Bradken Study SAG Liners

Diunggah oleh

Mr29RicardoHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Bradken Study SAG Liners

Diunggah oleh

Mr29RicardoHak Cipta:

Format Tersedia

CASE STUDY

Combating SAG Mill Feed End Wear with White Iron Inserts

The Challenge: Increase the wear life of the Feed End liners in a 32 x 16 SAG

Bradken observed a challenge that a customer was having with their SAG mill Feed End (FE) liners. These FE liners

were wearing sooner than the liners in the rest of the mill. The Discharge End (DE) liners and shell liners all have a

consistent wear life of six months enabling these liners to be removed and changed during the same mill shutdown.

Due to the higher wear on the FE liners, they had to be replaced after only four months, subsequently necessitating

extra mill stoppages beyond that required for the other liners and adding cost and reducing mill availability.

The mill environment is hard rock (12% Cu, 88% Au), with a 28% charge volume

(incl. 13% 125mm steel media). The challenge for Bradken was to increase the wear life

of the FE liners to match the wear life of liners in the rest of the mill.

OEM Design

Review of Current OEM Design of FE Outer and Middle Liners

At a charge level of 28%, the joint line between the outer and the

middle FE liners is aligned with the hightest wear area resulting

in both these liners needing replacement at the same time.

Trial Solution 1 - Move Joint Line

Actions:

Model of Trial

Solution 1

Extend the outer liner so that the joint

line is outside the high wear area

Increase lifter height to add wear life

Outcomes:

Removed the need to replace middle

liners at the same time as the outer

liners reducing the number of parts

requiring changeout from 48 to 32.

Middle liners no longer experience

high wear

Reduced the number of bolts

required in the FE

Restricted the higher wear zone to

the outer liner

Increased the wear life of the outer

liner by approximately 10%

^Caption...

The challenge Remains: Achieve six months wear life from outer

FE liners without adding more wear material and increasing liner mass

2014 BRADKEN Case Study_Combating SAG Mill Feed End Wear with White Iron inserts

Date: 11/07/14

bradken.com

Trial Solution 2 - Mitigate the High Wear Zone

Actions:

Any further increases in lifter height are restricted by maximum liner mass within the mill. Therefore other

alternatives were considered

Reviewed alternative wear materials to increase life. The liner material must be able to survive in the hard

rock SAG mill environment with 125mm steel balls whilst remaining economical

Introduced an insert of White Iron into the lifter across the high wear zone. White iron is too brittle in this

application to cast an entire FE liner, however by protecting the edge of the insert using the current alloyed

steel, significant improvment can be obtained in the abrasive wear life of the liner

CAD modelling incorporating DEM was undertaken ensuring correct positioning of the insert and

manufacturability of the liner

Original liners

without inserts

Middle liner with white iron insert

White Iron

Inserts

CrMo

Liners

Model of Trial Solution 2

DEM modelling to ensure

correct placement of inserts

Outcomes:

Three liners after removal from mill inner liner with WI insert demonstrates

maintained lifter height

The trial demonstrated that the use of white iron inserts into the lifters on the FE liners extended the wear life

from 3.8 months to 6.2 months an increase of 69%

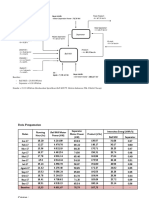

Qty per

Set

Liner Mass per Set

(kgs)

Change-out time

per Set (hrs)

Wear Life

(months)

Annualised Change

out time (hrs)

Middle Liner

16

24,000

4.53

3.8

14.3

Outer Liner

32

44,800

9.07

3.8

Liner

Original Feed

End

28.6

Total Mass: 68,800

Bradken

Feed End

Total Hours: 43

Middle Liner

16

10,816

4.53

42.7

1.3

Outer Liner

32

62,080

9.07

6.2

18.1

Total Mass: 72,896

Total Hours: 19

By increasing the wear life of the outer FE liners and matching the

shutdown/change out cycle of the remaining liners in the mills, the

Bradken solution reduced the annualised change out times by 24

hours thereby reducing mine operating costs

Full Implementation of Inserts in CrMo FE Liners

Overall Outcomes:

Excessive wear was tackled by the use of high wearing white iron inserts

in the CrMo steel FE mill liners

Consistent Wear on all liners with the FE, shell and DE liners now matching a 6 month shut

down cycle

Savings of one full reline shut per year and extended life of liners

2014 BRADKEN

Case Study_Combating SAG Mill Feed End Wear with White Iron inserts

For more information and to find your local representative visit bradken.com

Date: 11/07/14

bradken.com

Anda mungkin juga menyukai

- Differences Between Apron Feeder and Vibrating FeederDokumen1 halamanDifferences Between Apron Feeder and Vibrating FeederAnkon Mukherjee100% (1)

- Plasma Oxy Fuel: Metal CuttingDokumen20 halamanPlasma Oxy Fuel: Metal CuttingRIDHAMBelum ada peringkat

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementDari EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementBelum ada peringkat

- Ball Mill DrivesDokumen3 halamanBall Mill DrivesManne RajuBelum ada peringkat

- List of Government Circuit Bungalow Nuwara EliyaDokumen4 halamanList of Government Circuit Bungalow Nuwara EliyaAsitha Kulasekera78% (9)

- FELIPE Week 7 Size ReductionDokumen19 halamanFELIPE Week 7 Size ReductionRaymond FelipeBelum ada peringkat

- 1330 Rajiv Chandramohan SAG Mill Optimisation and Increasing Throughput at The Phu Kham Copper Gold OperationDokumen21 halaman1330 Rajiv Chandramohan SAG Mill Optimisation and Increasing Throughput at The Phu Kham Copper Gold Operationmamg4415Belum ada peringkat

- Belt Scale Application GuidelinesDokumen25 halamanBelt Scale Application Guidelinesบิ๊ก บิ๊กBelum ada peringkat

- Cold Vulcanizing SolutionDokumen4 halamanCold Vulcanizing Solutionritesh shrivastav0% (1)

- LL CompwrapDokumen11 halamanLL CompwrapJomer J SimpsonBelum ada peringkat

- Single RollDokumen8 halamanSingle RolltashdashBelum ada peringkat

- SAG Mill LinerDokumen7 halamanSAG Mill LinerHabram Miranda AlcantaraBelum ada peringkat

- OMM DOBA BrakeDokumen24 halamanOMM DOBA BrakeRakhmat yusuf100% (2)

- Chapter 1Dokumen56 halamanChapter 1Surbhi JainBelum ada peringkat

- Filter & Size ReductionDokumen20 halamanFilter & Size ReductionMuhammad Putra RamadhanBelum ada peringkat

- PeletizadoDokumen8 halamanPeletizadoJavier GómezBelum ada peringkat

- SAG & AG Mill Article - Mining Monthly - June10Dokumen8 halamanSAG & AG Mill Article - Mining Monthly - June10Peluche de PapelBelum ada peringkat

- KHD Tube MillDokumen2 halamanKHD Tube MillKeynes de SavaBelum ada peringkat

- 1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDokumen56 halaman1.1 Design Features of Bucket Elevator: Package M10: Auxiliary Equipment - Maintenance and RepairDilnesa EjiguBelum ada peringkat

- 5 8 2016 SAG Mill InspectionDokumen5 halaman5 8 2016 SAG Mill InspectionanjasBelum ada peringkat

- Trellex Mill Lining SystemsDokumen17 halamanTrellex Mill Lining SystemsJesus CHBelum ada peringkat

- Vertical Roller Mill Repair: Enduring PerformanceDokumen12 halamanVertical Roller Mill Repair: Enduring PerformanceSunny KumarBelum ada peringkat

- 8 - XCC Hammers UKDokumen2 halaman8 - XCC Hammers UKSampreeth TekkadBelum ada peringkat

- Ventilation MRT CatalogueDokumen28 halamanVentilation MRT Cataloguevikas gahlyanBelum ada peringkat

- Grinding With Tube MillDokumen43 halamanGrinding With Tube MillrecaiBelum ada peringkat

- Iron Ore Dressing Plant Auditing - LectureDokumen7 halamanIron Ore Dressing Plant Auditing - LectureravibelavadiBelum ada peringkat

- Ball MillDokumen3 halamanBall MillpassionBelum ada peringkat

- Comminution Ore TestingDokumen35 halamanComminution Ore TestingHarrison Antonio Mira NiloBelum ada peringkat

- Crushers: Wills' Mineral Processing Technology. © 2016 Elsevier Ltd. All Rights ReservedDokumen24 halamanCrushers: Wills' Mineral Processing Technology. © 2016 Elsevier Ltd. All Rights ReservedDanny Joaquin Flores CruzBelum ada peringkat

- 1286 Sme Mining Engineering Handbook: Figure 12.8-14 Ore-Handling System at Olympic Dam MineDokumen1 halaman1286 Sme Mining Engineering Handbook: Figure 12.8-14 Ore-Handling System at Olympic Dam MineYeimsBelum ada peringkat

- Christian Pfeiffer Grinding Media Sorting MachineDokumen1 halamanChristian Pfeiffer Grinding Media Sorting MachineMohamedBelum ada peringkat

- Pan ConveyorsDokumen24 halamanPan ConveyorswereerBelum ada peringkat

- SA01 GENXXX SDIN BSDS 0001 B04 A - Instrumentation Design Basis Sazeh CommentedDokumen31 halamanSA01 GENXXX SDIN BSDS 0001 B04 A - Instrumentation Design Basis Sazeh Commentedamini_mohiBelum ada peringkat

- S3 Product Range - EnglishDokumen35 halamanS3 Product Range - EnglishJuan Esteban Luque ZegarraBelum ada peringkat

- A Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueDokumen3 halamanA Meaningful Expression Between Bond Work Index, Grindability Index and Friability ValueVerónica CharresBelum ada peringkat

- MAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenDokumen1 halamanMAMMUT Single-Shaft Hammer Crusher: HilfsvorrichtungenpeymanBelum ada peringkat

- Feeder Breaker 1200mtph Project01!08!08Dokumen3 halamanFeeder Breaker 1200mtph Project01!08!08Herman AbdullahBelum ada peringkat

- GA Molino de Bolas 26x40.5 - PolymetDokumen1 halamanGA Molino de Bolas 26x40.5 - PolymetElias PaxiBelum ada peringkat

- Sinter Plant Single Toothed Roll Crusher PDFDokumen14 halamanSinter Plant Single Toothed Roll Crusher PDFrmsh301Belum ada peringkat

- Lab Manual For Trommel CitDokumen2 halamanLab Manual For Trommel CitRyle ArbonBelum ada peringkat

- Ultrasonic Test of Kiln ShellDokumen5 halamanUltrasonic Test of Kiln ShellaansewuBelum ada peringkat

- Ball MillDokumen10 halamanBall MillLuthfanBelum ada peringkat

- Failure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFDokumen9 halamanFailure Analysis of Belt Conveyor Damage Caused by The Falling Material. Part 1 PDFCezar PajaresBelum ada peringkat

- 15 X 21 Batch Ball MillDokumen12 halaman15 X 21 Batch Ball MillAnil Kumar KnBelum ada peringkat

- Hydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediaDokumen5 halamanHydrochloric Acid Regeneration - Wikipedia, The Free EncyclopediazamburittiBelum ada peringkat

- Utkarsh Sankrityayan-Effect of Particle Size Distribution On Grinding Kinetics in Dry and Wet Ball Milling OperationsDokumen26 halamanUtkarsh Sankrityayan-Effect of Particle Size Distribution On Grinding Kinetics in Dry and Wet Ball Milling OperationsUtkarsh SankrityayanBelum ada peringkat

- SAIL BSBK Visit Docx-15.06. R-1rtfDokumen7 halamanSAIL BSBK Visit Docx-15.06. R-1rtfsssadangi100% (1)

- Quality Improvement in The Production Process of Grinding BallsDokumen5 halamanQuality Improvement in The Production Process of Grinding BallsYaser Mohamed AbasBelum ada peringkat

- Tandem Cold Rolling MillsDokumen15 halamanTandem Cold Rolling Millszvonkomihajlovic4891Belum ada peringkat

- Chain Drive: NO. of Teeths On Driving Sprocket No. of Teeths On Driven Sprocket Engine Power Service FactorDokumen3 halamanChain Drive: NO. of Teeths On Driving Sprocket No. of Teeths On Driven Sprocket Engine Power Service FactorSUMEET SINGHBelum ada peringkat

- Corpare Bond Work Index and Hard GroveDokumen15 halamanCorpare Bond Work Index and Hard GroveWaterdrop' 'DewBelum ada peringkat

- Comparision of CrusherDokumen6 halamanComparision of CrusherVeerasamy SureshbabuBelum ada peringkat

- Calculating Power Draw When Sizing Ball Mills: Arabinda Bandyopadhyay (Bandyo)Dokumen11 halamanCalculating Power Draw When Sizing Ball Mills: Arabinda Bandyopadhyay (Bandyo)RAVI1972Belum ada peringkat

- Data Sheet For Rotary Valve VRT-301 Rev.1Dokumen1 halamanData Sheet For Rotary Valve VRT-301 Rev.1Long Ellery Pham0% (1)

- PROK Product CatalogueDokumen32 halamanPROK Product CatalogueDiego AndradeBelum ada peringkat

- Spiral Classifier English VersioinDokumen5 halamanSpiral Classifier English VersioinRogelio Israel LedesmaBelum ada peringkat

- Papers - Some Design Aspects For Selection of Heavy Duty Apron FeedersDokumen5 halamanPapers - Some Design Aspects For Selection of Heavy Duty Apron FeedersarsanioseBelum ada peringkat

- Cemag High Efficiency Cross Flow-Classifier PDFDokumen20 halamanCemag High Efficiency Cross Flow-Classifier PDFTran Huynh NamBelum ada peringkat

- Shaft Reclaim FeederDokumen7 halamanShaft Reclaim FeederWaris La Joi WakatobiBelum ada peringkat

- Sidewall Splicing MechanicalDokumen11 halamanSidewall Splicing MechanicalTamer EmamBelum ada peringkat

- Rexnord® High Performance Bucket Elevators PDFDokumen12 halamanRexnord® High Performance Bucket Elevators PDFJavier Alejandro Rodriguez MelgozaBelum ada peringkat

- OKRA Standards For UKDokumen8 halamanOKRA Standards For UKabc111007100% (2)

- Facts About Concussion and Brain Injury: Where To Get HelpDokumen20 halamanFacts About Concussion and Brain Injury: Where To Get HelpJess GracaBelum ada peringkat

- ClistDokumen14 halamanClistGuerraBelum ada peringkat

- Radproduction Chapter 2-9Dokumen276 halamanRadproduction Chapter 2-9Christian DioBelum ada peringkat

- White Vaseline: Safety Data SheetDokumen9 halamanWhite Vaseline: Safety Data SheetHilmi FauziBelum ada peringkat

- Distress Manual PDFDokumen51 halamanDistress Manual PDFEIRINI ZIGKIRIADOUBelum ada peringkat

- Borelog CP.101Dokumen1 halamanBorelog CP.101radixkusumaBelum ada peringkat

- Wilo Water PumpDokumen16 halamanWilo Water PumpThit SarBelum ada peringkat

- Constantino V MendezDokumen3 halamanConstantino V MendezNīc CādīgālBelum ada peringkat

- User Manual: 3603807 CONTACT US - 09501447202,8070690001Dokumen1 halamanUser Manual: 3603807 CONTACT US - 09501447202,8070690001Arokiaraj RajBelum ada peringkat

- Unit-7 (EVS)Dokumen32 halamanUnit-7 (EVS)g6614134Belum ada peringkat

- New Book "101 Costly HR Mistakes... and How To Fix Them" by Vanessa Nelson Released To Help Employers Avoid Costly HR Mistakes and Save MillionsDokumen2 halamanNew Book "101 Costly HR Mistakes... and How To Fix Them" by Vanessa Nelson Released To Help Employers Avoid Costly HR Mistakes and Save MillionsPR.comBelum ada peringkat

- ContinueDokumen2 halamanContinueNeal ReppBelum ada peringkat

- BS 65-1981Dokumen27 halamanBS 65-1981jasonBelum ada peringkat

- Adult Module 1 - Five Healthy Habits Handout (English) PDFDokumen2 halamanAdult Module 1 - Five Healthy Habits Handout (English) PDFKennedy FadriquelanBelum ada peringkat

- Packed Bed Reactor Slides (B)Dokumen32 halamanPacked Bed Reactor Slides (B)Meireza Ajeng PratiwiBelum ada peringkat

- UgpeDokumen3 halamanUgpeOlety Subrahmanya SastryBelum ada peringkat

- Building and Environment: Nabeel Ahmed Khan, Bishwajit BhattacharjeeDokumen19 halamanBuilding and Environment: Nabeel Ahmed Khan, Bishwajit Bhattacharjeemercyella prasetyaBelum ada peringkat

- People of The Philippines V. Crispin Payopay GR No. 141140 2003/07/2001 FactsDokumen5 halamanPeople of The Philippines V. Crispin Payopay GR No. 141140 2003/07/2001 FactsAb CastilBelum ada peringkat

- G.R. No. 178741Dokumen1 halamanG.R. No. 178741Jefferson BagadiongBelum ada peringkat

- Dryer Regenerative Blower Purge DBP 02250195 405 R00 PDFDokumen84 halamanDryer Regenerative Blower Purge DBP 02250195 405 R00 PDFjennyBelum ada peringkat

- Marketing Study of Mango JuiceDokumen18 halamanMarketing Study of Mango JuiceVijay ArapathBelum ada peringkat

- MAOH600 Ropu 48 Presentation Script and ReferencesDokumen10 halamanMAOH600 Ropu 48 Presentation Script and ReferencesFano AsiataBelum ada peringkat

- Aromatic Electrophilic SubstitutionDokumen71 halamanAromatic Electrophilic SubstitutionsridharancBelum ada peringkat

- Test On QuantifiersDokumen1 halamanTest On Quantifiersvassoula35Belum ada peringkat

- Tri-Partite Agreement AssociationDokumen9 halamanTri-Partite Agreement AssociationThiyagarjanBelum ada peringkat

- Beckhoff Service Tool - USB StickDokumen7 halamanBeckhoff Service Tool - USB StickGustavo VélizBelum ada peringkat

- Bioplan Nieto Nahum)Dokumen6 halamanBioplan Nieto Nahum)Claudia Morales UlloaBelum ada peringkat