Utoc Preliminary Wps Shell Project 270807 PDF

Diunggah oleh

Erick HoganDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Utoc Preliminary Wps Shell Project 270807 PDF

Diunggah oleh

Erick HoganHak Cipta:

Format Tersedia

UTOC ENGINEERING PTE LTD

SINGAPORE

Project No

: UE-OTA-60048

Doc.No :UTOC/ECC/WPS&PQR/0001

Revision :0.00

SHELL HOUDINI ECC PROJECT

PIPING FABRICATION, INSTALLATION AND TESTING CONTRACT

WELDING PROCEDURE SPECIFICATION (WPS) & PROCEDURE QUALIFICATION RECORDS

(PQR)

Client: SHELL EASTERN PETROLEUM PTE LTD

04217 Shell ECC Project, Singapore

Implementation Contract No.

04217-2603

EPCM Contractor ICDR

document code

Company Revision

Rev. No Rev Date

Reviewed without comments

RN-1

Reviewed with non-technical comments as noted

RN-2

Reviewed with technical comments as noted

RJ

Rejected

FI

For information only

E-00000-CA-6065-26030001

UTOC WPS & PQR FOR

SHELL PROJECT

Electronic File Name

8/27/2007

0.00

Company Document Number

0.00

Construction Review Status

Sub group No: N/A

First issue

Reviewed by:

Approved

Remarks/Descript

Prepared by

QA/QCM/CM

by: PM

ion of Revision

Status

UTOC ENGINEERING PTE LTD

SHELL ECC HOUNDINI PROJECT

UTOC ENGINEERING PTE LTD - SINGAPORE

WPS/PQR SUMMARY

Document No:UTOC/ECC/WPS&PQR/0001

Revision

Date

0.00

8/27/2007

Prepared by SIVAKUMAR

Reviewde by T.N.THAMBI

P1 - 007

TGS-50

E7016

LB52

SA106GrB

Dia168.3x

21.95WTx

350Lg

(P1)

(P1)

A106GrB,A672A106GrB,A672C65CL.22,API5LGrB,A53 C65CL.22,API5LGrB,A53

GrB,A105,S25C,S28C,A23 GrB,A105,S25C,S28C,A2

4WPB/Approved

34WPB/Approved

Equivalent

Equivalent

A106GrB,

A672-C65CL.22

ER70S-G

TGS-50

E7016

LB52

SA106GrB

Dia73X

9.53WT X

350Lg

(P1)

(P1)

A106GrB,A672A106GrB,A672C65CL.22,API5LGrB,A53 C65CL.22,API5LGrB,A53

GrB,A105,S25C,S28C,A23 GrB,A105,S25C,S28C,A2

4WPB/Approved

34WPB/Approved

Equivalent

Equivalent

A106GrB,

A672-C65CL.22

ER70S-G

TGS-50

NA

NA

A333Gr6

Dia60.3X5.54

WTX350Lg

(P1)

(P1)

A 333 Gr 6 /A671A 333 Gr 6 /A671CC65CL.22/ A420 WPL6 / CC65CL.22/ A420 WPL6 /

A 350 LF2 / Approved

A 350 LF2 / Approved

Equivalents

Equivalents

A333Gr6,A671CC65CL.22

ER70S-G

A333Gr6

(P1)

(P1)

A 333 Gr 6 /A671A 333 Gr 6 /A671Dia323.9X

33.32WTX350 CC65CL.22/ A420 WPL6 / CC65CL.22/ A420 WPL6 /

Lg

A 350 LF2 / Approved

A 350 LF2 / Approved

Equivalents

Equivalents

A333Gr6,A671CC65CL.22

A333Gr6

(P1)

(P1)

A 333 Gr 6 /A671A 333 Gr 6 /A671Dia273.1X9.27

CC65CL.22/ A420 WPL6 / CC65CL.22/ A420 WPL6 /

WTX350Lg

A 350 LF2 / Approved

A 350 LF2 / Approved

Equivalents

Equivalents

A333Gr6,A671CC65CL.22

A333Gr6,A671CC65CL.22

ER70S-G

TGS-1N

NA

NA

A335P1

ER80S-G

TGS-M

NA

NA

A335P11, A6911.25Cr

CL.22,A234WP11CL1,A234WP11CL1-W

ER80S-G

TGS-1CM

NA

NA

GTAW

To be qualified

P1-006

GTAW+

SMAW

To be qualified

P1-007

GTAW+

SMAW

GTAW

6G

All

1.6 ~18.5

A333Gr6

A333Gr6

(P1)

(P1)

A 333 Gr 6 /A671A 333 Gr 6 /A671Dia273.1X9.27

CC65CL.22/ A420 WPL6 / CC65CL.22/ A420 WPL6 /

WTX350Lg

A 350 LF2 / Approved

A 350 LF2 / Approved

Equivalents

Equivalents

GTAW

6G

All

1.6~13

A335P1

A335P1

Dia141.3X6.55

WTX350Lg

A335P11

Dia60.3X5.54

WTX350Lg

P1-008

P3 - 001

To be qualified

P3-001

To be qualified

P4-002

GTAW

6G

6G

6G

6G

All

>73

>73

All

1.6~11

>19~ 49.98

4.8 ~18.5

1.6~11

A333Gr6

A333Gr6

A333Gr6

A335P11

(P3)

A335P1/Equivalents

(P3)

A335P1/Equivalents

(P4)

A335P11/A691-1.25 Cr

CL.22/A234WP11CL1,A234-WP11

CL1-W Equivalent

(P4)

A335P11/A691-1.25 Cr

CL.22/A234WP11CL1,A234-WP11

CL1-W Equivalent

ER70S-G

ER70S-G

TGS-1N

TGS-1N

TGS-1N

NA

NA

E7016-G

E7016-G

NA

NA

LB52-NS

LB52-NS

MIN PREo

C

HEAT

Anmbient (Note1&2)

ER70S-G

TGS-50

NA

BT ME

NA

100

625 25

625 25

NA

100

IT

HT HYT

APPLICABLE PIPE LINE CLASSES TO BE WELDED

REFERENCE Doc.No.E-00000-P1-7737-0015 Rev.1.00

11000,11000-H1,11000-HV,11000XHV,11001,11002,11002-H2,11002XH1,11003,11003-UH1,11011,11011NA HV,11031,11031-H1,11031-HV,11031-UH1,11032HV,11071,11201,11261,11261H1,18011,18160,31000,31076-H2,31261,31261H1(SRT6&SRT3 Furnace jumpovers, SRT3Manifolds)

NA

11000,11000-H1,11000-HV,11000XHV,11001,11002,11002-H2,11002XH1,11003,11003-UH1,11011,11011NA HV,11031,11031-H1,11031-HV,11031-UH1,11032HV,11071,11201,11261,11261H1,18011,18160,31000,31076-H2,31261,31261H1(SRT6Furnace Manifolds, SRT6&SRT3

Risers,Down comers)

NA NA

NA

NA

NA

NA

11008,11008-H1,11008-UH1,11009,31000H1,31001,31002,31002-H1,31008,31011,31011H1,31031,31032-H1,31071,31073-H1,61008-H1,

11008,11008-H1,11008-UH1,11009,31000H1,31001,31002,31002-H1,31008,31011,31011H1,31031,31032-H1,31071,31073-H1,61008-H1,

625 25

NA

NA

2@ (- 48C)

SA106GrB

A106GrB,

A672-C65CL.22

SA106GrB

ER70S-G

TST

2@ (- 48C)

1.6~19.06

SA106GrB

Dia73X

9.53WT X

350Lg

(P1)

(P1)

A106GrB,A672A106GrB,A672C65CL.22,API5LGrB,A53 C65CL.22,API5LGrB,A53

GrB,A105,S25C,S28C,A23 GrB,A105,S25C,S28C,A2

4WPB/Approved

34WPB/Approved

Equivalent

Equivalent

A106GrB,

A672-C65CL.22

RT

Anmbient (Note1&2)

THICKNESS

RANGE

QUALIFIED

TEST

POSITION

MIN DIA TO BE

WELDED

All

>19~43.9

SA106GrB

Dia73X

7.01WT X

350Lg

SA106GrB

P4 - 002

6G

>73

4.8~19.06

SA106GrB

SMAW

(P1)

(P1)

A106GrB,A672A106GrB,A672C65CL.22,API5LGrB,A53 C65CL.22,API5LGrB,A53

GrB,A105,S25C,S28C,A23 GrB,A105,S25C,S28C,A2

4WPB/Approved

34WPB/Approved

Equivalent

Equivalent

To be qualified

P1 - 005

To be qualified

P1-008

10

GTAW

6G

>73

1.6~14.02

Brand Name

Mechanical Tests

PWHT o C

2@ (- 48C)

P1 - 006

To be qualified

P1-004

GTAW+

SMAW

6G

All

PNO-2

GTAW

Brand

Name

11085,11085-X,11085-H1,11085-XH1,11085H2,11380-H1,11380-UH1,11380-XH1,31071KS,31085,31085-H1,31085-H2,31180,31180H1,31180-H2,31380-H1,61071-KS,61180,66180H1,61180-H2

NA

31032-H1,31071-KS,31085,31085-H1,31085H2,31180,31180-H1,31180-H2,31380NA H1,61011,61031,61071-KS,61073-H1,61076H2,61180,61180-H1,61180H2,61261,151011,151011-H2

11085,11085-X,11085-H1,11085-XH1,11085H2,11380-H1,11380-UH1,11380-XH1,31071NA KS,31085,31085-H1,31085-H2,31180,31180H1,31180-H2,31380-H1,61071-KS,61180,66180H1,61180-H2

31032-H1,31071-KS,31085,31085-H1,31085H2,31180,31180-H1,31180-H2,31380NA H1,61011,61031,61071-KS,61073-H1,61076H2,61180,61180-H1,61180H2,61261,151011,151011-H2

625 25

2@ (- 48C)

P1 - 005

To be qualified

P1-003

GTAW+

SMAW

6G

PNO-1

ELECTRODE AWS/ASME SPECIFICATION

Anmbient

(Note1&2)

P1-004

To be qualified

P1-002

GTAW

BASE MAT-2

BASE MAT

Grade(s) to be

welded for ECC

Anmbient

(Note1&2)

P1 - 003

To be qualified

P1-001

BASE MAT-1

WPS BASE MAT.

Dia&Thick&

Lg(mm)

Anmbient

(Note1&2)

P1 - 002

TEST COUPON

Anmbient

(Note1&2)

P1 - 001

PQR NO

Anmbient

(Note1&2)

WPS NO.

PROCESS

SN

REV

Approved by NAZLY

NA

NA

NA

200

NA

NA

NA 32021 , 62020, 62021

Furnace Cracking Heater jumpovers LFP->UUMP &

UUMP->LUMP

SHELL ECC HOUNDINI PROJECT

UTOC ENGINEERING PTE LTD - SINGAPORE

WPS/PQR SUMMARY

Document No:UTOC/ECC/WPS&PQR/0001

Revision

Date

0.00

8/27/2007

Prepared by SIVAKUMAR

Reviewde by T.N.THAMBI

12

P5A - 004

To be qualified

P5A-004

GTAW

6G

All

1.6~14.22

A335P22

A335P22

Dia168.3x7.11

(P5A) A335P22/Equivalent

WTx350Lg

13

P5B - 005

To be qualified

P5B-005

GTAW

6G

All

1.6~17.48

A335P91

A335P91

Dia60.3X8.74

WTX350Lg

14

P5B - 006

To be qualified

P5B-006

GTAW+

SMAW

6G

>73

>13 to 67.86

A335P91

A335P91

Dia457.0X

45.24WTX350

Lg

15

P45 - 007

To be qualified

P45-001

GTAW

6G

All

1.6~ 7.82

16

P45 - 008

To be qualified

P45-002

GTAW+

SMAW

6G

>73

4.8~ 19.04

17

P8-001

To be qualified

P8-001

GTAW

6G

All

1.6~14.02

18

P8 - 002

To be qualified

P8-002

GTAW

6G

All

1.6~18.54

19

P8 - 003

To be qualified

P8-003

GTAW

6G

All

(P5A)

A335P22/Equivalent

(P5B2)

A 213 Gr T91/ A 335

Gr P91/ A 387 Gr 91

CL2/ Approved Eq.

(P5B2)

A 213 Gr T91/ A 335

Gr P91/ A 387 Gr 91

CL2/A234-WP91

SB423 UNS SB423 UNS Dia60.3x3.9

(P45)

(P45)

N08825

N08825 1WTX350Lg SB423 UNS N08825 SB423 UNS N08825

Dia323.9X

SB423 UNS SB423 UNS

(P45)

(P45)

9.52WTX35

SB423 UNS N08825 SB423 UNS N08825

N08825

N08825

0Lg

(P8)

(P8)

Dia73x

A312-TP304,A358- A312-TP304,A358SA312TP304 SA312TP304 7.01WTX35

TP304CL.1,SUS304, TP304CL.1,SUS304,

0Lg

TP304H,F304H

TP304H,F304H

SA312-TP316L SA312-TP316L

1.6 ~ 14.22

A312TP347H

A312TP347H

Dia168.3x

7.11WTx

350Lg

(P8)

(P8)

A 312 TP 347H/

A 312 TP 347H/

A358 TP 347H/A312 A358 TP 347H/A312

TP321/A358TP321/ TP321/A358TP321/

Approved Eq.

Approved Eq.

(P8)

SA240/312TP304/304L,SA

240/312TP316/316L,SA24

0/A312TP321,

A312/TP347H,A358/TP347

H or Equivalent

HP-Nb LOW C

(25Cr-35Ni)

20

P8-P1 - 001

To be qualified

P8-P1-001

GTAW+

SMAW

6G

>73

1.6 ~ 14.02

A312TP304

/3O4L

SA106GrB

21

25Cr -35Ni - 001

UTOC/PQR-002

GTAW

6G

All

4.8~21

HP-Nb LOW

C(25Cr-35Ni)

HP-Nb LOW

C(25Cr-35Ni)

NPS76.2X

10.5WT X

350Lg

Note:

Unless otherwise specified.All

Dimensions are in mm.

725 15

NA

NA 32011-H1, 32021 , 32110, 62020, 62021, 62120

NA

225

725 15

NA

NA

NA

NA

225

725 15

252091-H1,252091-H2(SRT6&SRT3 Manifolds and

Desuper heater loop.)

TGS-9cb

E9016-G

CM-9cb

225

725 15

252091-H1,252091-H2(SRT6&SRT3 Manifolds and

Desuper heater loop.)

ERNiCrMo-3

TGS-N625

NA

NA

NA

NA

NA 16095-H1

SB423 UNS

N08825

ERNiCrMo-3

TGS-N625

NIC-625

NA

NA

NA 16095-H1

A312-TP304,A358304CL.1

ER308L

TGS308L

NA

ER316L

TGS316L

NA

NA

NA

NA

A335P11, A6911.25Cr

CL.22,A234WP11CL1,A234WP11CL1-W

ER80S-G

TGS-1CM

A335P22/Equivalent

ER90S-G

TGS-2CM

NA

A335GrP91/A234WP91/Eq.

ER90S-G

TGS-9cb

A335GrP91/A234WP91/Eq.

ER90S-G

SB423 UNS

N08825

Dia273.1x

(P8)

(P8)

SA312TP316L,

9.27WTX35 SA312TP316L,A358- SA312TP316L,A358- A358-316L

316L CL.1

316L CL.1

0Lg

CL.1

Dia73X

7.01WT X

350Lg

LEGEND

RT-Radiography Test

TST-Tensile Test

BT-Bend Test

IT - Impact Test

ME- Macro Etch Test

HT- Hardness Survey

HYT-Hot Yield Test( P91)

(P5B2)

A 213 Gr T91/ A 335

Gr P91/ A 387 Gr 91

CL2/ Approved Eq.

(P5B2)

A 213 Gr T91/ A 335

Gr P91/ A 387 Gr 91

CL2/A234-WP91

200

2@ (20C)

A335P11

2@ (20C)

A335P11

P4 - 003

2@ (- 196C)

>13 ~ 42.88

(P4)

A335P11/A691-1.25 Cr

CL.22/A234WP11CL1,A234-WP11

CL1-W Equivalent

11

MIN PREo

C

HEAT

>73

(P4)

A335P11/A691-1.25 Cr

CL.22/A234WP11CL1,A234-WP11

CL1-W Equivalent

To be qualified

P4-003

Brand Name

SMAW

E8016-B2 CMA-96

A312TP321/347,A

358-321/347CL.1

ER347

TGS347

NA

NA

(P1)

SA106GrB,API 5L

GrB or Equivalent

ALL SS TO CS

SUPPORTS

ER309L

TGS309L

E309L-16

NC39L

HP-Nb LOW C

(25Cr-35Ni)

HP-Nb LOW C

(25Cr-35Ni)

WEL TIG

35CL

NA

NA

Preheat Requirements

Note -1: Preheat not required except to drive off surface moiture~preheat 20 C

Note- 2 : Preheat control by temperature inticative crayons or pyrometer(Except for P91)

Note -3 : Preheat control for P91 by Electric resistence method/Temperature Recorder.

Anmbient

Anmbient

(Note1&2

(Note1&2)

)

6G

Dia406.4X

21.44WTX350

Lg

PNO-2

GTAW

Brand

Name

Mechanical Tests

RT

TST

BT ME

IT

HT HYT

APPLICABLE PIPE LINE CLASSES TO BE WELDED

REFERENCE Doc.No.E-00000-P1-7737-0015 Rev.1.00

SRT6&SRT3 Furnace Cracking Heater manifolds

USSHI

13092,13095,13095-X,33092,33092H1,33095,33095-H1,33191,33191-H1,63095,63095H1,63096-H1(SRT6 Furnace Manifolds

DSSHI,DSSHO)

Anmbient

(Note1&2)

GTAW+

SMAW

PNO-1

ELECTRODE AWS/ASME SPECIFICATION

NA

Anmbient

(Note1&2)

BASE MAT-2

PWHT o C

BASE MAT

Grade(s) to be

welded for ECC

NA

Anmbient

(Note1&2)

BASE MAT-1

WPS BASE MAT.

Dia&Thick&

Lg(mm)

NA

NA

NA

Anmbient

(Note1&2)

TEST COUPON

NA

NA

NA ALL SS TO CS SUPPORTS

Anmbient

(Note1&2)

THICKNESS

RANGE

QUALIFIED

MIN DIA TO BE

WELDED

PQR NO

TEST

POSITION

WPS NO.

PROCESS

SN

REV

Approved by NAZLY

NA

13021,13032,13033,33021,33032,33033,63021,630

60,93021,153033-H1, 253021,

NA NA NA NA

33015-H2,33055,33055-H1,63013-H1,63015H2,(SRT6,SRT3 Furnace X-overs)

Furnace Cracking Heater Radiant coil

(EXSISTING PQR)

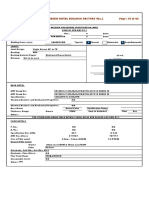

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P1 - 001

Date :

Supporting Procedure Qualification No.

: P1-001

Date :

Welding Process(es)

: GTAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

Non fushing metal

Non metalic X

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

TO

P. No. :

Group No. :

Specification Type & Grade to

A106GrB,A672-C65CL.22,API5LGrB,A53GrB,A105,S25C,S28C,A234WPB/Approved Equivalent

Specification Type & Grade

A106GrB,A672-C65CL.22,API5LGrB,A53GrB,A105,S25C,S28C,A234WPB/Approved Equivalent

Thickness Range :- Groove

: 1.6mm to 14.02mm

Diameter(mm)

: All

Fillet

: All

FILLER METALS (QW 404)

GTAW

Spec. SFA No

5.18

Weld Metal A-No

F- No

AWS No. (Class)

ER 70S - G

Manufacturer

Electrode/Filler trade name

KOBELCO/Equivalents

:

Dia of Electrode/Filler

Deposited weld metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

TGS- 50/Equivalents

1.6 ~ 2.4 mm

:

:

Electrode-Flux (Class)

Flux trade Name

Others

14.02mm maximum

_

NA

NA

_

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P1 - 001

Date :

POSITION (QW 405)

8/27/2007

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range :

NA

Time Range

NA

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

Preheat Temperature (Min)

NA

Interpass Temperature (Max)

300 C

Shielding :

Preheat Maintenance

None

Trailing

Backing

Flow rate

Argon

99.99%

10-20 LPM

NA

NA

NA

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

DC- EN

Amps Range

Refer below

Tungsten Electrode Size & Type

Process

Refer below

2.0 ~ 2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range) :

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~10 mm

Wire Bushing / Grinding

Nil, Single side welded joint

7mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

Root&Hot GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

90~160

10~20

50~120

Fill & Cap GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

90~160

10~20

50~120

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

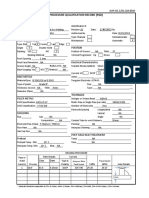

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P1 - 002

Date :

Supporting Procedure Qualification No. : P1-002

Date :

Welding Process(es)

: GTAW + SMAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

Non fushing metal

Non metalic X

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

TO

P. No. :

Group No. :

Specification Type & Grade to

A106GrB,A672-C65CL.22,API5LGrB,A53GrB,A105,S25C,S28C,A234WPB/Approved Equivalent

Specification Type & Grade

A106GrB,A672-C65CL.22,API5LGrB,A53GrB,A105,S25C,S28C,A234WPB/Approved Equivalent

Thickness Range :-Groove

: 4.8 mm to 19.06mm

Diameter(mm)

: All

>73mm

Fillet

: All

FILLER METALS (QW 404)

GTAW

SMAW

Spec. SFA No

5.18

5.1

Weld Metal A-No

F- No

AWS No. (Class)

ER 70S - G

E7016-G

KOBELCO/Equivalent

KOBELCO/Equivalent

TGS-50/Equivalent

LB52/Equivalent

1.6 ~ 2.4 mm

2.6 to 3.2mm

5mm Max

_

14mm

_

Manufacturer

Electrode/Filler trade name

Dia of Electrode/Filler

Deposited weld metal

:

:

Electrode-Flux (Class)

Flux trade Name

Others

:

:

:

NA

NA

_

NA

NA

_

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P1 - 002

Date :

POSITION (QW 405)

8/27/2007

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range :

NA

Time Range

NA

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

Flow rate

Preheat Temperature (Min)

NA

Interpass Temperature (Max)

300 C

Shielding :

Preheat Maintenance

None

Trailing

Backing

Argon

99.99%

10-20 LPM

NA

NA

NA

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

: GTAW(DC- EN) &SMAW (DC-EP)

Amps Range

Tungsten Electrode Size & Type

Refer below

Process

Refer below

2.0 ~ 2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range) :

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

GTAW

Stringer and/or Weave

1.6 ~ 10 mm

Wire Bushing / Grinding/Chipping

Nil, Single side welded joint

7mm

NA

Multiple pass

Single

See below

Not allowed

NA

SMAW

Stringer and/or Weave

NA

Wire Bushing / Grinding/Chipping

Nil, Single side welded joint

8mm for 2.6 :12mm for 3.2

NA

Fill and Cap

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

Root&Hot GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

100-115

10~14

50~70

Fill

SMAW

E7016-G

2.6mmto 3.2mm

DC EP

90-120

20~26

90~115

SMAW

E7016-G

2.6mmto 3.2mm

DC EP

95~26

20~26

95~130

Cap

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P1 - 003

Date : 8/27/2007

Rev :

Supporting Procedure Qualification No.

: P1-003

Date :

Rev :

Welding Process(es)

: GTAW & SMAW

Type :

Welding Code

: ASME section IX

Manual

(Manual/Semi-Auto / Fully-Auto)

Details of single 'V' -Butt joint

75 5

JOINTS (QW 402)

Joint Type

Backing

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

Non fushing metal

Non metalic

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P/S. No.

:

Group No. :

TO

P/S. No. :

Group No. :

Specification Type & Grade to

A106GrB,A672-C65CL.22,API5LGrB,A53GrB,A105,S25C,S28C,A234WPB/Approved Equivalent

Specification Type & Grade

A106GrB,A672-C65CL.22,API5LGrB,A53GrB,A105,S25C,S28C,A234WPB/Approved Equivalent

Thickness Range :-Groove

: >19.0mm to 43.9mm

Diameter(mm)

: >73mm

Fillet

: All

FILLER METALS (QW 404)

GTAW

SMAW

Spec. SFA No

5.18

5.1

Weld Metal A-No

F- No

AWS No. (Class)

ER 70S - G

E7016

KOBELCO/Equivalent

KOBELCO/Equivalent

TGS-50/Equivalent

LB52/Equivalent

1.6 ~ 2.4 mm

2.6 to 4.0mm

4.8mm

_

39.1mm

_

Manufacturer

Electrode/Filler trade name

Dia of Electrode/Filler

Deposited weld metal

:

:

Electrode-Flux (Class)

Flux trade Name

Others

:

:

:

NA

NA

_

NA

NA

_

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P1 - 003

Date :

POSITION (QW 405)

Rev :

8/27/2007

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range :

600~650 C

Time Range

1Hr/25mm(Min 1Hrs)

GAS (QW 408)

Preheat Temperature (Min)

Interpass Temperature (Max)

300 C

Preheat Maintenance

None

Percent Composition

Gas(es)

Mixture

100 C

Shielding :

Flow rate

Argon

99.99%

10-20 LPM

Trailing

NA

NA

NA

Backing

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

: DC- EN(GTAW), DCEP (SMAW)

Amps Range

Tungsten Electrode Size & Type

Refer below

Root & Hot

Process

GTAW

Fill & Cap SMAW

Filler Metal

Dia of Electrode

Spec. No

(mm)

Refer below

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~ 10 mm

Wire Bushing / Grinding

Nil, Single side welded joint

12mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

ER70S-G

1.6 ~ 2.4mm

DC EN

70-140

08 -16

60-150

E7016

2.6 ~ 4.0 mm

DC EP

80-180

20 -36

60-150

PREPARED BY

Name

2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range)

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P1 - 004

Date :

Supporting Procedure Qualification No.

: P1-004

Date :

Welding Process(es)

: GTAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

Non fushing metal

Non metalic X

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

TO

P. No. :

Group No. :

Specification Type & Grade to

A106GrB,A672-C65CL.22,API5LGrB,A53GrB,A105,S25C,S28C,A234WPB/Approved Equivalent

Specification Type & Grade

A106GrB,A672-C65CL.22,API5LGrB,A53GrB,A105,S25C,S28C,A234WPB/Approved Equivalent

Thickness Range :- Groove

: 1.6mm to 19.06mm

Diameter(mm)

: All

Fillet

: All

FILLER METALS (QW 404)

GTAW

Spec. SFA No

5.18

Weld Metal A-No

F- No

AWS No. (Class)

ER 70S - G

Manufacturer

Electrode/Filler trade name

KOBELCO/Equivalents

:

Dia of Electrode/Filler

Deposited weld metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

TGS- 50/Equivalents

1.6 ~ 2.4 mm

:

:

Electrode-Flux (Class)

Flux trade Name

Others

19.06mm maximum

_

NA

NA

_

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P1 - 004

Date :

POSITION (QW 405)

Rev :

8/27/2007

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range :

600~650 C

Time Range

1Hr/25mm(Min 1Hrs)

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

Preheat Temperature (Min)

NA

Interpass Temperature (Max)

300 C

Shielding :

Preheat Maintenance

None

Trailing

Backing

Flow rate

Argon

99.99%

10-20 LPM

NA

NA

NA

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

DC- EN

Amps Range

Refer below

Tungsten Electrode Size & Type

Process

Refer below

2.0 ~ 2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range) :

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~10 mm

Wire Bushing / Grinding

Nil, Single side welded joint

7mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

Root&Hot GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

90~160

10~20

50~120

Fill & Cap GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

90~160

10~20

50~120

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P1 - 005

Date :

Supporting Procedure Qualification No.

: P1 - 005

Date :

Welding Process(es)

: GTAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

Non fushing metal

X Non metalic

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

1 or 2

TO

P. No. :

Group No. :

Specification Type & Grade to

A 333 Gr 6 /A671-CC65CL.22/ A420 WPL6 / A 350 LF2 / Approved Equivalents

Specification Type & Grade

A 333 Gr 6 /A671-CC65CL.22/ A420 WPL6 / A 350 LF2 / Approved Equivalents

Thickness Range :- Groove

: 1.6mm to 11mm

Diameter(mm)

: All

Fillet

: All

FILLER METALS (QW 404)

GTAW

Spec. SFA No

5.28

Weld Metal A-No

F- No

AWS No. (Class)

ER 70S - G

Manufacturer

Electrode/Filler trade name

KOBELCO/Equivalents

:

Dia of Electrode/Filler

Deposited weld metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

TGS-1N/Equivalents

1.6 ~ 2.4 mm

:

:

Electrode-Flux (Class)

Flux trade Name

Others

11mm maximum

_

NA

NA

_

1 or 2

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P1 - 005

Date :

POSITION (QW 405)

8/27/2007

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range :

NA

Time Range

NA

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

Preheat Temperature (Min)

NA

Interpass Temperature (Max)

300 C

Shielding :

Preheat Maintenance

None

Trailing

Backing

Flow rate

Argon

99.99%

10-20 LPM

NA

NA

NA

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

DC- EN

Amps Range

Refer below

Tungsten Electrode Size & Type

Process

Refer below

2.0 ~ 2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range)

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~10 mm

Wire Bushing / Grinding

Nil, Single side welded joint

8mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

Root&Hot GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

75-95

11-14

70-90

Fill & Cap GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

80-110

11-14

80-105

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P1 - 006

Date :

Supporting Procedure Qualification No.

: P1 - 006

Date :

Welding Process(es)

: GTAW + SMAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

Non fushing metal

Non metalic X

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

1 or 2

TO

P. No. :

Group No. :

Specification Type & Grade to

A 333 Gr 6 /A671-CC65CL.22/ A420 WPL6 / A 350 LF2 / Approved Equivalents

Specification Type & Grade

A 333 Gr 6 /A671-CC65CL.22/ A420 WPL6 / A 350 LF2 / Approved Equivalents

Thickness Range :-Groove

: >19 mm to49.98mm

Diameter(mm)

:>73mm

Fillet

: All

FILLER METALS (QW 404)

GTAW

SMAW

Spec. SFA No

5.28

5.5

Weld Metal A-No

F- No

AWS No. (Class)

ER 70S - G

E7016-G

KOBELCO/Equivalent

KOBELCO/Equivalent

TGS-1N/Equivalent

LB52-NS/Equivalent

1.6 ~ 2.4 mm

2.6 to 4.0mm

4.8mm

_

45.18mm

_

Manufacturer

Electrode/Filler trade name

Dia of Electrode/Filler

Deposited weld metal

:

:

Electrode-Flux (Class)

Flux trade Name

Others

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

:

:

:

NA

NA

_

NA

NA

_

1 or 2

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P1 - 006

Date :

POSITION (QW 405)

3/15/2007

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

625 C 25 C

Temperature Range :

All

Down

Time Range

PREHEAT (QW 406)

1Hr/25mm(Min 1Hr)

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

Preheat Temperature (Min)

100 C

Interpass Temperature (Max)

300 C

Shielding :

Preheat Maintenance

None

Trailing

Backing

Flow rate

Argon

99.99%

10-20 LPM

NA

NA

NA

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

: GTAW(DC- EN) &SMAW (DC-EP)

Amps Range

Tungsten Electrode Size & Type

Refer below

Process

Refer below

2.0 ~ 2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range)

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~ 10 mm

Wire Bushing / Grinding/Chipping

Nil, Single side welded joint

8mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

Root&Hot GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

100-125

14-18

70-90

Fill & Cap SMAW

E7016-G

2.6mmto 4.0mm

DC EP

80-185

20~35

60-150

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 3/15/2007

: 3/15/2007

: 3/15/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P1 - 007

Date : 8/27/2007

Rev :

Supporting Procedure Qualification No.

: P1 - 007

Date :

Rev :

Welding Process(es)

: GTAW & SMAW

Type :

Welding Code

: ASME section IX

Manual

(Manual/Semi-Auto / Fully-Auto)

Details of single 'V' -Butt joint

75 5

JOINTS (QW 402)

Joint Type

Backing

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

X Non fushing metal

Non metalic

Other

Xmin

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P/S. No.

:

Group No. :

1 or 2

TO

P/S. No. :

Group No. :

Specification Type & Grade to

A 333 Gr 6 /A671-CC65CL.22/ A420 WPL6 / A 350 LF2 / Approved Equivalents

Specification Type & Grade

A 333 Gr 6 /A671-CC65CL.22/ A420 WPL6 / A 350 LF2 / Approved Equivalents

Thickness Range

: 4.8 mm to 18.5mm

:-Groove

Diameter(mm)

: >73mm

Fillet

: All

FILLER METALS (QW 404)

GTAW

SMAW

Spec. SFA No

5.28

5.5

Weld Metal A-No

F- No

AWS No. (Class)

ER 70S - G

E7016-G

KOBELCO/Equivalent

KOBELCO/Equivalent

TGS-1N/Equivalent

LB52-NS/Equivalent

1.6 ~ 2.4 mm

2.6 to 4.0mm

4.8mm

_

13.7mm

_

Manufacturer

Electrode/Filler trade name

Dia of Electrode/Filler

Deposited weld metal

:

:

Electrode-Flux (Class)

Flux trade Name

Others

:

:

:

NA

NA

_

NA

NA

_

1 or 2

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P1 - 007

Date :

POSITION (QW 405)

8/27/2007

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range:

NA

Time Range

NA

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

Preheat Temperature (Min)

NA

Interpass Temperature (Max)

300 C

Preheat Maintenance

None

Trailing

Nil

Backing

Shielding :

Flow rate

Argon

99.99%

10-20 LPM

NA

NA

NA

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

: DC- EN(GTAW), DCEP (SMAW)

Amps Range

Tungsten Electrode Size & Type

Refer below

Process

Refer below

2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range) :

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~ 10 mm

Wire Bushing / Grinding

Nil, Single side welded joint

12mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

80-120

09 -14

60-85

Fill & Cap SMAW

E7016-G

2.6 ~ 4.0 mm

DC EP

90-150

20 -28

70-180

Root & Hot

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P1 - 008

Date :

Supporting Procedure Qualification No.

: P1 - 008

Date :

Welding Process(es)

: GTAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

Non fushing metal

X Non metalic

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

1 or 2

TO

P. No. :

Group No. :

Specification Type & Grade to

A 333 Gr 6 /A671-CC65CL.22/ A420 WPL6 / A 350 LF2 / Approved Equivalents

Specification Type & Grade

A 333 Gr 6 /A671-CC65CL.22/ A420 WPL6 / A 350 LF2 / Approved Equivalents

Thickness Range :- Groove

: 1.6mm to 18.5mm

Diameter(mm)

: All

Fillet

: All

FILLER METALS (QW 404)

GTAW

Spec. SFA No

5.28

Weld Metal A-No

F- No

AWS No. (Class)

ER 70S - G

Manufacturer

Electrode/Filler trade name

KOBELCO/Equivalents

:

Dia of Electrode/Filler

Deposited weld metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

TGS-1N/Equivalents

1.6 ~ 2.4 mm

:

:

Electrode-Flux (Class)

Flux trade Name

Others

18.5mm maximum

_

NA

NA

_

1 or 2

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P1 - 008

Date :

POSITION (QW 405)

8/27/2007

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

625 C 25 C

Temperature Range :

All

Down

Time Range

PREHEAT (QW 406)

1Hr/25mm(Min 1Hr)

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

Preheat Temperature (Min)

NA

Interpass Temperature (Max)

300 C

Shielding :

Preheat Maintenance

None

Trailing

Backing

Flow rate

Argon

99.99%

10-20 LPM

NA

NA

NA

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

DC- EN

Amps Range

Refer below

Tungsten Electrode Size & Type

Process

Refer below

2.0 ~ 2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range)

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~10 mm

Wire Bushing / Grinding

Nil, Single side welded joint

8mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

Root&Hot GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

75-95

11-14

70-90

Fill & Cap GTAW

ER70S-G

1.6 ~ 2.4mm

DC EN

80-110

11-14

80-105

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P3 - 001

Date :

Supporting Procedure Qualification No.

: P3 - 001

Date :

Welding Process(es)

: GTAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

Non fushing metal

Non metalic

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

TO

Specification Type & Grade to

: SA335P1/Equivalent

Specification Type & Grade

: SA335P1/Equivalent

Thickness Range :-Groove

: 1.6mm to 13mm

Diameter(mm)

: All

Fillet

: All

FILLER METALS (QW 404)

:

5.28

Weld Metal A-No

F- No

AWS No. (Class)

ER80S-G

Manufacturer

Electrode/Filler trade name

P. No. :

GTAW

Spec. SFA No

KOBELCO/Equivalent

:

Dia of Electrode/Filler

Deposited weld metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

TGS-M/Equivalent

1.6 ~ 2.4 mm

:

:

Electrode-Flux (Class)

Flux trade Name

Others

13mm maximum

_

NA

NA

_

Group No. :

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P3 - 001

Date :

POSITION (QW 405)

8/27/2007

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range :

NA

Time Range

NA

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

Preheat Temperature (Min)

NA

Interpass Temperature (Max)

300 C

Shielding :

Preheat Maintenance

None

Trailing

Backing

Flow rate

Argon

99.99%

10-20 LPM

NA

NA

NA

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

DC- EN

Amps Range

Refer below

Tungsten Electrode Size & Type

Root &

Hot

Process

Refer below

2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range)

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~ 10 mm

Wire Bushing / Grinding

Nil, Single side welded joint

7mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

GTAW

ER80S-G

1.6 ~ 2.4mm

DC EN

85-110

9-15

55-85

Fill & Cap GTAW

ER80S-G

1.6 ~ 2.4mm

DC EN

90-120

9-15

60-100

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P4 - 002

Date :

Supporting Procedure Qualification No.

: P4 - 002

Date :

Welding Process(es)

: GTAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

7/27/2008

Non fushing metal

Non metalic X

Xmin

Other X

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

TO

P. No. :

Group No. :

Specification Type & Grade to

: A335P11/A691-1.25 Cr CL.22/A234-WP11CL1,A234-WP11CL1-W/Equivalent

Specification Type & Grade

: A335P11/A691-1.25 Cr CL.22/A234-WP11CL1,A234-WP11CL1-W/Equivalent

Thickness Range :-Groove

: 1.6 mm to 11mm

Diameter(mm)

: All

Fillet

: All

FILLER METALS (QW 404)

GTAW

Spec. SFA No

5.28

Weld Metal A-No

F- No

AWS No. (Class)

ER 80S - G/Equivalent

Manufacturer

Electrode/Filler trade name

KOBELCO/Equivalent

:

Dia of Electrode/Filler

Deposited weld metal

TGS-1CM

1.6 ~ 2.4 mm

:

:

Electrode-Flux (Class)

Flux trade Name

Others

11.0 max

_

NA

NA

_

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P4 - 002

Date :

POSITION (QW 405)

7/27/2008

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range :

NA

Time Range

NA

GAS (QW 408)

Preheat Temperature (Min)

Interpass Temperature (Max)

300 C

Preheat Maintenance

None

Percent Composition

Gas(es)

Mixture

200 C

Shielding :

Trailing

Backing

Flow rate

Argon

99.99%

10-20 LPM

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

: GTAW(DC- EN)

Amps Range

Tungsten Electrode Size & Type

Refer below

Root &

Hot

Process

Refer below

2 ~ 2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range)

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

1.6 ~ 10 mm

Wire Bushing / Grinding/Chipping

Nil, Single side welded joint

7mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

GTAW

ER80S-G

1.6 ~ 2.4mm

DC EN

100-170

9-15

55-85

Fill & Cap GTAW

ER80S-G

1.6 ~ 2.4mm

DC EN

100-170

9-15

55-85

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 7/27/2008

: 7/27/2008

: 7/27/2008

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P4 - 003

Date :

Supporting Procedure Qualification No.

: P4 - 003

Date :

Welding Process(es)

: GTAW+SMAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

Non fushing metal

X Non metalic

Other

Xmin

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

Group No. :

TO

P. No. :

Group No. :

Specification Type & Grade to

: A335P11/A691-1.25 Cr CL.22/A234-WP11CL1,A234-WP11CL1-W/Equivalent

Specification Type & Grade

: A335P11/A691-1.25 Cr CL.22/A234-WP11CL1,A234-WP11CL1-W/Equivalent

Thickness Range :-Groove

: >13 mm to 42.88mm

Diameter(mm)

:>73mm

Fillet

: All

FILLER METALS (QW 404)

GTAW

SMAW

Spec. SFA No

5.28

5.5

Weld Metal A-No

F- No

AWS No. (Class)

ER 80S - G/Equivalent

E8016-B2/Equivalent

KOBELCO/Equivalent

KOBELCO/Equivalent

TGS-1CM

CMA-96

1.6 ~ 2.4 mm

2.6~4.0mm

4.8mm

_

38.08

NA

NA

NA

NA

Manufacturer

Electrode/Filler trade name

Dia of Electrode/Filler

Deposited weld metal

:

:

Electrode-Flux (Class)

Flux trade Name

Others

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P4 - 003

Date :

POSITION (QW 405)

Rev :

8/27/2007

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

725 15C

Temperature Range :

All

Down

Time Range

PREHEAT (QW 406)

1Hr/25mm(Min 2Hrs)

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

200 C

Preheat Temperature (Min)

Interpass Temperature (Max)

300 C

Preheat Maintenance

None

Shielding :

Flow rate

Argon

99.99%

10-20 LPM

Trailing

NA

NA

NA

Backing

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

: GTAW(DC- EN) &SMAW (DC-EP)

Amps Range

Tungsten Electrode Size & Type

Refer below

Root &

Hot

Process

Refer below

2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range)

Filler Metal

Dia of Electrode

Spec. No

(mm)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

6 ~ 10 mm

Wire Bushing / Grinding/Chipping

Nil, Single side welded joint

7mm

NA

Multiple pass

Single

See below

Not allowed

NA

Current

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

GTAW

ER80S-G

1.6 ~ 2.4mm

DC EN

100-170

9-15

55-85

Fill & Cap SMAW

E8016-B2

2.6mm to 4.00mm

DC EP

80-210

20~35

60-150

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD

WELDING PROCEDURE SPECIFICATION (WPS)

Company Name

: UTOC ENGINEERING PTE LTD

Page : 01 of 02

Welding Procedure Specification No.

: P5A - 004

Date :

Supporting Procedure Qualification No.

: P5A - 004

Date :

Welding Process(es)

: GTAW

Type :

Welding Code

: ASME section IX

Rev :

Rev :

Manual

Details of single 'V' -Butt joint

75 5

Joint Type

Refer joint details

( Yes) :

(No):

1.50.8

Backing Material (Type)

Back gouging

: With or without backing

( Yes) : X

(No):

30.8

Method:

Linear unit(mm)

1.6mm(min)

Metal

Non fushing metal

Non metalic X

Other

Xmin

Sketches, production drawings, weld symbols or written description should show the general

arrangement of the parts to be welded. Where applicable, the root spacing and details of weld groove

may be specified.

(At the option of the manufacturer, sketches may be attached to illustrate joint design, weld layers and bead

sequence.eg., for notch toughness procedures and multi process procedures etc.,)

Xmin

Socket Weld Connection

1. Size of fillet 1 1/4 T, but not less than 3mm

2. Min 2 passes for fillet welds

Fillet Weld Size

The Lesser of T or 1/4in(6.4mm)

Xmin = The lesser of 1.4T or thickness of the hub

BASE METALS (QW 403)

P. No. :

P5A

Group No. :

TO

Specification Type & Grade to

: SA335P22/Equivalents

Specification Type & Grade

: SA335P22/Equivalents

Thickness Range :-Groove

: 1.6 mm to 14.22mm

Diameter(mm)

: All

Fillet

: All

FILLER METALS (QW 404)

:

5.28

Weld Metal A-No

F- No

AWS No. (Class)

ER90S-G

Manufacturer

Electrode/Filler trade name

P. No. :

GTAW

Spec. SFA No

KOBELCO/Equivalent

:

Dia of Electrode/Filler

Deposited weld metal

(Manual/Semi-Auto / Fully-Auto)

JOINTS (QW 402)

Backing

8/27/2007

TGS 2 CM/Equivalent

1.6 ~ 2.4 mm

:

:

Electrode-Flux (Class)

Flux trade Name

Others

14.22mm maximum

_

NA

NA

_

P5A

Group No. :

Company Name

: UTOC ENGINEERING PTE LTD

Page : 02 of 02

Welding Procedure Specification No.

: P5A - 004

Date :

POSITION (QW 405)

8/27/2007

Rev :

POSTWELD HEAT TEMPERATURE (QW 407)

Positions of Groove

Welding Progression

: Up

Positions of fillet

: All Positions

All

Down

PREHEAT (QW 406)

Temperature Range :

NA

Time Range

NA

GAS (QW 408)

Percent Composition

Gas(es)

Mixture

225 C

Preheat Temperature (Min)

Interpass Temperature (Max)

300 C

Preheat Maintenance

None

Shielding :

Flow rate

Argon

99.99%

10-20 LPM

Trailing

NA

NA

NA

Backing

NA

NA

NA

(Continuous or Special Heating where applicable should be recorded)

Post heating

Nil

ELECTRICAL CHARACTERISTICS (QW 409)

Current-Polority

DC- EN

Amps Range

Refer below

Tungsten Electrode Size & Type

Root &

Hot

Process

Refer below

2.4mm , 2% Thoriated

TECHNIQUE (QW 410)

Stringer or Weave Beads

Orifice or Gas Cup Size

Initial and Interpass Cleaning (Brushing, Grinding etc)

Method of Back Gouging

Max width of weave

Contact Tube to Work Distance

Multiple or Single Pass (Per side)

Multiple or Single Electrode

Travel speed

Peening

Others

Weld

run(s)

Volts (Range)

:

:

:

:

:

:

:

:

:

:

:

Stringer and/or Weave

1.6 ~ 10 mm

Wire Bushing / Grinding

Nil, Single side welded joint

7mm

NA

Multiple pass

Single

See below

Not allowed

NA

Filler Metal

Current

Dia of Electrode

Spec. No

(mm)

Type of Polarity

Amp Range

Volts Range

Travel Speed mm/min

GTAW

ER90S-G

1.6 ~ 2.4mm

DC EN

85-110

9-15

55-85

Fill & Cap GTAW

ER90S-G

1.6 ~ 2.4mm

DC EN

90-120

9-15

60-100

PREPARED BY

Name

: S.R.Sivakumar

CHECKED BY

Name

: T.N.Thambi

APPROVED BY

Name

: Mohammed Nazly

Signature :

Signature :

Signature :

Date

Date

Date

: 8/27/2007

: 8/27/2007

: 8/27/2007

UTOC ENGINEERING PTE LTD