Final PQR PDF

Diunggah oleh

Erick HoganDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Final PQR PDF

Diunggah oleh

Erick HoganHak Cipta:

Format Tersedia

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P8-P1-001) Rev-0

WPS No.

UTOC / WPS-(P8-P1-001) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

26-Sep-07

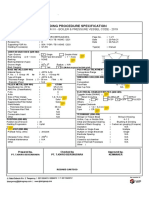

JOINTS (QW 402)

70

3

1.6mm

4

2

1

2.5 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

Temperature :

Type or Grade

GrB + 304L

Time

NA

P No.

P No. 1 / P No.8

Others

None

SA106GrB + SA 312 TP 304L

Thickness of Test Coupon

7.01 mm

Diameter of Test Coupon

73.0mm

Others :

GAS (QW 408)

Heat No:F 625006 / 24881

FILLER METALS (QW 404)

GTAW + SMAW

SFA Specification

A 5.9/A 5.4

AWS Specification

: ER 309L/ E309L-16

Filler Metal F-No.

Percent Composition

Shielding

Gas(es)

Argon

NA

NA

Backing

Argon

99.99%

15~20L/Min

8/8

2.4 / 2.6

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Others :

Manufacturer :

Batch Certificate :

Ampere / Volts

WEL TIG 309L / WEL Z 309L

NIPPON

E 63586 / 072019

POSITION (QW 405)

Direct Current

GTAW-Straight + SMAW -Reverse

:

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

20~25L/Min

NA

Polarity

Weld Progression

Flow rate

Trailing

Deposited Weld Metal : GTAW-2.0 / SMAW 5.01MM

Position of Groove :

Mixture

99.99%

F6 / F5

Weld Metal Analysis A-No. :

Size of Filler Metal

No PWHT

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

None

Oscillation

None

Interpass Temperature

108 C

Multiple or Single Pass

Multiple

Others

: Digital Thermometer

Single or Multiple Electrodes

Single

Others

None

(S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P8-P1-001) Rev-0

WPS No.

UTOC / WPS-(P8-P1-001) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

2 of 3

26-Sep-07

`

Electrical Characteristics ( TS-1)

Current

Volt

Type/

Amps

Dia. (mm)

Range

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Speed

(mm/min)

GTAW

ER-309L

2.4

DCEN

86

12

73

SMAW

E 309L - 16

2.6

DCEP

89

25

95

SMAW

E 309L - 16

2.6

DCEP

84

25

92

SMAW

E 309L - 16

2.6

DCEP

76

24

152

Volt

Range

Speed

(mm/min)

Electrical Characteristics(TS-2)

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

GTAW

ER-309L

2.4

DCEN

100

12

66

SMAW

E 309L - 16

2.6

DCEP

74

24

68

SMAW

E 309L - 16

2.6

DCEP

76

23

92

SMAW

E 309L - 16

2.6

DCEP

72

23

115

Tensile Test (QW 150) (Refer to PTS/23537-1)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

19.16

6.53

6.78

64.84

518

Broke at base metal

T2

19.17

4.6

57.91

66.90

515

Broke at base metal

Guided Bend Tests (QW 160) ( Refer to PTS/PTS/23537-1)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

Open discontinuity 1.1mm

Open discontinuity 1.7mm

No defect was observed

No defect was observed

Macro - Etch Examination (Refer to PTS/23537-1)

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

7.01

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P8-P1-001) Rev-0

WPS No.

UTOC / WPS-(P8-P1-001) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

26-Sep-07

ToughnessTests (QW 170)

Specimen

No.

-

Notch

Location

-

Specimen

Size

-

Test Temp.

C

-

J

-

Impact Values

Shear Mils

-

Drop Weight Break (Y/N)

-

Hardness Test ( Refer to PTS/PTS/23537-2,3)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Yee Kok Hong

: S 7260364H

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/23537-1/07

: 168939

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Wennie Concepcion Jr of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-005) Rev0

WPS No.

UTOC / WPS-(P1-005) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

12-Oct-07

72

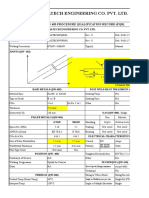

JOINTS (QW 402)

3

2

1.0 mm

3.4 - 3.5 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 333 Gr. 6

Type or Grade

Gr 6

Time

NA

P No.

P No. 1

Others

None

Thickness of Test Coupon

5.54 mm

Diameter of Test Coupon

60.3mm

Others :

Temperature :

GAS (QW 408)

Heat No: 385653

FILLER METALS (QW 404)

No PWHT

Percent Composition

GTAW

Shielding

Gas(es)

Argon

Mixture

99.99%

Flow rate

18L/Min

SFA Specification

A 5.28

Trailing

NA

NA

NA

AWS Specification

ER 70S-G

Backing

NA

NA

NA

Filler Metal F-No.

F6

Weld Metal Analysis A-No. :

Size of Filler Metal

Deposited Weld Metal :

Others :

Manufacturer :

Batch Certificate :

2.4

GTAW-5.54 mm

TGS - 1N

KOBELCO

EZ 60425

POSITION (QW 405)

Position of Groove :

Weld Progression

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Polarity

:

:

Ampere / Volts

Direct Current

GTAW-Straight

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

None

Oscillation

None

Interpass Temperature

142 C

Multiple or Single Pass

Multiple

Others

: Digital Thermometer

Single or Multiple Electrodes

Single

Others

None

(S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-005) Rev0

WPS No.

UTOC / WPS-(P1-005) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Electrical Characteristics ( TS-1)

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Volt

Range

Speed

(mm/min)

GTAW

ER-70S - G

2.4

DCEN

91

12

57

GTAW

ER-70S - G

2.4

DCEN

104

11

44

GTAW

ER-70S - G

2.4

DCEN

109

11

62

Volt

Range

Speed

(mm/min)

Electrical Characteristics(TS-2)

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

GTAW

ER-70S - G

2.4

DCEN

95

12

64

GTAW

ER-70S - G

2.4

DCEN

111

11

54

GTAW

ER-70S - G

2.4

DCEN

109

11

56

2 of 3

12-Oct-07

Tensile Test (QW 150) (Refer to PTS/24096 - 1 / 07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

13.20

5.36

70.75

35.81

506

Broke at base metal

T2

13.13

5.12

67.23

34.82

518

Broke at base metal

Guided Bend Tests (QW 160) (Refer to PTS/24096 - 1 / 07)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

No Defect was observed

No Defect was observed

Open discontinuity 0.8mm

Open discontinuity 1.0mm

Macro - Etch Examination (Refer to PTS/24096 - 1 / 07)

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

5.54

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

UTOC ENGINEERING PTE LTD

Page :

Date :

Company Name

Procedure Qualification Record No.

UTOC / PQR-(P1-005) Rev0

WPS No.

UTOC / WPS-(P1-005) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

12-Oct-07

ToughnessTests (QW 170) (Refer to PTS/24650 - 07)

Specimen

No.

1

2

3

1

2

3

Notch

Location

Specimen

Test Temp.

Size

C

WELD METAL 4 X 10 X 55 mm

-55

WELD METAL 4 X 10 X 55 mm

-55

WELD METAL 4 X 10 X 55 mm

-55

HAZ

4 X 10 X 55 mm

-55

HAZ

4 X 10 X 55 mm

-55

HAZ

4 X 10 X 55 mm

-55

Impact Values

J

Shear Mils

72

76

70

82

68

46

-

Drop Weight Break (Y/N)

-

Hardness Test (Refer to PTS/24096 - 3 / 07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Phoonlert Laphin

: F8433442K

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/24096 - 1 / 07

: 167501

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Wennie Concepcion Jr of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-008) Rev0

WPS No.

UTOC / WPS-(P1-008) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

12-Oct-07

70

755

3

JOINTS (QW 402)

2

1.0 mm

3.2 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 333 Gr. 6

Type or Grade

Gr 6

Time

1Hr / 25 mm (Min 1Hr)

P No.

P No. 1

Others

R07DG1101

Thickness of Test Coupon

5.54 mm

Diameter of Test Coupon

60.3mm

Others :

Temperature :

GAS (QW 408)

Heat No: 385653

FILLER METALS (QW 404)

640C

Percent Composition

GTAW

Shielding

Gas(es)

Argon

Mixture

99.99%

Flow rate

20L/Min

SFA Specification

A 5.28

Trailing

NA

NA

NA

AWS Specification

ER 70S-G

Backing

NA

NA

NA

Filler Metal F-No.

F6

Weld Metal Analysis A-No. :

Size of Filler Metal

Deposited Weld Metal :

Others :

Manufacturer :

Batch Certificate :

2.4

GTAW-5.54 mm

TGS - 1N

KOBELCO

EZ 60425

POSITION (QW 405)

Position of Groove :

Weld Progression

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Polarity

:

:

Ampere / Volts

Direct Current

GTAW-Straight

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

None

Oscillation

None

Interpass Temperature

130 C

Multiple or Single Pass

Multiple

Others

: Digital Thermometer

Single or Multiple Electrodes

Single

Others

None

(S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-008) Rev0

WPS No.

UTOC / WPS-(P1-008) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Electrical Characteristics ( TS-1)

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Volt

Range

Speed

(mm/min)

GTAW

ER-70S - G

2.4

DCEN

110

11

88

GTAW

ER-70S - G

2.4

DCEN

109

11

54

GTAW

ER-70S - G

2.4

DCEN

110

11

62

Volt

Range

Speed

(mm/min)

Electrical Characteristics(TS-2)

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

GTAW

ER-70S - G

2.4

DCEN

110

11

80

GTAW

ER-70S - G

2.4

DCEN

110

11

54

GTAW

ER-70S - G

2.4

DCEN

110

12

55

2 of 3

12-Oct-07

Tensile Test (QW 150) (Refer to PTS/24098 - 1 / 07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

13.19

5.38

70.96

34.5

486

Broke at base metal

T2

13.20

5.14

67.85

32.83

484

Broke at base metal

Guided Bend Tests (QW 160) (Refer to PTS/24098 - 1 / 07)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

No Defect was observed

No Defect was observed

No Defect was observed

No Defect was observed

Macro - Etch Examination (Refer to PTS/24098 - 1 / 07)

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

5.54

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

UTOC ENGINEERING PTE LTD

Page :

Date :

Company Name

Procedure Qualification Record No.

UTOC / PQR-(P1-008) Rev0

WPS No.

UTOC / WPS-(P1-008) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

12-Oct-07

ToughnessTests (QW 170) (Refer to PTS/24649 - 07)

Specimen

No.

1

2

3

1

2

3

Notch

Location

Specimen

Test Temp.

Size

C

WELD METAL 4 X 10 X 55 mm

-55

WELD METAL 4 X 10 X 55 mm

-55

WELD METAL 4 X 10 X 55 mm

-55

HAZ

4 X 10 X 55 mm

-55

HAZ

4 X 10 X 55 mm

-55

HAZ

4 X 10 X 55 mm

-55

Impact Values

J

Shear Mils

72

76

70

82

68

46

-

Drop Weight Break (Y/N)

-

Hardness Test (Refer to PTS/24098 - 3 / 07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Phoonlert Laphin

: F8433442K

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/24098 - 1 / 07

: 167501

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Wennie Concepcion Jr of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P3-001) Rev0

WPS No.

UTOC / WPS-(P3-001) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

12-Oct-07

74

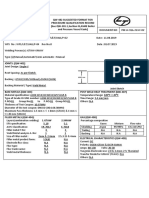

JOINTS (QW 402)

1.5 -2.0 mm

4

3

2

1

3.2 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 335 Gr. P1

Type or Grade

Gr P1

Time

NA

P No.

P No. 3

Others

None

Thickness of Test Coupon

6.55 mm

Diameter of Test Coupon

141.3mm

Others :

Temperature :

GAS (QW 408)

Heat No: 68503

FILLER METALS (QW 404)

No PWHT

Percent Composition

GTAW

Shielding

Gas(es)

Argon

Mixture

99.99%

Flow rate

15L/Min

SFA Specification

A 5.28

Trailing

NA

NA

NA

AWS Specification

ER80S-G

Backing

NA

NA

NA

Filler Metal F-No.

F6

Weld Metal Analysis A-No. :

Size of Filler Metal

Deposited Weld Metal :

Others :

Manufacturer :

Batch Certificate :

2.4

GTAW-6.55 mm

TGS - M

KOBELCO

EZ 50752

POSITION (QW 405)

Position of Groove :

Weld Progression

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Polarity

:

:

Ampere / Volts

Direct Current

GTAW-Straight

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

None

Oscillation

None

Interpass Temperature

102 C

Multiple or Single Pass

Multiple

Others

: Digital Thermometer

Single or Multiple Electrodes

Single

Others

None

(S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

Procedure Qualification Record No.

UTOC / PQR-(P3-001) Rev0

WPS No.

UTOC / WPS-(P3-001) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Weld

Process

Passes

UTOC ENGINEERING PTE LTD

Electrical Characteristics

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Class

Volt

Range

Speed

(mm/min)

GTAW

ER-80S-G

2.4

DCEN

101

12

80

GTAW

ER-80S-G

2.4

DCEN

111

11

95

GTAW

ER-80S-G

2.4

DCEN

119

12

75

GTAW

ER-80S-G

2.4

DCEN

120

11

72

GTAW

ER-80S-G

2.4

DCEN

121

12

76

GTAW

ER-80S-G

2.4

DCEN

121

12

74

2 of 3

12-Oct-07

Tensile Test (QW 150) (Refer to PTS/24648-1/07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

19.16

6.57

125.88

64.15

510

Broke at base metal

T2

19.18

6.28

120.45

61.75

513

Broke at base metal

Guided Bend Tests (QW 160) ( Refer to PTS/24648-1/07)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

No defect was observed

No defect was observed

No defect was observed

No defect was observed

Macro - Etch Examination (Refer to PTS/24648-1/07 & PTS/24648-3/07)

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

6.55

10

Accepted

No defect was observed

----

----

----

----

----

ToughnessTests (QW 170)

Specimen

No.

Comments:

Notch

Location

-

Specimen

Size

-

Test Temp.

C

-

J

-

Impact Values

Shear Mils

-

Drop Weight Break (Y/N)

-

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

UTOC ENGINEERING PTE LTD

Page :

Date :

Company Name

Procedure Qualification Record No.

UTOC / PQR-(P3-001) Rev0

WPS No.

UTOC / WPS-(P3-001) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Hardness Test (Refer to PTS/24648-2/07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Phoonlert Laphin

: F8433442K

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/24648 - 1 / 07

: 169050

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Henry Chong of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

3 of 3

12-Oct-07

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P5A-010) Rev0

WPS No.

UTOC / WPS-(P5A-010) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

12-Oct-07

74

JOINTS (QW 402)

4

1.6-2.0 mm

5

3

2

1

3.7 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 333 Gr. P22

Type or Grade

Gr P22

Time

1Hr / 25 mm (Min 1Hr)

P No.

P No. 1

Others

R07DG1101

Thickness of Test Coupon

7.11 mm

Diameter of Test Coupon

168.3mm

Others :

Temperature :

GAS (QW 408)

Heat No: 249617

FILLER METALS (QW 404)

GTAW + SMAW

760C

Percent Composition

Shielding

Gas(es)

Argon

Mixture

99.99%

Flow rate

15L/Min

SFA Specification

A 5.28 / A 5.5

Trailing

NA

NA

NA

AWS Specification

: ER 90S-G / E 9016 - B3

Backing

NA

NA

NA

Filler Metal F-No.

F6 / F4

Weld Metal Analysis A-No. :

Size of Filler Metal

4/4

2.4 / 2.6 & 3.2

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Deposited Weld Metal : GTAW-3.1 / SMAW 4.01mm

Polarity

Others :

Manufacturer :

Batch Certificate :

Ampere / Volts

TGS - 2CM / CMA 106

KOBELCO

EZ 70139 / A 751 & A 632

POSITION (QW 405)

Position of Groove :

Weld Progression

Direct Current

GTAW-Straight + SMAW -Reverse

:

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

225C

Oscillation

None

Interpass Temperature

250 C

Multiple or Single Pass

Multiple

Single or Multiple Electrodes

Single

Others

None

Others

: Preheat by Electric Resistance method

Electronic/Temp. Recorder ,Cal Rep No.:R07DB0603

Digital Thermometer (S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P5A-010) Rev0

WPS No.

UTOC / WPS-(P5A-010) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Electrical Characteristics

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Volt

Range

2 of 3

12-Oct-07

Speed

(mm/min)

GTAW

ER-90S-G

2.4

DCEN

112

11

95

SMAW

ER-9016-B3

2.6

DCEP

78

26

227

SMAW

ER-9016-B3

3.2

DCEP

95

29

106

SMAW

ER-9016-B3

2.6

DCEP

82

24

75

SMAW

ER-9016-B3

2.6

DCEP

83

24

138

Tensile Test (QW 150) (Refer to PTS/24647-1/07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

19.17

7.11

136.3

70.47

517

Broke at base metal

T2

19.16

7.03

135.27

70.08

518

Broke at base metal

Guided Bend Tests (QW 160) ( Refer to PTS/24647-1/07)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

No defect was observed

No defect was observed

Open discontinuity 1.3 mm

No defect was observed

Macro - Etch Examination (Refer to PTS/24647-1/07 & PTS/24647-3/07 )

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

7.11

10

Accepted

No defect was observed

----

----

----

----

----

ToughnessTests (QW 170)

Specimen

No.

Comments:

Notch

Location

-

Specimen

Size

-

Test Temp.

C

-

J

-

Impact Values

Shear Mils

-

Drop Weight Break (Y/N)

-

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

UTOC ENGINEERING PTE LTD

Page :

Date :

Company Name

Procedure Qualification Record No.

UTOC / PQR-(P3-001) Rev0

WPS No.

UTOC / WPS-(P3-001) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Hardness Test (Refer to PTS/24647-2/07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Yee Kok Hong

: S 7260364 H

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/24647 - 1 / 07

: 169528

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Henry Chong of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

3 of 3

12-Oct-07

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P4-003) Rev0

WPS No.

UTOC / WPS-(P4-003) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

20-Oct-07

74

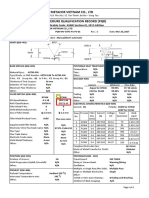

JOINTS (QW 402)

11 12 13 14 15

8

9 10

6

7

4

5

3

2.0 mm

2

1

3.8 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 335 Gr.P11

Type or Grade

Gr P11

Time

1Hr / 25 mm (Min 1Hr)

P No.

P No. 4

Others

R07DG1101

Thickness of Test Coupon

21.4 mm

Diameter of Test Coupon

406.4mm

Others :

Temperature :

GAS (QW 408)

Heat No: J7KI7C10

FILLER METALS (QW 404)

GTAW + SMAW

SFA Specification

A 5.28 / A 5.5

AWS Specification

: ER 80S-G / E 8016 - G

Filler Metal F-No.

Percent Composition

Shielding

Gas(es)

Argon

Mixture

99.99%

Flow rate

20L/Min

Trailing

NA

NA

NA

Backing

NA

NA

NA

F6 / F4

Weld Metal Analysis A-No. :

Size of Filler Metal

730C

3-Jan

: 2.4 / 2.6 , 3.2 & 4.0 mm

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Deposited Weld Metal : GTAW-4.4 / SMAW 17.00mm

Polarity

Others :

TGS - 1CM / CMA - 96

Manufacturer :

KOBELCO

Batch Certificate : ED 80228 / A 751, A 741 & A 751

Ampere / Volts

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

POSITION (QW 405)

Others

AC/DC Clamp Meter

Position of Groove :

Weld Progression

Direct Current

GTAW-Straight + SMAW -Reverse

:

See Table

6G

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

240C

Oscillation

None

Interpass Temperature

260C

Multiple or Single Pass

Multiple

Single or Multiple Electrodes

Single

Others

None

Others

: Preheat by Electric Resistance method

Electronic/Temp. Recorder ,Cal Rep No.:R07DG1101

Digital Thermometer (S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P4-003) Rev0

WPS No.

UTOC / WPS-(P4-003) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Electrical Characteristics

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Volt

Range

Speed

(mm/min)

GTAW

ER-80S - G

2.4

DCEN

86

12

28

GTAW

ER-80S - G

2.4

DCEN

142

12

87

SMAW

E-8016 - G

2.6

DCEP

91

28

95

SMAW

E-8016 - G

3.2

DCEP

114

32

100

SMAW

E-8016 - G

3.2

DCEP

116

34

95

SMAW

E-8016 - G

4.0

DCEP

142

36

99

SMAW

E-8016 - G

4.0

DCEP

147

36

82

SMAW

E-8016 - G

4.0

DCEP

147

37

96

SMAW

E-8016 - G

4.0

DCEP

140

35

87

10

SMAW

E-8016 - G

4.0

DCEP

149

38

69

11

SMAW

E-8016 - G

3.2

DCEP

111

34

90

12

SMAW

E-8016 - G

3.2

DCEP

111

32

90

13

SMAW

E-8016 - G

3.2

DCEP

112

33

93

14

SMAW

E-8016 - G

3.2

DCEP

113

33

96

15

SMAW

E-8016 - G

3.2

DCEP

112

33

101

2 of 3

20-Oct-07

Tensile Test (QW 150) (Refer to PTS/24090 - 1 / 07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

19.20

21.21

407.23

205.20

504

Broke at base metal

T2

19.20

21.21

404.54

202.50

501

Broke at base metal

Guided Bend Tests (QW 160) (Refer to PTS/24090 - 1 / 07)

Specimen No.

Type of Bend

Result

Remarks

S1

S2

S3

S4

Side Bend

Side Bend

Side Bend

Side Bend

Accepted

Accepted

Accepted

Accepted

No Defect was observed

No Defect was observed

No Defect was observed

Open discontinuity 0.5 mm

Macro - Etch Examination (Refer to PTS/24090 - 1 / 07 & PTS/24090 - 3 / 07)

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

21.44

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P4-003) Rev0

WPS No.

UTOC / WPS-(P4-003) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

20-Oct-07

ToughnessTests (QW 170)

Specimen

No.

-

Notch

Location

-

Specimen

Size Test Temp.

C

-

J

-

Impact Values

Shear Mils

-

Drop Weight Break (Y/N)

-

Hardness Test (Refer to PTS/24090- 2 / 07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Phoonlert Laphin / Mr Yee Kok Hong

: F8433442K / S 7260364 H

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/24090 - 1 / 07

: 169697

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Henry Chong of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-010) Rev0

WPS No.

UTOC / WPS-(P1-010) Rev-1

Welding Process(es)

GTAW + SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

26-Oct-07

74

JOINTS (QW 402)

6

4

1.5 mm

7

5

3

2

1

3.8 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 333 Gr. 6

Type or Grade

Gr 6

Time

1Hr / 25 mm (Min 1Hr)

P No.

P No. 1

Others

R07DG1101

Thickness of Test Coupon

9.27 mm

Diameter of Test Coupon

273.0 mm

Others :

Temperature :

GAS (QW 408)

Heat No: 83134

FILLER METALS (QW 404)

Percent Composition

GTAW + SMAW

SFA Specification

AWS Specification

: ER 70S-G / E 7016 - G

Filler Metal F-No.

A 5.28 / A 5.5

Shielding

Gas(es)

Argon

NA

NA

Backing

NA

NA

NA

1

2.4 / 2.6 & 3.2 mm

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Others :

Manufacturer :

Batch Certificate :

Ampere / Volts

TGS - 1N / LB52 - NS

KOBELCO

EZ 60425 / A 751 & A 632

POSITION (QW 405)

Direct Current

GTAW-Straight

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

20L/Min

NA

Polarity

Weld Progression

Flow rate

Trailing

Deposited Weld Metal : GTAW-3.3 / SMAW 5.97mm

Position of Groove :

Mixture

99.99%

F6 / F4

Weld Metal Analysis A-No. :

Size of Filler Metal

630C

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

None

Oscillation

None

Interpass Temperature

159 C

Multiple or Single Pass

Multiple

Others

: Digital Thermometer

Single or Multiple Electrodes

Single

Others

None

(S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-010) Rev0

WPS No.

UTOC / WPS-(P1-010) Rev-1

Welding Process(es)

GTAW + SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

2 of 3

26-Oct-07

`

Electrical Characteristics

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Volt

Range

Speed

(mm/min)

45

GTAW

ER-70S - G

2.4

DCEN

102

12

GTAW

ER-70S - G

2.4

DCEN

140

12

96

SMAW

E-7016 - G

2.6

DCEP

87

31

162

SMAW

E-7016 - G

2.6

DCEP

92

30

216

SMAW

E-7016 - G

2.6

DCEP

93

31

176

SMAW

E-7016 - G

3.2

DCEP

106

32

123

SMAW

E-7016 - G

3.2

DCEP

109

31

120

Tensile Test (QW 150) (Refer to PTS/25502-1 / 07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

19.17

9.36

179.43

82.00

457

Broke at base metal

T2

19.19

9.03

173.29

79.20

457

Broke at base metal

Guided Bend Tests (QW 160) (Refer to PTS/25502-1 / 07)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

No defect was observed

Open discontinuity 1.5mm

No defect was observed

Open discontinuity 1.3mm

Macro - Etch Examination (Refer to PTS/25502-1 / 07 & PTS/25502-3 / 07 )

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

9.27

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-010) Rev0

WPS No.

UTOC / WPS-(P1-010) Rev-1

Welding Process(es)

GTAW + SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

26-Oct-07

ToughnessTests (QW 170) (Refer to PTS/25502 - 07)

Specimen

No.

1

2

3

1

2

3

Notch

Location

Specimen

Test Temp.

Size

C

WELD METAL 9 X 10 X 55 mm

-48

WELD METAL 9 X 10 X 55 mm

-48

WELD METAL 9 X 10 X 55 mm

-48

HAZ

9 X 10 X 55 mm

-48

HAZ

9 X 10 X 55 mm

-48

HAZ

9 X 10 X 55 mm

-48

Impact Values

J

Shear Mils

178

279

283

281

286

279

-

Drop Weight Break (Y/N)

-

Hardness Test (Refer to PTS/25502 - 3 / 07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Phoonlert Laphin

: F8433442K

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/25502 - 1 / 07

: 169529

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Henry Chong of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-007) Rev0

WPS No.

UTOC / WPS-(P1-007) Rev-1

Welding Process(es)

GTAW + SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

26-Oct-07

74

JOINTS (QW 402)

6

4

1.5 mm

7

5

3

2

1

3.8 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 333 Gr. 6

Type or Grade

Gr 6

Time

NA

P No.

P No. 1

Others

None

Thickness of Test Coupon

9.27 mm

Diameter of Test Coupon

273.0 mm

Others :

Temperature :

GAS (QW 408)

Heat No: 83134

FILLER METALS (QW 404)

Percent Composition

GTAW + SMAW

SFA Specification

AWS Specification

: ER 70S-G / E 7016 - G

Filler Metal F-No.

A 5.28 / A 5.5

Shielding

Gas(es)

Argon

NA

NA

Backing

NA

NA

NA

1

2.4 / 2.6 & 3.2 mm

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Others :

Manufacturer :

Batch Certificate :

Ampere / Volts

TGS - 1N / LB52 - NS

KOBELCO

EZ 60425 / A 751 & A 632

POSITION (QW 405)

Direct Current

GTAW-Straight

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

20L/Min

NA

Polarity

Weld Progression

Flow rate

Trailing

Deposited Weld Metal : GTAW-3.2 / SMAW 6.07mm

Position of Groove :

Mixture

99.99%

F6 / F4

Weld Metal Analysis A-No. :

Size of Filler Metal

No PWHT

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

None

Oscillation

None

Interpass Temperature

159 C

Multiple or Single Pass

Multiple

Others

: Digital Thermometer

Single or Multiple Electrodes

Single

Others

None

(S/No:R113689)

6.07

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-007) Rev0

WPS No.

UTOC / WPS-(P1-007) Rev-1

Welding Process(es)

GTAW + SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

2 of 3

26-Oct-07

`

Electrical Characteristics

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Volt

Range

Speed

(mm/min)

GTAW

ER-70S - G

2.4

DCEN

102

12

88

GTAW

ER-70S - G

2.4

DCEN

138

12

113

SMAW

E-7016 - G

2.6

DCEP

90

30

170

SMAW

E-7016 - G

2.6

DCEP

91

31

206

SMAW

E-7016 - G

2.6

DCEP

100

31

184

SMAW

E-7016 - G

3.2

DCEP

107

33

108

SMAW

E-7016 - G

3.2

DCEP

108

32

116

Tensile Test (QW 150) (Refer to PTS/25500-1 / 07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

19.17

9.67

185.37

87.20

470

Broke at base metal

T2

19.12

8.84

169.02

80.50

476

Broke at base metal

Guided Bend Tests (QW 160) (Refer to PTS/25500-1 / 07)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

Open discontinuity 1.0 mm

No defect was observed

No defect was observed

No defect was observed

Macro - Etch Examination (Refer to PTS/25500-1 / 07 & PTS/25500-4 / 07 )

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

9.27

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-007) Rev0

WPS No.

UTOC / WPS-(P1-007) Rev-1

Welding Process(es)

GTAW + SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

26-Oct-07

ToughnessTests (QW 170) (Refer to PTS/25500 - 2 / 07)

Specimen

No.

1

2

3

1

2

3

Notch

Location

Specimen

Test Temp.

Size

C

WELD METAL 9 X 10 X 55 mm

-48

WELD METAL 9 X 10 X 55 mm

-48

WELD METAL 9 X 10 X 55 mm

-48

HAZ

9 X 10 X 55 mm

-48

HAZ

9 X 10 X 55 mm

-48

HAZ

9 X 10 X 55 mm

-48

Impact Values

J

Shear Mils

206

229

146

255

247

277

-

Drop Weight Break (Y/N)

-

Hardness Test (Refer to PTS/25500 - 3 / 07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Phoonlert Laphin

: F8433442K

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/25500 - 1 / 07

: 169529

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Henry Chong of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-006) Rev0

WPS No.

UTOC / WPS-(P1-006) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

3-Nov-07

JOINTS (QW 402)

15 16 17 18 19

11 12 13 14

8

9 10

6

7

4

5

3

14.32mm 10

19 mm

37

1.0 mm

2

1

3.8 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 333 Gr. 6

Type or Grade

Gr 6

Time

1Hr / 25 mm (Min 1Hr)

P No.

P No. 1

Others

R07DG1101

Thickness of Test Coupon

33.32 mm

Diameter of Test Coupon

323.9mm

Others :

Temperature :

GAS (QW 408)

Heat No: 90752

FILLER METALS (QW 404)

Percent Composition

GTAW + SMAW

SFA Specification

AWS Specification

: ER 70S-G / E 7016 - G

Filler Metal F-No.

A 5.28 / A 5.5

Shielding

Gas(es)

Argon

Mixture

99.99%

Flow rate

15L/Min

Trailing

NA

NA

NA

Backing

NA

NA

NA

F6 / F4

Weld Metal Analysis A-No. :

Size of Filler Metal

640C

: 2.4 / 2.6 , 3.2 & 4.0 mm

ELECTRICAL CHARACTERISTICS (QW 409)

Current

Deposited Weld Metal : GTAW-3.1 / SMAW 30.32mm

Polarity

Others :

TGS - 1N / LB52 - NS

Manufacturer :

KOBELCO

Batch Certificate : EZ 60425 / A 751, A 632 & A6415

Ampere / Volts

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

POSITION (QW 405)

Others

AC/DC Clamp Meter

Position of Groove :

Weld Progression

Direct Current

GTAW-Straight + SMAW -Reverse

:

See Table

6G

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

100C

Oscillation

None

Interpass Temperature

230C

Multiple or Single Pass

Multiple

Single or Multiple Electrodes

Single

Others

None

Others

: Preheat by Electric Resistance method

Electronic/Temp. Recorder ,Cal Rep No.:R07DG1101

Digital Thermometer (S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-006) Rev0

WPS No.

UTOC / WPS-(P1-006) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Electrical Characteristics

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Volt

Range

Speed

(mm/min)

GTAW

ER-70S - G

2.4

DCEN

93

12

101

GTAW

ER-70S - G

2.4

DCEN

101

12

101

SMAW

E-7016 - G

2.6

DCEP

90

32

115

SMAW

E-7016 - G

3.2

DCEP

124

34

96

SMAW

E-7016 - G

3.2

DCEP

127

31

98

SMAW

E-7016 - G

4.0

DCEP

156

34

85

SMAW

E-7016 - G

4.0

DCEP

150

34

65

SMAW

E-7016 - G

4.0

DCEP

157

34

77

SMAW

E-7016 - G

4.0

DCEP

154

33

85

10

SMAW

E-7016 - G

4.0

DCEP

156

33

68

11

SMAW

E-7016 - G

4.0

DCEP

149

35

75

12

SMAW

E-7016 - G

4.0

DCEP

153

35

60

13

SMAW

E-7016 - G

4.0

DCEP

151

35

52

14

SMAW

E-7016 - G

4.0

DCEP

149

35

58

15

SMAW

E-7016 - G

4.0

DCEP

137

34

86

16

SMAW

E-7016 - G

4.0

DCEP

142

35

74

17

SMAW

E-7016 - G

4.0

DCEP

129

32

57

18

SMAW

E-7016 - G

4.0

DCEP

155

35

83

19

SMAW

E-7016 - G

3.2

DCEP

120

28

70

2 of 3

3-Nov-07

Tensile Test (QW 150) (Refer to PTS/24097 - 1 / 07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

19.17

31.21

598.30

291.80

488

Broke at base metal

T2

19.16

31.17

597.22

288.70

483

Broke at base metal

Guided Bend Tests (QW 160) (Refer to PTS/24097 - 1 / 07)

Specimen No.

Type of Bend

Result

Remarks

S1

S2

S3

S4

Side Bend

Side Bend

Side Bend

Side Bend

Accepted

Accepted

Accepted

Accepted

No Defect was observed

No Defect was observed

No Defect was observed

No Defect was observed

Macro - Etch Examination (Refer to PTS/24097 - 1 / 07)

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

33.32

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P1-006) Rev0

WPS No.

UTOC / WPS-(P1-006) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

3-Nov-07

ToughnessTests (QW 170) (Refer to PTS/24097/2 - 07)

Specimen

No.

1

2

3

1

2

3

Notch

Location

Specimen

Size Test Temp.

C

WELD METAL 10 X 10 X 55 mm

-48

WELD METAL 10 X 10 X 55 mm

-48

WELD METAL 10 X 10 X 55 mm

-48

HAZ

10 X 10 X 55 mm

-48

HAZ

10 X 10 X 55 mm

-48

HAZ

10 X 10 X 55 mm

-48

Impact Values

J

Shear Mils

184

282

282

192

254

203

-

Drop Weight Break (Y/N)

-

ToughnessTests At Root (QW 170) (Refer to PTS/25988 - 07)

Specimen

No.

1

2

3

1

2

3

Notch

Location

Specimen

Size Test Temp.

C

WELD METAL 10 X 10 X 55 mm

-48

WELD METAL 10 X 10 X 55 mm

-48

WELD METAL 10 X 10 X 55 mm

-48

HAZ

10 X 10 X 55 mm

-48

HAZ

10 X 10 X 55 mm

-48

HAZ

10 X 10 X 55 mm

-48

Impact Values

J

Shear Mils

171

163

148

274

278

265

-

Drop Weight Break (Y/N)

-

Hardness Test (Refer to PTS/24097- 3 / 07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Welder's Name:

I/C No.:

: Mr. Phoonlert Laphin / Mr Yee Kok Hong

: F8433442K / S 7260364 H

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/24097 - 1 / 07

: 169431

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Wennie Concepcion Jr of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P8-001) Rev-0

WPS No.

UTOC / WPS-(P8-001) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

20-Oct-07

74

JOINTS (QW 402)

4

1.0 mm

5

3

2

1

3.8 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 312 TP 304L

Temperature :

Type or Grade

Gr. 304L

Time

NA

P No.

P No.8

Others

None

Thickness of Test Coupon

7.01 mm

Diameter of Test Coupon

73.02mm

Others :

GAS (QW 408)

Heat No:F 625006

FILLER METALS (QW 404)

GTAW

No PWHT

Percent Composition

Shielding

Gas(es)

Argon

Mixture

99.99%

Flow rate

20L/Min

SFA Specification

A 5.9

Trailing

NA

NA

NA

AWS Specification

ER 308L

Backing

Argon

99.99%

20L/Min

Filler Metal F-No.

F6

Weld Metal Analysis A-No. :

8/8

ELECTRICAL CHARACTERISTICS (QW 409)

Size of Filler Metal

2.4

Current

Deposited Weld Metal : GTAW-7.01mm

Polarity

Others :

Manufacturer :

Batch Certificate :

Ampere / Volts

WEL TIG 308LJ

NIPPON

G 77150

POSITION (QW 405)

Position of Groove :

Weld Progression

Direct Current

GTAW-Straight

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

None

Oscillation

None

Interpass Temperature

120 C

Multiple or Single Pass

Multiple

Others

: Digital Thermometer

Single or Multiple Electrodes

Single

Others

None

(S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P8-001) Rev-0

WPS No.

UTOC / WPS-(P8-001) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

Electrical Characteristics ( TS-1)

Current

Volt

Type/

Amps

Dia. (mm)

Range

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Speed

(mm/min)

GTAW

ER-308L

2.4

DCEN

73

11

50

GTAW

ER-308L

2.4

DCEN

109

11

111

GTAW

ER-308L

2.4

DCEN

73

11

50

GTAW

ER-308L

2.4

DCEN

119

11

45

GTAW

ER-308L

2.4

DCEN

116

12

89

GTAW

ER-308L

2.4

DCEN

117

12

91

Volt

Range

Speed

(mm/min)

Electrical Characteristics(TS-2)

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

2 of 3

26-Sep-07

GTAW

ER-308L

2.4

DCEN

77

10

47

SMAW

ER-308L

2.4

DCEN

118

11

100

SMAW

ER-308L

2.4

DCEN

118

12

78

GTAW

ER-308L

2.4

DCEN

118

12

99

GTAW

ER-308L

2.4

DCEN

115

12

56

GTAW

ER-308L

2.4

DCEN

115

12

93

Tensile Test (QW 150) (Refer to PTS/25087-1 / 07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

13.07

6.76

88.35

52.02

589

Broke at base metal

T2

13.11

6.67

87.44

53.33

610

Broke at base metal

Guided Bend Tests (QW 160) (Refer to PTS/25087-1 / 07)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

No defect was observed

No defect was observed

No defect was observed

No defect was observed

Macro - Etch Examination (Refer to PTS/25087-1 / 07 & PTS/25087-4 / 07)

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

7.01

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P8-P1-001) Rev-0

WPS No.

UTOC / WPS-(P8-P1-001) Rev-1

Welding Process(es)

GTAW+SMAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

26-Sep-07

ToughnessTests (QW 170) (Refer to PTS/25087-2 / 07)

Specimen

No.

1

2

3

1

2

3

Notch

Location

Specimen

Size Test Temp.

C

WELD METAL 6 X 10 X 55 mm

-196

WELD METAL 6 X 10 X 55 mm

-196

WELD METAL 6 X 10 X 55 mm

-196

HAZ

6 X 10 X 55 mm

-196

HAZ

6 X 10 X 55 mm

-196

HAZ

6 X 10 X 55 mm

-196

Impact Values

J

Shear Mils

53

47.64

62

53.15

58

49.21

131

75.59

133

76.77

134

77.56

Drop Weight Break (Y/N)

-

Hardness Test ( Refer to PTS/PTS/) (Refer to PTS/25087-3 / 07)

Type of Test

Vickers

Deposit Analysis

None

Other

None

----

----

----

Other Test

: Ferrite Content Measurement (PTS / 24978 - 1/ 07 & PTS / 24978 - 2/ 07)

Welder's Name:

I/C No.:

: Mr. Phoonlert Laphin

: F8433442K

Welding test Conducted by

Mechanical Test Report No.:

Radiographic Test Report No.

: UTOC Engineering Ptd. Ltd.

: PTS/25087-1 / 07

: 169799

Welding Test Witness by

: UTOC Engineering Pte. Ltd.

: Mr.Henry Chong of ABB-TEC-JV

: Mr.Ismail of Ace Quality Testing & Inspection Services Pte Ltd

We certify that the above statement in this record are correct and that the testing were prepared, welded and

tested in accordance with the requirements of ASME Code, Section IX-2004 Edition

Manufacturer:

Date:

UTOC Engineering Ltd.

By:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P8-002) Rev-0

WPS No.

UTOC / WPS-(P8-002) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

1 of 3

20-Oct-07

JOINTS (QW 402)

74

1.5mm

3

2

1

3.0 mm

Groove Design of Test Coupon

BASE METALS (QW 403)

POSTWELD HEAT TREATMENT (QW 407)

Metal Spec.

SA 312 TP 316L

Temperature :

Type or Grade

Gr. 316L

Time

NA

P No.

P No.8

Others

None

Thickness of Test Coupon

3.91 mm

Diameter of Test Coupon

60.3mm

Others :

GAS (QW 408)

Heat No:VLG020247

FILLER METALS (QW 404)

GTAW

No PWHT

Percent Composition

Shielding

Gas(es)

Argon

Mixture

99.99%

Flow rate

15L/Min

SFA Specification

A 5.9

Trailing

NA

NA

NA

AWS Specification

ER 316L

Backing

Argon

99.99%

15L/Min

Filler Metal F-No.

F6

Weld Metal Analysis A-No. :

8/8

ELECTRICAL CHARACTERISTICS (QW 409)

Size of Filler Metal

2.4

Current

Deposited Weld Metal : GTAW-3.91mm

Polarity

Others :

Manufacturer :

Batch Certificate :

Ampere / Volts

WEL TIG 316LJ

NIPPON

F 46377

POSITION (QW 405)

Position of Groove :

Weld Progression

Direct Current

GTAW-Straight

See Table

Tungsten Electrodes Size :

2% Thoriated

Tungsten, 2.4mm

Others

AC/DC Clamp Meter

6G

Uphill

PREHEAT (QW 406)

S/No. W0088331

Travel Speed

See Table

String or Weave Bead

String / Weave

Preheat Temperature

None

Oscillation

None

Interpass Temperature

107 C

Multiple or Single Pass

Multiple

Others

: Digital Thermometer

Single or Multiple Electrodes

Single

Others

None

(S/No:R113689)

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

Page :

Date :

Company Name

UTOC ENGINEERING PTE LTD

Procedure Qualification Record No.

UTOC / PQR-(P8-002) Rev-0

WPS No.

UTOC / WPS-(P8-002) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

2 of 3

20-Oct-07

`

Electrical Characteristics ( TS-1)

Current

Volt

Type/

Amps

Dia. (mm)

Range

Polarity

Range

Filler metal

Weld

Process

Passes

Class

Speed

(mm/min)

GTAW

ER-316L

2.4

DCEN

77

10

43

GTAW

ER-316L

2.4

DCEN

87

10

85

GTAW

ER-316L

2.4

DCEN

87

11

87

Volt

Range

Speed

(mm/min)

Electrical Characteristics(TS-2)

Current

Type/

Amps

Dia. (mm)

Polarity

Range

Filler metal

Weld

Process

Passes

Class

GTAW

ER-309L

2.4

DCEN

84

10

39

SMAW

E 309L - 16

2.6

DCEP

83

10

77

SMAW

E 309L - 16

2.6

DCEP

83

10

76

Tensile Test (QW 150) (Refer to PTS/25085-1 / 07)

Specimen

No.

Width

(mm)

Thickness

(mm)

Area

(mm2 )

Ultimate Tensile Load

(KN)

UTS

(N/mm2)

Type and Location of

failure

T1

13.20

3.84

50.69

28.34

559

Broke at base metal

T2

13.20

3.84

50.69

28.04

553

Broke at base metal

Guided Bend Tests (QW 160) (Refer to PTS/25085-1 / 07)

Specimen No.

Type of Bend

Result

Remarks

F1

F2

R1

R2

Face Bend

Face Bend

Root Bend

Root Bend

Accepted

Accepted

Accepted

Accepted

No defect was observed

No defect was observed

No defect was observed

No defect was observed

Macro - Etch Examination (Refer to PTS/25085-1 / 07 & PTS/25085-3 / 07)

Specimen No.

Thickness (mm)

width (mm)

Result

Remarks

3.9

10

Accepted

No Defect was observed

----

----

----

----

----

Comments:

QW-483 PROCEDURE QUALIFICATION RECORD (PQR)

(Refer to QW-200.2, SECTION IX, ASME BOILER & PRESSURE VESSEL CODE)

Record Actual Condition Used to Weld Test Coupon

UTOC ENGINEERING PTE LTD

Page :

Date :

Company Name

Procedure Qualification Record No.

UTOC / PQR-(P8-002) Rev-0

WPS No.

UTOC / WPS-(P8-002) Rev-1

Welding Process(es)

GTAW

Types (Manual, Automatic, Semi-Auto)

MANUAL

3 of 3

20-Oct-07

ToughnessTests (QW 170)

Specimen

No.

-

Notch