Sterile Air and Steam Filtration with (P)-GSL N Elements

Diunggah oleh

bmsengineeringJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Sterile Air and Steam Filtration with (P)-GSL N Elements

Diunggah oleh

bmsengineeringHak Cipta:

Format Tersedia

Process Filtration

From Pure to Sterile

(P)-GSL N

MAIN FEATURES & BENEFITS:

High dirt holding capacity at low differential

pressure and high flow rate

Regenerable by Back-flushing or

ultrasonication

For the filtration of air, gas & steam

Down to 0,01 m in saturated steam

Approved for Food Contact Use acc. to CFR

Title 21 & 1935/2004/EC

INDUSTRIES:

Dairy

Food & Beverage Industry

Fermentation

Pharmaceutical Industry

Chemical Industry

Donaldson Filtration Deutschland GmbH

Bssingstr. 1

42781 Haan

Germany

Web: www.donaldson.com

(P)-GSL N

Sterile Air, Steam & Liquid Filtration

PRODUCT DESCRIPTION

The (P)-GSL N filter consists of a regenerable

Typical applications for (P)-GSL N

pleated stainless steel filter matrix in a stainless

filter elements include:

steel cartridge. The retention rate extends from 1

m to 25 m.

Steam Filtration

The (P)-GSL N filter retains contaminants, such as

particles, abrasion of valves and sealings as well

as rust. An improved steam quality ensures longer

service life of the filters to be sterilized and

increases the efficiency of the entire process. The

(P)-GSL N filter element offers the possibility of a

particularly economic filtration, since the filter

medium can be regenerated by ultrasonic bath or

Breweries

Chemical industry

Pharmaceutical industry

Food and beverage

Aseptic packaging

Electronic industry

Dairy industry

Plastic industry

by back-flushing. This is especially essential at

high particle loads. The pleated stainless steel

Gas Filtration

filter matrix ensures a very low differential

Compressed air

pressure even at high contamination loads.

Carbon dioxide

Nitrogen

Tank Ventilation

Highly aggressive gases

The heavy-duty construction of the (P)-GSL N

filter is designed to withstand a maximum

differential pressure up to 10 bar. The filter may

also be used in a temperature range of 20C up

to 210C for the filtration of air, gases or liquids.

All components of the version with welded end

caps meet the USA requirements for Food

Contact Use in accordance with CFR (Code of

Federal Regulations) Title 21 and the EU

requirements for Food Contact use according to

EC/1935/2004.

manufactured

The

in

filter

element

accordance

with

is

the

manufacturing requirements, has no migration of

filter media and is non-fibre releasing.

-2-

PRODUCT DESCRIPTION

(P)-GSL N

Sterile Air, Steam & Liquid Filtration

PRODUCT SPECIFICATIONS

Product Specification

0,18 m2 per 250 mm element (10/30)

Filtration Surface*

For other element sizes see correction factor CF in

section Available end cap configurations

-20C (-68F) to 210C (410F)

Temperature Range

> 150C (300F) special O-rings are required

Maximum Differential Pressure

10 bar (75 psid), independent of the system pressure or

temperature

(Flow Direction: Outside to

Inside)

RETENTION RATES

Retention Rates (Air, 20 C, 90 Nm3/h, 10/30 Element)

Pore Size [m]

1

5

25

98 % [m]

0,1

1

15

>99,9 % [m]

<1

<5

25m

Thickness [mm]

0,37

0,35

0,17

Retention Rates (Saturated Steam, 121C, 90 kg/h, 10/30 Element)

Pore Size [m]

1

5

25

98 % [m]

0,1

1

15

>99,9 % [m]

<1

<5

25m

Thickness [mm]

0,37

0,35

0,17

Fractional Efficiency (P)-GSL N, 1m, Air / Saturated Steam

Fractional Efficiency [%]

Pore Size

[m]

0,01 m

0,07 m

0,1 m

0,2 m

0,3 m

0,4m

99,99

99,65

98,69

99,08

99,49

99,74

-3-

PRODUCT SPECIFICATIONS & RETENTION RATES

(P)-GSL N

Sterile Air, Steam & Liquid Filtration

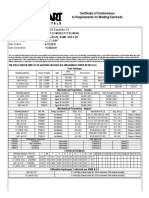

MATERIAL COMPLIANCE USA

All components of the (P)-GSL N filter element are FDA listed for food contact use in the Code of

Federal Regulations (CFR), Title 21.

Filter Materials

CFR Title

Filter Matrix:

Stainless Steel 1.4301

211.65

Support:

Stainless Steel 1.4301

211.65

End Caps:

Stainless Steel 1.4301

211.65

O-Rings:

EPDM

177.2600

Alternatively:

Fluoraz

177.2600

Silicone

177.2600

Buna

177.2600

EPR

177.2600

PTFE over silicone

177.1550

PTFE over viton

177.1550

All products have been inspected and

released by Quality Assurance as having

met the following requirements:

All filters are fabricated without the use of

All filter components based on plastics

binders, adhesives, additives or surface-

are non-toxic and are certified bio-safe in

active agents.

accordance with current USP Class VI

Tests for Plastic.

MATERIAL COMPLIANCE EU

The Donaldson (P)-GSL N filter element meets

For specific details on the O-rings, please

the guideline for Food Contact Use as given in

contact your Donaldson Sales Engineer.

European Regulation 1935/2004/EC.

-4-

MATERIAL COMPLIANCE

(P)-GSL N

Sterile Air, Steam & Liquid Filtration

FLOW CHARACTERISTICS

(P)-GSL N, 10/30, air,

Initial Diff. Pressure [mbar]

30

1 m

25

20 C,

1 bar absolute

20

15

5 m

10

25 m

5

0

0

20

40

60

80

100

120

Flow [Nm3/h]

(P)-GSL N, 10/30,

Initial Diff. Pressure [mbar]

30

saturated steam, 121 C,

1 m

25

2 bar absolute

20

15

5 m

25 m

10

5

0

0

20

40

60

Steam Flow [kg/h]

-5-

FLOW CHARACTERISTICS

80

100

120

(P)-GSL N

Sterile Air, Steam & Liquid Filtration

AVAILABLE END CAP CONFIGURATIONS

Dimensions (CODE 7 connection):

b

Size

5

10

20

30

mm

128

255

498

744

CODE 7

a

b

inch

mm

inch

5,04

150

5,91

10,04 277 10,91

19,61 520 20,47

29,29 766 30,16

c

mm

51

51

51

51

inch

2

2

2

2

CODE 7: 2 x 226 o-rings, bayonet 2 locking tabs,

locating fin

Dimensions (uf plug connection):

Size

03/10

04/10

04/20

05/20

07/20

03/30

05/30

07/30

10/30

15/30

20/30

30/30

10/50

a

mm

76

104

104

128

180

76

128

180

254

381

508

762

254

uf plug Connection

b

C*

CF**

inch mm inch mm inch

2,99 87

3,42

30 1,18 0,17

4,09 115 4,53

30 1,18 0,26

4,09 118 4,64

37 1,46 0,26

5,04 144 5,67

37 1,46 0,35

4,25 194 7,64

37 1,46 0,52

2,99 92

3,62

61 2,40 0,21

5,04 144 5,67

61 2,40 0,44

7,08 196 7,71

61 2,40 0,67

10 270 10,63 61 2,40 1,00

15 397 15,63 61 2,40 1,57

20 524 20,63 61 2,40 2,13

30 778 30,63 61 2,40 3,27

10 270 10,63 84 3,31 1,45

b

a

* Plug-type connection with double o-ring

** Correction factor Filtration surface & Flow rate

Technical alterations reserved 04/2009

For information on integrity test equipment or integrity test services,

please contact your Donaldson Sales Engineer and visit our website at

www.donaldson.com!

(Rev03 12/11)

Anda mungkin juga menyukai

- 014.070 EN - Donaldson (P) - GSL N Brochure Gas and SteamDokumen6 halaman014.070 EN - Donaldson (P) - GSL N Brochure Gas and SteamNg MeriedBelum ada peringkat

- Process Filtration From Pure To Sterile: (P) - GS VEDokumen6 halamanProcess Filtration From Pure To Sterile: (P) - GS VEYing Kei ChanBelum ada peringkat

- (P) SRFDokumen6 halaman(P) SRFYing Kei ChanBelum ada peringkat

- Sterile Air: Compressed Air & Process FiltrationDokumen8 halamanSterile Air: Compressed Air & Process Filtrationjonh366Belum ada peringkat

- GDS134Dokumen4 halamanGDS134Saurabh VermaBelum ada peringkat

- P-SRF N: Process Sterile Air Filter ElementsDokumen8 halamanP-SRF N: Process Sterile Air Filter ElementsDavid MartinBelum ada peringkat

- Pall Dia-Schumalith N: Ceramic Membrane Filter ElementsDokumen2 halamanPall Dia-Schumalith N: Ceramic Membrane Filter Elementspmg83Belum ada peringkat

- Filtros Sealkeen Emflon IIDokumen2 halamanFiltros Sealkeen Emflon IItheflamebearerBelum ada peringkat

- OMEGA AIR - Process and Sterile Filtration - EnglishDokumen12 halamanOMEGA AIR - Process and Sterile Filtration - EnglishOMEGA AIR d.o.o. LjubljanaBelum ada peringkat

- Compressed Air-Quality Optimisation For Pneumatic Control SystemDokumen19 halamanCompressed Air-Quality Optimisation For Pneumatic Control Systemupendra35Belum ada peringkat

- P-SRF N: Process Sterile Air Filter ElementsDokumen6 halamanP-SRF N: Process Sterile Air Filter ElementsParis AnabelBelum ada peringkat

- Select the Right Gas and Air Filter for Your ApplicationDokumen8 halamanSelect the Right Gas and Air Filter for Your ApplicationJulio OrtegaBelum ada peringkat

- Filtro de AireDokumen7 halamanFiltro de AirejlfyBelum ada peringkat

- Filter Od Aktivnog UgljaDokumen4 halamanFilter Od Aktivnog Ugljadragecc1Belum ada peringkat

- Micro FilterDokumen41 halamanMicro Filtermaxi1997Belum ada peringkat

- Breathers Mar 20 06Dokumen8 halamanBreathers Mar 20 06DANIZACHBelum ada peringkat

- Petrogas Filtration CatalogueDokumen12 halamanPetrogas Filtration Catalogueleandroperao5374Belum ada peringkat

- Zytel-All in One Extrusion ProcessesDokumen10 halamanZytel-All in One Extrusion ProcessesYiğit IlgazBelum ada peringkat

- PND1000-3 Stainless Steel FRLDokumen9 halamanPND1000-3 Stainless Steel FRLPartsGopher.comBelum ada peringkat

- Ultrapoly PE: The Prefilter For The Removal of Solid Contaminants in Gases With Absolute Retention EfficiencyDokumen2 halamanUltrapoly PE: The Prefilter For The Removal of Solid Contaminants in Gases With Absolute Retention EfficiencyDefenceDogBelum ada peringkat

- TF4 Mar 20 06Dokumen6 halamanTF4 Mar 20 06DANIZACHBelum ada peringkat

- HDP Pipe and Fittings CatalougeDokumen64 halamanHDP Pipe and Fittings CatalougeThiruvengadamBelum ada peringkat

- Filter ElementsDokumen8 halamanFilter ElementsSheikh ZakirBelum ada peringkat

- Coalescers ZM E25Dokumen2 halamanCoalescers ZM E25abaskmBelum ada peringkat

- TM CatalogDokumen58 halamanTM CataloghacenescribdBelum ada peringkat

- 049967Dokumen2 halaman049967Abu AlifBelum ada peringkat

- AB Emflon PFRDokumen2 halamanAB Emflon PFRsaulookBelum ada peringkat

- Filter Elements For Liquid Filters enDokumen22 halamanFilter Elements For Liquid Filters enTony Tony TonyBelum ada peringkat

- Total Quality Air Package: Atlas CopcoDokumen8 halamanTotal Quality Air Package: Atlas CopcoCastillo PercyBelum ada peringkat

- 41-60pages From Camfil Farr Product Catalog - Product - Catalogue - 2008 - En-Gb-3 PDFDokumen20 halaman41-60pages From Camfil Farr Product Catalog - Product - Catalogue - 2008 - En-Gb-3 PDFali_irvBelum ada peringkat

- General Product - Ultrafilter IndonesiaDokumen17 halamanGeneral Product - Ultrafilter IndonesiaYogi HandaruBelum ada peringkat

- SVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical InformationDokumen5 halamanSVL488 Stainless Steel Safety Valve For Clean Service Applications-Technical Informationhippong niswantoroBelum ada peringkat

- Duplex Filters Lube-Fuel OilDokumen10 halamanDuplex Filters Lube-Fuel Oilv_emmeBelum ada peringkat

- Nitrogen N-5050 FillingDokumen2 halamanNitrogen N-5050 FillingApriyan Tri KusumaBelum ada peringkat

- Compressed Air Treatment, Drier and StorageDokumen24 halamanCompressed Air Treatment, Drier and StorageAna PrisacariuBelum ada peringkat

- Filters - EPE PDFDokumen8 halamanFilters - EPE PDFSyed Mujtaba Ali BukhariBelum ada peringkat

- Donaldson FiltrationDokumen4 halamanDonaldson FiltrationLawrence AumillerBelum ada peringkat

- S 28AT XP EXP EngDokumen6 halamanS 28AT XP EXP EngpramodtryBelum ada peringkat

- ALG AAndingsluft SystemDokumen3 halamanALG AAndingsluft SystemDenim BeširovićBelum ada peringkat

- Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDDokumen11 halamanInline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLD Inline Filter RFLDAllan ArraisBelum ada peringkat

- 61482Dokumen2 halaman61482Izali NizarBelum ada peringkat

- Flat &pecsDokumen3 halamanFlat &pecsRachmi AdnitaBelum ada peringkat

- Edu251 401Dokumen2 halamanEdu251 401ckmuneesBelum ada peringkat

- Ultrapoly PE: The Prefilter For The Removal of Solid Contaminants in GasesDokumen2 halamanUltrapoly PE: The Prefilter For The Removal of Solid Contaminants in GasesYing Kei ChanBelum ada peringkat

- En Nex AirlineDokumen52 halamanEn Nex AirlineJoão SilvaBelum ada peringkat

- Pushin Fitting PDFDokumen4 halamanPushin Fitting PDFvishal.nithamBelum ada peringkat

- Tygon TubingDokumen23 halamanTygon TubingRip_BarBelum ada peringkat

- TD Pmo 6000 en 080108Dokumen16 halamanTD Pmo 6000 en 080108Ricardo DávilaBelum ada peringkat

- G2 to G4 Fan Coil FiltersDokumen1 halamanG2 to G4 Fan Coil FiltersGayashan KulathungaBelum ada peringkat

- Pall Red Filter Elements For Use in Hydac Filter Housings: Switching To Pall Is SimpleDokumen2 halamanPall Red Filter Elements For Use in Hydac Filter Housings: Switching To Pall Is SimpleMohamed SemedaBelum ada peringkat

- (P) - SRF E: Process Filtration From Pure To SterileDokumen4 halaman(P) - SRF E: Process Filtration From Pure To SterileRei_budBelum ada peringkat

- P GS VE Steam Filter ElementsDokumen6 halamanP GS VE Steam Filter ElementsmarianraulBelum ada peringkat

- Piping FG Smith FiberglassDokumen12 halamanPiping FG Smith Fiberglassnader0123100% (1)

- IFC FilterDokumen2 halamanIFC FilterFoo LoongBelum ada peringkat

- Air Differential Pressure Switches 930Dokumen2 halamanAir Differential Pressure Switches 930Anoop AppuBelum ada peringkat

- Gas Sweetening and Processing Field ManualDari EverandGas Sweetening and Processing Field ManualPenilaian: 4 dari 5 bintang4/5 (7)

- Contemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsDari EverandContemporary Anaesthetic Equipments.: An Aid for Healthcare ProfessionalsBelum ada peringkat

- Modeling, Control, and Optimization of Natural Gas Processing PlantsDari EverandModeling, Control, and Optimization of Natural Gas Processing PlantsPenilaian: 5 dari 5 bintang5/5 (1)

- Industrial Waste Treatment HandbookDari EverandIndustrial Waste Treatment HandbookPenilaian: 5 dari 5 bintang5/5 (1)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDari EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsPenilaian: 5 dari 5 bintang5/5 (1)

- Touchpoint Plus Datasheet DS01157 V2 0416 HoneywellDokumen5 halamanTouchpoint Plus Datasheet DS01157 V2 0416 HoneywellbmsengineeringBelum ada peringkat

- Atlas Copco SelectDokumen11 halamanAtlas Copco SelectbmsengineeringBelum ada peringkat

- Aceite Compresor Atlas - Roto Xtend Duty Fluid - tcm836-3558356Dokumen2 halamanAceite Compresor Atlas - Roto Xtend Duty Fluid - tcm836-3558356nelson bolivarBelum ada peringkat

- GA 11 BrochureDokumen20 halamanGA 11 BrochuredemetryxBelum ada peringkat

- Lode Star CatalogueDokumen4 halamanLode Star CataloguebmsengineeringBelum ada peringkat

- Pumps For Heat Transfer TechnologyDokumen12 halamanPumps For Heat Transfer TechnologybmsengineeringBelum ada peringkat

- Torit Dfe Dust Collector SystemDokumen12 halamanTorit Dfe Dust Collector SystembmsengineeringBelum ada peringkat

- Modular Frls ParkerDokumen84 halamanModular Frls ParkerbmsengineeringBelum ada peringkat

- PDFDokumen2 halamanPDFbmsengineeringBelum ada peringkat

- F79 Environmental Quality (Scheduled Wastes)Dokumen6 halamanF79 Environmental Quality (Scheduled Wastes)Bala Equal BalanceBelum ada peringkat

- Mandar Patil ResumeDokumen1 halamanMandar Patil ResumeSurajit GoswamiBelum ada peringkat

- Sec 07 AluminumDokumen51 halamanSec 07 Aluminumtravis8zimmermannBelum ada peringkat

- Microeconomics Test 2Dokumen26 halamanMicroeconomics Test 2a24dk100% (4)

- TruDokumen3 halamanTruLeiBelum ada peringkat

- Book of Spindles Part 2 PDFDokumen44 halamanBook of Spindles Part 2 PDFnirmalmthp100% (1)

- Config Docs BPDDokumen21 halamanConfig Docs BPDJitendra D DhandeBelum ada peringkat

- Mini ProjectDokumen23 halamanMini ProjectbpschbkBelum ada peringkat

- Caricom Regional Standard: Specification For CementDokumen21 halamanCaricom Regional Standard: Specification For CementHamed HamidpourBelum ada peringkat

- Certificado de Cumplimiento Alambre 0.062Dokumen2 halamanCertificado de Cumplimiento Alambre 0.062gizaloBelum ada peringkat

- LIST of GTDokumen5 halamanLIST of GTSonali BanerjeeBelum ada peringkat

- Test Report Astm f1055 Daa 4ix1 2c 10-12Dokumen3 halamanTest Report Astm f1055 Daa 4ix1 2c 10-12Haseeb Zahid100% (1)

- Copper ProductionDokumen4 halamanCopper ProductionkamalBelum ada peringkat

- Macdonald's Pakistan Supply ChainDokumen35 halamanMacdonald's Pakistan Supply ChainTaha Durrani0% (1)

- The 16 Losses PDFDokumen3 halamanThe 16 Losses PDFsenzo scholarBelum ada peringkat

- Wal-Mart Supply Chain Management Case StudyDokumen5 halamanWal-Mart Supply Chain Management Case StudyAnaszNazriBelum ada peringkat

- Certification 6g Aws d1Dokumen19 halamanCertification 6g Aws d1Dhamas FallenMonzstermthafvckaBelum ada peringkat

- Method Statement For Plastering WorkDokumen15 halamanMethod Statement For Plastering Workstrikersam100% (9)

- Reverse LogisticsDokumen28 halamanReverse LogisticsJc LC0% (1)

- Fea Services - Equipment AnalysisDokumen5 halamanFea Services - Equipment AnalysisMiguel A. GarciaBelum ada peringkat

- Receiving Inspections Power Point 10-22-16Dokumen52 halamanReceiving Inspections Power Point 10-22-16Darby MorganBelum ada peringkat

- 5s, Sixsigma, TPM, PQM, Pert Etc.Dokumen17 halaman5s, Sixsigma, TPM, PQM, Pert Etc.manpreetsodhi08Belum ada peringkat

- Chapter 6 Production Activity ControlDokumen7 halamanChapter 6 Production Activity ControlKamble AbhijitBelum ada peringkat

- Technical Appraisal of An Industrial ProjectDokumen8 halamanTechnical Appraisal of An Industrial ProjectVivek SavaliyaBelum ada peringkat

- IJETR041272Dokumen6 halamanIJETR041272erpublicationBelum ada peringkat

- MQ Ball Mill LMM GroupDokumen31 halamanMQ Ball Mill LMM Grouprmm99rmm99Belum ada peringkat

- Ford MotorDokumen35 halamanFord MotorJames NitsugaBelum ada peringkat

- Assignment IncotermsDokumen6 halamanAssignment IncotermsBaba NasheBelum ada peringkat

- Jit PDFDokumen28 halamanJit PDFRona S. Pepino - AguirreBelum ada peringkat

- Unit 13Dokumen17 halamanUnit 13Shobhit SaxenaBelum ada peringkat