Chapter 7 Hydro-Mechanical

Diunggah oleh

Sujan SinghDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Chapter 7 Hydro-Mechanical

Diunggah oleh

Sujan SinghHak Cipta:

Format Tersedia

Chapter-7: Hydropower Engineering

Chapter 7.0 Hydro-Electrical Machines

7.1

Hydro-mechanical installation: turbines- peloton Francis, Kaplan and their performance

characteristics

Turbines: are mechanical machines to transform the water potential energy of flowing fluid into

mechanical rotational energy. Turbines are called runners. The rotational energy is transformed to the

generators through the power shaft (connecting rod and fly wheel) to run the generator smoothly for

electricity production.

Turbines are developed form of water wheels in water mills used for ore crushing and flour mills

(developed 400-500 years ago)

Schematic diagram of turbines in powerhouse

1

Chapter-7: Hydropower Engineering

Types of Turbines:

Basis

Types

Pressure

Impulse Turbine: pressure less, energy of water is converted to kinetic in the form

of water jet issuing from nozzle/s and hitting the wheel vanes, runners.

Reactive Turbine: High pressure

Head

Low head 2-15 m propeller, Kaplan, High discharge low head turbines

Medium head: 16-70 m Kaplan/Francis Turbine

High head: 71-500 m Francis/pelton Turbine

Very high head>500 m Pelton Turbine, low discharge high head

Chapter-7: Hydropower Engineering

Interesting facts about turbine: Maximum output power from a single unit

a) Pelton 330000 hP,

b) Francis 960000 hP,

c)Kaplan 300000 hp

Performance Characteristics

Performance characteristics curves indicates the performance of the turbine over the full range of the

turbine running

The curves of discharge and efficiency verses speed at a constant head are called main characteristics

curves of the turbines.

Discharge Q

Kaplan

Pelton

)

Efficiency (

Francis

Speed of Turbine (rpm)

The performance curves are given by the turbine maker/manufacturer based on the design of the

turbine runner, its shape, used materials and shape of the blades. Universal characteristics curves are

generally used to compare the performance of the turbine under different heads. The parameters of the

Chapter-7: Hydropower Engineering

universal characteristics curves are Unit Discharge (Qu =

Power (Pu=

Q

N

), Unit Speed (Nu =

) and Unit

H

H

P

)

H

Typical small hydro turbines efficiencies at different values of Q

7.2

selection of turbines and their specific speed

The type, geometry and dimensions of the turbine will be fundamentally conditioned by the following

criteria:

Chapter-7: Hydropower Engineering

Net head, Range of discharges through the turbine,, Rotational speed, Cavitations problems , Cost

Specific Speed of a Turbine:

Since the generator and turbines are directly coupled, the rated speed of the turbine is same as that of the

synchronous speed of the generators.

60 * f

The speed of the generator is given by N =

where f = 50 HZ and P = number of pairs of magnetic

P

poles (fixed 8 to 10 pairs) and N is constant irrespective of the power output.

N P

H 5/4

Where Ns = Specific speed of the turbine i.e. it is the speed of the turbine in rpm which produce 1 metric

Horse power (1 hP) under the head of 1 m.

gQ H

P = Power produced from the turbine (hP) = P =

735.5

Types of Runner based on Specific Speed of Turbines (Ns in rpm)

Runner

Slow

Medium

High

Pelton

4-15

16-30

31-70

Francis

60-150

151-250

251-400

Kaplan

300-450

451-700

701-1100

Pelton Turbine with single nozzle jet, The Max Ns = 30 and the Ns value for the multiple nozzle jet n

= Nmj = n 30 and the maximum number of jet for a pelton turbine = 6 Hence the maximum speed

The Specific Speed of the Turbine Ns is given by Ns =

of the Pelton wheel Ns max = 6 30 = 73 70 . The use of single jet for large discharge is limited

and not convenient. The efficiency of the turbine can be increased with the introduction of multiple jet

(max 6) as it increase the specific speed Ns of the turbine. The jets interference should be avoided and

the water jet should strike the buckets tangentially. The Bucket deflection angle is to be about 1650.

Turbines and their maximum range of the Specific speed Ns used in the world

Type of Runner

Max head (m)

Max power (hP)

Pelton

Francis

Kaplan

300-2000

30-500

2-70

330000

960000

300000

Maximum wheel Specific Speed Ns

dia (m)

(rpm)

5.5

4-70

10

60-400

10

300-1100

Selection Guidelines of Turbines

Range of operating heads for each type of turbines (ESHA Guide line Part II)

Chapter-7: Hydropower Engineering

Numerical Examples: #1] the quantity of water available for a hydroelectric station is 275 m3/s under

the head of 18 m. assuming the speed of the turbine (N) to be 150 rpm and their efficiency to be 82%.

Determine the least number of machines, all of the same size, that will be needed if i) Francis turbine

whose Ns must not exceed 395, ii) Kaplan turbine whose Ns must not exceed 690 are chosen. What

would be the individual output of the units in two cases?

Solution: Power to be developed from the project

6

Chapter-7: Hydropower Engineering

Pout =

QH

Now Ns =

1000 9.81 275 18 0.82

= 54120 hP

735

N P

H 5/ 4

150 P

or P = 9530.75 hP

185 / 4

P

54120

= 5.678 6 nos so

Number of units to be installed for the Francis turbine = n = out =

P

9530.75

the power output from each unit = 54120/6 = 9020 hP

Hence the specific speed of the Francis turbine to be used in the power plant will be Ns =

N P 150 9020

=

= 384.24 384 rpm.

H 5/4

18 5 / 4

Case i) for Francis Turbine the limiting value of Ns = 395 =

150 P

or P = 29082.473 hP

185 / 4

Number of units =54120/2 = 27060 hP and the Specific speed of the Kaplan turbine will be Ns

N P 150 27060

=

= 665.5 666 rpm

=

H 5/4

185 / 4

Case ii) for Kaplan Turbine, the limited Ns = 690 =

Numerical Examples: #2] the quantity of water available for a hydroelectric station is 275

m3/s under the head of 18 m. assuming the speed of the turbine (N) to be 150 rpm and their

efficiency to be 82%. Determine the least number of machines, all of the same size, that will be

needed if i) Francis turbine whose Ns must not exceed 395, ii) Kaplan turbine whose Ns must

not exceed 690 are chosen. What would be the individual output of the units in two cases?

A powerhouse is equipped with 4 units of vertical shaft pelton turbines to be coupled with

70000 KVA 3 phase 50 hertz generators. The generators are provided with 10 pairs of poles.

The gross design head is 505 m and transmission efficiency of headrace tunnel and penstock

together is to be 94%. The four units together will provide total power of 348000 hP at the

guaranteed efficiency of 91% and the nozzle efficiency is 0.98 then find

a) jet diameter and numbers of jets

b) the nozzle tip diameter

c) the pitch circle diameter of the wheel

d) the specific speed of the turbine

e) number of buckets on the wheel

60 f 60 * 50

=

= 300 rpm

P

10

Water transmission efficiency = 94%, So, net head H = 505*0.94= 475 m

The total power output from all 4 units = 348000 hP so, Power output from each unit P =

87000 hP at overall efficiency of 91%.

QH

87000 735

So, for each turbine unit P =

or Q =

= 15.1 m3/s

735

9.81 1000 475 0.91

N P 300 87000

a) Specific speed of the turbine Ns =

=

= 39.90 40>Nsj max = 30 so multi

H 5/ 4

4755 / 4

Solution: Synchronous speed of the generators N =

Nmj 40

jet runners is required. Number of jet =

= = 4 nos taking Nsj 20

Nsj 20

7

Chapter-7: Hydropower Engineering

So, Discharge through each nozzle jet = 15.1/4 = 3.775 m3/s and the velocity of the nozzle jet

V = K 2 gH = 0.98 2 9.81 475 = 94.5m / s

4Q

For jet diameter Q =AV or d =

= 0.225481m = 22.55cm

V

b) Nozzle pipe diameter = 25% bigger than the diameter of the jet flow = 1.25*22.55=28.19 cm

c) For pitch circle diameter of the wheel: for maximum efficiency, linear velocity of moving

wheel u is kept 48% of the nozzle jet velocity i.e u = 0.48 V = 0.48*94.5 = 45.3 m/s. (Modi

and sethi, Hydraulics and fluid mechanics and hydraulic machines chapter 20-22)

DN

So, For the mean bucket circle diameter u =

60

so Diameter of the wheel = D = (45.3*60) /(300*22/7) = 2.88 m

D

2.88

d) Number of buckets or striking plates = Z = 15 + 0.5 = 15 + 0.5

= 21.39 22nos

d

0.2255

The term D/d is also called as jet ratio

7.3

Introduction to bulb draft tube, tailrace canal and their importance

Bulb units are derived from Kaplan turbines, with the generator contained in a waterproofed bulb

submerged in the flow. Figure 6.13 illustrates a turbine where the generator (and gearbox if

required), cooled by pressurized air, is lodged in the bulb. Only the electric cables, duly protected,

leave the bulb. The bulb unit are specially designed for low head (<10 m) power project. The draft

tube provided for the bulb turbine is called as bulb draft tube which connects the outlet of the

reactive turbine runner to the tail race. The draft tube recovers the velocity head creating negative

suction pressure at the runner outlet. The draft tube also permits to set up the turbine above the

tailrace which might be critical for very low head power plants.

Tail race canal is the canal in which water is discharged after passing through the turbine. If the

power house is close to the stream, the out flow may be discharged directly in to the stream.

The tail race canal should be designed in such a way to have non silting and non scouring and

the minimum head loss.

7.4

Electromechanical installation: Generators and their types

8

Chapter-7: Hydropower Engineering

Generators transform mechanical energy into electrical energy. Although most early hydroelectric

systems were of the direct current variety to match early commercial electrical systems, nowadays

only three-phase alternating current generators are used in normal practice. Depending on the

characteristics of the network supplied, the producer can choose between:

Synchronous generators: They are equipped with a DC electric or permanent magnet

excitation system (rotating or static) associated with a voltage regulator to control the output

voltage before the generator is connected to the grid. They supply the reactive energy required

by the power system when the generator is connected to the grid. Synchronous generators can

run isolated from the grid and produce power since excitation is not grid-dependent.

The synchronous generator is started before connecting it to the mains by the turbine rotation.

By gradually accelerating the turbine, the generator must be synchronized with the mains,

regulating the voltage, frequency, phase angle and rotating sense. When all these values are

controlled correctly, the generator can be switched to the grid. In the case of an isolated or off

grid operation, the voltage controller maintains a predefined constant voltage, independent of

the load. In case of the mains supply, the controller maintains the predefined power factor or

reactive power.

7.5

Asynchronous generators: They are simple squirrel-cage induction motors with no possibility

of voltage regulation and running at a speed directly related to system frequency. They draw

their excitation current from the grid, absorbing reactive energy by their own magnetism.

Adding a bank of capacitors can compensate for the absorbed reactive energy. They cannot

generate when disconnected from the grid because they are incapable of providing their own

excitation current. However, they are used in very small stand-alone applications as a cheap

solution when the required quality of the electricity supply is not very high.

Purpose and working principles of Governors

Turbines are designed for a certain net head and discharge. Any deviation from these parameters

must be compensated for by opening or closing the control devices, such as the wicket-gates,

vanes, spear nozzles or valves, to keep either the outlet power frequency constant.

In schemes connected to an isolated network, the parameter that needs to be controlled is the

turbine speed, which controls the frequency. if the generator becomes overloaded the turbine

slows-down therefore an increase of the flow of water is needed to ensure the turbine does not stall.

Chapter-7: Hydropower Engineering

If there is not enough water to do this then either some of the load must be removed or the turbine

will have to be shut down. Conversely if the load decreases then the flow to the turbine is to be

decreased.

A governor is a combination of devices and mechanisms, which detect speed deviation and convert

it into a change in servomotor position. A speed-sensing element detects the deviation from the set

point; this deviation signal is converted and amplified to excite an actuator, hydraulic or electric,

that controls the water flow to the turbine. In a Francis turbine, where there is a reduction in water

flow you need to rotate the wicket-gates. For this, a powerful governor is required to overcome the

hydraulic and frictional forces and to maintain the wicket-gates in a partially closed position or to

close them completely.

In a modern electrical-hydraulic governor a sensor located on the generator shaft continuously

senses the turbine speed. The input is fed into a summing junction, where it is compared to a speed

reference. If the speed sensor signal differs from the reference signal, it emits an error signal

(positive or negative) that, once amplified, is sent to the servomotor so this can act in the required

sense.

Schematic Diagram of a Mechanical Governor

7.6

Classifications and dimensions of powerhouses

Classification of powerhouse based on ground level: a) surface powerhouse, b) underground

powerhouse and c) semi underground powerhouse

a. Surface powerhouse

Surface powerhouse is made above the natural ground level and mostly used in small RoR to

PROR projects having low head and at the wide river valleys for powerhouse area. The surface

powerhouse generally does not have space limitations and need sound rock in foundation and

10

Chapter-7: Hydropower Engineering

some architectural design. Proper River training works is important to protect the powerhouse

from flood damage. Generally the surface powerhouse are economical and ease of construction

if the river valley is wide and free from land and rock slide having stable river banks free from

the flood hazard and bank erosion.

b. Underground powerhouse: under special circumstances such as when gorge or valley forms

is narrow providing not enough space for surface powerhouse, underground powerhouses are

worth. Underground powerhouse would be an appropriate proposition when there are more

surface hazards like rock slides, land slide, floods etc. the basic requirements of the

underground power house is the availability of good sound rocks at the desired location and

depth. Underground power houses are safe from air attack during war time. Important

characteristics of underground power house station are its flexibility of layout. The shortest

possible layout through various feasible alignments can be drawn up with minimum size of

pressure conduits and omissions of anchor and valves. The first fully underground power

station was constructed in 1911 in Sweden and operated under a head of 24 m. Khimti (69

MW) hydropower project is the underground powerhouse of Nepal.

Powerhouse Structures

The hydropower station can be broadly classified into three parts: i) Substructure ii) Intermediate

structure and iii) Super structures

The sub structure of the power house is that part of the structures which is situated below the turbine

level. This part is almost universally below the ground level and it includes the draft tube, tail water

11

Chapter-7: Hydropower Engineering

channel in case of impulse wheels, the other natural drainage pipes of waste water from the power

house, drainage galleries. The sub structure transmits the load of the structure above it to the

foundation strata and is usually a massive concrete construction.

The intermediate structures extend from the top of the draft tube to the top of the generator

foundation. The turbine including its casing, the galleries for the auxiliary machines and governor

servo-motor system are housed in this part. The turbine floor is generally provided immediately above

the turbine level and it can be used to have an access to the turbine runner and the regulating ring. The

turbine floor is below the generator floor and is accessible through stairs. For horizontal shaft

arrangement, the intermediate structures may be absent as the turbine and generators are housed in

adjacent halls at the same floor.

The superstructure of the powerhouse is the portion extending from the generating floor, called the

main floor, up to the roof top. It consists of the generators and governors, control room, the exciters

and the auxiliary equipment such as needed for ventilation and cooling. The generators themselves are

either entirely above the floor level or partially above the floor level. The super structure consists of

walls and the roof with a main travelling gantry crane at the roof level. The control room is often

provided with the large glass panel which looks down upon the generator floor. The super structure

also consists of one wing having the office and stores.

Powerhouse Dimensions

The superstructure of the power house has the following three bays: a) machine hall or the unit bay b)

erection or the loading bay, c) control bay.

Machine hall: Length of the machine hall depends upon the number of units, the distance between the

units, and size of the machines. For the vertical alignment unit, the centre to centre distance between

the units is controlled by the total width of the scroll casing layout. The standard distance of scroll

casing is about 4.5 D to 5 D with the turbine outlet diameter as D. The minimum clearance of about 2

to 3 m. so the centre to centre distance between the units is taken as (5D+2.5) m. for higher specific

speeds, this requirements can be reduced to (4D+2.5)m. knowing the total number of units, the total

length of the machine hall can be worked out. The additional fore for the erection//loading is generally

equal to minimum one unit length by size.

Width of the machine hall is also determined by the size and the clearance space from the walls needed

as a gangway. Since the gangway requirements are of the order of 2.5 m, as a first approximation, the

width of the machine hall can be presumed to be (5D+2.5)m. the width is kept as less as possible to

keep small span of the girder and roof structures. In machine halls, the generator placing is not exactly

on the centre line of the hall but shifted to one side so as to provide adequate operating space for the

crane operations on the other side.

Height: the height of the machine hall is fixed up by the head room requirements (about 2.0 m to 2.5

m) of the crane operations. The hall must have a height which will enable the cranes to lift the rotor of

the generator or the runner of the turbine clear off the floor without any other machine sets forming

obstruction. To this clearance space is to be added the depth of crane girder and head room for the

operating cabin.

Loading bay: the loading bay, also known as erection or service bay, is a space where the heavy

vehicles can be loaded and unloaded, the dismantled parts of the machines can be placed and where

small assembling of the equipments can be done. The loading bay should be of sufficient to receive the

large parts like the rotor and runner. The loading bay floor will be having a width at least equal to the

centre to centre distance between the machines.

Control bay: is the main room and control other equipments like runner, gate valves, generator etc. it

may be adjacent to the unit bay i.e. machine halls as it sends instructions to the operation bay from

where the operation control is achieved.

12

Chapter-7: Hydropower Engineering

7.7

Pumps: Centrifugal, reciprocating and their performance characteristics, selection

and starting speed

Pumps are mechanical devices which converts mechanical energy supplied to it from the external

source in to hydraulic energy. Almost all the pumps increase the pressure energy of the liquid which is

subsequently converted into potential energy as the liquid is lifted from a lower level to higher level.

The pumps can be broadly classified into two groups: a) reciprocating (positive displacement) pumps,

b) Centrifugal (Rotodynamic) pumps

Reciprocating Pump: A reciprocating pump are also called positive displacement pumps in which the

liquid is sucked and then it is actually pushed or displaced due to thrust exerted on it by moving

member which results in lifting the liquid to the required height. These pumps usually have one or

more chambers which are alternately filled with the liquid to be pumped and then emptied again. As

such the discharge of liquid pumped by these pumps almost wholly depends on the speed of the pump.

A reciprocating pump essentially consists of a piston or plunger which moves to and fro in close

fitting cylinder. The cylinder is connected to suction and delivery pipes, each of which is provided

with a non return or one way valve called suction valve and delivery valve respectively. The suction

valve allows the liquid only to enter the cylinder and the delivery valve permits only its discharge

from the cylinder. The piston or plunger is connected to a crank by means of connecting rod.

If the liquid is in contact with one side of the piston or plunger only, it is known as single acting pump.

If the liquid is in contact with both the sides of piston or plunger, it is known as double acting pump.

Double acting pump has two suction and two delivery pipes with appropriate valves, so that during

each stroke when suction takes place on one side of the piston, the other side delivers the liquid.

Discharge

Discharge

Efficiency

Input Power

Discharge Q

Efficiency

Head (m)

Typical characteristics curves of reciprocating curve

The operating characteristics curves are plotting of discharge, power input and overall efficiency

against the head developed by the pump when it is operating at a constant speed. Under the ideal

condition, the discharge of the reciprocating pump operating at constant speed is independent of the

13

Chapter-7: Hydropower Engineering

head developed by the pump. However, in actual practice it is observed that the discharge of a

reciprocating pump decreases as the head developed by the pump increases.

(See Modi and seth books on Fluid Mechanics and Hydraulic machines chapter 23

for details)

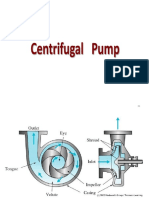

Centrifugal pump: also called as rotodynamic type of pumps in which dynamic pressure is developed

by rotating the fluid by a rotor. The basic principle on which centrifugal pump works is that when a

certain mass of fluid is made to rotate by an external force, it is thrown away from the central axis of

rotation and centrifugal head is impressed due to centrifugal action which enables it to rise to the

higher level. If more liquid is made available at the centre of rotation, a continuous supply of liquid at

higher level may be ensured.

Based on the direction of flow of liquid within the passage of the rotating wheel or impeller, the

rotodynamic pumps are classified as: i) centrifugal, ii) mixed flow and iii) axial flow or propeller

pumps

In centrifugal pump the liquid flows in the outward radial direction while the flow of liquid in a

propeller is in the axial direction parallel to the rotating shaft. The mixed flow pump, impeller has an

intermediate form so that the flow of liquid is in between the radial and axial directions. However

there are no rigid boundaries for separating these three types of pumps and often all the three types of

pumps are called centrifugal pumps. All these pumps are in close to the reverse of reactive turbine.

The main advantages of the centrifugal pump is that its discharging capacity is very much greater than

that of the reciprocating pump which can handle relatively small quantity of liquid only.

Reciprocating pumps may be in trouble due to clogging of valves in pumping muddy, viscous fluid etc

compared to that of the centrifugal pump. The maintenance cost of centrifugal pump is low and

reciprocating pumps are low speed pumps compared to that of the centrifugal pumps.

(See Modi and seth books on Fluid Mechanics and Hydraulic machines chapter 24

for details)

Head

Output Power

Input Power

Efficiency

Head

Efficiency

Input power

Output power

Discharge

Typical operating characteristics curves of the centrifugal pumps

14

Anda mungkin juga menyukai

- L2 Francis Turbine 2020 PDFDokumen73 halamanL2 Francis Turbine 2020 PDFBalkrishna ChaudharyBelum ada peringkat

- Pelton WheelDokumen17 halamanPelton WheelVineeta KanwalBelum ada peringkat

- New - Desk Study Report of Karnashi Thuligad Micro Hydro ProjectDokumen18 halamanNew - Desk Study Report of Karnashi Thuligad Micro Hydro ProjectManoj BaralBelum ada peringkat

- Francis Turbine ManualDokumen16 halamanFrancis Turbine ManualMuthu KumaranBelum ada peringkat

- Power Calculations For Pelton TurbinesDokumen19 halamanPower Calculations For Pelton TurbinestamailhamBelum ada peringkat

- C4ce22 Hydro Power Engineering Set1Dokumen9 halamanC4ce22 Hydro Power Engineering Set1bhkedarBelum ada peringkat

- Spherical Valve Foundation ForceDokumen1 halamanSpherical Valve Foundation ForceRakesh SapkotaBelum ada peringkat

- Asce Epri Guides 1989Dokumen59 halamanAsce Epri Guides 1989david_rosemberg50% (2)

- Hydraulic Turbines Explained: Types, Components & EfficienciesDokumen17 halamanHydraulic Turbines Explained: Types, Components & Efficiencieszakaria masud sonyBelum ada peringkat

- Banki Blade Turbine Calculations 19153Dokumen23 halamanBanki Blade Turbine Calculations 19153Juan FernándezBelum ada peringkat

- Selecting Hydraulic Turbines, Pump Turbines, Generators & MotorsDokumen160 halamanSelecting Hydraulic Turbines, Pump Turbines, Generators & MotorsDodik IstiantoBelum ada peringkat

- Impulse and Reaction TurbinesDokumen11 halamanImpulse and Reaction TurbinesjoshivishwanathBelum ada peringkat

- CFD Analysis of Pelton TurbineDokumen4 halamanCFD Analysis of Pelton TurbineSanam ManutdBelum ada peringkat

- National Institute of Technology, Rourkela Fluid Mechanics and Fluid Machines LaboratoryDokumen11 halamanNational Institute of Technology, Rourkela Fluid Mechanics and Fluid Machines LaboratoryBaishnaba KumbharBelum ada peringkat

- Design and Analysis of Conical Draft TubeDokumen31 halamanDesign and Analysis of Conical Draft TubeDhiraj NayakBelum ada peringkat

- Hydraulics and Hydraulic Machinery Exam QuestionsDokumen8 halamanHydraulics and Hydraulic Machinery Exam Questionshimabindugvsd71Belum ada peringkat

- IS-5496-Draft Tube Code PDFDokumen8 halamanIS-5496-Draft Tube Code PDFVardhanBelum ada peringkat

- LECTURE-1-Hydropower Basics PDFDokumen30 halamanLECTURE-1-Hydropower Basics PDFAfsar Ullah WazirBelum ada peringkat

- Seismic Failure of Radial Spillway GatesDokumen26 halamanSeismic Failure of Radial Spillway GatesFlorentina SuduBelum ada peringkat

- PUSHEP Underground Powerhouse PlanningDokumen4 halamanPUSHEP Underground Powerhouse PlanningPradeep SaxenaBelum ada peringkat

- Larji Hydropower Project ReportDokumen53 halamanLarji Hydropower Project ReportNishant Verma50% (4)

- Installation Specification for Hydraulic Turbine Generator UnitsDokumen104 halamanInstallation Specification for Hydraulic Turbine Generator Unitsearizabal100% (3)

- Parts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentDokumen15 halamanParts of Sprial Casing: Satish 12S/ME145 Mechanical Engineering DepartmentsatishBelum ada peringkat

- Retardation TestDokumen3 halamanRetardation TestalagurmBelum ada peringkat

- Design components of MHP for hydraulic dataDokumen34 halamanDesign components of MHP for hydraulic dataSomprasad PradhanBelum ada peringkat

- Hydropower Basic DesignDokumen76 halamanHydropower Basic Designfreak_brooklin100% (1)

- Disclosure To Promote The Right To InformationDokumen22 halamanDisclosure To Promote The Right To InformationDodik IstiantoBelum ada peringkat

- Samanala DamDokumen6 halamanSamanala DamefackopaBelum ada peringkat

- HYDRAULIC TURBINES - Hermod Brekke - 2015 (121-240)Dokumen120 halamanHYDRAULIC TURBINES - Hermod Brekke - 2015 (121-240)Emmanuel Alvarez100% (1)

- Malaysia Electricity TariffDokumen7 halamanMalaysia Electricity Tariffdumil100% (1)

- Hydropower Plant Pump EnglischDokumen13 halamanHydropower Plant Pump EnglischAnonymous CgFsILbeaBelum ada peringkat

- Pelton Turbine NotesDokumen24 halamanPelton Turbine NotesBalmukund KumarBelum ada peringkat

- Final - Report Hydroelectric Power PlantDokumen39 halamanFinal - Report Hydroelectric Power PlantnisarBelum ada peringkat

- Nepal College Hydropower ReportDokumen18 halamanNepal College Hydropower ReportAnurag JoshiBelum ada peringkat

- Surface Water IntakesDokumen26 halamanSurface Water IntakesKhalid AbeedBelum ada peringkat

- Optimum Design of Penstock For Hydro Projects PDFDokumen12 halamanOptimum Design of Penstock For Hydro Projects PDFTharindu Nuwan JayakodyBelum ada peringkat

- Run Away SpeedDokumen15 halamanRun Away SpeedSouravSawBelum ada peringkat

- Concept of E.on Netz For Offshore Grid ConnectionsDokumen33 halamanConcept of E.on Netz For Offshore Grid ConnectionsJACKBelum ada peringkat

- Introduction To Hydropower Francesco CarrascoDokumen102 halamanIntroduction To Hydropower Francesco Carrascojcasafranca100% (2)

- Managerial Structure of 500kv Grid StationDokumen18 halamanManagerial Structure of 500kv Grid StationSanaullah QaisraniBelum ada peringkat

- Technical Parameter of Spiral ClassifierDokumen1 halamanTechnical Parameter of Spiral ClassifierTerancen RajuBelum ada peringkat

- Converting To Variable Speed at A Pumped-Storage PlantDokumen9 halamanConverting To Variable Speed at A Pumped-Storage Plantle hoai NamBelum ada peringkat

- Design and Fabrication of Cross Flow Turbine Ok DisegnoDokumen39 halamanDesign and Fabrication of Cross Flow Turbine Ok DisegnoAdson JuniorBelum ada peringkat

- Variable Speed OperationDokumen10 halamanVariable Speed Operationmunagala balasubramanyamBelum ada peringkat

- Working Principle of Submersible PumpDokumen5 halamanWorking Principle of Submersible PumpSatinder saini100% (1)

- Pico Hydro Systems Univ of Nottingham PaperDokumen21 halamanPico Hydro Systems Univ of Nottingham PaperveguruprasadBelum ada peringkat

- Voith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesDokumen8 halamanVoith Siemens Hydro Power Generation Micro Turbines Harness Water ResourcesAshutosh VashishthaBelum ada peringkat

- 15-Hydraulic Turbines-New031211 (Compatibility Mode) PDFDokumen86 halaman15-Hydraulic Turbines-New031211 (Compatibility Mode) PDFMuhammad Noman50% (2)

- Water HammerDokumen22 halamanWater Hammerparvin_fBelum ada peringkat

- Guidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousesDokumen17 halamanGuidelines For Selection of Turbines, Preliminary Dimensioning and Layout of Surface Hydroelectric Power HousessubasratnaBelum ada peringkat

- Guide for Selection of Hydro Generators and Excitation SystemsDokumen44 halamanGuide for Selection of Hydro Generators and Excitation SystemsrajfabBelum ada peringkat

- Final Training ReportDokumen70 halamanFinal Training ReportkushalchandelBelum ada peringkat

- Literature Review HydroelectricDokumen6 halamanLiterature Review HydroelectricCham AmirruddinBelum ada peringkat

- CH7 Turbine SelectionDokumen34 halamanCH7 Turbine SelectionArus EdoBelum ada peringkat

- B59FC - Hydropower & Turbomachinery - TutorialDokumen13 halamanB59FC - Hydropower & Turbomachinery - Tutorialhansdavid.aquino2004Belum ada peringkat

- Icse (KMW) PDFDokumen5 halamanIcse (KMW) PDFtarrteaBelum ada peringkat

- AssignmentDokumen7 halamanAssignmentPrashannaBelum ada peringkat

- Hydraulic Machines Question BankDokumen11 halamanHydraulic Machines Question BankAdit Gaur100% (3)

- Scientific American Supplement, No. 633, February 18, 1888Dari EverandScientific American Supplement, No. 633, February 18, 1888Belum ada peringkat

- BeamDokumen1 halamanBeamSujan SinghBelum ada peringkat

- Basement Wall Design: Check For DepthDokumen1 halamanBasement Wall Design: Check For DepthSujan SinghBelum ada peringkat

- ND 4may2016 Endoscopy Cad-ModelDokumen1 halamanND 4may2016 Endoscopy Cad-ModelSujan SinghBelum ada peringkat

- Disaster Resilience and Safety:: A) Site ConsiderationDokumen9 halamanDisaster Resilience and Safety:: A) Site ConsiderationSujan SinghBelum ada peringkat

- FNDDokumen3 halamanFNDSujan SinghBelum ada peringkat

- BOQ NDokumen2 halamanBOQ NSujan SinghBelum ada peringkat

- Candidate Instruction ManualDokumen21 halamanCandidate Instruction ManualSujan SinghBelum ada peringkat

- NBD Eq6Dokumen80 halamanNBD Eq6Sujan SinghBelum ada peringkat

- Syllabus of Lok Sewa Aayog (First Part Exam) For Engineering Buildng and ArchitectDokumen4 halamanSyllabus of Lok Sewa Aayog (First Part Exam) For Engineering Buildng and ArchitectKiran Basu100% (2)

- Saiwzuzzr 06 V 7Dokumen3 halamanSaiwzuzzr 06 V 7Bibek BasnetBelum ada peringkat

- Building and Architecture TheoryDokumen3 halamanBuilding and Architecture Theoryशंकर थापाBelum ada peringkat

- List Of: S.No. ParticularsDokumen21 halamanList Of: S.No. ParticularsSujan SinghBelum ada peringkat

- Geometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseDokumen2 halamanGeometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseSujan SinghBelum ada peringkat

- Geometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseDokumen2 halamanGeometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseSujan SinghBelum ada peringkat

- Geometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseDokumen2 halamanGeometry of Staircase: (Limit State Method As Per IS 456-2000) Design of Stair-CaseSujan SinghBelum ada peringkat

- FNDDokumen3 halamanFNDSujan SinghBelum ada peringkat

- Staircase Design Calculation AnalysisDokumen3 halamanStaircase Design Calculation AnalysisSujan SinghBelum ada peringkat

- Structure Dhan BDR LasiwaDokumen37 halamanStructure Dhan BDR LasiwaSujan Singh100% (1)

- Pilla System PDFDokumen1 halamanPilla System PDFSujan SinghBelum ada peringkat

- JOSHI Bar ScheduleDokumen40 halamanJOSHI Bar ScheduleSujan SinghBelum ada peringkat

- Wall SystemDokumen1 halamanWall SystemSujan SinghBelum ada peringkat

- Slab PDFDokumen2 halamanSlab PDFSujan SinghBelum ada peringkat

- Disaster Resilience and Safety:: A) Site ConsiderationDokumen9 halamanDisaster Resilience and Safety:: A) Site ConsiderationSujan SinghBelum ada peringkat

- Design of Two Way Slab: StatusDokumen2 halamanDesign of Two Way Slab: StatusSujan SinghBelum ada peringkat

- List Of: S.No. ParticularsDokumen21 halamanList Of: S.No. ParticularsSujan SinghBelum ada peringkat

- Final RepDokumen32 halamanFinal RepSujan SinghBelum ada peringkat

- Staircase Design Calculation AnalysisDokumen3 halamanStaircase Design Calculation AnalysisSujan SinghBelum ada peringkat

- Structural Design OF: The Proposed Residential BuildingDokumen2 halamanStructural Design OF: The Proposed Residential BuildingSujan SinghBelum ada peringkat

- Agitator User ManualDokumen28 halamanAgitator User Manualmecmacho100% (1)

- Data Sheet Potable Sampling PumpDokumen2 halamanData Sheet Potable Sampling PumpHendri HermawanBelum ada peringkat

- API610 Pump Conform to API Standard 610, Tenth EditionDokumen13 halamanAPI610 Pump Conform to API Standard 610, Tenth EditionLukarsa2013100% (1)

- Allight Hl8whd A CatDokumen2 halamanAllight Hl8whd A CatAlbert AloepchaBelum ada peringkat

- 3b CHECKS TO BE DONE WHILE OVERHAULING A CENTRIFUGAL PUMPDokumen3 halaman3b CHECKS TO BE DONE WHILE OVERHAULING A CENTRIFUGAL PUMPДмитроBelum ada peringkat

- Brandt NOV Serie MDokumen124 halamanBrandt NOV Serie MArturo Suzan67% (3)

- FLUDEXDokumen50 halamanFLUDEXkingBelum ada peringkat

- Faf OmDokumen41 halamanFaf OmKRSRAMANBelum ada peringkat

- Maintenance Manual 2368.8000/A11-14 G2 (01/19/10) : LCC - Metal LCC - RubberDokumen35 halamanMaintenance Manual 2368.8000/A11-14 G2 (01/19/10) : LCC - Metal LCC - RubberJean Paul LezamaBelum ada peringkat

- Maintain Centrifugal PumpsDokumen3 halamanMaintain Centrifugal PumpsRohan NaikBelum ada peringkat

- KREBS UMD Mill Discharge Slurry Pump BrochureDokumen12 halamanKREBS UMD Mill Discharge Slurry Pump BrochureneshaBelum ada peringkat

- Wang 2018Dokumen17 halamanWang 2018Taxman HarrisonBelum ada peringkat

- IWAKI Magnetic Drive Pumps Resistant to Dry RunningDokumen8 halamanIWAKI Magnetic Drive Pumps Resistant to Dry RunningFernando LopezBelum ada peringkat

- Sewage Pump DASDokumen11 halamanSewage Pump DASindra putraBelum ada peringkat

- SJD (CEP) Sales PresentationDokumen29 halamanSJD (CEP) Sales Presentationpk198787Belum ada peringkat

- Boiler Feed PumpDokumen22 halamanBoiler Feed PumpnksatnamiBelum ada peringkat

- Pumps and CompressorsDokumen16 halamanPumps and CompressorsAbc AbcBelum ada peringkat

- Integrally Geared Compressors in The CPIDokumen5 halamanIntegrally Geared Compressors in The CPIAnonymous 1zdRSWskhgBelum ada peringkat

- RR250 - C30 OmmDokumen16 halamanRR250 - C30 OmmturboshaftBelum ada peringkat

- Gas-Liquid Flow Through Electric Submersible PumpsDokumen8 halamanGas-Liquid Flow Through Electric Submersible PumpspicapicBelum ada peringkat

- Canned Motor PumpDokumen35 halamanCanned Motor PumpHyoungyoon John MoonBelum ada peringkat

- Centrifugal Pump Technical SpecificationDokumen2 halamanCentrifugal Pump Technical SpecificationJose GalindoBelum ada peringkat

- MBN - E00657 Multistage Pump PDFDokumen8 halamanMBN - E00657 Multistage Pump PDFAlfonso BlancoBelum ada peringkat

- (4.2) HM ManualDokumen28 halaman(4.2) HM ManualGỗ Mộc0% (1)

- Fan Heater - B-011 - Data SheetsDokumen9 halamanFan Heater - B-011 - Data SheetsNadim Ahmad SiddiqueBelum ada peringkat

- MSI Centrifugal Impeller Structural Resonance PDFDokumen9 halamanMSI Centrifugal Impeller Structural Resonance PDFJigneshBelum ada peringkat

- Caprari TechSpec8Dokumen6 halamanCaprari TechSpec8Catalin SmarandaBelum ada peringkat

- Regent Dinflow BrochureDokumen4 halamanRegent Dinflow Brochurebob marleyBelum ada peringkat

- Centrifugal Pump Impeller Design and PerformanceDokumen105 halamanCentrifugal Pump Impeller Design and PerformanceMohamed Moataz100% (1)

- Centrifugal Pumps - How They Work & Key Design FeaturesDokumen42 halamanCentrifugal Pumps - How They Work & Key Design Featuresmostafa_ibrahim007Belum ada peringkat