Base Plate

Diunggah oleh

Sunil SinghJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Base Plate

Diunggah oleh

Sunil SinghHak Cipta:

Format Tersedia

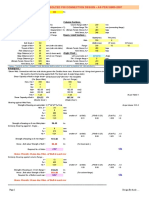

DESIGN OF BASE PLATE BP1:

APPROACH: LIMIT STATE DESIGN

FACTORED LOAD COMBINATIONS

Beam

L/C

4289

4288

4289

Axial

Shear-Y

Shear-Z

Force kN

kN

kN

2268 -5691.291 338.157 820.925

2267 3772.552

17.311

646.46

2268 -5682.655

402.82 873.128

Node

367

375

363

Factored Design Forces:

Pmax (P)

Ptension (T)

Max resultant shear (S)

Torsion Moment- Moment-Z

kNm

Y kNm

kNm

0.029

0

0

0

0

0

0.028

0

0

5691.300 kN

3772.600 kN

961.60 kN

Input

Yield stress of steel Fy =

Permissible bending stress fbs = Fy/1.1

Permissible bearing stress for M40 Grout =

(As per Cl. 8.4 of 3669-AXSG-002)

Dia of bolt =

Total no of bolts =

No of bolts on each side =

Limiting Tension capacity of bolt =

Limiting Shear capacity of bolt =

Ultimate Tension capacity of bolt=

Ultimate shear capacity of bolt=

250

227.27

24

60

8

4

531.00

306.57

774.1

446.915

(Ref, clause 8.2.1.2 IS800:2007)

(Ref, Clause 7.4.1, IS800-2007)

mm

nos.

nos.

kN

kN

kN

kN

Strength Increase Factors for Wind/Seismic loads.

Strength increase factor for Bolt Capacity

Stress increase factor for fbs

L=

Mpa

Mpa

Mpa

1

1

1100

mm

270

mm

column section

b eff.

600

B =

b eff.

350

a

a= 145

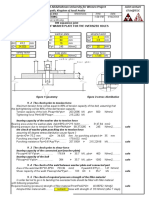

1) Check for bearing pressure:

for Beam

4289

L/C

Pmax (P)

5691.30 kN

Max pressure =

P/( L x B ) = 8.623

Permissible bearing pressure =

24

Max pressure < permissible bearing pressure

safe in bearing pressure

367

Mpa

Mpa

PG600X400A

As per Clause 7.4.3.1 (Fig-9) of IS 800: 2007,

ts = sqrt (2.5wc2gmo/fy)

Thus, c =

c=

ts x sqrt (fy/2.5wgmo)

97.31

mm

2) Check for Tension in bolt:

for Beam

4288

L/C

Ptension (T)

3772.60 kN

Tension per bolt = T / Total no of bolts

Tension per bolt =

(Provided all around the column, effective area somes within the

provided base plate only)

375

471.58 kN

Limiting Tension capacity of bolt =

531 kN

Tension per bolt < Tension capacity of bolt

Bolt is safe in tension

3) Check for Shear in bolt:

for Beam

4289

L/C

363

Max resultant shear (S)

961.60

kN

shear per bolt = Resultant shear / total no of bolt

shear per bolt =

120.20 kN

Permissible shear force in bolt =

306.57 kN

bolt is safe in Shear

4) Check for combined shear and tension in bolt:

( Cl. 10.3.6 of IS 800)

(Actual tension/allow. Tension)2 + (Actual shear/allow. Shear)2

0.94

Bolt is Safe in combined shear & tension

< 1.0

< 1.0

5) Calculation of base plate thickness:

Case 1) Due to max pressure with Three edges fixed:

Max pressure =

8.623 Mpa

Considering roark's formulae, for three edges fixed

a=

264 mm

a/b = 0.91

( By interpolation)

b3 =

b=

0.4060

291 mm

Thickness of plate t1 = sqrt[(b*qmax*b2)/1.5*fbs]

t1 =

29.490 mm

b=

291 mm

Case 2) Due to max Tension:

Max tension in bolt =

471.58 kN

Panel dimension:

Stiffener provided (insert YES or NO)

YES

a1

a=

262

mm

b=

290

mm

a1=

133

mm

b1=

165

mm

effective width b eff =min(a,b,2a1,2b1)

262

mm

Moment @ face =Mt=T.a1/(1+2(a1/b1))

(if stiffner is present)

=T.max(a1,b1) (otherwise)

Mt =

24.0109359 kNm

Thickness of plate t2 = sqrt[(6*Mt)/(1.5*fbs*b eff)]

t2 =

40.16 mm

b1

Case 3) Due to max pressure for Cantilever:

Moment @ section Flange =qmax x lever arm (a)^2 / 2

Mt =

0.0907 kNm/mm

Thickness of plate t3 = sqrt[(6*Mt)/(1.5*fbs*1)]

t3 =

39.94 mm

Hence provide base plate thickness

50

mm

CHECK FOR BOLT CAPACITY AS PER CLAUSE 12.12.2

For design of Shear Key consider Tension case

Column Section used:

Designation of member =

Depth of membe r= d =

Thickness of web = tw =

Width of flange = fw =

Thickness of flange = tf =

PG600X400A

600 mm

20 mm

400 mm

32 mm

Shear check for web:

Full Shear Capacity of web = Vfull = fy/sqrt(3)*d*tw

Design shear = 1.2*.Vfull =

1732.05 kN

2078.46 kN

Shear on each bolt =

Shear resistance of bolt in combination with tension

259.81 kN

140.92 kN

(section 8.4.1)

(as per clause 12.12.2)

X

Shear Key is requied

20

Z

Shear to be resisted by web of shear key =

951.08 kN

200

20

Thickness of web plate for shear key = twp =

20 mm

16

Depth of web plate required for shear key = dp =

Provide depth of web plate for shear key =

164.73 mm

185 mm

185

16

217

Depth of shear key below TOC =

Thickness of grout

Moment due to web shear = Mw =

Bending stress = Mw / Zxx

Permissible bending stress = fy / gmo

125 mm

Ixx =

Izz =

Zxx =

Zzz =

Area =

25 mm

83.219 kNm

105.134 N/mm2

<

227.27 N/mm2

Thickness of flange plate for shear key = tfp =

16 mm

Provide Width of flange plate for shear key =

200 mm

OK

(section 8.2.1.2)

UNSAFE

8.59E+07

6.89E+07

7.92E+05

6.89E+05

10100

mm4

mm4

mm3

mm3

mm2

DESIGN OF BASE PLATE BP2:

APPROACH: LIMIT STATE DESIGN

FACTORED LOAD COMBINATIONS

Beam

L/C

238

237

238

Axial

Shear-Y

Shear-Z

Force kN

kN

kN

163 -8315.828

31.43 1348.476

162

5850

16.829 1375.722

163 -7736.491

8.718 1452.939

Node

338

312

323

Factored Design Forces:

Pmax (P)

Ptension (T)

Max resultant shear (S)

Torsion

kNm

Moment-Y Moment-Z

kNm

kNm

0

0

0

0.004

0

0

0.002

0

0

8316.000 kN

5850.000 kN

1375.82 kN

Input

Yield stress of steel Fy =

Permissible bending stress fbs = Fy/1.1

Permissible bearing stress for M40 Grout =

(As per Cl. 8.4 of 3669-AXSG-002)

Dia of bolt =

Total no of bolts =

No of bolts on each side =

Limiting Tension capacity of bolt =

Limiting Shear capacity of bolt =

Ultimate Tension capacity of bolt=

Ultimate shear capacity of bolt=

250

227.27

24

72

8

4

778.50

449.47

1134.9

655.223

(Ref, clause 8.2.1.2 IS800:2007)

(Ref, Clause 7.4.1, IS800-2007)

mm

nos.

nos.

kN

kN

kN

kN

Strength Increase Factors for Wind/Seismic loads.

Strength increase factor for Bolt Capacity

Stress increase factor for fbs

L=

Mpa

Mpa

Mpa

1

1

1100

mm

270

mm

column section

PG600X600

b eff.

600

B =

b eff.

350

a

a= 140

1) Check for bearing pressure:

for Beam

238

L/C

Pmax (P)

8316.00 kN

Max pressure =

P/( L x B ) = 12.600

Permissible bearing pressure =

24

Max pressure < permissible bearing pressure

safe in bearing pressure

338

Mpa

Mpa

As per Clause 7.4.3.1 (Fig-9) of IS 800: 2007,

ts = sqrt (2.5wc2gmo/fy)

Thus, c =

c=

ts x sqrt (fy/2.5wgmo)

97.31

mm

(Provided all around the column, effective area somes within the

provided base plate only)

2) Check for Tension in bolt:

for Beam

237

L/C

Ptension (T)

5850.00 kN

Tension per bolt = T / Total no of bolts

Tension per bolt =

312

731.25 kN

Limiting Tension capacity of bolt =

778.5 kN

Tension per bolt < Tension capacity of bolt

Bolt is safe in tension

3) Check for Shear in bolt:

for Beam

238

L/C

323

Max resultant shear (S)

530.98

kN

shear per bolt = Resultant shear / total no of bolt

shear per bolt =

66.37 kN

Permissible shear force in bolt =

(As shear key is provided, shear to be resisted by bolt is

total shear - shear capacity of shear key)

449.47 kN

bolt is safe in Shear

4) Check for combined shear and tension in bolt:

( Cl. 10.3.6 of IS 800)

(Actual tension/allow. Tension)2 + (Actual shear/allow. Shear)2

0.90

Bolt is Safe in combined shear & tension

< 1.0

< 1.0

5) Calculation of base plate thickness:

Case 1) Due to max pressure with Three edges fixed:

Max pressure =

12.600 Mpa

Considering roark's formulae, for three edges fixed

a=

263 mm

a/b = 0.91

( By interpolation)

b3 =

b=

0.4010

290 mm

Thickness of plate t1 = sqrt[(b*qmax*b2)/1.5*fbs]

t1 =

35.305 mm

b=

290 mm

Case 2) Due to max Tension:

Max tension in bolt =

731.25 kN

Panel dimension:

Stiffener provided (insert YES or NO)

YES

a1

a=

263

mm

b=

290

mm

a1=

133

mm

b1=

165

mm

effective width b eff =min(a,b,2a1,2b1)

263

mm

Moment @ face =Mt=T.a1/(1+2(a1/b1))

(if stiffner is present)

=T.max(a1,b1) (otherwise)

Mt = 37.23267111 kNm

Thickness of plate t2 = sqrt[(6*Mt)/(1.5*fbs*b eff)]

t2 =

49.92 mm

b1

Case 3) Due to max pressure for Cantilever:

Moment @ section Flange =qmax x lever arm (a)^2 / 2

Mt =

0.1235 kNm/mm

Thickness of plate t3 = sqrt[(6*Mt)/(1.5*fbs*1)]

t3 =

46.62 mm

Hence provide base plate thickness

50

mm

CHECK FOR BOLT CAPACITY AS PER CLAUSE 12.12.2

For design of Shear Key consider Tension case

Column Section used:

Designation of member =

Depth of membe r= d =

Thickness of web = tw =

Width of flange = fw =

Thickness of flange = tf =

PG600X600

600 mm

20 mm

600 mm

32 mm

Shear check for web:

Full Shear Capacity of web = Vfull = fy/sqrt(3)*d*tw

Design shear = 1.2*.Vfull =

1732.05 kN

2078.46 kN

Shear on each bolt =

Shear resistance of bolt in combination with tension

259.81 kN

154.20 kN

(section 8.4.1)

(as per clause 12.12.2)

X

Shear Key is requied

16

Z

Shear to be resisted by web of shear key =

844.84 kN

200

16

Thickness of web plate for shear key = twp =

16 mm

16

Depth of web plate required for shear key = dp =

Provide depth of web plate for shear key =

182.91 mm

185 mm

185

16

217

Depth of shear key below TOC =

Thickness of grout

125 mm

25 mm

Moment due to web shear = Mw =

73.923 kNm

Bending stress = Mw / Zxx

98.217 N/mm2

<

227.27 N/mm2

Permissible bending stress = fy / gmo

Ixx =

Izz =

Zxx =

Zzz =

Area =

Thickness of flange plate for shear key = tfp =

16 mm

Provide Width of flange plate for shear key =

200 mm

OK

(section 8.2.1.2)

UNSAFE

8.17E+07

6.32E+07

7.53E+05

6.32E+05

9360

mm4

mm4

mm3

mm3

mm2

DESIGN OF BASE PLATE BP3:

APPROACH: LIMIT STATE DESIGN

FACTORED LOAD COMBINATIONS

Beam

L/C

244

244

244

Axial

Shear-Y

Force kN

kN

168 -4397.427 -277.345

168 2807.451 199.346

168 -1668.595 -681.364

Node

336

311

321

Factored Design Forces:

Pmax (P)

Ptension (T)

Max resultant shear (S)

Shear-Z

kN

31.795

20.254

37.347

Torsion

kNm

Moment-Y Moment-Z

kNm

kNm

0

0

0

0.001

0

0

0

0

0

4397.000 kN

2807.450 kN

682.40 kN

Input

Yield stress of steel Fy =

Permissible bending stress fbs = Fy/1.1

Permissible bearing stress for M40 Grout =

(As per Cl. 8.4 of 3669-AXSG-002)

Dia of bolt =

Total no of bolts =

No of bolts on each side =

Limiting Tension capacity of bolt =

Limiting Shear capacity of bolt =

Ultimate Tension capacity of bolt=

Ultimate shear capacity of bolt=

250

227.27

24

52

8

4

396.00

228.63

577.3

333.293

(Ref, clause 8.2.1.2 IS800:2007)

(Ref, Clause 7.4.1, IS800-2007)

mm

nos.

nos.

kN

kN

kN

kN

Strength Increase Factors for Wind/Seismic loads.

Strength increase factor for Bolt Capacity

Stress increase factor for fbs

L=

Mpa

Mpa

Mpa

1

1

1100

mm

270

mm

column section

PG600X400

b eff.

600

B =

b eff.

350

a

a= 140

1) Check for bearing pressure:

for Beam

244

L/C

Pmax (P)

4397.00 kN

Max pressure =

P/( L x B ) = 6.662

Permissible bearing pressure =

24

Max pressure < permissible bearing pressure

safe in bearing pressure

336

Mpa

Mpa

As per Clause 7.4.3.1 (Fig-9) of IS 800: 2007,

ts = sqrt (2.5wc2gmo/fy)

Thus, c =

c=

ts x sqrt (fy/2.5wgmo)

77.85

mm

(Provided all around the column, effective area somes within the

provided base plate only)

2) Check for Tension in bolt:

for Beam

244

L/C

Ptension (T)

2807.45 kN

Tension per bolt = T / Total no of bolts

Tension per bolt =

311

350.93 kN

Limiting Tension capacity of bolt =

396 kN

Tension per bolt < Tension capacity of bolt

Bolt is safe in tension

3) Check for Shear in bolt:

for Beam

244

L/C

321

Max resultant shear (S)

682.40

kN

shear per bolt = Resultant shear / total no of bolt

shear per bolt =

85.30 kN

Permissible shear force in bolt =

228.63 kN

bolt is safe in Shear

4) Check for combined shear and tension in bolt:

( Cl. 10.3.6 of IS 800)

(Actual tension/allow. Tension)2 + (Actual shear/allow. Shear)2

0.92

Bolt is Safe in combined shear & tension

< 1.0

< 1.0

5) Calculation of base plate thickness:

Case 1) Due to max pressure with Three edges fixed:

Max pressure =

6.662 Mpa

Considering roark's formulae, for three edges fixed

a=

269 mm

a/b = 0.92

( By interpolation)

b3 =

b=

0.5110

291 mm

Thickness of plate t1 = sqrt[(b*qmax*b 2)/1.5*fbs]

t1 =

29.080 mm

b=

291 mm

Case 2) Due to max Tension:

Max tension in bolt =

350.93 kN

Panel dimension:

Stiffener provided (insert YES or NO)

YES

a1

a=

269

mm

b=

290

mm

a1=

140

mm

b1=

165

mm

effective width b eff =min(a,b,2a1,2b1)

269

mm

Moment @ face =Mt=T.a1/(1+2(a1/b1))

(if stiffner is present)

=T.max(a1,b1) (otherwise)

Mt = 18.21688062 kNm

Thickness of plate t2 = sqrt[(6*Mt)/(1.5*fbs*b eff)]

t2 =

34.52 mm

b1

Case 3) Due to max pressure for Cantilever:

Moment @ section Flange =qmax x lever arm (a)^2 / 2

Mt =

0.0653 kNm/mm

Thickness of plate t3 = sqrt[(6*Mt)/(1.5*fbs*1)]

t3 =

33.90 mm

Hence provide base plate thickness

40

mm

CHECK FOR BOLT CAPACITY AS PER CLAUSE 12.12.2

For design of Shear Key consider Tension case

Column Section used:

Designation of member =

Depth of membe r= d =

Thickness of web = tw =

Thickness of flange = tf =

PG600X400

600 mm

20 mm

25 mm

Shear check for web:

Full Shear Capacity of web = Vfull = fy/sqrt(3)*d*tw

Design shear = 1.2*.Vfull =

1732.05 kN

2078.46 kN

Shear on each bolt =

Ultimate shear capacity of each bolt =

Shear resistance of bolt in combination with tension

259.81 kN

333.293 kN

105.93 kN

(section 8.4.1)

(as per clause 12.12.2)

X

Shear Key is requied

25

Z

Shear to be resisted by web of shear key =

1231.02 kN

200

25

Thickness of web plate for shear key = twp =

25 mm

16

Depth of web plate required for shear key = dp =

Provide depth of web plate for shear key =

170.58 mm

185 mm

185

16

217

Depth of shear key below TOC =

Shear on each bolt =

Ultimate shear capacity of each bolt =

150 mm

649.52 kN

333.293 kN

Shear Key is requied

Shear to be resisted by flange of shear key =

Thickness of flange plate for shear key = tfp =

Width of flange plate required for shear key = wp =

Provide Width of flange plate for shear key =

Ixx =

Izz =

4348.72 kN

16 mm

941.52 mm

200 mm

UNSAFE

9.12E+07 mm4

7.38E+07 mm4

DESIGN OF BASE PLATE BP4:

APPROACH: LIMIT STATE DESIGN

FACTORED LOAD COMBINATIONS

Beam

L/C

5854

5854

5854

Axial

Shear-Y

Force kN

kN

220 -5978.742

95.225

220 3397.123

-83.404

220 -3988.509

-42.115

Node

333

314

367

Factored Design Forces:

Pmax (P)

Ptension (T)

Max resultant shear (S)

Shear-Z

kN

497.518

-409.165

697.369

Torsion Moment-Y Moment-Z

kNm

kNm

kNm

-0.002

0.001

-0.003

-0.004

-0.001

0

-0.005

0.001

-0.003

5979.000 kN

3398.000 kN

699.00 kN

Input

Yield stress of steel Fy =

Permissible bending stress fbs = Fy/1.1

Permissible bearing stress for M40 Grout =

(As per Cl. 8.4 of 3669-AXSG-002)

Dia of bolt =

Total no of bolts =

No of bolts on each side =

Limiting Tension capacity of bolt =

Limiting Shear capacity of bolt =

Ultimate Tension capacity of bolt=

Ultimate shear capacity of bolt=

250

227.27

24

60

10

5

531.00

306.57

774.1

446.915

(Ref, clause 8.2.1.2 IS800:2007)

(Ref, Clause 7.4.1, IS800-2007)

mm

nos.

nos.

kN

kN

kN

kN

Strength Increase Factors for Wind/Seismic loads.

Strength increase factor for Bolt Capacity

Stress increase factor for fbs

L=

Mpa

Mpa

Mpa

1

1

1100

mm

270

mm

column section

PG600X600

b eff.

800

B =

b eff.

270

a

a= 145

1) Check for bearing pressure:

for Beam

5854

L/C

Pmax (P)

5979.00 kN

Max pressure =

P/( L x B ) = 6.794

Permissible bearing pressure =

24

Max pressure < permissible bearing pressure

safe in bearing pressure

333

Mpa

Mpa

As per Clause 7.4.3.1 (Fig-9) of IS 800: 2007,

ts = sqrt (2.5wc2gmo/fy)

Thus, c =

c=

ts x sqrt (fy/2.5wgmo)

97.31

mm

(Provided all around the column, effective area somes within the

provided base plate only)

2) Check for Tension in bolt:

for Beam

5854

L/C

Ptension (T)

3398.00 kN

Tension per bolt = T / Total no of bolts

Tension per bolt =

314

339.80 kN

Limiting Tension capacity of bolt =

531 kN

Tension per bolt < Tension capacity of bolt

Bolt is safe in tension

3) Check for Shear in bolt:

for Beam

5854

L/C

367

Max resultant shear (S)

699.00

kN

shear per bolt = Resultant shear / total no of bolt

shear per bolt =

69.90 kN

Permissible shear force in bolt =

306.57 kN

bolt is safe in Shear

4) Check for combined shear and tension in bolt:

( Cl. 10.3.6 of IS 800)

(Actual tension/allow. Tension)2 + (Actual shear/allow. Shear)2

0.46

Bolt is Safe in combined shear & tension

< 1.0

< 1.0

5) Calculation of base plate thickness:

Case 1) Due to max pressure with Three edges fixed:

Max pressure =

6.794 Mpa

Considering roark's formulae, for three edges fixed

a=

262 mm

a/b = 0.67

( By interpolation)

b3 =

b=

0.5110

390 mm

Thickness of plate t1 = sqrt[(b*qmax*b 2)/1.5*fbs]

t1 =

39.358 mm

b=

390 mm

Case 2) Due to max Tension:

Max tension in bolt =

339.80 kN

Panel dimension:

Stiffener provided (insert YES or NO)

YES

a1

a=

262

mm

b=

390

mm

a1=

133

mm

b1=

125

mm

effective width b eff =min(a,b,2a1,2b1)

250

mm

Moment @ face =Mt=T.a1/(1+2(a1/b1))

(if stiffner is present)

=T.max(a1,b1) (otherwise)

Mt =

14.4480179 kNm

Thickness of plate t2 = sqrt[(6*Mt)/(1.5*fbs*b eff)]

t2 =

31.89 mm

b1

Case 3) Due to max pressure for Cantilever:

Moment @ section Flange =qmax x lever arm (a)^2 / 2

Mt =

0.0714 kNm/mm

Thickness of plate t3 = sqrt[(6*Mt)/(1.5*fbs*1)]

t3 =

35.46 mm

Hence provide base plate thickness

50

mm

CHECK FOR BOLT CAPACITY AS PER CLAUSE 12.12.2

For design of Shear Key consider Tension case

Column Section used:

Designation of member =

Depth of membe r= d =

Thickness of web = tw =

Thickness of flange = tf =

PG600X600

600 mm

20 mm

32 mm

Shear check for web:

Full Shear Capacity of web = Vfull = fy/sqrt(3)*d*tw

Design shear = 1.2*.Vfull =

1732.05 kN

2078.46 kN

Shear on each bolt =

Ultimate shear capacity of each bolt =

Shear resistance of bolt in combination with tension

207.85 kN

446.915 kN

235.58 kN

(section 8.4.1)

(as per clause 12.12.2)

X

No need for Shear Key

20

Z

Shear to be resisted by web of shear key =

0.00 kN

200

20

Thickness of web plate for shear key = twp =

20 mm

16

Depth of web plate required for shear key = dp =

Provide depth of web plate for shear key =

mm

185 mm

185

16

217

Depth of shear key below TOC =

Shear on each bolt =

Ultimate shear capacity of each bolt =

150 mm

665.11 kN

446.915 kN

Shear Key is requied

Shear to be resisted by flange of shear key =

Thickness of flange plate for shear key = tfp =

Width of flange plate required for shear key = wp =

Provide Width of flange plate for shear key =

Ixx =

Izz =

4295.25 kN

16 mm

929.95 mm

200 mm

UNSAFE

8.59E+07 mm4

6.89E+07 mm4

DESIGN OF BASE PLATE BP5:

APPROACH: LIMIT STATE DESIGN

FACTORED LOAD COMBINATIONS

Beam

L/C

255

255

243

Axial

Shear-Y

Force kN

kN

178

-404.36

-17.512

178

-404.36

-17.512

167 -339.266

-14.98

Node

381

381

337

Factored Design Forces:

Pmax (P)

Ptension (T)

Max resultant shear (S)

Shear-Z

kN

-204.709

-204.709

209.387

Torsion Moment-Y Moment-Z

kNm

kNm

kNm

0.002

0

0

0.002

0

0

-0.002

0

0

405.000 kN

0.000 kN

210.00 kN

Input

Yield stress of steel Fy =

Permissible bending stress fbs = Fy/1.1

Permissible bearing stress for M40 Grout =

(As per Cl. 8.4 of 3669-AXSG-002)

Dia of bolt =

Total no of bolts =

No of bolts on each side =

Limiting Tension capacity of bolt =

Limiting Shear capacity of bolt =

Ultimate Tension capacity of bolt=

Ultimate shear capacity of bolt=

250

227.27

24

33

4

2

156.15

90.15

227.6

131.423

(Ref, clause 8.2.1.2 IS800:2007)

(Ref, Clause 7.4.1, IS800-2007)

mm

nos.

nos.

kN

kN

kN

kN

Strength Increase Factors for Wind/Seismic loads.

Strength increase factor for Bolt Capacity

Stress increase factor for fbs

L=

Mpa

Mpa

Mpa

1

1

600

mm

250

mm

column section NPB 500 x 200 x 90.7

b eff.

300

B =

b eff.

180

a

a= 50

1) Check for bearing pressure:

for Beam

255

L/C

Pmax (P)

405.00 kN

Max pressure =

P/( L x B ) = 2.250

Permissible bearing pressure =

24

Max pressure < permissible bearing pressure

safe in bearing pressure

381

Mpa

Mpa

As per Clause 7.4.3.1 (Fig-9) of IS 800: 2007,

ts = sqrt (2.5wc2gmo/fy)

Thus, c =

c=

ts x sqrt (fy/2.5wgmo)

77.85

mm

(Provided all around the column, effective area somes within the

provided base plate only)

2) Check for Tension in bolt:

for Beam

255

L/C

Ptension (T)

0.00 kN

Tension per bolt = T / Total no of bolts

Tension per bolt =

381

0.00 kN

Limiting Tension capacity of bolt = 156.15 kN

Tension per bolt < Tension capacity of bolt

Bolt is safe in tension

3) Check for Shear in bolt:

for Beam

243

L/C

337

Max resultant shear (S)

210.00

kN

shear per bolt = Resultant shear / total no of bolt

shear per bolt =

52.50 kN

Permissible shear force in bolt =

90.15 kN

bolt is safe in Shear

4) Check for combined shear and tension in bolt:

( Cl. 10.3.6 of IS 800)

(Actual tension/allow. Tension)2 + (Actual shear/allow. Shear)2

0.34

Bolt is Safe in combined shear & tension

< 1.0

< 1.0

5) Calculation of base plate thickness:

Case 1) Due to max pressure with Three edges fixed:

Max pressure =

2.250 Mpa

Considering roark's formulae, for three edges fixed

a=

228 mm

a/b = 1.57

( By interpolation)

b3 =

b=

1.0730

144.9 mm

Thickness of plate t1 = sqrt[(b*qmax*b2)/1.5*fbs]

t1 =

12.194 mm

b=

144.9 mm

Case 2) Due to max Tension:

Max tension in bolt =

Panel dimension:

Stiffener provided (insert YES or NO)

0.00 kN

a1

YES

a=

228

mm

b=

144.9

mm

a1=

119

mm

b1=

84.9

mm

effective width b eff =min(a,b,2a1,2b1)

144.9

mm

Moment @ face =Mt=T.a1/(1+2(a1/b1))

(if stiffner is present)

=T.max(a1,b1) (otherwise)

Mt =

0 kNm

Thickness of plate t2 = sqrt[(6*Mt)/(1.5*fbs*b eff)]

t2 =

0.00 mm

b1

Case 3) Due to max pressure for Cantilever:

Moment @ section Flange =qmax x lever arm (a)^2 / 2

Mt =

0.0028 kNm/mm

Thickness of plate t3 = sqrt[(6*Mt)/(1.5*fbs*1)]

t3 =

7.04 mm

Hence provide base plate thickness

40

mm

CHECK FOR BOLT CAPACITY AS PER CLAUSE 12.12.2

For design of Shear Key consider Tension case

Column Section used:

Designation of member =

Depth of membe r= d =

Thickness of web = tw =

Thickness of flange = tf =

NPB 500 x 200 x 90.7

500 mm

10.2 mm

16 mm

Shear check for web:

Full Shear Capacity of web = Vfull = fy/sqrt(3)*d*tw

Design shear = 1.2*.Vfull =

736.12 kN

883.35 kN

Shear on each bolt =

Ultimate shear capacity of each bolt =

Shear resistance of bolt in combination with tension

220.84 kN

131.423 kN

90.15 kN

(section 8.4.1)

(as per clause 12.12.2)

X

Shear Key is requied

16

Z

Shear to be resisted by web of shear key =

522.73 kN

110

16

Thickness of web plate for shear key = twp =

16 mm

20

Depth of web plate required for shear key = dp =

113.18 mm

Provide depth of web plate for shear key =

120 mm

Depth of shear key below TOC =

125 mm

Shear on each bolt =

Ultimate shear capacity of each bolt =

277.13 kN

131.423 kN

Shear Key is requied

120

20

160

OK

Ixx =

Izz =

2.63E+07 mm4

1.04E+07 mm4

Shear to be resisted by flange of shear key =

Thickness of flange plate for shear key = tfp =

Width of flange plate required for shear key = wp =

Provide Width of flange plate for shear key =

747.90 kN

20 mm

129.54 mm

110 mm

UNSAFE

DESIGN OF BASE PLATE BP5:

APPROACH: LIMIT STATE DESIGN

FACTORED LOAD COMBINATIONS

Beam

L/C

3205

3205

3205

Axial

Shear-Y

Force kN

kN

3488 -138.602

-46.267

3488 -138.602

-46.267

3488 -124.696

-50.892

Node

317

317

321

Factored Design Forces:

Pmax (P)

Ptension (T)

Max resultant shear (S)

Shear-Z

kN

-0.002

-0.002

0.003

Torsion Moment-Y Moment-Z

kNm

kNm

kNm

0.004

0

0

0.004

0

0

0

0

0

140.000 kN

0.000 kN

60.00 kN

Input

Yield stress of steel Fy =

Permissible bending stress fbs = Fy/1.1

Permissible bearing stress for M40 Grout =

(As per Cl. 8.4 of 3669-AXSG-002)

Dia of bolt =

Total no of bolts =

No of bolts on each side =

Limiting Tension capacity of bolt =

Limiting Shear capacity of bolt =

Ultimate Tension capacity of bolt=

Ultimate shear capacity of bolt=

250

227.27

24

24

4

2

79.43

45.86

115.8

66.848

(Ref, clause 8.2.1.2 IS800:2007)

(Ref, Clause 7.4.1, IS800-2007)

mm

nos.

nos.

kN

kN

kN

kN

Strength Increase Factors for Wind/Seismic loads.

Strength increase factor for Bolt Capacity

Stress increase factor for fbs

L=

Mpa

Mpa

Mpa

1

1

400

mm

200

mm

column section

UB 305 x 165 x 46

b eff.

200

B =

b eff.

150

a

a= 50

1) Check for bearing pressure:

for Beam

3205

L/C

Pmax (P)

140.00 kN

Max pressure =

P/( L x B ) = 1.750

Permissible bearing pressure =

24

Max pressure < permissible bearing pressure

safe in bearing pressure

317

Mpa

Mpa

As per Clause 7.4.3.1 (Fig-9) of IS 800: 2007,

ts = sqrt (2.5wc2gmo/fy)

Thus, c =

c=

ts x sqrt (fy/2.5wgmo)

0

mm

(Provided all around the column, effective area somes within the

provided base plate only)

2) Check for Tension in bolt:

for Beam

3205

L/C

Ptension (T)

0.00 kN

Tension per bolt = T / Total no of bolts

Tension per bolt =

317

0.00 kN

Limiting Tension capacity of bolt = 79.425 kN

Tension per bolt < Tension capacity of bolt

Bolt is safe in tension

3) Check for Shear in bolt:

for Beam

3205

L/C

321

Max resultant shear (S)

60.00

kN

shear per bolt = Resultant shear / total no of bolt

shear per bolt =

15.00 kN

Permissible shear force in bolt =

45.86 kN

bolt is safe in Shear

4) Check for combined shear and tension in bolt:

( Cl. 10.3.6 of IS 800)

(Actual tension/allow. Tension)2 + (Actual shear/allow. Shear)2

0.11

Bolt is Safe in combined shear & tension

< 1.0

< 1.0

5) Calculation of base plate thickness:

Case 1) Due to max pressure with Three edges fixed:

Max pressure =

1.750 Mpa

Considering roark's formulae, for three edges fixed

a=

135.5 mm

a/b = 1.40

( By interpolation)

b3 =

b=

1.0730

96.65 mm

Thickness of plate t1 = sqrt[(b*qmax*b 2)/1.5*fbs]

t1 =

7.173 mm

b=

96.65 mm

Case 2) Due to max Tension:

Max tension in bolt =

Panel dimension:

Stiffener provided (insert YES or NO)

0.00 kN

a1

YES

a=

135.5

mm

b=

96.65

mm

a1=

94

mm

b1=

71.65

mm

effective width b eff =min(a,b,2a1,2b1)

96.65

mm

Moment @ face =Mt=T.a1/(1+2(a1/b1))

(if stiffner is present)

=T.max(a1,b1) (otherwise)

Mt =

0 kNm

Thickness of plate t2 = sqrt[(6*Mt)/(1.5*fbs*b eff)]

t2 =

0.00 mm

b1

Case 3) Due to max pressure for Cantilever:

Moment @ section Flange =qmax x lever arm (a)^2 / 2

Mt =

0.0022 kNm/mm

Thickness of plate t3 = sqrt[(6*Mt)/(1.5*fbs*1)]

t3 =

6.20 mm

Hence provide base plate thickness

32

mm

CHECK FOR BOLT CAPACITY AS PER CLAUSE 12.12.2

For design of Shear Key consider Tension case

Column Section used:

Designation of member =

Depth of membe r= d =

Thickness of web = tw =

Thickness of flange = tf =

UB 305 x 165 x 46

306.6 mm

6.7 mm

11.8 mm

Shear check for web:

Full Shear Capacity of web = Vfull = fy/sqrt(3)*d*tw

Design shear = 1.2*.Vfull =

296.50 kN

355.80 kN

Shear on each bolt =

Ultimate shear capacity of each bolt =

Shear resistance of bolt in combination with tension

88.95 kN

66.848 kN

45.86 kN

(section 8.4.1)

(as per clause 12.12.2)

X

Shear Key is requied

Z

Shear to be resisted by web of shear key =

Thickness of web plate for shear key = twp =

172.38 kN

100

16

16 mm

12

Depth of web plate required for shear key = dp =

Provide depth of web plate for shear key =

74.64 mm

100 mm

OK

100

12

124

Depth of shear key below TOC =

Shear on each bolt =

Ultimate shear capacity of each bolt =

125 mm

169.33 kN

66.848 kN

Shear Key is requied

Shear to be resisted by flange of shear key =

Thickness of flange plate for shear key = tfp =

Width of flange plate required for shear key = wp =

Provide Width of flange plate for shear key =

Ixx =

Izz =

493.90 kN

12 mm

142.58 mm

100 mm

UNSAFE

8.89E+06 mm4

2.03E+06 mm4

DESIGN OF BASE PLATE BP7:

APPROACH: LIMIT STATE DESIGN

FACTORED LOAD COMBINATIONS

Beam

L/C

3064

3064

3032

Axial

Shear-Y

Force kN

kN

3490

-565.64

-32.703

3490

-565.64

-32.703

91 -302.407 -202.787

Node

319

319

321

Factored Design Forces:

Pmax (P)

Ptension (T)

Max resultant shear (S)

Shear-Z

kN

24.962

24.962

-1.309

Torsion Moment-Y Moment-Z

kNm

kNm

kNm

0.157

0

0

0.157

0

0

0.006

0

0

566.000 kN

0.000 kN

203.00 kN

Input

Yield stress of steel Fy =

Permissible bending stress fbs = Fy/1.1

Permissible bearing stress for M40 Grout =

(As per Cl. 8.4 of 3669-AXSG-002)

Dia of bolt =

Total no of bolts =

No of bolts on each side =

Limiting Tension capacity of bolt =

Limiting Shear capacity of bolt =

Ultimate Tension capacity of bolt=

Ultimate shear capacity of bolt=

250

227.27

24

27

4

2

103.28

59.63

150.6

86.921

(Ref, clause 8.2.1.2 IS800:2007)

(Ref, Clause 7.4.1, IS800-2007)

mm

nos.

nos.

kN

kN

kN

kN

Strength Increase Factors for Wind/Seismic loads.

Strength increase factor for Bolt Capacity

Stress increase factor for fbs

L=

Mpa

Mpa

Mpa

1

1

550

mm

200

mm

column section NPB 400 x 180 x 66.3

b eff.

300

B =

b eff.

150

a

a= 50

1) Check for bearing pressure:

for Beam

3064

L/C

Pmax (P)

566.00 kN

Max pressure =

P/( L x B ) = 3.430

Permissible bearing pressure =

24

Max pressure < permissible bearing pressure

safe in bearing pressure

319

Mpa

Mpa

As per Clause 7.4.3.1 (Fig-9) of IS 800: 2007,

ts = sqrt (2.5wc2gmo/fy)

Thus, c =

c=

ts x sqrt (fy/2.5wgmo)

62.28

mm

(Provided all around the column, effective area somes within the

provided base plate only)

2) Check for Tension in bolt:

for Beam

3064

L/C

Ptension (T)

0.00 kN

Tension per bolt = T / Total no of bolts

Tension per bolt =

319

0.00 kN

Limiting Tension capacity of bolt = 103.275 kN

Tension per bolt < Tension capacity of bolt

Bolt is safe in tension

3) Check for Shear in bolt:

for Beam

3032

L/C

321

Max resultant shear (S)

203.00

kN

shear per bolt = Resultant shear / total no of bolt

shear per bolt =

50.75 kN

Permissible shear force in bolt =

59.63 kN

bolt is safe in Shear

4) Check for combined shear and tension in bolt:

( Cl. 10.3.6 of IS 800)

(Actual tension/allow. Tension)2 + (Actual shear/allow. Shear)2

0.72

Bolt is Safe in combined shear & tension

< 1.0

< 1.0

5) Calculation of base plate thickness:

Case 1) Due to max pressure with Three edges fixed:

Max pressure =

3.430 Mpa

Considering roark's formulae, for three edges fixed

a=

180.5 mm

a/b = 1.24

( By interpolation)

b3 =

b=

0.8000

145.7 mm

Thickness of plate t1 = sqrt[(b*qmax*b2)/1.5*fbs]

t1 =

13.072 mm

b=

145.7 mm

Case 2) Due to max Tension:

Max tension in bolt =

Panel dimension:

Stiffener provided (insert YES or NO)

0.00 kN

a1

YES

a=

180.5

mm

b=

145.7

mm

a1=

94

mm

b1=

70.7

mm

effective width b eff =min(a,b,2a1,2b1)

141.4

mm

Moment @ face =Mt=T.a1/(1+2(a1/b1))

(if stiffner is present)

=T.max(a1,b1) (otherwise)

Mt =

0 kNm

Thickness of plate t2 = sqrt[(6*Mt)/(1.5*fbs*b eff)]

t2 =

0.00 mm

b1

Case 3) Due to max pressure for Cantilever:

Moment @ section Flange =qmax x lever arm (a)^2 / 2

Mt =

0.0043 kNm/mm

Thickness of plate t3 = sqrt[(6*Mt)/(1.5*fbs*1)]

t3 =

8.69 mm

Hence provide base plate thickness

32

mm

CHECK FOR BOLT CAPACITY AS PER CLAUSE 12.12.2

For design of Shear Key consider Tension case

Column Section used:

Designation of member =

Depth of membe r= d =

Thickness of web = tw =

Thickness of flange = tf =

NPB 400 x 180 x 66.3

400 mm

8.6 mm

13.5 mm

Shear check for web:

Full Shear Capacity of web = Vfull = fy/sqrt(3)*d*tw

Design shear = 1.2*.Vfull =

496.52 kN

595.83 kN

Shear on each bolt =

Ultimate shear capacity of each bolt =

Shear resistance of bolt in combination with tension

148.96 kN

86.921 kN

59.63 kN

(section 8.4.1)

(as per clause 12.12.2)

X

Shear Key is requied

25

Z

Shear to be resisted by web of shear key =

357.32 kN

150

25

Thickness of web plate for shear key = twp =

25 mm

12

Depth of web plate required for shear key = dp =

Provide depth of web plate for shear key =

49.51 mm

100 mm

100

12

124

OK

Depth of shear key below TOC =

Shear on each bolt =

Ultimate shear capacity of each bolt =

125 mm

210.44 kN

86.921 kN

Shear Key is requied

Shear to be resisted by flange of shear key =

Thickness of flange plate for shear key = tfp =

Width of flange plate required for shear key = wp =

Provide Width of flange plate for shear key =

Ixx =

Izz =

603.27 kN

12 mm

174.15 mm

150 mm

UNSAFE

1.55E+07 mm4

1.95E+07 mm4

JINDAL STEEL & POWER LTD.

ional Properties of Parallel Flange Beams & Columns, Rails, Crane Rails & Channels produced at RUBM, Raigarh

Sectio

nal

Beams/ Columns

w

Kg/m

PARALLEL FLANGE BEAMS

UB 203X133X 25

25.1

UB 254x146x37

37

UB 305 x 165 x 40

40.3

UB 305 x 165 x 46

46.1

UB 356 x 171 x 51

51

UB 406 X 178 X 60

60.1

NPB 400 x 180 x 66.3

66.3

NPB 450 x 190 x 77.6

77.6

NPB 500 x 200 x 90.7

90.7

PG400X400

201

PG600X400

234.7

PG600X400A

300

PG600X600

359

NPB 600 x 220 x 122.4

122.4

UB 610 x 229 x 125.1

125.1

WPB 600 x 300 x 128.8

128.8

WPB 600 x 300 x 177.8

177.8

WPB 700 x 300 x 204.5

204.5

UC 152x152x23

23

UC 152x152x30

30

UC 203 x 203 X 46

46.1

UC 203 x 203 X 52

52

UC 254 X 254 X 73

73.1

UC 254 X 254 X 89

88.9

UC 305 x 305 x 97

97

UC 305 x 305 x 118

117.9

UC 305 x 305 x 137

136.9

Description

UC 203x203x46

UC 203x203x52

UC 203x203x60

UC 203x203x71

46.1

52

60

71

Total

Depth

H

mm

Flange

Width

b

mm

Thickness Thickness

of Web of Flange

tw

tf

mm

mm

203.2

256

303.4

306.6

355

406.4

400

450

500

400

600

600

600

600

612.2

571

590

690

152.4

157.6

203.2

206.2

254.1

260.3

307.9

314.5

320.5

133.2

146.4

165

165.7

171.5

177.9

180

190

200

400

600

400

600

220

229

300

300

300

152.2

152.9

203.6

204.3

254.6

256.3

305.3

307.4

309.2

5.7

6.3

6

6.7

7.4

7.9

8.6

9.4

10.2

16

20

20

20

12

11.9

12

13

14.5

5.8

6.5

7.2

7.9

8.6

10.3

9.9

12

13.8

7.8

10.9

10.2

11.8

11.5

12.8

13.5

14.6

16

25

25

32

32

19

19.6

15.5

25

27

6.8

9.4

11

12.5

14.2

17.3

15.4

18.7

21.7

203.2

206.2

209.6

215.8

203.6

204.3

205.8

206.4

7.2

7.9

9.4

10

11

12.5

14.2

17.3

UC 203x203x86

86.1

222.2

209.1

12.7

20.5

UC 254x254x73

UC 254x254x89

UC 254x254x107

UC 254x254x132

UC 254x254x167

73.1

88.9

107.1

132

167.1

254.1

260.3

266.7

276.3

289.1

254.6

256.3

258.8

261.3

265.2

8.6

10.3

12.8

15.3

19.2

14.2

17.3

20.5

25.3

31.7

CRANE RAILS

CR-80

CR-100

64.2

As per IS : 3443 -1980

89

SPECIFICATION FOR CRANE RAIL SECTIONS

RAILS

UIC60

IRS -52

60.34

52

As per IRS -T-12 1996

Channels

ISMC 250 x 80

30.6

250

80

7.2

14.1

ISMC 250 x 82

34.2

250

82

14.1

ISMC 300 x 90

36.3

300

Cyy is centre of gravity along YY Axis

90

7.8

13.6

UC - Bristish Univeral Columns

UB - British Universal Beams

NPB - Narrow Parallel Flange Beams IS Code 12778 -2004

WPB - Wide Parallel Flange Beams IS Code 12778 - 2004

HE - European Wide Flange Beams

IPE - European Narrow flange Parallel b

Sections highlighted is available in market as on 20th august 09 as conveyed by

pean Wide Flange Beams

pean Narrow flange Parallel beams

th august 09 as conveyed by Jindal representative on 20th august 09.

Anda mungkin juga menyukai

- Base Plate Design for Bagging Tower SupportDokumen9 halamanBase Plate Design for Bagging Tower SupportbuildconBelum ada peringkat

- Design of Base PlateDokumen3 halamanDesign of Base Plateravi4paperBelum ada peringkat

- Combined Gusset Plate DesignDokumen3 halamanCombined Gusset Plate Designkalpanaadhi100% (3)

- Base Plate Design for Column SupportDokumen180 halamanBase Plate Design for Column Supportbuildcon62% (13)

- Base Plate DesignDokumen32 halamanBase Plate DesignGautam Sharma50% (2)

- BASE PLATE DESIGN OPTIMIZATIONDokumen45 halamanBASE PLATE DESIGN OPTIMIZATIONMuhammed Ali60% (5)

- Design of base plates for steel structureDokumen43 halamanDesign of base plates for steel structureGautam SharmaBelum ada peringkat

- Column Base PlateDokumen3 halamanColumn Base PlatePurnima ArkalgudBelum ada peringkat

- 321 Chapter 5 Splice DesignDokumen91 halaman321 Chapter 5 Splice DesignHemant Ramesh NarkarBelum ada peringkat

- Pinned Base Anchor Bolt DesignDokumen2 halamanPinned Base Anchor Bolt Designkhan84mindBelum ada peringkat

- Base PlateDokumen12 halamanBase PlateD SRINIVAS100% (1)

- Rafter-Column Bracing DesignDokumen3 halamanRafter-Column Bracing Design4geniecivilBelum ada peringkat

- AISC ASD Base Plate Thickness V2016-2Dokumen9 halamanAISC ASD Base Plate Thickness V2016-2yusuf_jtBelum ada peringkat

- Design of Shear KeyDokumen13 halamanDesign of Shear KeyRonnie SmithBelum ada peringkat

- 1.0bolted Truss ConnectionDokumen7 halaman1.0bolted Truss ConnectionklynchelleBelum ada peringkat

- Purlin Design LSMDokumen10 halamanPurlin Design LSMFazilat Mohammad Zaidi0% (1)

- Crane Beam Web Splice DesignDokumen7 halamanCrane Beam Web Splice DesignCrystal JaneBelum ada peringkat

- Moment ConnectionDokumen39 halamanMoment ConnectionRitwick MishraBelum ada peringkat

- Base Plate With Moment & Axial CompressionDokumen2 halamanBase Plate With Moment & Axial CompressionAnonymous b3NKZUb100% (3)

- Typ-Base PlateDokumen11 halamanTyp-Base PlateManoj Jaiswal100% (2)

- Load Calc3Dokumen43 halamanLoad Calc3Saravanan SilambanBelum ada peringkat

- Aa - Bracket DesignDokumen2 halamanAa - Bracket Design4geniecivilBelum ada peringkat

- Combined Footing NUNNA Bldg. R0Dokumen6 halamanCombined Footing NUNNA Bldg. R0prabhat_iitdBelum ada peringkat

- Pinned and fixed base plate design calculations for I-section and tube columnsDokumen7 halamanPinned and fixed base plate design calculations for I-section and tube columnsabdul karee100% (6)

- Design of I-Shape Column Base PlateDokumen6 halamanDesign of I-Shape Column Base PlatebuildconBelum ada peringkat

- Weld ConnectionDokumen70 halamanWeld ConnectionSudhakar KrishnamurthyBelum ada peringkat

- End Plate-Beam To Column Moment ConnectionDokumen81 halamanEnd Plate-Beam To Column Moment ConnectionHemant Ramesh Narkar50% (6)

- LRFD Steel BeamDokumen30 halamanLRFD Steel Beam정영철Belum ada peringkat

- Input Data: Subject: Base Plate ConnectionDokumen5 halamanInput Data: Subject: Base Plate ConnectionSambhav PoddarBelum ada peringkat

- Moment Connection Portal FrameDokumen18 halamanMoment Connection Portal Frametmssorin100% (1)

- Design of Steel Plate - R0 - 20.04.21Dokumen1 halamanDesign of Steel Plate - R0 - 20.04.21Srishti Project ConsultantsBelum ada peringkat

- 4-Base Plate - Pin ConnectionDokumen3 halaman4-Base Plate - Pin ConnectionMUTHUKKUMARAMBelum ada peringkat

- Cleat Connection For PlatformsDokumen29 halamanCleat Connection For PlatformsRajveer SinghBelum ada peringkat

- Beam To Col. Pin Connection DesignDokumen2 halamanBeam To Col. Pin Connection DesignmaheshbandhamBelum ada peringkat

- Beam SpliceDokumen17 halamanBeam SpliceBoddu Ramakrishna100% (1)

- Design Calculation Main Column 11M LC I 06052011Dokumen10 halamanDesign Calculation Main Column 11M LC I 06052011Goutam Chakraborty100% (1)

- UB254 To UB457Dokumen7 halamanUB254 To UB457ihpeterBelum ada peringkat

- End Plate Beam To Column Moment ConnectionDokumen84 halamanEnd Plate Beam To Column Moment Connectionakshay chauhanBelum ada peringkat

- Isolated Foundation Calculation (ACI 318M-95) : Input DataDokumen7 halamanIsolated Foundation Calculation (ACI 318M-95) : Input DatadhawanaxitBelum ada peringkat

- End Plate-Splice ConnectionDokumen76 halamanEnd Plate-Splice ConnectionHemant Ramesh Narkar100% (6)

- Fin Plate - Beam To ColumnDokumen78 halamanFin Plate - Beam To ColumnHemant Ramesh NarkarBelum ada peringkat

- Base Plate Design (Fixed Base)Dokumen3 halamanBase Plate Design (Fixed Base)Saravana NBelum ada peringkat

- Design of anchor bolts for steel pole foundationDokumen3 halamanDesign of anchor bolts for steel pole foundationJayBelum ada peringkat

- Base Connection Design DetailsDokumen11 halamanBase Connection Design DetailsmaheshbandhamBelum ada peringkat

- Baseplate DesignDokumen14 halamanBaseplate DesignmaheshbandhamBelum ada peringkat

- MM Met D19084 RP 012Dokumen96 halamanMM Met D19084 RP 012Dass DassBelum ada peringkat

- Rafter Splice DesignDokumen2 halamanRafter Splice DesignkalpanaadhiBelum ada peringkat

- Design Calculation For Column (Staad Member No. 1219) : Section PropertiesDokumen63 halamanDesign Calculation For Column (Staad Member No. 1219) : Section PropertiesSreeraja SreevilasanBelum ada peringkat

- Base Plate With Shear KeyDokumen3 halamanBase Plate With Shear Keyvpjagannaath100% (1)

- End Plate DesignDokumen26 halamanEnd Plate DesignNitesh SinghBelum ada peringkat

- Washer PlateDokumen2 halamanWasher PlateНемања Караклајић100% (2)

- Anchor Bolt and Base Plate Design CheckDokumen48 halamanAnchor Bolt and Base Plate Design CheckmaheshbandhamBelum ada peringkat

- Sample Base Plate As Per Is800 20Dokumen45 halamanSample Base Plate As Per Is800 20mtech structuresBelum ada peringkat

- Truss load calculation spreadsheetDokumen40 halamanTruss load calculation spreadsheetk varalakshmiBelum ada peringkat

- Batten Plates DesiDokumen7 halamanBatten Plates DesiSuhas MangaloreBelum ada peringkat

- Design of square footing for 600 KN column loadDokumen2 halamanDesign of square footing for 600 KN column loadVishwajith KadriBelum ada peringkat

- Design of Composite Steel Girder BridgeDokumen10 halamanDesign of Composite Steel Girder BridgesorowareBelum ada peringkat

- Base Plate Design Is 800-2007Dokumen6 halamanBase Plate Design Is 800-2007Suneesh P91% (11)

- TB1Dokumen7 halamanTB1Feliciano Esteban DominguezBelum ada peringkat

- Pile Cap ForDokumen3 halamanPile Cap ForSunil SinghBelum ada peringkat

- MC AsdDokumen8 halamanMC AsdParag PandyaBelum ada peringkat

- Buloane de Ancoraj PDFDokumen29 halamanBuloane de Ancoraj PDFAndrei Cretu100% (1)

- Preliminary Design of Steel StructuresDokumen17 halamanPreliminary Design of Steel StructuresAltayeb Yassin100% (5)

- Base PlateDokumen48 halamanBase PlatePrantik Adhar Samanta0% (1)

- Piggy on railway line nursery rhymeDokumen3 halamanPiggy on railway line nursery rhymeSunil SinghBelum ada peringkat

- Base PlateDokumen48 halamanBase PlatePrantik Adhar Samanta0% (1)

- This Is The Way We Pump The Tyre: Piggy On The Railway Line. Picking Up The StonesDokumen3 halamanThis Is The Way We Pump The Tyre: Piggy On The Railway Line. Picking Up The StonesSunil SinghBelum ada peringkat

- This Is The Way We Pump The Tyre: Piggy On The Railway Line. Picking Up The StonesDokumen3 halamanThis Is The Way We Pump The Tyre: Piggy On The Railway Line. Picking Up The StonesSunil SinghBelum ada peringkat

- Piggy on railway line nursery rhymeDokumen3 halamanPiggy on railway line nursery rhymeSunil SinghBelum ada peringkat

- This Is The Way We Pump The Tyre: Piggy On The Railway Line. Picking Up The StonesDokumen3 halamanThis Is The Way We Pump The Tyre: Piggy On The Railway Line. Picking Up The StonesSunil SinghBelum ada peringkat

- Base PlateDokumen48 halamanBase PlatePrantik Adhar Samanta0% (1)

- This Is The Way We Pump The Tyre: Piggy On The Railway Line. Picking Up The StonesDokumen3 halamanThis Is The Way We Pump The Tyre: Piggy On The Railway Line. Picking Up The StonesSunil SinghBelum ada peringkat

- Base PlateDokumen48 halamanBase PlatePrantik Adhar Samanta0% (1)

- Aaloo Kachaaloo Beta Kahan Gaye They?Dokumen3 halamanAaloo Kachaaloo Beta Kahan Gaye They?Sunil SinghBelum ada peringkat

- PoemDokumen3 halamanPoemSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- SectionDokumen1 halamanSectionSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- MC AsdDokumen8 halamanMC AsdParag PandyaBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- ZZ PDFDokumen1 halamanZZ PDFSunil SinghBelum ada peringkat

- A829Dokumen4 halamanA829Deepak GovindanBelum ada peringkat

- Pages From Hydril 521Dokumen1 halamanPages From Hydril 521Fabian Romero BecerraBelum ada peringkat

- Curing in ConstructionDokumen7 halamanCuring in ConstructionNgissah NketiahBelum ada peringkat

- BVG4P 1 LOCK Parker Brass Ball ValveDokumen2 halamanBVG4P 1 LOCK Parker Brass Ball ValveMROstop.comBelum ada peringkat

- SIMONA PVC-C CORZAN Engineered From Post-Chlorinated PVC For Exceptional PerformanceDokumen6 halamanSIMONA PVC-C CORZAN Engineered From Post-Chlorinated PVC For Exceptional PerformanceIsrael AristaBelum ada peringkat

- Giw LCCDokumen8 halamanGiw LCCCesar Leonardo Mendoza LoyolaBelum ada peringkat

- Sachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997Dokumen14 halamanSachpazis Raft Foundation Design Analysis Design For Multistorey Building. Calculation According To Bs 8110-1-1997sitheeqBelum ada peringkat

- Ceiling Support System and CeilingsDokumen24 halamanCeiling Support System and CeilingsRoland CepedaBelum ada peringkat

- Material CalculationDokumen10 halamanMaterial CalculationMono BasiranBelum ada peringkat

- Buttress DamDokumen65 halamanButtress DamAF.RISHARD FAIS77% (13)

- Preliminary Design of BeamDokumen4 halamanPreliminary Design of BeamSaroj DwaBelum ada peringkat

- Zinc-Coated Steel Strand For Messenger Support of Figure 8 CableDokumen3 halamanZinc-Coated Steel Strand For Messenger Support of Figure 8 CableSha ZhaBelum ada peringkat

- BS 3533 PDFDokumen22 halamanBS 3533 PDFKarunakaran Nallasingam100% (2)

- Repairing Damaged Anchor Bolts - Ask The Expert (HTTPWWW - Portlandbolt.comtechnicalfaqscorrecting-Anchor-Bolt-Damage) PDFDokumen3 halamanRepairing Damaged Anchor Bolts - Ask The Expert (HTTPWWW - Portlandbolt.comtechnicalfaqscorrecting-Anchor-Bolt-Damage) PDFahmedsabercgBelum ada peringkat

- Mechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesDokumen12 halamanMechanical Seamless Tubings Mechanical Seamless Tubings: Pipes & Tubes Pipes & TubesEric S Y KwokBelum ada peringkat

- Norma Cmaa 70Dokumen90 halamanNorma Cmaa 70jargoti164877100% (2)

- Construction Site Visit OverviewDokumen12 halamanConstruction Site Visit OverviewCaereel LopezBelum ada peringkat

- Welded Connections DesignDokumen35 halamanWelded Connections DesignBelkacem AchourBelum ada peringkat

- Ciclones de Presas de Relaves - GV CyclonesDokumen2 halamanCiclones de Presas de Relaves - GV CyclonesLuis LabradorBelum ada peringkat

- Prevention, Fishing and Casing Repair - Jim Short - Part 2Dokumen249 halamanPrevention, Fishing and Casing Repair - Jim Short - Part 2MitsúMilagrosToroSayasBelum ada peringkat

- Bar STDDokumen8 halamanBar STDtushk20100% (1)

- DomesDokumen18 halamanDomesbhansalianiket96100% (1)

- Saudi Arabian Oil Company: SECTION 15060 Chilled Water PipingDokumen10 halamanSaudi Arabian Oil Company: SECTION 15060 Chilled Water Pipingthahar ali syedBelum ada peringkat

- Dams Types and StabilityDokumen141 halamanDams Types and StabilityAdegoke samuel charlesBelum ada peringkat

- Tyrolean Rendering Texture GuideDokumen2 halamanTyrolean Rendering Texture GuidenanoBelum ada peringkat

- Spellnumber10m Bulo-NawoyDokumen186 halamanSpellnumber10m Bulo-NawoyBeverly Nicole Dugao CutiBelum ada peringkat

- 2-Stage D - Part 2 - Structural Design Report - FX Rev1Dokumen168 halaman2-Stage D - Part 2 - Structural Design Report - FX Rev1Prima AdhiyasaBelum ada peringkat

- PMC IpdDokumen19 halamanPMC IpdAbhik BhattacharjeeBelum ada peringkat

- Research Paper Proposal TemplateDokumen3 halamanResearch Paper Proposal TemplatePablo MoralesBelum ada peringkat

- NBC107 Fire SafetyDokumen10 halamanNBC107 Fire SafetyManoj Paudel0% (1)