Cleanse & Detox Tech Spec

Diunggah oleh

fuentenaturaDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Cleanse & Detox Tech Spec

Diunggah oleh

fuentenaturaHak Cipta:

Format Tersedia

ABOCA S.p.A.

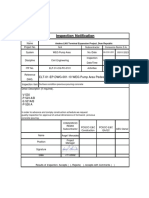

Technical specification

ASUSDETOXOPW-A rev. del 20/03/2006

TECHNICAL SPECIFICATION: INGREDIENT LIST

PRODUCT

CLEANSE & DETOX PHYTOSOLUTION - CAPSULES

PACKAGE PRESENTATION

Pharmaceutical grade glass bottle or pharmaceutical grade

blister. Outer box. Tamper proof packaged

CATEGORY

Food Supplement

SUGGESTED USE

Two capsules a day

INGREDIENTS PER CAPSULE :

INGREDIENTS

Dandelion root whole phytocomplex concentrate

Milk thistle seed freeze dried extract

Aloe vera leaf gel freeze dried

Proprietary blend

76

36

28

244

mg

mg

mg

mg

Ortosiphon leaf whole phytocomplex concentrate,

Rooibos leaf whole phytocomplex concentrate,

Other ingredients

Natural gelatin capsule

DESCRIPTION OF THE INGREDIENTS :

Orthosiphon whole phytocomplex concentrate Freeze-dried Orthosiphon stamineus Benth

(leaf)

extract (D.E.R. 10:1) and powdered leaf, 0.05%

sinensetin

Rooibos whole phytocomplex concentrate

Freeze-dried Aspalathus linearis L. extract

(leaf)

(D.E.R. 7:1) and powdered leaf, 3 % total

flavonoids as hyperoside

Dandelion whole phytocomplex concentrate Freeze-dried Taraxacum officinale Weber extract

(root)

(D.E.R. 5:1) and powdered root, 0.3 % caffeic

acids derivatives

Milk thistle freeze dried extract (seed)

Freeze-dried Silybum marianum L. seed extract

(D.E.R. 10:1), 30% silymarin

Aloe vera gel (leaf)

Freeze dried Aloe vera L. leaf gel (concentrated

200:1)

Gelatin capsules

Consists only of pharmaceutical-grade animal

gelatin used in conformity with the requirements

published in:

European Pharmacopoeia (EP) 4th edition

Monograph

of

the

European

Pharmacopoeia regarding Transmitting

agents

of

animal

spongiform

encephalopathies

Page 1/8

ABOCA S.p.A. Technical specification

ASUSDETOXOPW-A rev. del 20/03/2006

TECHNICAL SPECIFICATION: INGREDIENT LIST

Average values

Calories

Protein(Nx6.25)

Carbohydrates

Fats

100 g of product

254 kcal / 1079 kJ

26.7 g

32.6 g

1.9 g

1 capsule 480 mg

1.22 kcal / 5.18 kJ

0.13 g

0.16 g

0.01 g

STORAGE:

Store in a cool, dry place

SHELF LIFE:

48 months

COLOR:

Green powder

SHAPE:

Capsule size 0 ( h 21.7 mm 7.64 mm)

Page 2/8

ABOCA S.p.A. Technical specification

ASUSDETOXOPW-A rev. del 20/03/2006

TECHNICAL SPECIFICATION: REQUIREMENTS

RAW MATERIAL

Pesticides:

The pesticides must not exceed the limits provided for by European Directives no. 97/41/CE,

1999/65/CE, 1999/71/CE and their successive update.

Heavy Metals

Pb < 3 ppm

Cd < 0.5 ppm

Microbiological analyses:

Aerobic mesophilic germ count

Yeasts and moulds

Escherichia coli

Salmonella

< 10.000.000 cfu/g

<

10.000 cfu/g

<

100 cfu/g

absent in 25 g

Specific analysis:

INGREDIENTS

SPECIFIC

CONSTITUENT/MARKER

SUBSTANCE

Orthosiphon leaf whole phytocomplex concentrate

Rooibos leaf whole phytocomplex concentrate

Dandelion root whole phytocomplex concentrate

Milk thistle seed freeze dried extract

sinensetin: 0.05%

total flavonoids as hyperoside 3%

caffeic acids derivatives: 0.24%

silymarin 30 %

FINISHED PRODUCT

Microbiological analyses:

Aerobic mesophilic germ count

Yeasts and molds

Escherichia Coli

Salmonella

Page 3/8

< 100.000 cfu/g

< 1.000 cfu/g

absent in 1 g

absent in 25 g

ABOCA S.p.A. Technical specification

ASUSDETOXOPW-A rev. del 20/03/2006

TECHNICAL SPECIFICATION: ANALYSIS PERFORMED (*)

RAW MATERIALS:

Heavy metals

Pesticides

Microbiological analyses

Specific analysis

INGREDIENTS

Orthosiphon leaf whole phytocomplex

concentrate

Rooibos leaf whole phytocomplex

concentrate

Dandelion root whole phytocomplex

concentrate

Milk thistle seed freeze dried extract

SPECIFIC

CONSTITUENT/MARKER

SUBSTANCE

sinensetin: 0.05%

ASSAYS METHOD

European Pharmacopoeia 5th ed. 2005

total flavonoids as hyperoside 3% Internal Method (Spectrophotometric)

caffeic acids derivatives: 0.24%

Internal Method (HPLC)

silymarin 30 %

Internal Method (HPLC)

FINISHED PRODUCT

Microbiological analyses

(*) All the analysis are performed according to HACCP (Hazard Analysis and Critical Control Point)

integrated by internal protocols. The analysis are performed by ABOCA laboratories that have adequate

testing capabilities and equipment. However, for some analysis, outside certified laboratories can be

used. Written records of analysis results are kept.

Page 4/8

ABOCA S.p.A. Technical specification

ASUSDETOXOPW-A rev. del 20/03/2006

TECHNICAL SPECIFICATION: MANUFACTURING PROCESS

ROOIBOS, ORTHOSIPHON ,

DANDELION, MILK THISTLE.

ORTHOSIPHON, ROOIBOS,

DANDELION.

SELECTION/CUT

(A)

SELECTION/CUT

(A)

GRINDING

EXTRACTION

FREEZE-DRYING

(B)

MIXING

CAPSULE FILLING

(C)

FINISCHED PRODUCT

(D)

CONTROLS:

Page 5/8

(A):

Specific analysis

Pesticides

Heavy metals

Microbiological analyses

PACKING

(C)

ALOE VERA GEL

FREEZE DRIED

GELATINE CAPSULES

ABOCA S.p.A. Technical specification

(B):

(C):

(D):

Page 6/8

Specific analysis

In-process control

Microbiological analyses

ASUSDETOXOPW-A rev. del 20/03/2006

ABOCA S.p.A. Technical specification

ASUSDETOXOPW-A rev. del 20/03/2006

TECHNICAL SPECIFICATION: MANUFACTURING PROCESS (continued)

1. Freeze-dried extracts production

The dried herbs are selected and cut for the extraction process.

Following Quality Control approval, the dried herbs are extracted either by a mixture of water and

alcohol, having a specific alcoholic strength, or by water.

The extract then undergoes vacuum distillation until an ethanol-free concentrate, with a dry residue of

about 30% w/w, is obtained.

The concentrate is then freeze-dried and undergoes lab analysis.

2. Powder production

The dried herbs are selected and cut for the grinding process.

Following Quality Control approval, the dried herbs are ground by a mill until the established

granulometry is obtained.

3. Capsule production

The freeze-dried extracts and fine powders are weighed and mixed in a stainless-steel mixer.

Next, the capsules are filled with the mixture by volumetric dosage.

Finally, the capsules are packed.

4.

Production process control

The semi-finished product manufacturing and packing methods are described in the technical

specifications available through the production department. These specifications also contain the "inprocess" controls and the recommended testing schedule. The operators are required to perform these

routine tests and record the results on proper forms for filling.

Controls include: weight uniformity of capsules, correct filling and closure of capsules, capsule-count

control per blister/bottle, sealing, labeling, coding and net weight control.

Page 7/8

ABOCA S.p.A. Technical specification

ASUSDETOXOPW-A rev. del 20/03/2006

TECHNICAL SPECIFICATION: Abocas Quality Control Policy

This product is manufactured in compliance to the following Abocas Quality Control Policy:

1. Buildings and Facility

Adequate space has been allotted for all phases of the process including receiving, manufacturing, storage,

laboratory, etc.

Appropriate cleaning schedules and procedures are established.

Facility layout diagram available upon request.

2.

Equipment

Appropriate equipment is used in all phases of the process.

Cleaning and maintenance schedules and procedures are established.

Cleaners, sanitizers, lubricants, etcused on utensils and equipment are suitable for use in processing areas

and MSDS information is available.

3.

Component Controls

Procedures are set up to ensure the proper care and handling of received materials.

Lot traceability is monitored by record-keeping practices.

Raw material approval protocol is established.

4.

Process Controls

Written procedures exist and records are kept for all steps of the process.

Steps are taken to prevent cross-contamination with other products.

Written procedures exist for the maintenance of product specifications/master formulations.

Procedures exist for the control of non-conforming product, including identification, segregation, disposition

authority, and control of re-work activities.

A calibration process with appropriate documentation has been established for all measurement/test equipment.

5.

Personnel

Organizational chart available upon request

Responsibilities and authorities for each position are clearly defined.

Employees receive adequate training to ensure compliance with federal regulations, customer requirements,

and quality policies and procedures.

6. Laboratory Capabilities

Facility has adequate testing capabilities.

List testing capabilities and equipment used available upon request.

7. Quality Program

Standard Operating Procedures (SOPs) are established for all stages of the manufacturing process.

Quality-related third-party certifications achieved by the company: UNI EN ISO 14001 European

Environmental Management System - Organic Certification according to EU Directive 2092/91 from CCPB

Bologna

Companies facilities are subjected to regulatory inspections carried by Italian Ministry of Health that verifies

compliance with Italian GMP for Food Supplements.

Page 8/8

Anda mungkin juga menyukai

- Techniques for Downstream process for Biologic Drugs and VaccinesDari EverandTechniques for Downstream process for Biologic Drugs and VaccinesBelum ada peringkat

- Vit C HPLC-UV PDFDokumen10 halamanVit C HPLC-UV PDFKiki Dian TBelum ada peringkat

- Banana JuiceDokumen33 halamanBanana JuiceDeepak Ola50% (2)

- Processing Contaminants in Edible Oils: MCPD and Glycidyl EstersDari EverandProcessing Contaminants in Edible Oils: MCPD and Glycidyl EstersBelum ada peringkat

- MFR SaumyaDokumen6 halamanMFR SaumyasamBelum ada peringkat

- ExtractsDokumen3 halamanExtractsLaurentiu DinuBelum ada peringkat

- ValidationDokumen35 halamanValidationGianinna Zegarra QuevedoBelum ada peringkat

- MLG - Appendix - 1.10 MediosDokumen42 halamanMLG - Appendix - 1.10 MedioscynthiaBelum ada peringkat

- An 335 Natural ProductsDokumen3 halamanAn 335 Natural ProductsTonnyLeiteBelum ada peringkat

- Methodology and Proximate AnalysisDokumen46 halamanMethodology and Proximate Analysisvijaynarote67% (3)

- Bioseparaciones Mistura GrandeDokumen182 halamanBioseparaciones Mistura GrandeTeresaCastelo-grandeBelum ada peringkat

- Ultra Pure Water Treatment For Pharmaceutical IndustryDokumen4 halamanUltra Pure Water Treatment For Pharmaceutical Industryraju1559405100% (1)

- US Environmental Protection Agency Office of Pesticide ProgramsDokumen17 halamanUS Environmental Protection Agency Office of Pesticide ProgramsAngeles SuarezBelum ada peringkat

- Department of Pharmacy: The Extraction MR - Ahmed AlmohhmmedDokumen10 halamanDepartment of Pharmacy: The Extraction MR - Ahmed AlmohhmmedcrtgyhujikBelum ada peringkat

- Audit 022 Auditing An Oral Solid Solution Area SampleDokumen4 halamanAudit 022 Auditing An Oral Solid Solution Area SamplemarwaBelum ada peringkat

- Renata Industrial TrainingDokumen10 halamanRenata Industrial TrainingShonar KellaBelum ada peringkat

- SMS LabDokumen64 halamanSMS LabDivya DiyaBelum ada peringkat

- UCM397228 Pharmaceutical Microbiology ManualDokumen91 halamanUCM397228 Pharmaceutical Microbiology Manualnsk79in@gmail.com100% (1)

- 5 - Cleaning and Disinfection of Dialysis Water Equipment - Final - 2012Dokumen7 halaman5 - Cleaning and Disinfection of Dialysis Water Equipment - Final - 2012Denisse Ro100% (1)

- Laboratory Cleaning and MaintenanceDokumen8 halamanLaboratory Cleaning and MaintenanceJenner ButlongBelum ada peringkat

- PILONT PLANT Design Liquid Semisolid InjDokumen101 halamanPILONT PLANT Design Liquid Semisolid InjRamesh RajBelum ada peringkat

- Enzymas Extracción 2015Dokumen10 halamanEnzymas Extracción 2015John JohnBelum ada peringkat

- A Report Overview On Drug ProductionDokumen37 halamanA Report Overview On Drug ProductionOyemomi Samuel Adeyemi100% (5)

- Microbial Monitoring - Bioburden - Pda Journal May June 2015Dokumen15 halamanMicrobial Monitoring - Bioburden - Pda Journal May June 2015Kinomi100% (2)

- en-1605900506-AFDC 12 (6597) P3 fRUIT JUICE AND NECTARS - SPECIFICATION-1Dokumen21 halamanen-1605900506-AFDC 12 (6597) P3 fRUIT JUICE AND NECTARS - SPECIFICATION-1Christian Tsachoua MandzessiBelum ada peringkat

- Pharma Science Monitor 6 (2), Apr-Jun 2015 Pharma Science MonitorDokumen12 halamanPharma Science Monitor 6 (2), Apr-Jun 2015 Pharma Science MonitorAhmad BukhariBelum ada peringkat

- Phyto Pharmacy: Current Concepts and GMP NormsDokumen22 halamanPhyto Pharmacy: Current Concepts and GMP NormsSunitha Katta100% (1)

- Listeria Selective AgarDokumen7 halamanListeria Selective AgarAni IoanaBelum ada peringkat

- Ase 350Dokumen5 halamanAse 350TonnyLeiteBelum ada peringkat

- Stability Testing of Herbal Medicinal ProductsDokumen20 halamanStability Testing of Herbal Medicinal ProductsMagesh S100% (1)

- Stability Testing of New Drug Substances and ProductsDokumen22 halamanStability Testing of New Drug Substances and ProductsAgnimitra DindaBelum ada peringkat

- Validation Protocol For Disinfectant Efficacy ValidationDokumen12 halamanValidation Protocol For Disinfectant Efficacy ValidationMubarak PatelBelum ada peringkat

- Alicyclobacillus Best Practice GuidelineDokumen29 halamanAlicyclobacillus Best Practice GuidelineAlvaro Montaño Mayorquín100% (1)

- Challenges in Analytical Method Development ForDokumen3 halamanChallenges in Analytical Method Development ForTanuja PathareBelum ada peringkat

- Final Exame NumanDokumen16 halamanFinal Exame NumanMayson BaliBelum ada peringkat

- Lyphochek Assayed Chemistry Control Levels 1 and 2Dokumen4 halamanLyphochek Assayed Chemistry Control Levels 1 and 2Gaurav MauryaBelum ada peringkat

- #C-310-5 Lot.89740 EinsertDokumen3 halaman#C-310-5 Lot.89740 Einsertjnyng222100% (2)

- CPOB Liquid Dan Semi SolidDokumen109 halamanCPOB Liquid Dan Semi SolidNadia Ananda Puteri100% (5)

- Fundamentals of An Environmental Monitoring ProgramDokumen71 halamanFundamentals of An Environmental Monitoring Programtito1628Belum ada peringkat

- Sops IndexDokumen3 halamanSops IndexIbrahim IssaBelum ada peringkat

- New Family Names: Old Family Name New Family Name Common Family NameDokumen39 halamanNew Family Names: Old Family Name New Family Name Common Family NameClarenceBelum ada peringkat

- Lyphochek Assayed Chemistry Control Levels 1 and 2Dokumen16 halamanLyphochek Assayed Chemistry Control Levels 1 and 2PATH LABBelum ada peringkat

- HACCP AnalysisDokumen75 halamanHACCP AnalysisSankar Chinnathambi100% (3)

- Microbiological Testing of BeveragesDokumen20 halamanMicrobiological Testing of BeveragesSahil Sethi100% (1)

- Determination of L-Ascorbic Acid in Fruit Juice Samples: Biochrom LTD Certificate No: 890333Dokumen4 halamanDetermination of L-Ascorbic Acid in Fruit Juice Samples: Biochrom LTD Certificate No: 890333Natalia Valentina Toledo AguilarBelum ada peringkat

- H-046-000774-00 CK-MB CalibratorDokumen19 halamanH-046-000774-00 CK-MB CalibratorJorge Stban PerezBelum ada peringkat

- Ayurvedic Pharmacy: Current Concepts and GMP NormsDokumen22 halamanAyurvedic Pharmacy: Current Concepts and GMP NormsbrahmapulseBelum ada peringkat

- Contaminating Microorganisms in Products With ProbioticsDokumen8 halamanContaminating Microorganisms in Products With ProbioticsJose Alfredo DiazBelum ada peringkat

- Pharmacuetical Microbiology Manual 2014 PDFDokumen86 halamanPharmacuetical Microbiology Manual 2014 PDFteaBelum ada peringkat

- Diacough Cough SyrupDokumen19 halamanDiacough Cough SyrupMulayam Singh YadavBelum ada peringkat

- AIJN Alicyclobacillus Best Practice Guideline July 2008Dokumen29 halamanAIJN Alicyclobacillus Best Practice Guideline July 2008Almin CoricBelum ada peringkat

- USP 42 Chapter 1231Dokumen26 halamanUSP 42 Chapter 1231Chetalee NaikBelum ada peringkat

- Rice HullDokumen12 halamanRice HullClaire NakilaBelum ada peringkat

- M1990IDokumen2 halamanM1990IDr. Shantanu KodapeBelum ada peringkat

- Standardization of 70% Ethanol Extract Chayote Fruit (Sechium Edule (Jacq.) SW.)Dokumen8 halamanStandardization of 70% Ethanol Extract Chayote Fruit (Sechium Edule (Jacq.) SW.)Nur PutriBelum ada peringkat

- 4.7extraction of Proteins From Plant TissuesDokumen7 halaman4.7extraction of Proteins From Plant TissuesferrariF1loveBelum ada peringkat

- Industry ReportDokumen26 halamanIndustry ReportRudra PangeniBelum ada peringkat

- Downstream Processing: Reported By: Angela Marie M. DiwaDokumen20 halamanDownstream Processing: Reported By: Angela Marie M. DiwaAngela Miranda DiwaBelum ada peringkat

- Fraksinasi IsolasiDokumen40 halamanFraksinasi Isolasisalsabila JacobBelum ada peringkat

- Healthcare Management DictionaryDokumen232 halamanHealthcare Management DictionaryfuentenaturaBelum ada peringkat

- 17-0079 FL CO Synafil v1 RZicDokumen2 halaman17-0079 FL CO Synafil v1 RZicfuentenaturaBelum ada peringkat

- Martignani K800 Electrostatic Backpack Sprayer - CatalogueDokumen1 halamanMartignani K800 Electrostatic Backpack Sprayer - CataloguefuentenaturaBelum ada peringkat

- Creating A Paradigm Shift in Renal CareDokumen6 halamanCreating A Paradigm Shift in Renal CarefuentenaturaBelum ada peringkat

- AC139 Electrostatic SprayerDokumen40 halamanAC139 Electrostatic SprayerfuentenaturaBelum ada peringkat

- External HDD FixDokumen1 halamanExternal HDD FixfuentenaturaBelum ada peringkat

- RecipesDokumen38 halamanRecipesfuentenaturaBelum ada peringkat

- Bottled Water Market in MexicoDokumen18 halamanBottled Water Market in MexicofuentenaturaBelum ada peringkat

- Antiinflammatory Activities of Lactoferrin389s.fullDokumen7 halamanAntiinflammatory Activities of Lactoferrin389s.fullfuentenaturaBelum ada peringkat

- RecipesDokumen38 halamanRecipesfuentenaturaBelum ada peringkat

- Cdc-Guideline For Disinfection and Sterilization in Health-Care Facilities-2008Dokumen158 halamanCdc-Guideline For Disinfection and Sterilization in Health-Care Facilities-2008fuentenatura100% (1)

- Bulk Image Downloader v3.0 User's GuideDokumen42 halamanBulk Image Downloader v3.0 User's GuidefuentenaturaBelum ada peringkat

- Contemporary World Reflection PaperDokumen8 halamanContemporary World Reflection PaperNyna Claire GangeBelum ada peringkat

- Blood Angels Ref SheetsDokumen4 halamanBlood Angels Ref SheetsAndrew ThomasBelum ada peringkat

- Philippine Literature During Spanish ColonizationDokumen4 halamanPhilippine Literature During Spanish ColonizationCharisel Jeanne CasalaBelum ada peringkat

- Basic Accounting Equation Exercises 2Dokumen2 halamanBasic Accounting Equation Exercises 2Ace Joseph TabaderoBelum ada peringkat

- Starmada House RulesDokumen2 halamanStarmada House Ruleshvwilson62Belum ada peringkat

- Financial Amendment Form: 1 General InformationDokumen3 halamanFinancial Amendment Form: 1 General InformationRandolph QuilingBelum ada peringkat

- In-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsDokumen5 halamanIn-CIV-201 INSPECTION NOTIFICATION Pre-Pouring Concrete WEG Pump Area PedestalsPedro PaulinoBelum ada peringkat

- Civil Law 2 Module 1 Case #008 - Andamo vs. IAC, 191 SCRA 195Dokumen6 halamanCivil Law 2 Module 1 Case #008 - Andamo vs. IAC, 191 SCRA 195Ronald MedinaBelum ada peringkat

- Project Driven & Non Project Driven OrganizationsDokumen19 halamanProject Driven & Non Project Driven OrganizationsEkhlas Ghani100% (2)

- MC Script For StorytellingDokumen1 halamanMC Script For StorytellingPPD LUBOK ANTU-CM15 KPMBelum ada peringkat

- The Key To The Magic of The Psalms by Pater Amadeus 2.0Dokumen16 halamanThe Key To The Magic of The Psalms by Pater Amadeus 2.0evitaveigasBelum ada peringkat

- Tally Trading and Profit Loss Acc Balance SheetDokumen14 halamanTally Trading and Profit Loss Acc Balance Sheetsuresh kumar10Belum ada peringkat

- Chapter 1 Introduction To Quranic Studies PDFDokumen19 halamanChapter 1 Introduction To Quranic Studies PDFtaha zafar100% (3)

- Lecture 3 Islamic StudiesDokumen10 halamanLecture 3 Islamic StudiesDr-Hassan JunaidBelum ada peringkat

- SMART Train ScheduleDokumen1 halamanSMART Train ScheduleDave AllenBelum ada peringkat

- C1 Level ExamDokumen2 halamanC1 Level ExamEZ English WorkshopBelum ada peringkat

- Adobe Scan 03-May-2021Dokumen22 halamanAdobe Scan 03-May-2021Mohit RanaBelum ada peringkat

- HDFC Bank Summer Internship Project: Presented By:-Kandarp SinghDokumen12 halamanHDFC Bank Summer Internship Project: Presented By:-Kandarp Singhkandarp_singh_1Belum ada peringkat

- An Introduction: by Rajiv SrivastavaDokumen17 halamanAn Introduction: by Rajiv SrivastavaM M PanditBelum ada peringkat

- Jurisdiction and Kinds of JurisdictionDokumen3 halamanJurisdiction and Kinds of JurisdictionANUKULBelum ada peringkat

- PMP PDFDokumen334 halamanPMP PDFJohan Ito100% (4)

- Beowulf Essay 1Dokumen6 halamanBeowulf Essay 1api-496952332Belum ada peringkat

- Literacy Technology of The IntellectDokumen20 halamanLiteracy Technology of The IntellectFrances Tay100% (1)

- Before The Judge - Roger EDokumen26 halamanBefore The Judge - Roger ELexLuther1776100% (4)

- Correctional Case StudyDokumen36 halamanCorrectional Case StudyRaachel Anne CastroBelum ada peringkat

- Is Modern Capitalism Sustainable? RogoffDokumen107 halamanIs Modern Capitalism Sustainable? RogoffAriane Vaz Dinis100% (1)

- Surahduha MiracleDreamTafseer NoumanAliKhanDokumen20 halamanSurahduha MiracleDreamTafseer NoumanAliKhanspeed2kxBelum ada peringkat

- Glories of Srimad Bhagavatam - Bhaktivedanta VidyapithaDokumen7 halamanGlories of Srimad Bhagavatam - Bhaktivedanta VidyapithaPrajot NairBelum ada peringkat

- Daniel Salazar - PERSUASIVE ESSAYDokumen2 halamanDaniel Salazar - PERSUASIVE ESSAYDaniel SalazarBelum ada peringkat

- Calendario General 2Dokumen1 halamanCalendario General 2Santiago MuñozBelum ada peringkat

- Mini Farming: Self-Sufficiency on 1/4 AcreDari EverandMini Farming: Self-Sufficiency on 1/4 AcrePenilaian: 4 dari 5 bintang4/5 (76)

- The Hidden Life of Trees: What They Feel, How They CommunicateDari EverandThe Hidden Life of Trees: What They Feel, How They CommunicatePenilaian: 4 dari 5 bintang4/5 (1003)

- Midwest-The Lost Book of Herbal Remedies, Unlock the Secrets of Natural Medicine at HomeDari EverandMidwest-The Lost Book of Herbal Remedies, Unlock the Secrets of Natural Medicine at HomeBelum ada peringkat

- The Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldDari EverandThe Encyclopedia of Spices & Herbs: An Essential Guide to the Flavors of the WorldPenilaian: 3.5 dari 5 bintang3.5/5 (5)

- Root to Leaf: A Southern Chef Cooks Through the SeasonsDari EverandRoot to Leaf: A Southern Chef Cooks Through the SeasonsPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- The One-Straw Revolution: An Introduction to Natural FarmingDari EverandThe One-Straw Revolution: An Introduction to Natural FarmingPenilaian: 4.5 dari 5 bintang4.5/5 (272)

- The Orchid Thief: A True Story of Beauty and ObsessionDari EverandThe Orchid Thief: A True Story of Beauty and ObsessionPenilaian: 3.5 dari 5 bintang3.5/5 (686)

- Teaming With Nutrients: The Organic Gardener's Guide to Optimizing Plant NutritionDari EverandTeaming With Nutrients: The Organic Gardener's Guide to Optimizing Plant NutritionPenilaian: 4.5 dari 5 bintang4.5/5 (15)

- Gardening Hacks: 300+ Time and Money Saving HacksDari EverandGardening Hacks: 300+ Time and Money Saving HacksPenilaian: 5 dari 5 bintang5/5 (1)

- Square Foot Gardening: How To Grow Healthy Organic Vegetables The Easy WayDari EverandSquare Foot Gardening: How To Grow Healthy Organic Vegetables The Easy WayPenilaian: 5 dari 5 bintang5/5 (3)

- Permaculture for the Rest of Us: Abundant Living on Less than an AcreDari EverandPermaculture for the Rest of Us: Abundant Living on Less than an AcrePenilaian: 4.5 dari 5 bintang4.5/5 (33)

- Gardening Hacks: 300+ Time and Money Saving HacksDari EverandGardening Hacks: 300+ Time and Money Saving HacksPenilaian: 5 dari 5 bintang5/5 (1)

- Soil: The Story of a Black Mother's GardenDari EverandSoil: The Story of a Black Mother's GardenPenilaian: 4.5 dari 5 bintang4.5/5 (16)

- Psilocybin Mushrooms: A step-by-step guide to growing your own magic fungi at homeDari EverandPsilocybin Mushrooms: A step-by-step guide to growing your own magic fungi at homeBelum ada peringkat

- Carpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresDari EverandCarpentry Made Easy - The Science and Art of Framing - With Specific Instructions for Building Balloon Frames, Barn Frames, Mill Frames, Warehouses, Church SpiresPenilaian: 1 dari 5 bintang1/5 (2)

- Protecting Pollinators: How to Save the Creatures that Feed Our WorldDari EverandProtecting Pollinators: How to Save the Creatures that Feed Our WorldPenilaian: 4 dari 5 bintang4/5 (8)

- The Green Witch's Garden: Your Complete Guide to Creating and Cultivating a Magical Garden SpaceDari EverandThe Green Witch's Garden: Your Complete Guide to Creating and Cultivating a Magical Garden SpacePenilaian: 5 dari 5 bintang5/5 (18)

- Square Foot Gardening: A Beginner's Guide to Square Foot Gardening at HomeDari EverandSquare Foot Gardening: A Beginner's Guide to Square Foot Gardening at HomePenilaian: 1.5 dari 5 bintang1.5/5 (2)

- Wild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesDari EverandWild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesPenilaian: 5 dari 5 bintang5/5 (34)

- Gardening Basics For Dummies: 2nd EditionDari EverandGardening Basics For Dummies: 2nd EditionPenilaian: 5 dari 5 bintang5/5 (1)

- The Lean Micro Farm: How to Get Small, Embrace Local, Live Better, and Work LessDari EverandThe Lean Micro Farm: How to Get Small, Embrace Local, Live Better, and Work LessPenilaian: 5 dari 5 bintang5/5 (3)

- Mini Farming: Self-Sufficiency on 1/4 AcreDari EverandMini Farming: Self-Sufficiency on 1/4 AcrePenilaian: 4.5 dari 5 bintang4.5/5 (6)

- Wild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesDari EverandWild Witchcraft: Folk Herbalism, Garden Magic, and Foraging for Spells, Rituals, and RemediesPenilaian: 5 dari 5 bintang5/5 (3)

- The Family Garden Plan: Grow a Year's Worth of Sustainable and Healthy FoodDari EverandThe Family Garden Plan: Grow a Year's Worth of Sustainable and Healthy FoodPenilaian: 4.5 dari 5 bintang4.5/5 (14)

- A Girl and Her Greens: Hearty Meals from the GardenDari EverandA Girl and Her Greens: Hearty Meals from the GardenPenilaian: 3.5 dari 5 bintang3.5/5 (7)

- African Holistic Health for Women Ancient Tribal Remedies, African American Herbalism, Black Medicine and Other Ancestral Cures to Revive your Divine Feminine Energy by Healing the BodyDari EverandAfrican Holistic Health for Women Ancient Tribal Remedies, African American Herbalism, Black Medicine and Other Ancestral Cures to Revive your Divine Feminine Energy by Healing the BodyPenilaian: 5 dari 5 bintang5/5 (1)

- The Intelligent Gardner: Growing Nutrient-Dense FoodDari EverandThe Intelligent Gardner: Growing Nutrient-Dense FoodPenilaian: 4.5 dari 5 bintang4.5/5 (8)

- The Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsDari EverandThe Regenerative Grower's Guide to Garden Amendments: Using Locally Sourced Materials to Make Mineral and Biological Extracts and FermentsPenilaian: 5 dari 5 bintang5/5 (3)