Advanced Fuel Inj Technology Future Diesel Powertrain

Diunggah oleh

Dan SerbDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Advanced Fuel Inj Technology Future Diesel Powertrain

Diunggah oleh

Dan SerbHak Cipta:

Format Tersedia

Advanced Fuel Injection Equipment Technology serving Future Diesel

Powertrains

Prof. Dr.-Ing. Jrgen Hammer, Diesel Systems Business Unit PC,

Robert Bosch GmbH, Stuttgart

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

1. Summary

Since introduction of the Common Rail Diesel injection system on the PC/LDV

market in the year 1997, BOSCH production plants output is bigger than 70 millions

systems til today.

Anyway since launch date markets were strong changing. Facing this also

requirements on modern diesel engines did change dramatically. Core market for

Diesel PC and LDV is mainly driven out of emission legislation EU6 ff and in parallel

fulfilling benchmark targets in fuel consumption. Diesel powertrains are the key

enablers to reach the given CO2 targets for carmakers fleets in Western Europe. Due

to Diesels cost attractiveness in the competition of powertrains against gasoline,

alternative fuels and at least electrification aiming the target of 95 g/km in 2020, the

Diesel share in almost all vehicle segments will be pushed. To reach in parallel

stringend NOx emissions also under real driving conditions, beside exhaust gas

treatment, the FIE technology plays a key role to reduce raw emissions and optimize

the combustion towards highest power output at lowest fuel consumption on gasoline

like comfort level.

Looking to the strong growing markets in India and China, Diesel powertrain

technology is serving basic mobility and transportation needs at lowest fuel

consumption and therefore costs. High value for money also on the injection

technology side is required together with robustness needs and wide range of fuel

quality acceptance for use in also very big range of vehicles for transportation and offhighway applications.

This broad project landscape from robust cost innovation up to benchmark

performance levels BOSCH is serving with a modular product strategy in FIE. This

paper gives an overview on those systems which equips from dedicated products

families 1-cylinder load carriers up to premium luxury vehicles also foreseen with

hybridization.

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

2. Market and Drivers

ATZ_Standard fr Grundschrifttexte

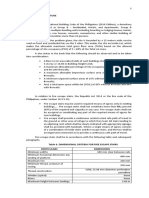

Fig.1: Market forecast shares of different powertrains worldwide

Fig.1 shows overall prognosis worldwide of powertrain shares. Since Diesel is stable

slightly growing towards 2020 around 24 % overall market share the main regions

serving that trend is WEU all time high with around 50 %. US is expected to ignite in

Diesel share in the LDT and SUV segment but also coming in the sedan area e.g.

known from the VW Jetta and announced Cruze from GM other will follow. Last but

not least luxury limousines from german carmakers are already successful lauchend.

Stable growth in IN due to the immense transport need of all people suffering on cost

attractive vehicles beside 2 wheelers. In addition CN market is seen to be growing in

the off road and light commercial area.

Out of thermodynamic reasons Diesel is and will stay as the most efficient ICE

concepts. In addition at least CO2 target in WEU of 2020 of 95 g/km Diesel will be

also the most cost effective solution gaining the overall fleet value, Fig2. Both leads to

an attractiveness of the Diesel powertrain in almost all segments to the TCO for end

consumer in addition to an overall powertrain portfolio for the carmakers gaining their

CO2 fleet targets.

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

Fig.2: cost comparison fuel price and consumption Diesel vs. Gasoline

Fig.3: CO2 Emissions versus Costs: Tank-to-Wheel, 2015, Compact Class CC

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

Fig.4: Diesel technology modules gaining WEU Emission Legislation

Fig.5: Diesel technology modules gaining IN Emission Legislation

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

Looking at the overall technology key stones for a Diesel PT one can state some basic

findings for FIE besides Diesel engine technology and exhaust gas treatment

equipment:

Overall main requirements on FIE Technology:

full flexible injection pressure

maximum pressure depending on combustion, air and EGR

system and rated power target

full flexible multiple injection capability

application specific no of

minimum quantity and tolerances

injections,

dwell

time,

nozzle technology with robust compromise coking vs. hole

efficiency, optimized sac hole volume

These so-called CR standard requirements [1-8] to be specifically quantified for each

application, have to be extended segment- and market-wise. For example looking into

Diesel powertrains for luxury cars even combined with hybrid technology extends this

basic requirements towards ultimate efficiency of the hydraulic system, comfort issues

and last but not least towards best class fuel metering capabilities like special injection

rate shapes for partial and full load, lowest tolerances using 8 injection events per

stroke by having smallest injection quantities up to rated pressure. Due to benchmark

maximum torque demands and rated power outputs similar to gasoline engines,

highest injection pressures like 2500 bar and in future gaining still more is demanded,

Fig. 4. Addressing future hybridization in this segment which is short term foreseen,

FIE has to be qualified in terms of additional needs like higher numbers of start

events, very fast speed up to the high pressure pump, stand by pressure during stop

phases, long sleeping modes of the ICE etc. ,Fig. 6

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

On the other hand the emerging market is addressing completely different add-ons

like cost down first and robustness resp. simplification for application and oil

lubrication of the high pressure pump is mandatory. Load carrier applications

combining very low engine displacements with relatively high good loads and total

vehicle weights lead to very high duration times at full load operation and strong load

collectives on the components. This addresses robustness measures on the

components those have to be included into the modular FIE components system, Fig.

8.

Fig.7: Special view WEU and US luxury applications on FIE requirements

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

Fig8: Special view India applications on FIE requirements

Since maximum injection pressure is always a key topic in Diesel due to the fact that

mixing time is pretty short, spray momentum and spray formation are key enablers for

lowest raw emissions and fuel consumption and finally nozzle flow rate have to be

optimized in the balance of maximum rated power and spray quality [1-8] some words

to upcoming trends in high pressure requirements all over the world, Fig. 9.

Fig.9: RB CR Systems by pressure and region

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

All in a nut shell, western world standard and high end applications are front runners

in maximum pressures of todays 2200 bar and foreseen 2500 bar in 2014.

Requirements are already on the table gaining the magic 3000 bars. In the average

2000 bar is establishing as a standard in WEU-applications. Looking to India and

China we have 1400 bar and 1600 bar as next step. Additionally development is

addressing 1800 bar for upcoming emission legislation e.g., CN5 and applications in

the LD and MD segments using full load EGR.

3. BOSCH Modular Common Rail System Technology

The overall road map of BOSCH Common Rail System Technology for PC and LDV

shows 3 Generations which basically are built up on specific components

technologies, Fig. 10.

Fig.10: Roadmap CRS generations for PC/LD

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

While on the injector technology CRS 1 and CRS2 uses top head solenoid valves to

control the servo driven Diesel fuel injectors is CRS 3 based on the so called Piezo

inline injector technology. High pressure pumps are divided in oil lubricated

unit pumps for different flow rates used in Gen 1, fuel lubricated pumps from 1600 up

to 2500 bar pressure ranges in all Generations, while the 1 and 2 plunger CP4

family is exlusively used in the Gens 2 und 3. A derivate of a engine intergrated oil

lubricated version of the CP4.1, the so called CP4i is under development to serve

also car makers who want to built engilnes for world wide use and combine 2nd Gen

CRS with oil lubricated high pressure pumps, a system architecture example will be

given later.

Fig.11: Common Rail Pump CP4 Modularity

Looking on the system architecture of the so called CRS1-14 UP one can see the

focus what is really needed for the dedicated market. In generell 1 upt to 3 cylinders

are equipped with the CRS-14 UP. Performing up to 25 resp. 50 kW/L with naturally

aspirated resp. turbo charged engines. Max. system pressure is 1450 bar, max. 3 no of

injections per stroke, dwell time min of 800 microseconds fulfilling lifetime

requirements of 200 000 km and targeting emission levels BS3/4.[9]

10

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

Fig.12: System architecture CRS1-14 UP

As an example a 2 cylinder system is shown. Starting from the tank with electrical lift

pump as pre supply modul the fuel runs over the main filter to the Fuel Control Unit

(FCU) which is separately placed in front of the Unit Pump (UP). The FCU provides a

controlled amount of fuel on a constant pressure to be filled in the UP. Using this

device only the demanded fuel flow to keep the rail pressure on its target value is

pressurized. In comparison to maximum pumping all the time, consumption benefits

on the engine of up to 8 % can be realized. Doing so the standard UP former used in

standard cam-driven injection systems can be carried over w/o any changes on the

engine, staying oil lubricated and with only minor changes for example at the I/O

valves and cam slopes at the pump drive. For the OEM which uses normally a engine

family for decades gives this a lot of commercial benefits.After pressurizing the fuel

runs to the Rail Pressure Sensor Block (RPS-Block) which has the main functions to

distribute the fuel to the injectors and carries the rail pressure sensor for pressure

metering. Skipping the rail and using RPS-block saves money, mounting space and

reduces the weight of the high pressure storage. Last but not least used CRI1-14

injectors are special inventions for IN market needs in terms simplified components

for attractive prices. Based on the well known top head solenoid injectors of

BOSCH launched in 1997 the CRI1-14 was designed with a simplified solenoid group

with a non-guided one part armature, extended tolerances and de-contending measures

like skipping the C-coating on the nozzle needle. The system has already entered

successfully different PC and LDV applications in the Indian market.

11

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

Looking on the WEU all time high Diesel market we have to address both focus

points like attractive cost at high performance simultaneously. Fig. 13 shows a new

approach consisting already established components with brand new ones in a

innovative high intergrated FIE on the engine.

Fig.13: System architecture CRS2-20 with CP4i

While rail configuration with pressure control valve and sensor stays well know as

always first big change shows the pump. The so called CP4i is an engine intergrated

oil lubricated high pressure pump which is driven directly via roller tapet and cam

slope from the engine cam shaft. Therefore no lubrication flow to the pump dieselwise

is needed which gives the opportunity to skip the backflow line and reduces the power

and delivery capacity of the pre-supply pump drastically. Challenge in this concept is

the sealing system of the pump drive which has to tighten the oil chamber of the

engine to the fuel element of the high pressure pump. Both pathes fuel in oil and oil in

fuel requires very low leackege rates to avoid oil dilution on the engine and to prevent

oil contamination in the fuel which leads to nozzle cocking and particulate trap

blogging due to oil ashes. The CP4i itself is quantity controlled by a electrical suction

12

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

valve which shows benefits in dynamics and damping low pressue pulses in

comparison to an suction control via throttling.

The CR2-20 as the benchmark common rail injector technology of top head solenoids

is shown in Fig. 14. Using unique pressure balanced valve technology introduced in

2007 [11] with the CRI 2-18, was successfully tranfered to the CRI2-20 concept. Very

fast switching armature with only 25 m stroke gives the chance to control the long

needle for the sake of very small quantities and dwell times lower than 200

mircoseconds. Capability of up to 8 injection events per stroke at lowest control and

leackage quantities. Since the needle is also pressure balanced there is no leckeage to

the low pressure back flow.

Fig.14: CRI2-20 with closed loop control

Special design of the CRI2-20 allows to locate a pre -rail volume in the injector to

feed fuel after opening the needle very fast and damping the pressure waves coming

from a previous injection to the next leading to accurate multiple injection quantities

lowest hydraulic dwell times. Due to the fact that the control chamber topside of the

needle is closed by the armature bolt each and every pressure change in the chamber

leads to a force change on the lower side of the armature bolt. This force change now

can be used to detect the needle opening and closing behavior and in the end to

calculate via model the hydraulic open time of the needle. The force is guided via

amature bolt to a piezo element which measures the signal and put this via wiring

13

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

harness to the ECU. No additional cable is needed. Fig. 14 shows typical signals out

of the injector during injection events. Having this signal one is able to control

injection quantities over life time via closed loop control in the CRI2-20. [12]

Since 2003 with the very impressive lauch for the Audi A8 V6 TDI fulfilling EU4

legislation w/o additional exhaust gas treatment first time Piezo inline injection

technology from BOSCH, the so called 3rd generation was used. Based on this we

develop the ultimative piezo injection technology with 2500 bar maximum system

pressure for premium segment vehicle classes.

Fig.15: System architecture CRS3-25 6. cylinder

Al high pressure components are qualified to the 2500 bar pressure level in a

optimized hydraulic efficiency, package and of course weight an life time manner.

By qualifying the CRI3-25 on the high pressure level we did change the control valve

design to a force reduced approach in comparison to the previous generations [11].

Leaving the piezo actor coupler actor chain as very successful in the market with

benchmark quality figures in the CRI3-20, we adjust the load on the servo valve by

placing a bold guided in a sleeve to the low pressure side of the throttle plate. His

allows to switch the 2500 bar pressure level with lower actor forces like we have on

the CRI3.20 using 2000 bar injector. With sophisticated hydraulic layout tools we

were able to create a injector performance fulfilling requirements of the engine like

smallest pilot quantities at highest pressure, 8 injections per stroke, lowest dwell times

and extended life time, Fig. 16.

14

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

Fig.16: CRI3-25 functional sketch

15

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

Literature

[1] Dohle, U., Drnholz, M., Hammer. J., Kampmann, S., Hinrichsen, C., Ziegler, G.:

4th Generation Common Rail Injection System for Future Emission Legislation,

FISITA Barcelona 2004

[2] Dohle, U., Drnholz, M., Hammer, J.: Evolution on Advanced Common Rail

Injection Systems for Diesel, ATA International Diesel Conference - Low PM and

NOx Technology, Bari 2004

[3] Dohle, U., Drnholz, M., Hammer. J., Kampmann, S., Hinrichsen, C., Wintrich,

T.: Die 4. Generation Common Rail Dieseleinspritzung Neue Anstze zur Erfllung

hchster Kundenerwartung und gesetzlicher Anforderungen, 4. Tagung Diesel und

Benzindirektreinspritzung, Haus der Technik, Berlin 2004

[4] Kampmann, S., Hammer, J., Mattes, P.: Weiterentwicklung von Common Rail

Einspritzsystemen zur Erreichung knftiger Emissionsgrenzen, 7. Tagung Motorische

Verbrennung Aktuelle Probleme und moderne Lsungsanstze, Haus der Technik,

Mnchen Mrz 2005.

[5] Dohle, U., Kampmann, S., Hammer, J., Bcking, F.: Potenzial moderner Diesel Common Rail Einsritzsysteme zur Erreichung knftiger Emissionsgrenzen, 26.

Internationales Wiener Motorensymposium, Wien April 2005

[6] Bcking, F., Dohle, U., Hammer, J., Kampmann, S.: Pkw Common Rail Systeme

fr knftige Emissionsanforderungen, MTZ, 66. Jahrgang, Juli/August 2005, S. 552

557

16

Advanced Fuel Injection Equipment - Technology serving Future Diesel Powertrains

[7] Hammer, J.: Evolution of the Common Rail Technology, Ingegneria dell

AUTOVEICOLO, Giornale ed atti della Associazoone technical dellaAutomobile,

Vol. 58 N.7/8 Luglio/Augosto 2005, p. 24 28

[8] Dohle, U., Drnholz, M., Kampmann S., Naber, D., Hammer, J., Lehle, W.:

Common Rail Einspritzsysteme Kernbaustein knftiger Pkw Dieseltechnologie,

10. Symposium Dieselmotorentechnik, Stuttgart Mrz 2006

[9] Kremer A,: Besondere Anforderungen und FIE Lsungen fr aufstrebende Diesel

Mrkte, Diesel- und Benzindirekteinspritzung, 8. Tagung, Haus der Technik, Berlin

28th November 2012

[10] Maier R. : The next genaration BOSCH Common Rail Injectors with digital rate

shaping akey factor for meeting future requirements, 33rd International Vienna

Motor Symposium Wien 2012

[11] Leonhard R., Warga J. Pauer T., Boecking F., Straub D.: Bosch 200bar Common

Rail System for Passenger Cars and Light Duty vehicles

[12] Meyer S., Krauss, J.; Przise Zumessung ber Lebensdauer in einem CommonRail-System, Diesel- und Benzindirekteinspritzung, 8. Tagung, Haus der Technik,

Berlin 28th November 2012

17

Anda mungkin juga menyukai

- DOPE Personality TestDokumen8 halamanDOPE Personality TestMohammed Hisham100% (1)

- Common Rail Injector FailuresDokumen2 halamanCommon Rail Injector FailuresshashirajBelum ada peringkat

- CRSN4 25Dokumen2 halamanCRSN4 25Fernando GarcíaBelum ada peringkat

- 1.6 Turbo Gdi Hyundai Kim eDokumen24 halaman1.6 Turbo Gdi Hyundai Kim egiampaoloBelum ada peringkat

- 4510 0018 04 PDFDokumen248 halaman4510 0018 04 PDFHobbyLogicBelum ada peringkat

- Excel VBA Programming For Solving Chemical Engineering ProblemsDokumen42 halamanExcel VBA Programming For Solving Chemical Engineering ProblemsLeon FouroneBelum ada peringkat

- Bosch MaquinasDokumen13 halamanBosch MaquinasnomecBelum ada peringkat

- Bosch Paper On Fuel Injection 2005 PDFDokumen9 halamanBosch Paper On Fuel Injection 2005 PDFiocsachinBelum ada peringkat

- Delphi DieselMax and Turbocharger Extra Modules PDFDokumen3 halamanDelphi DieselMax and Turbocharger Extra Modules PDFSherita Thomas100% (1)

- Pizzo InjiDokumen3 halamanPizzo InjiprakashBelum ada peringkat

- TK1035 enDokumen2 halamanTK1035 enSutiknoBelum ada peringkat

- CZ 2012 2013 DieselDokumen14 halamanCZ 2012 2013 DieselSoeAyeBelum ada peringkat

- The Common Rail Diesel Injection System Explained: Technical FeaturesDokumen3 halamanThe Common Rail Diesel Injection System Explained: Technical FeaturesDejan MihajlovicBelum ada peringkat

- Bosch ECI Injection - ECIDokumen17 halamanBosch ECI Injection - ECIBeTOBelum ada peringkat

- 8096CRSN3 25 - Factsheet e PDFDokumen2 halaman8096CRSN3 25 - Factsheet e PDFLuis MirandaBelum ada peringkat

- Common Rail Systems CRS2 With 1,600 To 2,000 Bar and Solenoid ...Dokumen2 halamanCommon Rail Systems CRS2 With 1,600 To 2,000 Bar and Solenoid ...Mihai AncutaBelum ada peringkat

- Manual Diesel Test BenchDokumen18 halamanManual Diesel Test BenchMelchor EstradaBelum ada peringkat

- Delphi DDU CRSDokumen2 halamanDelphi DDU CRSFaraz HaiderBelum ada peringkat

- Bosch Diesel FolderDokumen8 halamanBosch Diesel FolderBranco88Belum ada peringkat

- Solenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorDokumen8 halamanSolenoid Valve Colis For Siemens Continental VDO Common Rail Injector A2C59517051 BK2Q9K546AG and Other Vdo InjectorWinston Wolf0% (1)

- hk1400 - NMDokumen2 halamanhk1400 - NMAhmet BuyrucuBelum ada peringkat

- Ds-Datenbl Crs1 14up enDokumen2 halamanDs-Datenbl Crs1 14up encrastoverkillBelum ada peringkat

- Bosch Vp44 Diesel Pump Fitted To Vauxhall Astra Corsa Combo Frontera 10816147Dokumen3 halamanBosch Vp44 Diesel Pump Fitted To Vauxhall Astra Corsa Combo Frontera 10816147Duško GrbićBelum ada peringkat

- Makalah Wirausahawan SuksesDokumen6 halamanMakalah Wirausahawan SuksesSurya IrawanBelum ada peringkat

- SABRE Hartridge CRIPC AVM2PC CENADokumen10 halamanSABRE Hartridge CRIPC AVM2PC CENAHong Seok ChoiBelum ada peringkat

- Common-Rail Pumps Repair: Standard Equipment ForDokumen10 halamanCommon-Rail Pumps Repair: Standard Equipment ForPool Quispe AlcántaraBelum ada peringkat

- DieselBrochure 10-2012Dokumen68 halamanDieselBrochure 10-2012enriBelum ada peringkat

- Sabre Expert Brochure en WebDokumen4 halamanSabre Expert Brochure en WebayazBelum ada peringkat

- En 063 Diagnostics Parts and Services For Vans and TrucksDokumen32 halamanEn 063 Diagnostics Parts and Services For Vans and TrucksmugavanaBelum ada peringkat

- Bosch ESI (Tronic) 1Q.2015 News PDFDokumen2 halamanBosch ESI (Tronic) 1Q.2015 News PDFAdrián Molina MiguelBelum ada peringkat

- ESI - 2 - 0 BoschDokumen8 halamanESI - 2 - 0 Boschbadboyigor100% (1)

- Piezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingDokumen10 halamanPiezo CR Bosch Manual - Nozzle Assembling Disassembling and Injector AdjustingZdravko DudicBelum ada peringkat

- 123Dokumen21 halaman123Evans MagalhãesBelum ada peringkat

- Diesel Nozzle PDFDokumen49 halamanDiesel Nozzle PDFAdam Johnson100% (1)

- TECHNEWS 12 2016 - Piezo RegenerationDokumen3 halamanTECHNEWS 12 2016 - Piezo RegenerationAbraaj-TTSBelum ada peringkat

- The New Mercedes Benz Four Cylinder Diesel Engine For Passenger CarsDokumen8 halamanThe New Mercedes Benz Four Cylinder Diesel Engine For Passenger CarsBobCavBelum ada peringkat

- Basic Problems Common RailDokumen10 halamanBasic Problems Common Railarimbi jatisasongkoBelum ada peringkat

- Parts VDO 2008Dokumen30 halamanParts VDO 2008Edinson Ariel Chavarro QuinteroBelum ada peringkat

- Delphi ETC 2.1 Medium / Heavy-Duty Diesel Controller: DescriptionDokumen2 halamanDelphi ETC 2.1 Medium / Heavy-Duty Diesel Controller: Descriptionjamesmarin007Belum ada peringkat

- Delphi Heavy Duty Emissions Brochure 2011 2012Dokumen100 halamanDelphi Heavy Duty Emissions Brochure 2011 2012Younwoo NamBelum ada peringkat

- Pressure-Amplified Common Rail System For Commercial VehiclesDokumen6 halamanPressure-Amplified Common Rail System For Commercial VehiclesMichele GuerriniBelum ada peringkat

- Mo TronicDokumen2 halamanMo TronicdromakiBelum ada peringkat

- Gasoline Direct InjectionDokumen20 halamanGasoline Direct InjectionLalith Kumar100% (1)

- 1805-CreditParts + Fuel Injector Repair Kits Catalogue PDFDokumen25 halaman1805-CreditParts + Fuel Injector Repair Kits Catalogue PDFRespaldo GregoryBelum ada peringkat

- SSP 351 Common Rail Fuel Injection System Fitted in The 30l v6 Tdi EngineDokumen56 halamanSSP 351 Common Rail Fuel Injection System Fitted in The 30l v6 Tdi EngineNhuong Hoang DinhBelum ada peringkat

- MTBR - Operating Manual V2017.1Dokumen66 halamanMTBR - Operating Manual V2017.1Elias Tito Avalos Apaza100% (1)

- Brand Code Type: Carbon Zapp (AZO) Database Release v1.46.1.1Dokumen44 halamanBrand Code Type: Carbon Zapp (AZO) Database Release v1.46.1.1BaytolgaBelum ada peringkat

- Common RailDokumen5 halamanCommon RailPushkar Nath100% (3)

- CRDiDokumen6 halamanCRDibe_aeonBelum ada peringkat

- Bosch Diesel Emissions InformationDokumen28 halamanBosch Diesel Emissions InformationBarcanescu ConstantinBelum ada peringkat

- CRDiDokumen18 halamanCRDiSuhel InamdarBelum ada peringkat

- Shim Catalogue To PrintDokumen32 halamanShim Catalogue To PrintAkram SiddigBelum ada peringkat

- TCT Segmentfolder 201409 en LowresDokumen80 halamanTCT Segmentfolder 201409 en LowreszglogovicBelum ada peringkat

- Unit Injectors With Piezo Valves: Self-Study Programme 352Dokumen24 halamanUnit Injectors With Piezo Valves: Self-Study Programme 352Truong Tran van100% (1)

- Delphi DPGE Medium Duty Diesel Rotary Fuel Injection Pump: Powertrain SystemsDokumen2 halamanDelphi DPGE Medium Duty Diesel Rotary Fuel Injection Pump: Powertrain SystemsAsif ShahBelum ada peringkat

- Delphi's Diesel Unit Pump Common Rail System 2012Dokumen6 halamanDelphi's Diesel Unit Pump Common Rail System 2012qingcaohe100% (1)

- Electrical Supercharging For Future Diesel Powertrain ApplicationsDokumen10 halamanElectrical Supercharging For Future Diesel Powertrain ApplicationsAbdoel Wahied ArohmanBelum ada peringkat

- Holset - Dresden Technical Paper - New Range of Turbochargers For Light Commercial Vehicle MarketsDokumen17 halamanHolset - Dresden Technical Paper - New Range of Turbochargers For Light Commercial Vehicle MarketsPetter LonningBelum ada peringkat

- Marine Engine Programme bbb4Dokumen252 halamanMarine Engine Programme bbb4Thomas CuerqBelum ada peringkat

- Research Article Tailored Centrifugal Turbomachinery For Electric Fuel Cell TurbochargerDokumen14 halamanResearch Article Tailored Centrifugal Turbomachinery For Electric Fuel Cell TurbochargerBharath kumarBelum ada peringkat

- Bosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveDari EverandBosch Automotive Electrics and Automotive Electronics: Systems and Components, Networking and Hybrid DriveRobert Bosch GmbHBelum ada peringkat

- Bachelors - Project Report 1Dokumen43 halamanBachelors - Project Report 1divyaBelum ada peringkat

- Chuck Eesley - Recommended ReadingDokumen7 halamanChuck Eesley - Recommended ReadinghaanimasoodBelum ada peringkat

- Q3 - Summative Test2 - Statprob 2022 2023Dokumen2 halamanQ3 - Summative Test2 - Statprob 2022 2023Christian Lloyd ReandinoBelum ada peringkat

- Prescriptions For Closing The Seven Service Quality GapsDokumen1 halamanPrescriptions For Closing The Seven Service Quality GapsReema NegiBelum ada peringkat

- Strata Ene 2023Dokumen8 halamanStrata Ene 2023gabyBelum ada peringkat

- If You Restyou RustDokumen4 halamanIf You Restyou Rusttssuru9182Belum ada peringkat

- Grade 8 For Demo Cigarette SmokingDokumen3 halamanGrade 8 For Demo Cigarette SmokingSteven TaperoBelum ada peringkat

- CV LeTranNguyen enDokumen4 halamanCV LeTranNguyen enLe Tran NguyenBelum ada peringkat

- Brochure Exterior LightingDokumen49 halamanBrochure Exterior Lightingmurali_227Belum ada peringkat

- ZEOS-AS ManualDokumen2 halamanZEOS-AS Manualrss1311Belum ada peringkat

- Configuration Diagrams: Group 80ADokumen24 halamanConfiguration Diagrams: Group 80ASaHdo AbdelHamid100% (1)

- Lesson 2 Principles of Cooperative ConversationDokumen9 halamanLesson 2 Principles of Cooperative Conversationdelilah o balladBelum ada peringkat

- 3949-Article Text-8633-1-10-20180712Dokumen10 halaman3949-Article Text-8633-1-10-20180712Volodymyr TarnavskyyBelum ada peringkat

- A Research Paper On DormitoriesDokumen5 halamanA Research Paper On DormitoriesNicholas Ivy EscaloBelum ada peringkat

- Adsa Ka SyllabusDokumen3 halamanAdsa Ka SyllabusHacker RanjanBelum ada peringkat

- McKinsey On Marketing Organizing For CRMDokumen7 halamanMcKinsey On Marketing Organizing For CRML'HassaniBelum ada peringkat

- Smartor manualENDokumen148 halamanSmartor manualENPP043100% (1)

- 1 - Unit 3 MCQDokumen11 halaman1 - Unit 3 MCQRAMESH KUMAR MAURYABelum ada peringkat

- Restrictions AOP30 enDokumen1 halamanRestrictions AOP30 enRicardo RamirezBelum ada peringkat

- C1 L2D Quadratic FormulaDokumen3 halamanC1 L2D Quadratic FormulaJo-Amver Valera ManzanoBelum ada peringkat

- Loading and Hauling Dump Truck: DumperDokumen2 halamanLoading and Hauling Dump Truck: DumperRJBelum ada peringkat

- Cutting Aws C5.3 2000 R2011Dokumen33 halamanCutting Aws C5.3 2000 R2011Serkan AkşanlıBelum ada peringkat

- Problems 1Dokumen2 halamanProblems 1Andoy Don M.Belum ada peringkat

- Catholic Social TeachingsDokumen21 halamanCatholic Social TeachingsMark de GuzmanBelum ada peringkat

- Student Report: Social Studies Class TestDokumen4 halamanStudent Report: Social Studies Class Testila thakurBelum ada peringkat

- Analysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabDokumen3 halamanAnalysis and Design of Cantilever Slab Analysis and Design of Cantilever SlabMesfinBelum ada peringkat

- Brittan Bradford ResumeDokumen2 halamanBrittan Bradford Resumeapi-574584381Belum ada peringkat

- SThe Electric Double LayerDokumen1 halamanSThe Electric Double LayerDrishty YadavBelum ada peringkat