Icramid 11126

Diunggah oleh

Arun KumarJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Icramid 11126

Diunggah oleh

Arun KumarHak Cipta:

Format Tersedia

International Conference on Recent Advances in Mechanical Engineering and Interdisciplinary Developments [ICRAMID - 2014]

Design And Analysis Of Cooling Cabinet For

Vaccine Storage

N.Saravanan*,

Assistant Professor

,Dept. ofMechanical Engineering,

University College of Engineering,Nagercoil

Campus.

saravananenn@yahoo.com

V.Ananchasivan

Assistant professor,

Dept. of Mechanical Engineering,

Ponjesly college of Engineering.Nagercoil

ananth.kadukkarai@gmail.com

The impact of solar intensity on performance of the

Abstract

Solar

powered

adsorption

system is significant. The cooling cabinet model is

refrigeration

completely analysied for varies capacity and it is able

system is renewable source in the future energy

to calculate the cooling cabinet coil length .The

demands and more useful for off-grid area. In this

designed mathematical model is analyzed by the use

paper a mathematical model was developed to

of coolpack software and the results are compared

investigate the performance of a cooling cabinet of

with ansys software. It is observed that the system

aactivated carbon-ammonia adsorption refrigeration

operate more efficient while maximum solar intensity

system, and a new effective method about the

and the cooling effect.

refrigeration studies. A brief thermodynamic study of

the cooling cabinet is carried out and the effect of

Key

words:

Solar,

Adsorption

Refrigeration,

operating parameters such as temperature, pressure,

Mathematical model, Analysis, Solar intensity.

cooling effect of the system is numerically analyzed.

energy can be converted to both high grade and low

1.Introduction

grade either of which can be used to power

The Electrical Energy supply to refrigeration

refrigeration systems. The idea is not new, a solar-

and air-conditioning systems constitutes aimportant

driven refrigerator was first recorded in Paris in 1872

role in the world. The International Institute of

by AlbelPifre (Thvenot, 1979)[2].

Refrigeration (IIR) has calculate that approximately

A solar boiler was used to supply heat to a

15% of all electricity produced across the wrold is

absorption machine, producing a small amount of ice.

used for refrigeration and air-conditioning processes.

Later, solar powered refrigeration systems have been

According to the survey of International Institute of

installed in many countries across the world.e.g.

Refrigeration the demand for refrigeration worldwide

Australia, Spain, and the USA. Most are powered by

has the fundamental tendency is increases (IIR,

thermal energy absorption systems, designed for air-

2006)[1]. The global growth rate is about 17%.The

conditioning purposes. Being provided with a good

cooling effect is generally high when solar radiation

electricity grid worldwide, people are, however, more

is high. Together with existing technologies[3], solar

likely

ISBN 978-93-80609-17-1

1599

to

choose

vapour

compression

air-

International Conference on Recent Advances in Mechanical Engineering and Interdisciplinary Developments [ICRAMID - 2014]

conditioning system. Before the energy crisis in the

by 50 mm Energylite, and covered by 3 mm white

1970s[4], research and development on solar thermal

Perspex sheet at the inside and outside. The

driven refrigeration systems was notably reduced.

dimensions are based on required capacity, material,

Subsequently, electricity-driven vapour compression

and economical use of materials.

systems have played a significant role on the market.

3.Cabinet specifications for six litres capacity.

At that time, photovoltaic (PV) technology was

expensive, had low efficiency and was not as widely

available as today.but the solar sysem give the

following advantages[5,6]

(i) It is an eco-friendly system

(ii) Suitable for off-grid areas

(iii)Running cost is low

Interior dimensions

deep.

:0.2 m x 0.1 m x 0.3 m

Usable capacity

: 6litres.

Exterior dimensions

high.

: 0.3 m x 0.2 m x 0.4 m

Cabinet construction

: 3 mm Perspex sheeting

Insulation

: 50 mm thick Energylite

cool the six liters of water from 30 oC to 5 oC, heat

removed (Qev) is given by:

Nagercoil region is the very cloudy in Kanyakumari

district,and some places in nagercoil region it is very

(i)

difficult to prevent the vaccine because of no

Qev

electricity.So in this the solar power vaccine storage

Qev

= Mw x Cpw x (Ti T0)

= 6 x 4.19 x (30 5)103

= 6.29105 J

system is preferred.

Qrefr= 0.087103 +2.3105 + 6.29105

2.Design of system components

= 8.59105J

Qref= hcon .A. (Tat Tevap),

A cooling cabinet is a refrigerated space

where evaporation of water vapour and refrigeration

19.89

effect takesplace. A well-insulated rectangular type

cabinet was chosen to save the cooling coil length

and and simplifythe design. The cabinet is design for

varieslitre containers and to avoidtoo much change of

temperature during the day. The cabinet is insulated

ISBN 978-93-80609-17-1

1600

= 9.66A (30-5)

= DL

0.082

= 0.00635L

= 4.1285 m

(ii)

International Conference on Recent Advances in Mechanical Engineering and Interdisciplinary Developments [ICRAMID - 2014]

Fig 1: Design of cooling cabinet using Pro-E software.

Table 1: Cooling effect for different Evaporator Temperature

Month & Date

July(1-15)

July(16-31)

Aug(1-15)

Aug(16-31)

Sep(1-15)

Sep(16-31)

Imont

h

Tin

Tout

Tout

Tout

Qe

J(6*4.2

)

Qe

J(6*4.2

)

Qe

J(6*4.

2)

689

28

604.8

579.6

554.4

692

29

630

604.8

579.6

700

30

655.2

630

604.8

710

31

680.4

655.2

630

732

32

705.6

680.4

655.2

744

33

730.8

705.6

680.4

Table 2: Cooling effect for various capacity of cooling cabinet

Mass(Kg)

6

12

18

24

30

36

42

48

54

60

Cp

4.2

4.2

4.2

4.2

4.2

4.2

4.2

4.2

4.2

4.2

Ti

30

30

30

30

30

30

30

30

30

30

ISBN 978-93-80609-17-1

1601

To

5

5

5

5

5

5

5

5

5

5

Qevp

630

1257

1890

2520

3150

3780

4410

5040

5670

6300

International Conference on Recent Advances in Mechanical Engineering and Interdisciplinary Developments [ICRAMID - 2014]

4. Analysis of the system using ansys software

Fig 2: Meshing of cooling cabinet

Fig 3: Temperature profile of colling cabinet

Fig 4: Pressure profile of the cooling cabinet

ISBN 978-93-80609-17-1

1602

International Conference on Recent Advances in Mechanical Engineering and Interdisciplinary Developments [ICRAMID - 2014]

Fig 5: Velocity profile of the cooling cabinet

Table 3: Cooling effect obtained from Ansys readings:

Month & Date

Max(I

month)

July(1-15)

July(16-31)

Aug(1-15)

Aug(16-31)

Sep(1-15)

Sep(16-31)

689

692

700

710

732

744

Evaporator

Temperature in C

ITotal

(KJ)

2138

2147

2172

2203

2271

2308

Tin

22

Tout

23

24

23

23

24

refrigeration

5.Results& Discussions

Qref

(KJ)

38

38

40

40

41

43

decreases

420

450

480

510

540

570

while

224

the

evaporator

temperature decreases. The required total heat is

The calculations of the study has been given

decreases

in Chapter 3. In the each case, some optimal values

while the evaporation temperature is

increases. In the below graph 1 shows that the

had been used as initial parameters and only one

cooling effect of the system is increases with the

parameter has been varied for analyzing dependence

increase of the solar irradiance. It shows that the solar

of each parameter on performance of system.In table

intensity is gradually increases in the period of

1 different evaporator temperature was analyzed for

8.00am to 12.00 and gradually decreases in the

the performance of the system . Changing the

period of 12.00 to 16.00pm,when the solar intensity

evaporation temperature means, changing the cooled

is increases the Cooling effect of the system is

zones temperature. It shows that the cooling effect of

increases, if the solar intensity is decreases the

refrigeration is increases With the increases of

Cooling effect of the system is decreases

evaporator temperature, and the cooling effect of the

ISBN 978-93-80609-17-1

1603

International Conference on Recent Advances in Mechanical Engineering and Interdisciplinary Developments [ICRAMID - 2014]

Graph 1: Time Vs Solar intensity

variation in Air mean temperature and solar

1000

irradiance is shown in graphs 1 . The performance of

100

the optimized system at Nagercoil during September

800

is shown in graph. From the graph the performance

80

of the system is increases with the increases of solar

600

intensity

Bed

400

Ambient

Graph 2: Mass of water Vs Cooling effect

200

TemperatureC

60

40

20

0

5

10

15

20

25

30

Time of the day in hr

35

80

-200

Mass of water

-20

Solar intensity W/m2

120

60

Mass Vs

Cooling effect

40

20

Linear (Mass

Vs Cooling

effect)

And in table 2 shows the various cooling

cbinet capacity and the corresponding cooling effect

5000

10000

Cooling effect

and plot the result in graph 2..In chapter 4 the ansys

software was used to analyzed of the system in the

fig1,2,3,4,5, The different evaporator temperature

was analyzed for the performance of the system .

Changing

the

evaporation

temperature

6.Conclusion

means,

The main energy consumption are made of

changing the cooled zones temperature. It shows that

from

the Cooling effect of refrigeration is increases With

transportation areas. The use of energy in an

the increases of evaporator temperature, and the

economical and efficient way is getting so much

cooling effect of the refrigeration decreases while the

importance in our days with decreasing energy

evaporator temperature decreases. The required total

sources and increasing air pollution. Because of these

heat is decreases while the evaporation temperature

conditions the renewable energy sources are getting

is increases. Below graph shows the change of the

so much importance. The solar energy is one of the

and Qevp with respect to the different evaporator

most important energy source. A cooling and also a

temperature

heating unit which is driven by solar power in

.solar

intensity.Andshows

the

industry,

from

residences

and

from

comparision of the cooilng effect of the system

residences

obtained by the mathematical calculation, coolpack

transportation vehicles within a more applicable way

software and ansys software with the solar intensity

is going to be so economical and environmental

for the same initial conditions. The Unsteady analysis

conditions.The initial investment of these types of

was carried out form data collected from the source

systems may occur much expensive than classical

www.weatheranalysis.com for

Nagercoil Sensor

vapour compression refrigeration system . But in

461975:Elev(m) 49.0: Lat/Long (8.273, 76.875). The

progressive with the effect of a very little dependence

ISBN 978-93-80609-17-1

1604

or

in

industry

further

more

in

International Conference on Recent Advances in Mechanical Engineering and Interdisciplinary Developments [ICRAMID - 2014]

of electricity (can be neglected).. The performance

values are also so small with respect to the classical

ways of cooling.

In this project,

adsorption

refrigerator thermodynamic analyses have been done.

And the results are checkedwith the help of Ansys

software. Finally conclude the solar adsorption

system is used for remote off-grid area and this

system is environmental friendly.

7.Reference

[1].

RUTHVEN,

D. M. 1984.

Principles of

adsorption and adsorption processes. New York::

John Wiley & Sons

[2] .TCHERNEV, D. I. 1978. Natural zeolites:

Occurrence properties and use. London: Pergamon

Press.

[3].

DUPONT,

M.,

GUILLEMINOT,

J.

J.,

MENUIER, F., & NGUYEN, P. 1982. Study of solar

ice conservators using day night intermittent zeolite

13Xwater cycle in temperate and tropical climates.

Paper presented at the International Institute of

Refrigeration.

[4]. GRENIER, P. H., GUILLEMINOT, J. J.,

MESTER, M., MEUNIER, F., & PONS, M. 1983.

Experimental Results on a 12 m3 Solar Powered

Cold Store using the intermittent Zeolite 13X + H2O

Cycle. Perth.

[5]. PONS, M., & GUILLEMINOT, J. J. 1986.

Design of an experimental solar-powered, solidadsorption ice maker. Journal of Solar Energy

Engineering,

108,

332337.

MEDINI,

N.,

MARMOTTANT, B., EL GOLLI, S., & GRENIER,

P. H. 1991. Study of a package solar ice maker

International Journal of Refrigeration, 14(6), 363-367

[6]. HAJJI, A., & KHALLOUFI, S. 1995. Theoretical

and Experimental investigation of a constant-pressure

adsorption process.International Journal of mass

transfer, 38(18), 3349-3358.

ISBN 978-93-80609-17-1

1605

Anda mungkin juga menyukai

- Development of Asbestos - Free Brake Pad Using BagasseDokumen7 halamanDevelopment of Asbestos - Free Brake Pad Using BagasseArun KumarBelum ada peringkat

- EPSRC Thermal Management Sheffield Progress Report July 2010Dokumen76 halamanEPSRC Thermal Management Sheffield Progress Report July 2010Junaid MugholBelum ada peringkat

- 2010 03Dokumen288 halaman2010 03Shijumon KpBelum ada peringkat

- Corrosion Resistance Through The Application of Anti-Corrosion Coatings PDFDokumen30 halamanCorrosion Resistance Through The Application of Anti-Corrosion Coatings PDFCemalOlgunÇağlayanBelum ada peringkat

- High Tensile Steel 4340Dokumen2 halamanHigh Tensile Steel 4340Arun KumarBelum ada peringkat

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)

- Leaflet US5Ge ProtectedDokumen3 halamanLeaflet US5Ge Protectedquochung0606Belum ada peringkat

- MclogitDokumen19 halamanMclogitkyotopinheiroBelum ada peringkat

- Domain Controllers and Active DirectoryDokumen121 halamanDomain Controllers and Active Directoryjamesmcd05100% (1)

- BX Tuner ManualDokumen4 halamanBX Tuner ManualdanielthemanBelum ada peringkat

- ANEP-25 (Environmental Factors For Surface Ships)Dokumen81 halamanANEP-25 (Environmental Factors For Surface Ships)Bahadır HarmancıBelum ada peringkat

- Terminal - Exam - Section 4A-4B - Signal & System FA14 COMSATDokumen3 halamanTerminal - Exam - Section 4A-4B - Signal & System FA14 COMSATAli RazaBelum ada peringkat

- SAP Material Management MRP Mechanics MRP Type "VB" Re-Order PointDokumen15 halamanSAP Material Management MRP Mechanics MRP Type "VB" Re-Order PointmohhitBelum ada peringkat

- 08L76 HR3 A21Dokumen6 halaman08L76 HR3 A21liebofreakBelum ada peringkat

- Report For Neha Lem ArchitectureDokumen17 halamanReport For Neha Lem ArchitecturewafasaBelum ada peringkat

- Eminence Deltalite II 2515Dokumen1 halamanEminence Deltalite II 2515Suto BandBelum ada peringkat

- Arun Et al-2019-ChemistrySelectDokumen8 halamanArun Et al-2019-ChemistrySelectRavi Kumar ARunBelum ada peringkat

- Commodity Sourcing Strategy ProjectDokumen5 halamanCommodity Sourcing Strategy ProjectMohit TalwarBelum ada peringkat

- 200+ Network Management Tools - Open Source, Free and Commercial SoftwareDokumen29 halaman200+ Network Management Tools - Open Source, Free and Commercial SoftwarenscintaBelum ada peringkat

- Poly BoreDokumen2 halamanPoly BoreMarian OpreaBelum ada peringkat

- BPQ REV. 0 Interactive FormDokumen2 halamanBPQ REV. 0 Interactive FormcosmicbunnyBelum ada peringkat

- Patrick C Hall@yahoo - com-TruthfinderReportDokumen13 halamanPatrick C Hall@yahoo - com-TruthfinderReportsmithsmithsmithsmithsmithBelum ada peringkat

- GCC TutorialDokumen4 halamanGCC Tutorialistanbulizma5803100% (5)

- Email Id of Controllers PDFDokumen10 halamanEmail Id of Controllers PDFAbhishek KumarBelum ada peringkat

- cHIPSET AND CONTROLLERDokumen9 halamancHIPSET AND CONTROLLERMelody MwhengwereBelum ada peringkat

- InfoWorks ICM Overview 60 Mins PDFDokumen31 halamanInfoWorks ICM Overview 60 Mins PDFAnonymous lyVIwA60% (2)

- Confined Spaces: Avoiding Common Mistakes in Gas DetectionDokumen1 halamanConfined Spaces: Avoiding Common Mistakes in Gas Detectiontrravi1983Belum ada peringkat

- Data Structures and Algorithms: (CS210/ESO207/ESO211)Dokumen24 halamanData Structures and Algorithms: (CS210/ESO207/ESO211)Moazzam HussainBelum ada peringkat

- Indonesia's First Maritime Service Solution Provider: Company ProfileDokumen10 halamanIndonesia's First Maritime Service Solution Provider: Company Profilemuh_akbar2451Belum ada peringkat

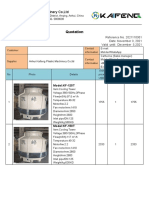

- KAIFENG Quotation For 150T Cooling TowerDokumen13 halamanKAIFENG Quotation For 150T Cooling TowerEslam A. FahmyBelum ada peringkat

- Network Management Card - Installation Manual - EngDokumen30 halamanNetwork Management Card - Installation Manual - EngZunaira ShafiBelum ada peringkat

- Implementing The IBM Storwize V7000 V6.3: Front CoverDokumen630 halamanImplementing The IBM Storwize V7000 V6.3: Front CoverMimiLakicBelum ada peringkat

- Lab - 17-WAN ConfigurationDokumen12 halamanLab - 17-WAN ConfigurationMuhammad Asghar Khan100% (1)

- Accounts Payable by ORACLEUGDokumen164 halamanAccounts Payable by ORACLEUGPraveenReddyBBelum ada peringkat

- 2019 02 01 Racecar EngineeringDokumen100 halaman2019 02 01 Racecar EngineeringGregory Aguilera LopesBelum ada peringkat