

0

0

0

1

1

1

0

0

3

0

0

0

0

0

0

331

710

585

463

769

3757

440

1122

724

590

891

5032

254

145

143

128

85

154

912

1281

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

123

145

221

187

293

1223

65

123

111

93

134

671

56

123

92

78

173

665

21

92

85

69

145

540

87

98

71

43

51

435

2

201

0

0

1

358

0

2

0

1

0

4

1

0

0

1

1

4

0

0

0

0

0

0

0

0

0

0

1

2

0

0

0

0

0

0

355

784

580

472

799

3902

497

1230

721

571

923

5224

312

159

165

154

121

188

1102

1555

SET -JU

Page 27

Designing of Retaining Wall and Box Portion of Underpass 2014

17

00

18

00

18

00

19

00

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

154

134

320

176

354

1450

70

123

164

131

301

948

71

159

109

111

178

793

29

123

91

92

165

654

78

141

82

51

61

534

1

222

2

0

0

413

2

2

0

2

1

8

1

0

1

1

2

6

0

0

0

0

0

0

1

2

1

0

1

6

0

0

0

0

0

0

407

906

770

564

1063

4812

535

1431

955

714

1351

6541

343

178

201

171

121

221

1240

1743

1-3

2-1

2-3

3-1

3-2

Tot

al

1-2

169

176

348

232

404

1672

65

165

182

156

321

1067

64

183

121

101

231

901

43

98

132

104

197

745

113

145

87

72

51

589

4

263

0

0

1

489

1

1

0

1

1

6

1

1

1

2

0

6

0

0

0

0

0

0

0

1

1

3

0

7

0

0

0

0

0

0

460

1033

872

671

1206

5482

625

1645

1072

856

1489

7430

356

193

198

182

151

231

1319

1884

1-3

2-1

2-3

3-1

3-2

Tot

al

181

198

178

231

419

1563

77

132

204

143

332

1081

73

199

112

133

212

927

43

131

134

98

211

799

98

153

93

65

76

636

3

281

1

2

2

520

3

3

2

2

1

13

1

3

1

0

2

10

0

0

0

0

0

0

1

3

2

1

3

13

0

0

0

0

0

0

480

1103

727

675

1258

5562

635

1709

1000

841

1580

7649

Table 4.6.3

Traffic Volume at the Junction of Magadi Road and Basaveshwara Nagar Road,

Bangalore(WEDNESDAY)

Fast Moving Vehicles

Ti

m

e

Pe

rio

d

Dir

ect

ion

08

00

12

SET -JU

Two

Wheele

r

Auto

365

265

Car

/

Jee

p/

Tax

i

134

Trucks

Van /

Tem

po

Min

i

Bus

Bus

LC

V

H

CV

178

125

193

Slow Moving

Vehicles

Ani C

mal / y

Ot

Han c

he

d

l

rs

Dra e

wn

s

0

2 0

Total

Vehicle

s

Total

PCU

1264

1819

Page 28

Designing of Retaining Wall and Box Portion of Underpass 2014

09

00

09

00

10

00

10

00

11

00

11

00

-

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

SET -JU

183

143

114

71

89

603

810

401

221

253

187

151

236

1456

2044

287

193

131

103

69

786

991

163

124

86

76

71

520

688

385

165

178

183

49

966

1095

1784

1111

896

798

554

431

5595

7446

434

272

183

198

141

213

1453

2046

189

164

121

76

88

646

874

465

265

261

211

143

264

1616

2256

340

201

139

99

88

876

1104

192

133

99

103

76

609

784

420

197

193

204

63

1081

1251

2040

1232

996

891

599

485

15

10

6281

8314

392

263

171

193

121

193

1

3

1

1339

1884

183

132

112

76

91

599

799

411

241

243

181

145

234

1458

2053

299

173

141

96

81

795

991

163

121

102

87

71

547

715

371

177

156

182

49

940

1087

1819

1107

925

815

558

434

5678

7529

322

222

143

145

97

163

1095

1550

Page 29

Designing of Retaining Wall and Box Portion of Underpass 2014

12

00

12

00

13

00

13

00

14

00

14

00

15

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

SET -JU

156

112

87

71

65

498

655

345

205

221

145

134

204

1262

1788

133

143

98

92

71

540

737

142

102

76

65

59

445

582

332

145

151

152

51

833

956

1430

929

776

670

477

372

4673

6267

265

191

121

141

91

141

954

1358

132

101

67

139

56

498

636

276

158

181

45

112

165

939

1361

221

141

88

131

61

644

804

98

89

59

79

54

380

511

251

134

131

72

41

629

749

1243

814

647

607

415

309

4044

5418

249

176

108

121

76

131

864

1227

119

93

71

63

63

412

554

243

138

163

109

101

156

913

1298

181

124

89

54

53

501

643

103

81

63

61

47

360

475

246

104

112

119

40

622

714

1141

716

606

527

380

293

3672

4912

239

132

123

120

87

154

860

1221

Page 30

Designing of Retaining Wall and Box Portion of Underpass 2014

00

15

00

16

00

16

00

17

00

17

00

18

00

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

1

2

SET -JU

109

62

51

31

78

335

468

132

90

131

69

113

187

723

1139

256

115

89

91

63

616

744

167

97

75

71

52

462

580

193

226

145

139

34

740

960

1096

722

614

521

427

347

3736

5113

254

143

154

133

101

165

952

1351

123

64

54

32

78

355

486

141

109

123

93

120

198

784

1239

253

134

78

81

54

601

738

178

103

93

75

60

510

642

303

259

172

159

51

947

1192

1252

812

674

573

464

366

4149

5648

312

163

167

153

121

187

1107

1563

134

67

61

42

91

398

542

165

143

145

97

138

229

922

1465

320

149

105

89

80

747

915

187

139

91

91

54

566

725

359

302

187

167

61

1076

1361

1477

963

756

639

545

419

4816

6572

339

192

186

149

141

215

1226

1760

Page 31

Designing of Retaining Wall and Box Portion of Underpass 2014

18

00

19

00

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

171

79

71

43

109

480

653

189

161

183

121

143

267

1067

1676

345

181

121

131

78

858

1048

238

132

123

86

71

652

809

417

321

119

199

68

1129

1431

1699

1066

803

729

610

487

5412

7376

365

201

198

178

153

234

1337

1914

171

67

76

43

109

474

634

189

171

195

112

14

272

958

1428

367

176

112

134

99

896

1102

253

143

131

91

78

700

876

446

345

243

223

67

1328

1644

1791

1103

955

781

520

514

10

1

0

5693

7598

Total

Vehicle

s

Total

PCU

1216

1688

Table 4.6.4

Fast Moving Vehicles

Ti

m

e

Pe

rio

d

08

00

09

Trucks

Dir

ect

ion

12

SET -JU

Two

Wheele

r

365

Auto

Car /

Jeep

/

Taxi

Van

/

Tem

po

Min

i

Bus

Bus

LC

V

HC

V

240

162

175

85

185

Slow Moving

Vehicles

Ani

ma

l/

Cy Ot

Ha

cle her

nd

s

s

Dr

aw

n

0

2

0

Page 32

Designing of Retaining Wall and Box Portion of Underpass 2014

00

09

00

10

00

10

00

11

00

11

00

12

00

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

1

2

SET -JU

178

145

99

75

90

589

800

405

212

250

165

135

252

1430

2011

283

178

129

102

70

762

953

160

125

101

95

72

554

726

362

170

175

183

55

948

1096

1753

1070

916

795

507

440

10

5499

7274

436

271

189

215

130

254

1507

2132

183

150

125

75

97

637

864

483

265

285

183

142

249

1616

2233

352

205

135

116

85

902

1127

193

135

119

101

65

615

780

395

205

180

180

60

1023

1204

2042

1231

1033

870

579

514

12

11

6300

8340

401

300

150

174

125

205

1364

1964

165

135

98

95

90

586

791

385

245

265

171

151

251

1475

2109

298

192

145

110

78

828

1039

165

125

92

100

70

554

724

352

175

173

185

55

944

1098

1766

1172

923

835

569

461

10

5751

7725

319

220

135

142

111

160

1093

1560

Page 33

Designing of Retaining Wall and Box Portion of Underpass 2014

12

00

13

00

13

00

14

00

14

00

15

00

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

1-

SET -JU

51

110

84

60

82

395

596

342

185

215

135

135

190

1208

1700

250

163

117

95

68

694

877

138

101

89

82

59

469

606

323

161

135

129

39

792

920

1423

940

775

643

494

356

4651

6258

255

172

115

129

70

145

892

1261

132

98

78

135

65

509

653

285

159

185

65

111

155

961

1368

201

125

93

139

62

625

775

105

85

72

69

45

379

494

272

135

121

72

39

639

753

1250

774

664

609

392

303

4005

5304

245

160

108

115

70

119

823

1151

121

90

70

55

60

401

539

240

135

165

102

92

152

890

1259

185

120

85

59

52

504

639

102

75

65

57

45

346

452

252

106

99

121

52

632

740

1145

686

592

509

371

279

3596

4780

235

151

141

38

98

145

817

1203

105

52

48

29

78

316

440

Page 34

Designing of Retaining Wall and Box Portion of Underpass 2014

15

00

16

00

16

00

17

00

17

00

18

00

3

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

12

13

SET -JU

135

117

135

85

99

195

767

1202

251

132

78

83

62

607

752

162

111

83

61

55

474

609

270

236

165

151

48

873

1103

1158

799

650

447

440

348

3854

5310

265

142

139

120

102

155

932

1319

132

55

45

28

75

341

459

140

140

130

85

104

201

802

1275

255

125

88

91

55

615

742

161

99

93

75

45

474

588

292

245

155

162

52

910

1148

1245

806

650

561

433

363

4074

5531

299

165

179

125

125

188

1087

1555

141

62

65

45

90

406

544

165

129

155

99

145

292

989

1603

322

163

109

110

78

788

969

203

131

95

85

65

583

744

365

295

186

185

55

1086

1356

1495

945

789

649

558

487

10

4939

6770

355

170

218

135

112

245

1240

1751

180

65

68

40

83

447

579

Page 35

Designing of Retaining Wall and Box Portion of Underpass 2014

18

00

19

00

21

23

31

32

Tot

al

12

13

21

23

31

32

Tot

al

175

165

190

105

145

265

1048

1663

351

172

110

125

88

846

1036

265

129

115

62

60

637

776

420

341

243

173

56

1239

1549

1746

1042

944

640

544

525

5457

7355

378

173

221

175

135

225

1319

1834

175

78

73

45

120

499

683

180

165

195

135

165

285

1134

1797

345

180

115

119

85

849

1048

263

145

120

111

65

713

878

445

349

245

232

60

1334

1647

1786

1090

969

817

630

522

17

5848

7887

Day 1

SET -JU

Page 36

Designing of Retaining Wall and Box Portion of Underpass 2014

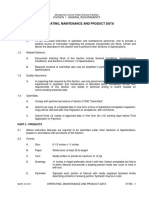

Hourly variation of traffic flow

9000

8000

7000

6000

5000

4000

Total PCU day 1

3000

2000

1000

0

0800 - 0900 - 1000 - 1100 - 1200 - 1300 - 1400 - 1500 - 1600 - 1700 - 1800 0900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900

Day-1 Hourly variation of Traffic flow(fig.4.6.1)

Day 2

Hourly variation of traffic flow

9000

8000

7000

6000

5000

4000

Total PCU day 2

3000

2000

1000

0

0800 - 0900 - 1000 - 1100 - 1200 - 1300 - 1400 - 1500 - 1600 - 1700 - 1800 0900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900

Day-2 Hourly variation of Traffic flow(fig.4.6.2)

Day 3

SET -JU

Page 37

Designing of Retaining Wall and Box Portion of Underpass 2014

Hourly variation of traffic flow

9000

8000

7000

6000

5000

4000

Total PCU day 3

3000

2000

1000

0

0800 0900 1000 1100 1200 1300 1400 1500 1600 1700 1800

0900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900

Day-2 Hourly variation of Traffic flow(fig.5)

Day 4

Hourly variation of traffic flow

9000

8000

7000

6000

5000

4000

Total PCU day 4

3000

2000

1000

0

0800 - 0900 - 1000 - 1100 - 1200 - 1300 - 1400 - 1500 - 1600 - 1700 - 1800 0900 1000 1100 1200 1300 1400 1500 1600 1700 1800 1900

Day-2 Hourly variation of Traffic flow(fig.6)

SET -JU

Page 38

Designing of Retaining Wall and Box Portion of Underpass 2014

Chapter - 5

Designing

Chapter - 5

SET -JU

Page 39

Designing of Retaining Wall and Box Portion of Underpass 2014

Design

Fig.5

5.1 Planning and Investigations

The Junction Improvement Scheme has been discussed in Detail in Chapter

6. Diversion of the Underground Services like Water, Sewer, Electricity,

etc., which will affect the Construction Activities will be programmed prior

to the Excavation Work.

5.2 General Arrangement

SET -JU

Page 40

Designing of Retaining Wall and Box Portion of Underpass 2014

Care has been taken while designing so that the structure generally fulfills

the following requirements.

The Soundness of the Structure and its Durability are of the highest

standards.

Aesthetics is in harmony with the surroundings.

Speedy and Practicable Construction.

Economy in Construction.

5.3 Design Loads

1. Live Load

Live Load has been considered as per IRC: 6 2010.

2. Seismic Force

The Underpass has been designed for the Seismic Force as per the

Provisions of IRC: 6 2010.

3. Earth Pressure

The Soil Properties for Embankment like Dry Density of Soil 1.85 t /

0

cum.; Saturated Density 2.00 t / cum.; = 30 and c = 0 have been

considered for Estimation Purpose.

Saturated Density of the Backfill (minimum 2 t / cum) has been

considered for calculating Active Earth Pressure for Estimation

Purpose.

4. Temperature Range

For Design of Structure, to account for Temperature, the following Formula

has been considered.

(DL) = Lt,

SET -JU

Page 41

Designing of Retaining Wall and Box Portion of Underpass 2014

0

The value of t shall be 17 C.

Where = Coefficient of expansion or contraction

L = Length of the member

(DL) = Expansion / Contraction due to Temperature Variation in Appropriate

Units.

The Super Structure has been designed for Effects of Distribution of Temperature

across the Deck Depth as per the relevant Codal Provisions. For Calculation,

Thermal ForceEffect (E) of 50% of the Insulation Value has been considered so

that to account for Effect of Creep on Thermal Strain.

5.4 Design of Underpass

5.4.1 General

The Length of the Underpass has been determined based on the Depth of

Deck Slab, where a minimum Vertical Clearance of 5.5m has to be provided.

By considering the Economy of the Project, Open Cut System has been

considered both for Ramp and Covered Portion of the Underpass. The

Covered Portion of the proposed Underpass has been designed as Cast in

Situ RCC Closed Box Section. For Approaches and Open Box,

Conventional RCC Retaining Structure has been adopted.

5.4.2 Foundation

a. Retaining Walls

The Retaining Walls for the Approaches have been proposed to be of RCC

appropriate with the Site Conditions. The Depth of the Foundation shall

be determined based on the Soil Investigation Report. Maximum

Settlement allowed is 10mm. Adequate Protection shall be given to

Reinforcement against Corrosion.

b. Concrete Grade

SET -JU

Page 42

Designing of Retaining Wall and Box Portion of Underpass 2014

Closed and Open Portions of the Underpass including Retaining Walls shall be

of minimum M35 Grade Ready Mix Concrete.

5.4.3 Joints

5.4.3.1 Expansion Joint

Expansion Joint in Covered and Open Portions of the Underpass has been

considered at every 30m interval and also at the Junction of Wall and Slab at

top and bottom with size 12mm X 25mm with Gun Grade Polysulphide

Elastomeric Joint Sealant over a Bitumen Pad fixed in the Joints, applying

the Joints with NITOSEAL Primer or equivalent, including Preparation of

Surface, Primer Coat, Finishing Cost of all Materials, Labour including Cost

of Bitumen Pad.

5.4.3.2 Contraction Joint

Contraction Joint will be provided along the Pavement in the Underpass as per the

Design approved by the Engineer.

5.4.4 Crash Barriers

Concrete Crash Barriers shall conform to Clause 809 of MoRT&H Specifications.

The Height of the Concrete Crash Barrier is 1000mm above the Finished Road

Level. It has been designed to resist an Impact of 30t Axle Loads.

5.4.5 Wearing Coat

Wearing Coat conforming to Clause 2702.1 of MoRT&H Specifications for

Road and Bridge Works (Latest Edition) has been provided for Smooth

Riding Surface.

5.4.6 Approach Slab

The Approach Slab conforming to Clause 2704 of MoRT&H Specifications

for Road and Bridge Works (Latest Edition) has been provided.

5.5 Durability

From the Durability Consideration, the following minimum Grades of

Concrete are to be considered for Plain Cement Concrete (PCC) and

Reinforced Cement Concrete (RCC).

a. Minimum Grade of Concrete shall be as below.

SET -JU

Page 43

Designing of Retaining Wall and Box Portion of Underpass 2014

PCC for Levelling Course M15

RCC for Open Foundation, Substructure and Superstructure M35

b. Minimum Cement Content, Diameter of Bar and Cover Requirements

For PCC and RCC, the value given below regarding minimum Cement

Content and maximum Water Cement Ratio shall be followed.

The minimum Nominal Diameter of Reinforcement is 8mm.

5.6 Drainage

Drainage of Storm Water collected in the Underpass and at Surface Level

Roads are essentially based on

IRC: SP: 42 1994 Guidelines on Road Drainage.

IRC: SP: 50 1999 Guidelines on Urban Drainage.

The Drainage Spouts conform to Clause 2705 of MoRT&H Specifications.

5.7 Traffic Signs, Markings and other Road Appurtenances

Traffic Signs, Markings and other Road Appurtenances shall conform to

Clause 800 of the MoRT&H Specifications for Road and Bridges (Latest

Edition). Road Markings shall conform to IRC: 35 1997 and Road Signs

shall confirm to IRC: 67 2012.

5.8 Medians, Kerbs and Footpaths

Medians, Kerbs and Footpaths shall conform to Clause 407, 408 and 409 of the

MoRT&H Specifications for Road and Bridges (Latest Edition).

5.9 Lighting

The Lighting within the Covered and Open Portion of Underpass, Slip Roads,

Junction at Surface Level over the Covered Portion of Underpass, etc. has been

provided as per relevant Codal Provisions. The Illumination proposed is an average

40 lux throughout.

SET -JU

Page 44

Designing of Retaining Wall and Box Portion of Underpass 2014

5.9.1 Designing of Retaining walls

What are retaining walls?

Retaining walls are soil structure systems intended to support earth back fills

Some of the types of retaining wall

Gravity retaining wall

Semi-gravity retaining wall

Cantilever retaining wall

Counterfort retaining wall

Basic Principles of Cantilever wall

Cantilever walls are made of reinforced concrete, and come in different

geometries.

Rely on their self-weight to resist sliding & overturning, but derive part of

their stability from the weight of backfill above the heel of the wall. Basic

principles of cantilever wall

SET -JU

Page 45

Designing of Retaining Wall and Box Portion of Underpass 2014

(fig 5.9.1)

SET -JU

Page 46

Designing of Retaining Wall and Box Portion of Underpass 2014

Typical dimension of Cantilever Retaining wall

(fig.5.9.2)

External stability

In analyzing or designing for external stability, all the forces acting on

the structure are considered. These forces include lateral earth pressures,

the self-weight of the structure, & the reaction from the foundation soil.

The stability of the wall is then evaluated by considering the relevant

forces for each potential failure mechanism.

The wall has to stable against

Sliding FS>1.5

Overturning FS>2.0

Bearing failure FS>1.5

SET -JU

(fig 10)

Page 47

Designing of Retaining Wall and Box Portion of Underpass 2014

SET -JU

Page 48

Designing of Retaining Wall and Box Portion of Underpass 2014

Retaining walls of Underpass

Underpass consists of eight Retaining walls and the of all the eight

Retaining walls are shown below

Designing of retaining wall R1

Problem :Density of soil =20KN/m

= 30

= 0

= 20

= 90

SET -JU

Page 49

Designing of Retaining Wall and Box Portion of Underpass 2014

SBC = 350KN/m

Ka = (1-sin)/(1+sin)=0.33

Kp = (1+sin)/(1-sin)=3

SET -JU

Page 50

Designing of Retaining Wall and Box Portion of Underpass 2014

Design constant

fck = 30 Mpa

fy = 500 Mpa

cbc =7.5(IRC 21-2000 Tab-9)

st = 200(IRC 21-2000Tab-10)

modular ratio m = 280/3cbc = 12.44

Co-efficient of N.A K= (mcbc)/(mcbc+st) =

co-efficient of Leq Arm j =1-

=1-

=0.893

co-efficient of moment of resistance R= cbc Kj

=0.5*7.5*0.318*0.893

=1.06

Stability Analysis

To calculate BM

Earth pressure

Ph= KaH

=0.5*0.33*20*(2.75)

=25KN

M=Ph*

=25*

=22.9KN-m

Surcharge pressure

Ph = KaqH

SET -JU

Page 51

Designing of Retaining Wall and Box Portion of Underpass 2014

q=1.2*20[IRC-6-2000 Cl 217.1]

= 24 KN/m

Ph= 0.33*24*2.75

= 21.78 KN

M = Ph*

= 29.94 KN-m

Total over turning movement

M = 22.9+29.94

= 52.84 KN-m

Total pressure Ph = 25+21.78

= 46.78 KN

Item

Stem

Rectangle

Triangular

Base slab

Earth filling

Above heel

Super imposed

Load

Load in

(KN)

Distance from

Toe

(m)

0.8+(0.2/2)=0.90

1*0.2*2.45*25=

12.25

(1/2)*0.1*2.45*25= 0.8+0.2+(0.1/2)=

3.0625 KN

1.05

2.5*0.3*1*25=

(2.5/2)=1.25

18.75 KN

1*1.4*2.45*20 =

0.8+0.3+(1.4/2) =

68.6 KN

1.8

1*1.4*24=

0.8+0.3+(1.4/2)=

33.6 KN

1.8

W=136.26

BM

(KN-m)

11.25

3.21

23.43

123.48

60.48

M=221.85

Check Against overturning :FOS = (MR/M)=

SET -JU

= 4.19 > 1.44(safe)

Page 52

Designing of Retaining Wall and Box Portion of Underpass 2014

Check against sliding

FOS = (/Ph) =

= 1.45 1.44(safe)

Let ((MR-M)/ =

= 1.24

Eccentricity e = (b/2)-

=

-1.24

= 0.01 <

=0.41 (ok)

max,min = (/b)[1(6c/b)]

=

[1

max = 54.78 KN/m < SBC (350 KN/m) (ok)

min = 52.21 KN/m > 0 (ok)

Design of Stem

Earth pressure Ph =

*Kah2 = 0.5*0.33*20*2.452 = 19.8 KN

MEp =19.8 *

SET -JU

= 16.1KN-m

Page 53

Designing of Retaining Wall and Box Portion of Underpass 2014

Surcharge pressure Ph = Kaqh = 0.33*24*2.45 = 19.4 KN

Msp = 19.4*

= 23.76 KN-m

Total moment = MEP+Msp

M = 16.1+23.76

= 39.86 KN-m

Mn = 39.86*1.5

= 59.79 KN-m

Check for depth

Mn = 0.138 fCK bd2

59.79*106 = 0.138*30*1000*d2

d = 120mm < 200mm (safe)

(Mn/bd2) =

*106

=2.65

Assume clear cover 50mm

D = 200mm

d= 200-50 = 150mm

From Sp-16,Table-4

Pt = 0.689

Ast =

*1000*150

= 1033.5

for #12mm

Spacing =

*1000

= 109.43 mm

Provide #12mm Spacing @ 100mm c/c

SET -JU

Page 54

Designing of Retaining Wall and Box Portion of Underpass 2014

Curtailment of Bars

Curtail by 50%

)2 = 0.5

h = 1.94 m

actual cut off = h-Ld

Ld = 50 = 50*

= 600 mm

Cutoff = 1.94-0.6

= 1.34 m From Top

Provide Spacing #12 mm @ 200 mm c/c

Distribution of Steel

Ast =

=

*b*D

*1000*200

= 300mm2

for # 8mm2 Spacing = (((8)2/4)/240) *100 = 209.44mm

Provide Spacing 38mm @200mmc/c

Check for Shear

v = (Vn/bd) =

= 0.392 N/mm2

tab 19,PP73 IS456-2000

c = 0.59 N/mm2

Hence v < c (safe)

SET -JU

Page 55

Designing of Retaining Wall and Box Portion of Underpass 2014

Design of Toe Slab

M1 = [0.8*0.3*1*25]

(self Wt)

M2 = [0.8*53.95*1]

(moment clue to upward

pressure)

M3 = [ *0.8*0.83*1]

(moment clue to upward pressure)

[M]=15.03 KN-m

Mn = 15.03*1.5 = 22.54 KN-m

SET -JU

Page 56

Designing of Retaining Wall and Box Portion of Underpass 2014

*106 = 0.36

from Sp-16

Pt = 0.0842

Ast =

= 210.5 mm2

for # 10mm spacing =

*102*1000

Hence provide spacing # 10@ 190 mmc/c

Distribution of Steel

Ast =

*1000*300 = 360 mm2

Spacing for #10mm =

*102 = 218 mm

Provide spacing # 10 @ 200mm c/c

Check for shear :

v = (Vn/bd)

Vu = [(0.8*0.3*1*25)-(0.8*53.95*1)+(0.5*0.8*0.83)]

= 56.25 KN

v =

*103 = 0.22 N/mm2

=

c = 0.29 (IS456-2000,PP73)

Hence u < c (safe)

Design of Heel slab

SET -JU

Page 57

Designing of Retaining Wall and Box Portion of Underpass 2014

M1= 1.4*52.1

Upward pressure

M2=

Upward pressure

M3= 1.4*0.3*25

Soil over Burden pressure

M4= 1.4*2.45*20

Self wt

M5=1.4*24*

Surcharge load

*1.4*1.43

64.77 KN-m

M = 64.77 KN-m

(M2/bd2)=

*106 = 1.55

from Sp-16 Pt = 0.381

SET -JU

Page 58

Designing of Retaining Wall and Box Portion of Underpass 2014

Ast =

*1000*250

= 952.5 mm2

Spacing for #10mm =

*1000

= 82.41 mm

provide spacing #10 @ 75 mm c/c

Distribution of Steel

Ast =

*1000*300

Ast = 360 mm2

Spacing for Shear :

*103=0.23 N/mm2

v = (vn/bd)=

=

as per PP- 73, IS456-2000

c = 0.458

v < c

(safe)

Designing of retaining wall R2

Density of soil =20KN/m

= 30

= 0

= 20

SET -JU

Page 59

Designing of Retaining Wall and Box Portion of Underpass 2014

= 90

SBC = 350KN/m

Ka = (1-sin)/(1+sin)=0.33

Kp = (1+sin)/(1-sin)=3

Design constant

fck = 30 Mpa

fy = 500 Mpa

cbc =7.5(IRC 21-2000 Tab-9)

st = 200(IRC 21-2000Tab-10)

modular ratio m = 280/3cbc = 12.44

Co-efficient of N.A K= (mcbc)/(mcbc+st) =

SET -JU

Page 60

Designing of Retaining Wall and Box Portion of Underpass 2014

co-efficient of Leq Arm j =1-

=1-

=0.893

co-efficient of moment of resistance R= cbc Kj

=0.5*7.5*0.318*0.893

=1.06

Stability Analysis

To calculate BM

Earth pressure

Ph= KaH

=0.5*0.33*20*(3.75)