Project Abstract

Diunggah oleh

Michelle CollinsDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Project Abstract

Diunggah oleh

Michelle CollinsHak Cipta:

Format Tersedia

Green plasticizer for polymeric material.

PVC is the third largly used polymeric material after PE & PP. Even

though it is commodity polymer, It is thermally sensitive, difficult to

process and brittle material. In order to ease process ability & induce

flexibility various method like co-polymerization, blending, grafting,

increasing molecular weight, addition of fibre fillers & addition of

plasticizers have been investigated for PVC. Among all the above

mentioned methods addition of the plasticizers have been investigated

more beneficial for PVC. Plasticizers like Dioctyl thalate, Diethyl hexyl

thalate, Di-isoneonyl thalate, Dibutyl thalate, tritrolyl phosphate etc.

have been utilized for PVC plasticization. Though these plasticizers are

easily available & cost effective, they are found to be environmentally

toxic & health hazardous. Many countries have been banned or

restricted the import of the PVC product (European union and US) using

these plasticizers. So, there is need to produce green plasticizers using

non toxic renewable resources. Available plant source is topic of recent

research in academics & industries.

In present research work, we propose to synthesize green

plasticizer using Ricinolic acid (RA) which is cheap, non-toxic, nonrenewable raw material obtained from plant source. We aim to

synthesize ester amide of RA by reacting with dimethyl amine and

benzoic acid. Using two step non-solvent based condensation process

to synthesize ester amide of RA can be used as both primary &

secondary plasticizer for PVC. This plasticizer is expected to induce

plasticization effect on PVC on the basis of following points-

Oligomeric structure of plasticizer

Polarity induced by amide linkage

Polarity induced by ester linkage

Polarity induced by resonance structure of benzene

This would help in generating higher level of intermolecular forces of

attraction in plasticizer & PVC material. Plasticized PVC is utilized/

tested for various characterization studies like mechanical, thermal,

rheological, color, crystallinity , chemical resistance etc.

When used as secondary plasticizer, synthesized plasticizer

would be used as partial replacement for DOP upto 40phr, and above

characterization tests will be taken place.

Gaur gum is natural polymer obtained from ground endosperm of gaur

bean. India is largest producer, about 80% of world production. It is

extremely hydrophilic polymer & films prepared from it are too brittle.

It is usually added with 20% (w/w) ethylene glycol (EG) in order to make

it flexible and capable for film formation. However EG is non

renewable, costly & non-ecofriendly. Thus this research work is tried to

replace conventional plasticizer of gaur gum with cheap, renewable and

eco-friendly raw material ie. Castor oil (CA). concentration of CA varied

as 1, 3, 5 w% in gaur gum to prepare film, which are characterized for

mechanical, thermal, rheological, crystallinity, color, optical etc.

properties.

Thus greener of plasticization for commodity polymer like

polyvinyl chloride and bio polymer like gaur gum will be investigated.

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Understanding Consumer and Business Buyer BehaviorDokumen47 halamanUnderstanding Consumer and Business Buyer BehaviorJia LeBelum ada peringkat

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Project Management: Chapter-2Dokumen26 halamanProject Management: Chapter-2Juned BhavayaBelum ada peringkat

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Canopy CountersuitDokumen12 halamanCanopy CountersuitJohn ArchibaldBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- (ENG) Visual Logic Robot ProgrammingDokumen261 halaman(ENG) Visual Logic Robot ProgrammingAbel Chaiña Gonzales100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- Relevant Cost For Decision: Kelompok 2Dokumen78 halamanRelevant Cost For Decision: Kelompok 2prames tiBelum ada peringkat

- Tindara Addabbo, Edoardo Ales, Ylenia Curzi, Tommaso Fabbri, Olga Rymkevich, Iacopo Senatori - Performance Appraisal in Modern Employment Relations_ An Interdisciplinary Approach-Springer Internationa.pdfDokumen278 halamanTindara Addabbo, Edoardo Ales, Ylenia Curzi, Tommaso Fabbri, Olga Rymkevich, Iacopo Senatori - Performance Appraisal in Modern Employment Relations_ An Interdisciplinary Approach-Springer Internationa.pdfMario ChristopherBelum ada peringkat

- Sony SL HF-900 Owners ManualDokumen53 halamanSony SL HF-900 Owners ManualThomas Christoph100% (1)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

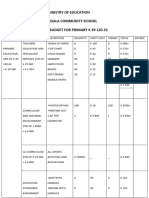

- Ministry of Education Musala SCHDokumen5 halamanMinistry of Education Musala SCHlaonimosesBelum ada peringkat

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Managerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Dokumen40 halamanManagerial Accounting-Fundamental Concepts and Costing Systems For Cost Analysis Module 1Uzma Khan100% (1)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- CH 2 Nature of ConflictDokumen45 halamanCH 2 Nature of ConflictAbdullahAlNoman100% (2)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Awais Inspector-PaintingDokumen6 halamanAwais Inspector-PaintingMohammed GaniBelum ada peringkat

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- Bismillah SpeechDokumen2 halamanBismillah SpeechanggiBelum ada peringkat

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- EC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - ADokumen29 halamanEC2 406006 001 EFE 0121 - Controgen Generator Excitation System Description - Rev - AAnonymous bSpP1m8j0n50% (2)

- Descriptive Statistics - SPSS Annotated OutputDokumen13 halamanDescriptive Statistics - SPSS Annotated OutputLAM NGUYEN VO PHIBelum ada peringkat

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- T3A-T3L Servo DriverDokumen49 halamanT3A-T3L Servo DriverRodrigo Salazar71% (7)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- Agoura Hills DIVISION - 6. - NOISE - REGULATIONSDokumen4 halamanAgoura Hills DIVISION - 6. - NOISE - REGULATIONSKyle KimBelum ada peringkat

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- Circuitos Digitales III: #IncludeDokumen2 halamanCircuitos Digitales III: #IncludeCristiamBelum ada peringkat

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- YeetDokumen8 halamanYeetBeLoopersBelum ada peringkat

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- Windsor Machines LimitedDokumen12 halamanWindsor Machines LimitedAlaina LongBelum ada peringkat

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- Outage Analysis of Wireless CommunicationDokumen28 halamanOutage Analysis of Wireless CommunicationTarunav SahaBelum ada peringkat

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- Crawler Base DX500/DX600/DX680/ DX700/DX780/DX800: Original InstructionsDokumen46 halamanCrawler Base DX500/DX600/DX680/ DX700/DX780/DX800: Original InstructionsdefiunikasungtiBelum ada peringkat

- Brief Curriculum Vitae: Specialisation: (P Ea 1. 2. 3. Statistical AnalysisDokumen67 halamanBrief Curriculum Vitae: Specialisation: (P Ea 1. 2. 3. Statistical Analysisanon_136103548Belum ada peringkat

- EW160 AlarmsDokumen12 halamanEW160 AlarmsIgor MaricBelum ada peringkat

- 950 MW Coal Fired Power Plant DesignDokumen78 halaman950 MW Coal Fired Power Plant DesignJohn Paul Coñge Ramos0% (1)

- Department of Labor: 2nd Injury FundDokumen140 halamanDepartment of Labor: 2nd Injury FundUSA_DepartmentOfLabor100% (1)

- Entrep Q4 - Module 7Dokumen5 halamanEntrep Q4 - Module 7Paula DT PelitoBelum ada peringkat

- CPE Cisco LTE Datasheet - c78-732744Dokumen17 halamanCPE Cisco LTE Datasheet - c78-732744abds7Belum ada peringkat

- Bisleri 2.0Dokumen59 halamanBisleri 2.0Dr Amit Rangnekar100% (4)

- Alternator: From Wikipedia, The Free EncyclopediaDokumen8 halamanAlternator: From Wikipedia, The Free EncyclopediaAsif Al FaisalBelum ada peringkat

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Aluminium Extrusion Industry in IndiaDokumen3 halamanAluminium Extrusion Industry in Indiakalan45Belum ada peringkat

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)