Body MK5 Jetta Golf

Diunggah oleh

vixentdDeskripsi Asli:

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Body MK5 Jetta Golf

Diunggah oleh

vixentdHak Cipta:

Format Tersedia

Volkswagen Golf V: Lock carrier

Page 1 / 6

50 - 1

Lock carrier

Tools

Required special tools, workshop equipment, testing and

measuring equipment, and aids

Guide rod T 10093

Torque wrench 550 Nm V.A.G 1331

Torque wrench 40200 Nm V.A.G 1332

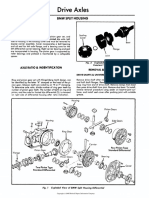

Lock carrier service position, assembly overview

Lock carrier

Page 2 / 6

Lock carrier with attachments

Removing and installing

50-1, Lock carrier with

attachments, removing and

installing

Service position

Service position

Screw

Qty 4

8 Nm

Screw

Qty. 8

60 Nm

50-1,

Lock carrier

Service position

Performing service position

- Remove front bumper 63-1, Front

bumper cover, removing and installing

- Disengage hood release cable in

coupling 55-1, Hood release cable,

disconnecting

- In vehicles with charge air cooler,

disconnect pressure hoses 50-1,

Releasing pressure hoses .

- Remove signal horn - 4 - with bracket

from longmember at right side

Page 3 / 6

Lock carrier

Repair Manual, Electrical Equipment,

Repair Group 96, Lights, lamps, interior

switch, signal horn, removing and

installing

- Unscrew bolts - 3 - at left and right

longmembers.

- Screw in guide rod T 10093 at left and

right longmembers.

- Remove bolts - 2 - at left and right on

top of lock carrier - 1 - .

- Lock carrier - 1 - can be pulled toward

front approx. 10 cm on guide rod T

10093 .

Resetting service position

Installation is performed in the reverse order of removal.

- Center lock carrier on side rails and between fenders

Repair Manual, Body Collision Repair, Repair Group 00,

Technical data; Body gap dimensions

Note:

Make sure that pressure hoses for charge air cooler

are re-engaged correctly.

Hoses and lines must not be pinched.

Releasing pressure hoses

- Disengage connector coupling - 1 - and disconnect

Page 4 / 6

Lock carrier

pressure hose - 2 - in - direction of arrow - from

coupling.

- When re-connecting pressure hoses, make sure that

connector couplings engage audibly.

Lock carrier with attachments, removing and installing

Removing

- Perform service position of lock carrier

with attachments - 1 50-1,

Performing service position .

- Disconnect the electrical harness

connectors present.

- Drain coolant and disconnect coolant

lines

Page 5 / 6

Lock carrier

Repair Manual, 2.0 Liter 4-Cyl. 4V

Turbo Engine Mechanical, Fuel Injection

Ignition, Engine Code(s): BPY, Repair

Group 19, Cooling system parts; draining

and filling coolant

- Disconnect condenser lines

Repair Manual, Heating Air

Conditioning, Repair Group 87, A/C

system; removing and installing

condenser

- With a second technician, unscrew

guide rod T 10093 on longmember on

left and right sides and lift out lock

carrier.

Warning!

If lines for A/C system and/or for coolant are

disconnected, the powertrain aggregate must no

longer be started.

Note:

Do not hang condenser and hydraulic oil cooler on

hoses.

Lines for condenser and hydraulics must not be

kinked.

Installing

Installation is performed in the reverse order of removal.

Make sure that all plug and hose connections are

corrected installed when re-assembling.

- Center lock carrier on side rails and between fenders

Repair Manual, Body Collision Repair, Repair Group 00,

Technical data; Body gap dimensions

Page 6 / 6

Volkswagen Golf V: Fender

Page 1 / 6

50 - 2

Fender

Tools

Special tools, testers and auxiliary items required

Torque wrench 210 Nm V.A.G 1783

Heat gun V.A.G 1416

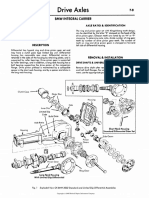

Front fender, assembly overview

Note :

The illustration shows the left side. The right side is

similar and can be determined from this.

Fender

Page 2 / 6

Fender

removing and installing

50-2, Fender, removing and

installing

Screw

Qty. 1, A-pillar

Qty. 2, side member

Qty. 2, wheel housing

Qty. 2, fender brace

Qty. 3, fender connecting

piece

6 Nm

Fender

Page 3 / 6

Foam piece

Fender brace

Loosely inserted between

fender and upper

longmember

Removing and installing

50-2, Fender brace,

removing and installing

Molded foam part

Placed on upper

longmember.

Secures at fender.

Hex nut

Qty. 1, at fender connecting

piece

6 Nm

Fender, removing and installing

Note:

Removing and installing is described only for the left

fender. Removing and installing right fender is

derived accordingly from this.

Removing

Fender

Page 4 / 6

- Remove front bumper 63-1, Front

bumper cover, removing and installing

- Remove wheelhousing liners 66-1,

Front wheel housing liner, removing and

installing

- Unscrew guide profile

Item - 10 -

- Loosen hex nut - 6 - and remove bolts

- 2- .

- Pull out foam piece - 3 - between

fender and longmember.

- Lightly heat fender - 1 - from outside in

area of molded foam element - arrow with hot air gun V.A.G 1416 .

- The adhesive on molded foam element

- 5 - loosens and fender - 1 - can be

removed.

Fender

Installing

Installation is performed in the reverse order of removal.

- Make sure gaps are parallel and pay attention to gap

dimensions

Repair Manual, Body Collision Repair, Repair Group 00,

Technical data; Body gap dimensions

Fender brace, removing and installing

Note:

Removing and installing is described only for the left

fender brace. Removing and installing right fender

brace is derived accordingly from this.

Removing

Fender is removed.

- Remove screws - 2 - and remove fender brace - 1 - .

Installing

Page 5 / 6

Fender

- Assemble the fender brace - 1 - .

- Tightening torques: Bolts - 2 - 6 Nm.

- Fender brace is installed together with fender to hood

and bumper:

Repair Manual, Body Collision Repair, Repair Group 00,

Technical data; Body gap dimensions

Page 6 / 6

Volkswagen Golf V: Noise insulation

Page 1 / 3

50 - 3

Noise insulation

Tools

Special tools, testers and auxiliary items required

Torque wrench 210 Nm V.A.G 1783

Noise insulation panel, assembly overview

Note :

Slight changes may have to be made to removal and

installation procedures, depending upon engine

installed in vehicle.

Noise insulation

Noise insulation

- Arrow - points in direction

of travel.

Removing:

- Remove bolts - 2 - and 3 - .

Screw

Qty. 8

2 Nm

Screw

Qty. 3

Page 2 / 3

Noise insulation

6 Nm

Page 3 / 3

Volkswagen Golf V: Underbody trim

Page 1 / 3

50 - 4

Underbody trim

Tools

Special tools, testers and auxiliary items required

Torque wrench 210 Nm V.A.G 1783

Underbody trim, assembly overview

Note :

The illustration shows the left side. The right side is

similar and can be determined from this.

Underbody trim

Underbody cover

- Arrow - points in direction

of travel.

Removing:

- Remove hex nuts - 2 - .

Hex nut

Qty. 8

1.5 Nm

Rear underbody cover

Only installed on the left

side.

Page 2 / 3

Underbody trim

Removing:

- Remove hex head nuts 4 - and screws - 5 - .

Hex nut

1x

1.5 Nm

Screw

Qty. 3

2 Nm

Cover

Removing:

- Remove bolts - 7 - .

Screw

Qty. 2

2 Nm

Page 3 / 3

Volkswagen Golf V: Plenum chamber bulkhead

Page 1 / 2

50 - 5

Plenum chamber bulkhead

Tools

Special tools, testers and auxiliary items required

Torque wrench 210 Nm V.A.G 1783

Plenum chamber bulkhead, assembly overview

Plenum chamber bulkhead

Plenum chamber bulkhead

Hex nut

Seal for plenum chamber

bulkhead

8 Nm

Ensure seal is seated

correctly when installing

bulkhead.

Screw

8 Nm

Page 2 / 2

Volkswagen Golf V: Front hood

Page 1 / 18

55 - 1

Front hood

Tools

Special tools, testers and auxiliary items required

Torque wrench 550 Nm V.A.G 1331

Pry lever - RMV outside mirror 80-200

Hood, assembly overview

Front hood

Page 2 / 18

Hood

Removing and installing

55-1, Hood, removing and

installing

Adjusting

adjusting

55-1, Hood,

Adjustment buffer

Qty. 2

Adjusting

adjusting

Stop buffer

Qty. 2

55-1, Hood,

Front hood

Insulation

Removing and installing

55-1, Noise insulation,

removing and installing

Guide piece

Page 3 / 18

Qty. 2

Hinge

Removing and installing

55-1, Hood hinge, removing

and installing

Adjusting

adjusting

55-1, Hood,

Gas strut

Removing 55-1,

Removing gas-filled strut

Venting gas 55-1, Gasfilled strut, venting

Hood seal

Secured to interior hood with

17 clips.

Hood, removing and installing

Removing

Front hood

- Remove left and right spray nozzles - 6

-

Repair Manual, Electrical Equipment,

Repair Group 92, Windshield washer and

wiper system; Windshield washer

system; Windshield washer system spray

nozzles, removing and installing

- Unclip line - 2 - from hinge - 3 - and

hood - 5 - .

- Remove line - 2 - from opening of

hood - 5 - .

- Loosen hex nuts - 1 - at left and right

(do not unscrew completely).

A second technician is required for the

rest of the removal procedure.

Page 4 / 18

Front hood

Page 5 / 18

- Remove gas-filled strut - 4 - at hood 55-1, Removing gas-filled strut

5- Remove hex nuts - 1 - and lift hood - 5

- from hinges - 3 - .

Installing

Installation is performed in the reverse order of removal.

- Tightening torques: Hood hex head nut, 22 Nm

- Adjust hood - 1 -

55-1, Hood, adjusting

- Route line - 2 - as shown - arrow - . If line is installed

twisted, the line is kinked.

Removing gas-filled strut

- Open hood and support hood.

- Reach under spring clips - 2 - using a small

screwdriver.

- Lift spring clips - 2 - only far enough so that the spring

clips can be slid over ball socket in - direction of arrow .

- Remove gas-filled strut - 1 - from ball studs - 3 - and - 4

- .

After removing gas-filled strut - 1 - , immediately slide

back spring clips - 2 - again.

Warning!

Front hood

Page 6 / 18

Proceed carefully when re-using gas-filled strut.

Spring clips must not be pried completely out of ball

socket, otherwise spring clips will be damaged. Gasfilled strut springs out of mount and leads to damage

and injury to the operator.

- Tightening torques of ball studs - 3 - and - 4 - : 22 Nm.

- Gas-filled strut, venting

55-1, Gas-filled strut, venting

Gas-filled strut, venting

- Clamp gas-filled strut in vice area - x - . Dimension of x - = 50 mm (2 in.).

Warning!

Clamping the gas-filled strut must only be done in this

area - x - , otherwise there is a risk of an accident.

- Using saw, cut into cylindrical part of strut at point within

first third of cylinders length (measured from cover edge at

piston rod end of cylinder).

Note:

Always wear eye protection when performing this

procedure.

Cover the area of the separated portion with a clean

rag.

Dispose of fluid and cleaning rag in a proper

manner.

Hood hinge, removing and installing

Note:

Front hood

Page 7 / 18

Removing and installing is described only for the left

hood hinge. Removing and installing right hood

hinge is derived accordingly from this.

Removing

- Hood, removing

55-1, Removing

- Remove screws - 2 - and remove hood hinge - 1 - .

Installing

- Assemble the hood hinge - 1 - .

- Tightening torque for bolts - 2 - : 22 Nm

Front hood

- Hood, installing

Page 8 / 18

55-1, Installing

Noise insulation, removing and installing

Removing

- Using pry lever 80-200 , pry out

retaining clips - 1 - (qty. 10) from noise

insulation - 2 - .

- Pull noise insulation - 2 - out of

longitudinal holes.

Installing

Front hood

- Slide noise insulation - 2 - under gasfilled strut and insert mounting tabs into

longitudinal holes.

- Engage all retaining clips - 1 - (qty. 10)

in noise insulation - 2 - .

When installing noise insulation - 2

- , make sure that retaining clips 1 - are inserted with wide side

facing outside.

Locking and unlocking components of hood, assembly

overview

Page 9 / 18

Front hood

Page 10 / 18

Catch

Removing:

- Unscrew bolts - 2 - and

remove catch.

Adjusting:

- Catch can be adjusted

toward the left or right in its

longitudinal holes.

Screw

Qty. 3

10 Nm

Spreader nut

Front hood

Page 11 / 18

Qty. 2

Mounting bracket

Hood release cable

Screw

Qty. 2

1.5 Nm

Release lever

Clipped in on wheelhousing

and lock carrier.

Hood release cable coupling

Removing and installing

55-1, Release lever,

removing and installing

Hood release cable

Clipped into mounting

bracket.

Disconnecting

release cable,

disconnecting

55-1, Hood

Hood lock

Removing and installing

55-1, Hood lock, removing

and installing

Adjusting

adjusting

55-1, Hood lock,

Hood lock, removing and installing

Removing

Front hood

Page 12 / 18

- Open hood.

- Remove radiator grille

and installing

66-3, Radiator grille, removing

- Disconnecting hood release cable

cable, disconnecting

55-1, Hood release

- Disconnect harness connector - 5 - for Front Hood

Switch F 266 .

Harness connector is secured over right headlight.

- Remove bolts - 4 - (three pieces) on lock carrier - 3 and remove hood lock - 1 - upward.

- To unclip hood release cable - 2 - , press together tabs

on hood release cable - arrows - .

- The locking mechanism is released and hood release

cable - 2 - can be removed from hood lock - 1 - .

Installing

Front hood

Page 13 / 18

- Clip hood release cable - 2 - into hood lock - 1 - .

- Install hood lock - 1 - in lock carrier - 3 - Tightening torque for bolts - 4 - : 12 Nm.

- Connect harness connector - 5 - for Front Hood Switch F

266 .

- Install hood release cable - 2 cable, disconnecting .

- Adjust hood lock

55-1, Hood release

55-1, Hood lock, adjusting

Before the hood is closed, a function test of the

release lever and hood release cable must be

performed.

Hood release cable, disconnecting

- Open hood.

Front hood

- Unclip hood release cable coupling - 1 - over headlight

on drivers side of lock carrier - 2 - .

- Open hood release cable coupling - 1 - and remove

hood release cable - 3 - in - direction of arrow - from

hood release cable coupling.

Note:

When installing, make sure that hood release cable

sleeve is inserted correctly and coupling is locked.

Before the hood is closed, a function test of the

operating lever and hood release cable must be

performed.

Hood, adjusting

- For Basic Setting of hood - 1 - , vehicle

must stand on the ground and catches

Page 14 / 18

Front hood

Page 15 / 18

must be removed.

- Remove catches - 9 -

Item - 1 - .

- Remove gas-filled strut - 2 - at hood 55-1, Removing gas-filled strut

1- By loosening hex nuts - 5 - and bolt 3 - at left and right on hood hinge - 4 (do not unscrew completely), hood - 1 can be aligned between fenders.

- In rear area, height of hood - 1 - can

be adjusted to fenders with adjusting

screw - 6 - on left and right sides.

- Stop buffers - 7 - (qty. 2) do not serve

to adjust. Their function is to stabilize and

to cushion the hood - 1 - .

- Hood - 1 - can be adjusted in height

relative to fenders in the front area using

the stops - 8 - (qty. two).

- Ensure gap dimensions are even

Repair Manual, Body Collision Repair,

Repair Group 00, Technical data; Body

gap dimensions

- After installing or adjusting perform

corrosion protection measures on hinges

- 4 - , hex head nuts - 5 - screws - 3 .

- After hood - 1 - has been adjusted,

catches can be reinstalled and adjusted:

Item - 1 Hood lock, adjusting

Front hood

Page 16 / 18

- If after closing hood the gap dimensions are no longer as

they had been adjusted, adjustment can be corrected

slightly by the hood lock and catches.

- Remove radiator grille

and installing

66-3, Radiator grille, removing

- If the bolts - 1 - are loosened now, hood gap dimensions

can be corrected or adjusted

Repair Manual, Body Collision Repair, Repair Group 00,

Technical data; Body gap dimensions

- Tightening torques: Bolts - 1 - 12 Nm

- Adjust catches

Item - 1 - .

Release lever, removing and installing

Removing

Front hood

- Engage the release lever - 1 - and release hood.

- Insert a small screwdriver into gap between release lever

- 1 - and clip - 2 - .

- Remove clip - 2 - from release lever - 1 - and pull

release lever off.

Installing

- Slide clip - 2 - completely into release lever - 1 - .

- Then push release lever - 1 - onto mount in mounting

bracket and lock the release lever.

Before the hood is closed, a function test of the

Page 17 / 18

Front hood

release lever and hood release cable must be

performed.

Page 18 / 18

Volkswagen Golf V: Rear lid

Page 1 / 19

55 - 2

Rear lid

Tools

Special tools, testers and auxiliary items required

Torque wrench 550 Nm V.A.G 1331

Rear lid, assembly overview

Rear lid

Page 2 / 19

Rear lid

Removing and installing

55-2, Rear lid, removing and

installing

Adjusting

adjusting

Rear lid lock

55-2, Rear lid,

Removing and installing

55-2, Rear lid lock, removing

and installing

Adjustment buffer

Left and right

Adjusting 55-2,

Adjustment buffer, adjusting

Rear lid

Page 3 / 19

Gas strut

Removing 55-2,

Removing gas-filled strut

Venting gas 55-2, Gasfilled strut, venting

Hinge

Removing and installing

55-2, Rear lid hinge,

removing and installing

Striker pin

Removing and installing

55-2, Latch bracket,

removing and installing

Adjusting 55-2, Adjusting

latch bracket

Cap

Left and right

Adjustment buffer stop.

Rear lid, removing and installing

Removing

Rear lid

- Open rear lid - 1 - .

- Remove rear lid trim

Repair Manual, Body Interior, Repair

Group 70, Trim panels, insulation; rear lid

trim

- Disconnect connectors on electrical

components present and remove rear

window washer system hose.

- Guide lines and hose through opening.

- Loosen bolts - 3 - at left and right lid

hinges - 4 - (do not unscrew

completely).

A second technician is required for the

rest of the removal procedure.

Page 4 / 19

Rear lid

Page 5 / 19

- Remove left and right gas struts - 2 - at

rear lid - 1 55-2, Removing gas-filled

strut

- Remove screws - 3 - and remove rear

lid - 1 - .

Installing

Installation is performed in the reverse order of removal.

- Rear lid screw torque specification: 10 Nm.

- Rear lid, adjusting

55-2, Rear lid, adjusting

Before the rear lid is closed, a function test of the

unlocking components must be performed.

Removing gas-filled strut

- Open rear lid and support rear lid.

- Reach under spring clips - 2 - using a small

screwdriver.

- Lift spring clips - 2 - only far enough so that the spring

clips can be slid over ball socket in - direction of arrow .

- Remove gas-filled strut - 1 - from ball studs - 3 - and - 4

- .

After removing gas-filled strut - 1 - , immediately slide

Rear lid

Page 6 / 19

back spring clips - 2 - again.

Warning!

Proceed carefully when re-using gas-filled strut.

Spring clips must not be pried completely out of ball

socket, otherwise spring clips will be damaged. Gasfilled strut springs out of mount and leads to damage

and injury to the operator.

- Tightening torques of ball studs - 3 - and - 4 - : 21 Nm.

- Gas-filled strut, venting

55-2, Gas-filled strut, venting

Gas-filled strut, venting

- Clamp gas-filled strut in vice area - x - . Dimension of x - = 50 mm (2 in.).

Warning!

Clamping the gas-filled strut must only be done in this

area - x - , otherwise there is a risk of an accident.

- Using saw, cut into cylindrical part of strut at point within

first third of cylinders length (measured from cover edge at

piston rod end of cylinder).

Note:

Always wear eye protection when performing this

procedure.

Cover the area of the sawn portion with a clean rag.

Dispose of fluid and cleaning rag in a proper

manner.

Rear lid hinge, removing and installing

Rear lid

Page 7 / 19

Note:

Removal and installation is described for right rear

lid hinge. Removal and installation for the left-hand

rear lid hinge is performed in the same manner.

Removing

- Remove rear lid - 1 Removing

55-2,

- Lower rear molded headliner

Repair Manual, Body Interior, Repair

Group 70, Trim, noise insulation; roof

trim; removing and installing molded

headliner

- Remove hex head nut - 3 - and rear lid

Rear lid

Page 8 / 19

hinge - 2 - from roof side member.

Installing

Note :

After installing rear lid - 1 - , retighten hex head nut

- 3 - for rear lid hinge - 2 - to 24 Nm.

- Install rear lid hinge - 2 - and tighten

hex head nut - 3 - to 24 Nm.

- Install rear lid - 1 -

55-2, Installing

- At end of installation, retighten hex

head nut - 3 - to 24 Nm.

- Install molded headliner

Rear lid

Repair Manual, Body Interior, Repair

Group 70, Trim, noise insulation; roof

trim; removing and installing molded

headliner

Latch bracket, removing and installing

Removing

- Remove lock carrier cover

Repair Manual, Body Interior, Repair Group 70,

Luggage compartment trim; removing and installing lock

carrier cover

.

- Remove screws - 1 - and striker pin.

Installing

- Assemble the latch bracket - 2 - .

- Tightening torque for bolts - 1 - : 23 Nm.

Page 9 / 19

Rear lid

- Adjust latch bracket

Page 10 / 19

55-2, Adjusting latch bracket

Further installation is in reverse order of removal.

Rear lid, adjusting

Note:

Vehicle must be standing on its wheels for basic

setting of rear lid.

Rear lid lock is bolted directly to the lid. It does not

have longitudinal holes and therefore cannot be

adjusted.

Stops recognized in other vehicles do not serve to

adjust the lid. They serve to stabilize and to cushion

the lid.

Next, adjusting the rear lid is described in several steps.

To adjust or check the gap dimensions, use special tool

3371

Repair Manual, Body Collision Repair, Repair Group 00,

Technical data; Body gap dimensions

- Remove gas-filled strut

strut

55-2, Removing gas-filled

- Adjust rear lid at striker pin

bracket

55-2, Adjusting latch

- Adjust rear lid at rear lid hinge by loosening screws - 3 55-2, Removing

- Adjust rear lid with rear lid hinge by loosening hex head

nut - 3 55-2, Removing

- Adjustment buffer, adjusting

adjusting

55-2, Adjustment buffer,

Note:

Rear lid is properly adjusted when there is an overall

even gap dimension when closed, it is not too far

inward or outward and contours align.

Adjusting latch bracket

Rear lid

- Remove lock carrier cover

Repair Manual, Body Interior, Repair Group 70,

Luggage compartment trim; removing and installing lock

carrier cover

.

- Disengage the latch bracket - 2 - .

- Bring striker pin - 2 - to rear position - arrow - and

tighten screws - 1 - .

- Close rear lid and test the adjustment.

- Latch bracket - 2 - can be slid in oversized holes by

loosening bolts - 1 - .

- Tightening torque for bolts - 1 - : 23 Nm

Adjustment buffer, adjusting

Note:

The following adjustment is only for the right

adjustment buffer. Adjustment for the left adjustment

buffer is derived accordingly from this.

Page 11 / 19

Rear lid

- Loosen clamping screw - 2 - far enough until it is visible

in rubber buffer.

- Now pull notched slider - 1 - out of adjustment buffer.

- Set notched slider to dimension - a - = 12.5 mm.

- Close rear lid to initial locking position using light

pressure over the center.

Page 12 / 19

Rear lid

Page 13 / 19

- Open rear lid again.

- Screw in adjustment buffer locking screw - 1 - to a depth

of dimension - a - 25 mm.

- Check the adjustment.

Locking and unlocking components of rear lid, assembly

overview

Rear Lid Handle Unlock Switch E234

removing and installing

55-2, Unlocking element,

removing and installing

Screw

Qty. 5

4 Nm

Rear lid

Page 14 / 19

Emergency release

Emergency release is

accessed through an

opening in the rear lid trim.

Rear lid lock

removing and installing

55-2, Rear lid lock, removing

and installing

Lid lock connector

Angle bracket

Unlocking element connector

Unlocking element, removing and installing

Note:

If rear lid does not open, it can opened by hand via

the emergency release - 3 - on lid lock - 4 - .

Emergency release is accessed through an opening

in the rear lid trim.

Removing

Rear lid

- Remove rear lid trim

Repair Manual, Body Interior, Repair

Group 70;, Trim panels, insulation; rear

lid trim

- Rear window washer motor, removing

Repair Manual, Electrical Equipment,

Repair Group 92, Window wiper and

washer system; Rear window washer

system

- Disconnect harness connector - 7 from unlocking element - 1 - .

- Remove bolts - 2 - .

Page 15 / 19

Rear lid

- Disengage unlocking element opposite

- arrow - angle brackets - 6 - .

- Then you can remove the unlocking

element - 1 - .

Installing

Installation is performed in the reverse order of removal.

- Tightening torques for unlocking element: 4 Nm

Before the rear lid is closed, a function test of the

unlocking components must be performed.

Rear lid lock, removing and installing

Note:

If rear lid does not open, it can opened by hand via

the emergency release - 1 - on lid lock - 2 - .

Emergency release is accessed through an opening

in the rear lid trim.

Removing

- Remove rear lid trim

Repair Manual, Body Interior, Repair Group 70;, Trim

Page 16 / 19

Rear lid

panels, insulation; rear lid trim

- Disconnect harness connector - 4 - from lid lock - 2 - .

- Remove screws - 3 - and guide lid lock - 2 - downward

out of lid.

Installing

- Guide lid lock - 2 - into lid and install screws - 3 - .

- Tightening torque for bolts - 3 - : 23 Nm

- Connect harness connector - 4 - to lid lock - 2 - .

Further installation is in reverse order of removal.

Before the rear lid is closed, a function test of the

unlocking components must be performed.

Rear lid seal

Rear lid seals are equipped at the factory with sealant,

applied to rear lid flange and then rolled on.

Note:

During removal of the seal, sealant is distributed on

interior side of seal and flanks are bent up easily. If

the seal is re-installed, the sealing performance and

proper seating are no longer guaranteed.

For this reason, every completely removed seal

Page 17 / 19

Rear lid

must be replaced with a so-called "hammer-stroke

seal" .

For partially removed seals, seal flanks must be

pressed together before installation.

Rear lid seal, removing and installing

Removing

- Pull off rear lid seal - 1 - from body flange.

Installing

Page 18 / 19

Rear lid

- Align rear lid seal - 1 - with vulcanized point - arrow - to

center of left tail light.

Page 19 / 19

Volkswagen Golf V: Tank lid unit

Page 1 / 6

55 - 3

Tank lid unit

Tools

Special tools, testers and auxiliary items required

Socket wrench T 10010

Tank flap unit, assembly overview

Tank lid unit

Tank lid unit

removing 55-3, Fuel tank

flap unit, removing

Screw

1.5 Nm

Drain hose

Assembly component

Release rod

Mounting bolt for actuator

Qty. 2

1.5 Nm

Page 2 / 6

Tank lid unit

Fuel Filler Cap Central Locking

Actuator (F219)

Page 3 / 6

Removing

removing

55-3, Actuator,

Gasket

Fuel tank flap unit, removing

Note :

If tank flap does not open, it can be opened by hand

via the release rod - 5 - . Side trim must be

removed for this.

- Open fuel tank filler flap.

- Unscrew fuel tank cap.

Tank lid unit

- Remove bolt - 2 - .

- Remove rubber part from tank filler

flange.

- Pull tank flap unit - 1 - with drain hose 3 - toward rear and swivel tank flap unit

out of side panel.

- Unclip assembly piece - 4 - from side

panel and pull off assembly piece from

release rod - 5 - .

Installing

Assembly piece - 4 - is slid on.

- Insert drain hose - 3 - through opening

in tank flap unit and pull drain hose

through until it stops.

Page 4 / 6

Tank lid unit

- Guide drain hose into side panel.

- Slide tank flap unit - 1 - with hinge side

first into side panel.

- Then swivel tank flap unit completely

into side panel, make sure that upper and

lower catches engage correctly in side

panel.

- Pull rubber piece over tank filler neck

and tighten bolt - 2 - .

Tightening torque for bolt - 2 - : 1.5 Nm.

Actuator, removing

- Remove side luggage compartment

trim

Page 5 / 6

Tank lid unit

Repair Manual, Body Interior, Repair

Group 70, Trim/noise insulation; luggage

compartment trim

- Disconnect harness connector at

actuator - 7 - .

- Remove actuator - 7 - using special

tool socket wrench T 10010 .

- Remove actuator - 7 - together with

release rod - 5 - from seal - 8 - .

Installing

Installation is performed in the reverse order of removal.

Page 6 / 6

Volkswagen Golf V - Front door

Page 1 / 44

57 - 1

Front door

Tools

Special tools, testers and auxiliary items

required

Socket wrench T 10072

Assembly tool T 10118

Door adjusting wrench 3320

Joint for 3320 3320/1

Box wrench 3320/2

Front door

Box wrench 3320/3

Application roller for door insulation

foil 3356

Torque wrench 550 Nm V.A.G

1331

Adjusting gauge 3371

Special tools, testers and auxiliary items

required

Cartridge gun V.A.G 1628

Page 2 / 44

Front door

Page 3 / 44

Cartridge heater V.A.G 1939 A

Trim removal wedge 3409

Assembly tool set T 10237

Materials

DH 009 100 01 1) 2)

1C- window adhesive

Glass primer/paint primer

Cleaning solution

Primer applicator

3) Materials

1) Observe

D 009 401 04 3)

D 009 500 25 3)

are stored in box D 004 700.

minimum curing time

D 009 200 02 3)

57-1, Minimum curing

time

2) Heat

according to manufacturers instructions using

cartridge heater V.A.G 1939 .

Door construction, assembly overview

The door consists of inner door part - 6 and outer door plate - 1 - .

Parts are joined by the front - 7 - and the

rear - 5 - retaining tracks.

Retaining tracks are bolted to inner door

part and bonded to outer door plate.

Inner door part - 6 - undertakes among

other things the function of the previously

known subframe. Loudspeakers, window

regulators, window regulator motors,

wires, window guide, exterior mirror and

door lock are installed on inner door part.

Outer door plate - 1 - is also bolted to

inner door part on the lower edge.

Front door

Page 4 / 44

Exterior window shaft seal, insulation and

outer door handle are installed on outer

door plate.

Caution!

Various bolts are used to secure the

outer door plate. Outer door plate is

damaged if not allocated correctly.

Outer door plate

Removing and installing

58-1, Outer door plate,

removing and installing

Edge protection

Between outer door panel

and inner door part.

Front door

Screw

Characteristic: Bolt has point

and thinner washer.

6 pieces on lower edge

2 piece in rear rail area

10 Nm

Rear retaining track

Characteristic: Bolt without

point but with thick washer.

Qty. 10 for both retaining

tracks on 4-door version

Qty. 11 for both retaining

tracks on 2-door version

14 Nm

Inner door part

Assembly overview 57-1,

Inner door part, assembly

overview

Front retaining track

Adhesive: DH 009 100 03

Screw

Page 5 / 44

Adhesive: DH 009 100 03

Screw

Characteristic: Bolt has point

and thick washer

Qty. 1 for front rail area

10 Nm

Insulation

Self-adhesive

Front door

To adhere, insulation must

be preheated and then

pressed on firmly

Clip

Page 6 / 44

Qty. 6

Window shaft seal

Must be installed before

installing outer door shell.

Door hinges, assembly overview

Caution!

The nut for eccentric pin - 9 - must

not be loosened under any

circumstances. It cannot be secured

again using workshop equipment.

Note :

The description applies to the right side. The left side

is derived accordingly from this.

Bolts for door hinges must always be replaced after

loosening.

Hinges are no longer manufactured as separated

parts.

Front door

Page 7 / 44

Door

Removing and installing

57-1, Door, removing and

installing

Adjusting

adjusting

57-1, Door,

Guide bolt

10 Nm

Door hinge with door arrester

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

Front door

Page 8 / 44

loosening

Socket head bolt

Installed from the vehicle

interior

Remove lower A-pillar trim

Repair Manual, Body Interior, Repair

Group 70, Trim panels/insulation; Pillar

and side trim

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Guide screws

10 Nm

Nut

Always replace bolts after

loosening

For the eccentric pin, must

not be loosened. Used for

making adjustments during

production.

Door hinge

Front door

Page 9 / 44

Door hinge is no longer

manufactured as separated

parts.

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Door, removing and installing

Note:

Removing and installing is described only for the

right door. Removing and installing the left door is

derived accordingly from this.

Removing

Front door

- Release boots - 6 - by pressing on

locking mechanism - arrow a - and

remove boots from A-pillar.

- Swivel locking lever - 7 - downward arrow b - and disconnect electrical

harness connector - 8 - from connector

station.

- Remove screws - 4, 5 and 11 - using

door adjustment wrench 3320 and bit

insert 3320/3 from hinge.

- Pull door in - direction of arrow - from

guide bolts - 2 and 9 - .

Installing

Installation is performed in the reverse order of removal.

- Torque specification for screws - 4, 5 and 11 - : 20 Nm +

Page 10 / 44

Front door

/ 4 (90

Page 11 / 44

) additional turn.

Screws - 4, 5 and 11 - must always be replaced.

- Observe gap dimension of front door

Repair Manual, Body Collision Repair, Repair Group 00,

Technical data; Body gap dimensions

Door, adjusting

Warning!

The nut for eccentric pin - 9 - must

not be loosened under any

circumstances. The nut cannot be

secured again using workshop

equipment.

Front door

Note :

The door is properly adjusted when there is an

overall even gap dimension when closed, it is not too

far inward or outward and contours align.

Vehicle must stand on its wheels in order to be able

to perform the adjustment.

If outer door plate is removed, window frame of inner

door part must be adjusted in relation to roof frame

and B-pillar, and to rear door.

- Observe gap dimension of front door

Repair Manual, Body Collision Repair,

Repair Group 00, Technical data; Body

gap dimensions

For correct gap dimension adjustment,

screws - 5, 7, 12 and 13 - at A-pillar

must be loosened. For screw - 5 - ,

lower A-pillar trim must be removed

Repair Manual, Body Interior, Repair

Group 70, Pillar and side trim

.

Other measures, such as aligning the

door upward, are not effective. Excess

pressure thereafter will again cause the

door to sag.

For correct alignment adjustment, screws

- 4, 6 and 14 - and guide screws - 2 and

8 - must be loosened.

Door adjusting wrench 3320 with bit

insert 3320/3 must be used for this.

Outer door plate, removing and installing

Removing

Page 12 / 44

Front door

- Pry off clips - 3 - beginning at bottom

of door - 1 - and remove cover - 2 - .

Page 13 / 44

Front door

- Removing lock cylinder

installing

- Remove door handle

installing

Page 14 / 44

57-1, Housing, removing and

57-1, Door handle, removing and

- Remove screw - 1 - from bearing bracket - 2 - , located

behind outer door plate.

- Remove all screws - 2, 3, 4 - .

- Carefully remove outer door plate.

Installing

Caution!

Various bolts are used to secure the outer door plate.

Outer door plate is damaged if not allocated correctly.

Front door

Page 15 / 44

- Carefully set outer door plate in.

- Start all screws - 2, 3, 4 - .

Make sure that the various bolts

are used correctly.

Characteristic for bolt - 2 - : Bolt has point and

thinner washer.

Characteristic for bolt - 3 - : Bolt without point but

with thick washer.

Characteristic for bolt - 4 - : Bolt has point and thick

washer

- Check whether guide pins for retaining

tracks are located in the corresponding

guide holes of inner door part. Then

Front door

tighten all screws - 2, 3, 4 - .

Observe the correct tightening

torques for the various bolts.

Tightening torque for bolt - 2 - : 10 Nm.

Tightening torque for bolt - 3 - : 14 Nm.

Tightening torque for bolt - 4 - : 10 Nm.

Further installation is performed in the

reverse order of removal.

New outer door plate, installing

Caution!

Various bolts are used to secure the outer door plate.

Outer door plate is damaged if not allocated correctly.

Note:

Observe the chapter of installation notes, bonding

new outer door plate 57-1, Installation notes for

adhering a new outer door plate

Page 16 / 44

Front door

Old (damaged) outer door plate

with retaining tracks removed

57-1, Outer door plate, removing

and installing

- Install front - 2 - and rear - 6 retaining tracks on inner door part. For

this, use the "bolt without point with thick

washer" .

Torque for bolt - 3 - and - 5 - : 10 Nm.

- Screw two guide screws into bottom

edge of inner door part.

Page 17 / 44

Front door

The painted outer door plate is fitted first

without applying adhesive.

The assembly block from the assembly

tool set T 10237 is needed to fit the outer

door shell. One strip of "Tesa Power

Strips large" - 6 - is affixed onto the

lowered side. The pin has the minimum

dimension for the gap width. The surface

without adhesive is placed onto the

neighboring component until it makes

contact.

- Adhere assembly blocks - 3 - to outer

door plate.

- Guide the outer door plate - 1 - in

lower edge of inner door part via the

guide bolts.

- Using wedges - 4 - from assembly tool

set T 10237 , adjust gap dimension to sill

panel and outer door shell height.

Page 18 / 44

Front door

- Lay outer door panel with assembly

blocks on adjoining components - 2 and

5- .

- Check gap dimension with adjustment

gauge 3371

Repair Manual, Body Collision Repair,

Repair Group 00, Technical data; Body

gap dimensions

- If gap dimensions can no longer be

adjusted, inner door part must be

adjusted 57-1, Door, adjusting

- Remove outer door plate again.

- Apply adhesive beads - 2 - onto front 1 - and rear - 3 - retaining tracks

Page 19 / 44

Front door

cartridge gun V.A.G 1628 .

The securing block from assembly tool

set T 10237 is needed to insert outer

door panel. Two strips of "Tesa Power

Strips large" - 5 - are affixed onto

contact surface.

- Guide the outer door plate - 1 - in

lower edge of inner door part via the

guide bolts.

- Bring outer door plate with assembly

blocks - 3 - into contact with neighboring

components.

- Using wedges - 4 - from assembly tool

set, adjust gap dimension to sill panel

and outer door plate height.

- Check gap dimensions with adjustment

gauge 3371

Page 20 / 44

Front door

Repair Manual, Body Collision Repair,

Repair Group 00, Technical data; Body

gap dimensions

- Affix short securing blocks - 2 uniformly onto door to be replaced and

neighboring components.

Note:

A waiting time of 180 minutes must be observed

before performing further work on the affixed door.

- Rest of installation is performed in the reverse order of

removal 57-1, Installing

Retaining track on outer door plate, removing and

installing

Removing retaining track

Caution!

The following work must be performed very carefully.

Since the outer door plate is to be re-used, dents and

scratches must be prevented.

When cutting through adhesive bead, always hold

retaining track and outer door plate together as shown

in the illustration. Otherwise, outer door plate flaps off

the retaining track and must no longer be used again.

Note:

The following work is to be performed only with a

second technician.

Page 21 / 44

Front door

Outer door plate with retaining tracks removed

Removing

Page 22 / 44

57-1,

- Store the outer door plate - 1 - on a firm surface and

protect outer door plate against scratches.

- Secure spooling tool - 2 - .

- Secure cord - 5 - onto spooling tool and retainer - 4 - .

- Hold retaining track and outer door plate firmly together

when cutting through adhesive bead.

- Using cord, cut through adhesive bead from retaining

track - 3 - and outer door plate - 1 - until slightly out over

the center.

Front door

- After adhesive bead has been cut up to halfway in the

first step, move the spooling tool - 2 - and insert cord - 5 on the side not yet cut.

- Hold retaining track - 3 - and outer door plate - 1 - firmly

together when continuing to cut through adhesive bead.

- Cut through the second half of the adhesive bead.

Installing retaining track

- Carefully, cut remaining adhesive bead on outer door

plate up to the highest possible minimum without damaging

paintwork while doing so.

- Further work steps are described in chapter "installing

new outer door plate" 57-1, New outer door plate,

installing .

Note:

"Installation notes for adhering new outer door plate"

are also to be followed to install a new retaining

track.

- Install a new retaining track onto inner door part on

location of the removed retaining track.

- Apply adhesive onto the new retaining track.

- Firmly bolt door plate on lower edge and on the retaining

track.

- Secure outer door panel to new retaining track with

securing blocks.

Installation notes for adhering a new outer door plate

Note:

If both outer door plates must be replaced on a side,

follow the sequence. First the rear outer door plate

and then the front outer door plate is aligned and

adhered. For alignment of rear outer door panel to

front outer door panel, adhere long securing blocks.

If the cataphoretic paint coating of outer door plate is

damaged on the inside in the adhesion area, or was

damaged there, this area must be primed using

glass/paint primer D 009 200 02.

1K window adhesive DH 009 100 must be heated for

Page 23 / 44

Front door

Page 24 / 44

20 minutes in cartridge heater V.A.G 1939 A .

- Clean application surfaces on retaining tracks with

cleaning solution D 009 401 04.

- Apply adhesive material using cartridge gun V.A.G 1628

onto application surfaces at a right angle to the retaining

track.

Warning!

Outer door plate must be installed within 10 minutes,

otherwise bonding properties of adhesive will be

impaired.

Place outer door panel on retaining tracks with help

of both assembly blocks, center with wedges and

adjustment gauge 3371 and press assembly block

application surfaces onto surrounding components.

Secure outer door panel during curing time with

securing blocks.

After installing, align outer door plate to the other

components and gap dimensions must be uniform.

If the adhesive bead has been applied too thickly

and the adhesive expands out between retaining

track and outer door plate, then the excess adhesive

must be removed.

Minimum curing time

Warning!

Special requirements must be fulfilled for replacing

bonded outer door plates. One of these standards for

Front door

example is, that a freshly bonded outer door plate

must comply with the safety elements, even in an

accident, once the adhesive has exceeded the

prescribed curing time.

The minimum curing time for outer door panel with 1K

adhesive DH 009 100 is 180 minutes.

By minimum curing time, it is meant the time from bonding

in the outer door plate up to use in the vehicle, or until

further work can be performed. During this time, the vehicle

must stand on an even surface at room temperature (at

least 15 C).

Warning!

The vehicle is operationally ready only after the

minimum curing time has elapsed.

Cleaning when soiled by adhesive sealing material

- It is recommended to use adhesive remover D 002 000

10 as a cleaning solution. Observe safety precautions

when processing.

Caution!

When cleaning the vehicle, outer door plate bonded in

immediately beforehand must not be shifted.

- First clean paint surface coarsely using a dry rag.

Eliminate remaining soiling using adhesive removal

solution D 002 000 10.

- Clean plastic trim: Allow adhesive sealing material to

harden (about 1 hour) and then peel off.

Inner door part, assembly overview

Note :

The description applies to the right side. The left side

is derived accordingly from this.

Page 25 / 44

Front door

Page 26 / 44

Inner door part

Window shaft seal

Loudspeaker

Window regulator motor

removing 64-2, Window

regulator motor, removing

and installing

Insulation

4x

20 mm x 40 mm

commercially available cloth

reinforced adhesive tape

Front door

Page 27 / 44

Door handle and door lock, assembly overview

Note :

The illustration shows the left side. The right side is

similar and can be determined from this.

Door lock

Cable

Removing and installing

57-1, Door lock, removing

and installing

For disengaging lock of

exterior door handle.

Screw

Front door

For securing lock to inner

door part

18 Nm

Qty. 2

Mounting bracket

Removing and installing

57-1, Bearing bracket,

removing and installing

Screw

Page 28 / 44

For lock cylinder.

Bolt

Not available on all versions.

This screw is installed for

additional securing of

mounting bracket.

Backing

Lock cylinder housing

Only on drivers side.

Only one housing is installed

on front passengers side.

Removing and installing

57-1, Housing, removing and

installing

Cover cap

For the lock cylinder

housing.

Is secured to lock cylinder

housing with three tabs.

Key

Changing battery 57-2,

Radio-frequency remote

Front door

Page 29 / 44

control key (foldable) battery

- assembly overview

Door handle with backing plate

Not installed in Rabbit/GTI.

Cable

Not installed in Rabbit/GTI.

Angle bracket

Socket wrench T 10072

Expanding rivet

Is a component of door

handle.

Torx screw

Removing and installing

57-1, Door handle, removing

and installing

Backing

Adapting new/additional

keys to remote control and

immobilizer 57-2,

Adaptation of keys with

radio-frequency remote

control

To lock release mechanism

of door handle.

Cover

Does not belong to

packaged contents of door

lock

Is secured to door lock with

three tabs.

Front door

Housing, removing and installing

Note:

Removing and installing is described only for the

housing. Removing and installing lock cylinder is

derived accordingly from this.

Removing

- Pry out cover cap in front of bolt - 1 - .

- Pull door handle - 2 - in - direction of arrow - and turn

screw - 1 - with socket wrench T 10072 until housing - 3 can be removed.

Installing

- Insert housing - 3 - in right angle - arrow - into door

handle bearing bracket.

Door handle - 2 - must make contact only lightly at door

plate.

- Install the bolt - 1 - into bearing bracket using socket

wrench T 10072 .

Door handle - 2 - engages again into housing - 3 - with a

Page 30 / 44

Front door

Page 31 / 44

very audible click.

Note:

During installation, housing must be pressed onto

door plate. The door handle rests only lightly against

the door panel.

Further installation is in reverse order of removal.

Then a function test must be performed with door

open, since the door cannot be opened if hood

release cable is not correctly adjustment or clipped

in.

Door handle, removing and installing

Note:

Removing and installing is described only for the

right door handle. Removing and installing the left

door handle is derived accordingly from this.

Removing

- Remove housing

installing .

57-1, Housing, removing and

- Pry out clip - 2 - from door handle - 1 - .

- Swivel door handle - 1 - out of door - arrow - .

Installing

Front door

- Guide assembly tool T 10118 into door

through opening in inner door plate.

- Light the inner part of door using a

flashlight for better view.

- Hook assembly tool T 10118 into

spring - arrow A - .

- Engage spring into door lock by pulling

assembly tool T 10118 - arrow B - .

Release lever is now locked in position.

Note :

Lock is secured by engaging spring in the operating

lever. This prevents the cable from subsequently

being clipped in at door handle incorrectly.

Page 32 / 44

Front door

Page 33 / 44

- Swivel door handle - 1 - into door.

- Pull clip - 2 - into plate cutout and engage clip into door

handle - 1 - - arrow - .

Note:

During installation, door handle - 1 - must be

pressed onto door plate.

Clip - 2 - must engage into door handle - 1 - with a

very audibly click.

Install housing

57-1, Installing .

Then a function test must be performed with door

open, since the door cannot be opened if hood

release cable is not correctly adjustment or clipped

in.

Bearing bracket, removing and installing

Note:

Removing and installing is described only for the

right bearing bracket. Removing and installing the

left bearing bracket is derived accordingly from this.

Removing

Front door

- Remove lock cylinder housing

Housing, removing and installing

Page 34 / 44

57-1,

- Remove door handle 57-1, Door

handle, removing and installing

- Remove outer door panel 58-1,

Outer door plate, removing and

installing

- Pull retaining rubber - 4 - upward from

guide pin.

- Pull bearing bracket - 1 - in - direction

of arrow - with guide pin - 2 - out of

mounts - 3 - .

Installing

Front door

- Slide bearing bracket - 1 - with guide

pin - 2 - into mounts - 3 - .

- Secure retaining rubber - 4 - on guide

pin and mounting pin on bearing bracket

mount.

Further installation is in reverse order of

removal.

Door lock, removing and installing

Note:

Removing and installing is described only for the

right door lock. Removing and installing the left door

lock is derived accordingly from this.

Removing

Page 35 / 44

Front door

- Remove outer door panel 58-1,

Outer door plate, removing and

installing

- Remove mounting bracket 57-1,

Bearing bracket, removing and installing

- Disconnect connector - 5 - .

- Remove bolts - 6 - .

- Disengage cable - 1 - from actuator

lever - 8 - and remove door lock - 4 - .

Cover - 3 - is not supplied with delivery

casing of door lock.

Installing

Installation is performed in the reverse order of removal.

Tightening torques for bolts: 18 Nm.

Page 36 / 44

Front door

Page 37 / 44

Then a function test must be performed with door

open, since the door cannot be opened if hood

release cable is not correctly adjustment or clipped

in.

Side impact protection, assembly overview

Caution!

The side impact member screws and nuts are painted

during production. That means that the threads could

shear off during removal with significant force.

Loosening of screws and nuts should be avoided

when possible

Side impact protection

Screw

4x

Front door

Page 38 / 44

20 Nm

Insulation

Nut

Qty. 2

20 Nm

Inner door seal

Inner door seals are equipped at the factory with sealant,

applied to door flange and then rolled on.

Note:

During removal of the seal, sealant is distributed on

interior side of seal and flanks are bent up easily. If

the seal is re-installed, the sealing performance and

proper seating are no longer guaranteed.

For this reason, every completely removed seal

must be replaced with a so-called "hammer-stroke

seal" .

For partially removed seals, seal flanks must be

pressed together before installation.

Inner door seal, removing and installing

Note:

Removing and installing is described only for the left

inner door seal. Removing and installing the right

inner door seal is derived accordingly from this.

Removing

Front door

- Pull off inner door seal from body

flange.

Installing

Page 39 / 44

Front door

- Align inner door seal with vulcanized

point - arrow b - at the height of the

lower hinge.

- Start installation of inner door seal in

upper radius - arrow a - of door

opening.

Outer door seal, removing and installing

Note:

Removing and installing is described only for the

right outer door seal. Removing and installing the left

outer door seal is derived accordingly from this.

Remove protective foil only immediately prior to

assembly. Processing temperature approx. 20 C.

Adhesive remover D 002 000 10 is to be used

Page 40 / 44

Front door

exclusively.

The outer door seal must be applied immediately

after cleaning.

After 10 minutes, check the seal for a secure fit.

Removing

- Pull off outer door seal from door.

Installing

Page 41 / 44

Front door

- Remove any adhesive residue still

present using radial disc for streak

remover Z 432 290 TE

- Thoroughly clean the adhesion surface

with adhesive remover D 002 000 10

immediately before adhering the outer

door seal.

Adhesion surfaces must be free of

dust and grease and there must be

no residual adhesive present.

- Align outer door seal with cut-out arrow b - with door lock securing

screw.

- Vulcanized point - arrow c - of outer

door seal is then located in center area of

door entry sill.

- Pull off foil cover and apply seal onto

Page 42 / 44

Front door

door. Do not stretch outer door seal

excessively so that the seal is not too

long at the end.

- Press entire adhesive area of seal all

around onto door using application roller

3356 , starting in upper radius - arrow a

- of door.

Note :

Part numbers are for reference only. Always check

with your Parts Department for the latest part

number information

Checking seal for secure seating

Check seal for firm setting 10 minutes

after adhering the seal.

- Place seal - 1 - facing outward by

Page 43 / 44

Front door

hand.

- If adhered area does not pull off in any

areas, press seal on further once more

using application roller 3356 .

Page 44 / 44

Volkswagen Golf V - Central locking system

Page 1 / 9

57 - 2

Central locking system

Component locations overview of components for

central locking system

Coupling station

Location: A-pillar, right

To disconnect harness

connector, release boots at

pillar 57-1, Removing

Comfort System Central Control

Module -J393

Location: below passenger

side instrument panel,

behind glove compartment

Central locking system

Page 2 / 9

Removing

Repair Manual, Body Interior, Repair

Group 68, Interior equipment;

Compartments, covers and trim; Glove

compartment, removing and installing

Front Passengers Door Control

Module -J387

Integrated in window

regulator motor.

Removing

Removing

64-2,

Door lock

Door lock is secured to inner

door part.

Electrical central locking

system is integrated in door

lock.

Removing

Removing

57-1,

Coupling station

Location: B-pillar, right.

To disconnect harness

connector, release boots at

pillar 58-1, Removing

Right Rear Door Control Module

-J389

Integrated in window

regulator motor.

Removing

Removing

64-3,

Door lock

Door lock is secured to inner

Central locking system

Page 3 / 9

door part.

Electrical central locking

system is integrated in door

lock.

Removing

Removing

58-1,

Right rear lid connector station

Location: behind C-pillar

trim.

Removing and installing

Repair Manual, Body Interior, Repair

Group 70, Trim/insulation; Pillars and

side trim; Upper C-pillar trim, removing

and installing

Fuel Tank Lid Unlock Motor V155

Location: behind right

luggage compartment trim.

Removing

removing

55-3, Actuator,

Rear lid lock

Location: screwed to rear lid.

Removing

Removing

55-2,

Unlocking element with button

Location: screwed into rear

lid.

Removing

Removing

55-2,

Left rear lid connector station

Location: behind C-pillar

trim.

Central locking system

Page 4 / 9

Removing and installing

Repair Manual, Body Interior, Repair

Group 70, Trim/insulation; Pillars and

side trim; Upper C-pillar trim, removing

and installing

Door lock, LR

Door lock is secured to inner

door part.

Electrical central locking

system is integrated in door

lock.

Removing

Removing

58-1,

Left Rear Door Control Module J388

Integrated in window

regulator motor.

Removing

Removing

64-3,

Coupling station

Location: Left B-pillar.

To disconnect harness

connector, release boots at

pillar 58-1, Removing

Door lock, LF

Door lock is secured to inner

door part.

Electrical central locking

system is integrated in door

lock.

Removing

Removing

57-1,

Central locking system

Central switch for window

regulator

Location: installed in door

trim

Remove and installing

central window regulator

switch

Repair Manual, Electrical Equipment,

Repair Group 96, Electrical Equipment;

Lights, Lamps, switches - interior, lights

and switches in doors

Drivers Door Control Module J386

Integrated in window

regulator motor.

Removing 64-2,

Removing and 57-1,

Removing

Coupling station

Location: Left A-pillar.

To disconnect harness

connector, release boots at

pillar 57-1, Removing

Alarm signal horn

Location: below plenum

chamber cover.

Removing 64-1, Remove

plenum chamber cover

Front Hood Switch -F266

Contact switch for anti-theft

warning system, cannot be

replaced individually.

Location: On hood lock.

Page 5 / 9

Central locking system

Removing

Removing

Page 6 / 9

55-1,

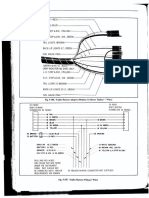

Adaptation of keys with radio-frequency remote control

Adaptation of keys with remote control is performed using

Vehicle Diagnostic, Testing and Information System VAS

5051 A .

- Select "Guided Fault-Finding" on Vehicle Diagnostic,

Testing and Information System VAS 5051 A .

- Via the "Go to" button, select "Function-/Component

selection" and the following menu points in sequence:

Body

Body Repairs

01 - On Board Diagnostic (OBD) capable systems

Comfort system

Functions - Comfort system

Adaptation of keys with radio-frequency remote

control

Radio-frequency remote control key (foldable) battery assembly overview

Central locking system

Page 7 / 9

Key with variable code

transponder

Radio frequency unit - upper

part

LED

This LED must blink when

remote control is operated.

If LED does not blink when

remote control is operated,

the battery is completely

discharged and must be

replaced.

Battery

Removing battery

Removing

57-2,

Central locking system

Installing battery

Installing

Page 8 / 9

57-2,

Radio frequency unit - lower

part

Battery for key with radio-frequency remote control

(foldable), removing and installing

Removing

- Insert screwdriver in the slot between radio-frequency

unit - 1 - and key - 2 - .

- Rotate screwdriver in - direction of arrow - and detach

radio frequency unit from key.

- Press radio frequency unit - 1 - apart with key bit on key

- 2- .

Central locking system

- Use a screwdriver to unclip battery - 1 - out of holders 2 - in - direction of arrow - .

Installing

Note polarity and installation position of battery when

installing.

- Place battery - 1 - in radio-frequency unit - 2 - with

positive terminal downward (positive terminal is marked in

housing).

- Press on battery with light pressure to engage it in radiofrequency unit.

- Attach the cover and the radio frequency unit together

(do not damage seal).

- Then lock radio-frequency unit with key.

Page 9 / 9

Volkswagen Golf 5 - Rear door

Page 1 / 44

58 - 1

Rear door

Tools

Special tools, testers and auxiliary items

required

Socket wrench T 10072

Assembly tool T 10118

Door adjusting wrench 3320

Joint for 3320 3320/1

Box wrench 3320/2

Rear door

Box wrench 3320/3

Application roller for door insulation

foil 3356

Torque wrench 550 Nm V.A.G

1331

Adjusting gauge 3371

Special tools, testers and auxiliary items

required

Cartridge gun V.A.G 1628

Page 2 / 44

Rear door

Page 3 / 44

Cartridge heater V.A.G 1939 A

Trim removal wedge 3409

Assembly tool set T 10237

Materials

DH 009 100 01 1) 2)

1C- window adhesive

Glass primer/paint primer

Cleaning solution

Primer applicator

3) Materials

1) Observe

D 009 401 04 3)

D 009 500 25 3)

are stored in box D 004 700.

minimum curing time

D 009 200 02 3)

58-1, Minimum curing

time

2) Heat

according to manufacturers instructions using

cartridge heater V.A.G 1939 .

Door construction, assembly overview

The door consists of inner door part - 6 and outer door plate - 1 - .

Parts are joined by the front - 7 - and the

rear - 4 - retaining tracks.

Retaining tracks are bolted to inner door

part and bonded to outer door plate.

Loudspeakers, window regulators,

window regulator motors, wires, window

guide and door lock are installed on inner

door part.

Outer door plate - 1 - is also bolted to

inner door part on the lower edge.

Exterior window shaft seal, insulation and

outer door handle are installed on outer

Rear door

Page 4 / 44

door plate.

Caution!

Various bolts are used to secure the

outer door plate. Outer door plate is

damaged if not allocated correctly.

Outer door plate

Edge protection

Outer door plate, removing

and installing 58-1, Outer

door plate, removing and

installing

Between outer door panel

and inner door part.

Screw

Rear door

Page 5 / 44

Characteristic: Bolt has point

and thinner washer.

4 pieces on lower edge

2 piece in rear rail area

10 Nm

Rear retaining track

Screw

Characteristic: Bolt without

point but with thick washer.

11 pieces on both retaining

tracks

14 Nm

Inner door part

Assembly overview 58-1,

Inner door part, assembly

overview

Front retaining track

Adhesive: DH 009 100 03

Adhesive: DH 009 100 03

Screw

Characteristic: Bolt has point

but thick washer.

Qty. 1 for front rail area

10 Nm

Insulation

Self-adhesive

To adhere, insulation must

be preheated and then

pressed on firmly

Rear door

Page 6 / 44

Clip

Qty. 5

Window shaft seal

Must be installed before

installing outer door panel.

Door hinges, assembly overview

Caution!

The nut for eccentric pin - 9 - must

not be loosened under any

circumstances. It cannot be secured

again using workshop equipment.

Note :

The description applies to the right side. The left side

is derived accordingly from this.

Bolts for door hinges must always be replaced after

loosening.

Hinges are no longer manufactured as separated

parts.

Rear door

Page 7 / 44

Door

Removing and installing

58-1, Door, removing and

installing

Adjusting

adjusting

58-1, Door,

Guide bolt

10 Nm

Door hinge with door arrester

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

Rear door

Page 8 / 44

loosening

Socket head bolt

Installed from the vehicle

interior

Remove lower B-pillar trim

Repair Manual, Body Interior, Repair

Group 70, Trim panels/insulation; Pillar

and side trim

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Guide bolt

10 Nm

Nut

Always replace bolts after

loosening

For the eccentric pin, must

not be loosened. Used for

making adjustments during

production.

Door hinge

Rear door

Page 9 / 44

Hinge is no longer

manufactured as separated

parts.

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Socket head bolt

20 Nm + 1 / 4 turn further (90

)

Always replace bolts after

loosening

Door, removing and installing

Note:

Removing and installing is described only for the

right door. Removing and installing the left door is

derived accordingly from this.

Removing

Rear door

- Release boots - 6 - by pressing on

locking mechanism - arrow a - and

remove boots from B-pillar.

- Swivel locking lever - 7 - downward arrow b - and disconnect electrical

harness connector - 8 - from connector

station.

- Remove screws - 4, 5 and 11 - using

door adjustment wrench 3320 and bit

insert 3320/3 from hinge.

- Pull door in - direction of arrow - from

guide bolts - 3 and 9 - .

Installing

Installation is performed in the reverse order of removal.

- Tightening torque: Screws - 4, 5 and 11 - : 20 Nm + 1 / 4

Page 10 / 44

Rear door

(90

) additional turn

Screws - 4, 5 and 11 - must always be replaced.

- Observe gap dimension of rear door

Repair Manual, Body Collision Repair, Repair Group 00,

Technical data; Body gap dimensions

Door, adjusting

Caution!

The nut for eccentric pin - 9 - must

not be loosened under any

circumstances. It cannot be secured

again using workshop equipment.

Note :

Page 11 / 44

Rear door

The door is properly adjusted when there is an

overall even gap dimension when closed, it is not too

far inward or outward and contours align.

Vehicle must stand on its wheels in order to be able

to perform the adjustment.

If outer door plate is removed, window frame of inner

door part must be adjusted in relation to roof frame

and C-pillar, and front door.

- Observe gap dimension of rear door

Repair Manual, Body Collision Repair,

Repair Group 00, Technical data; Body

gap dimensions

To adjust the gap dimension correctly

screws - 5, 7, 12 and 13 - must be

loosened. For screw - 5 - , lower B-pillar

trim must be removed

Repair Manual, Body Interior, Repair

Group 70, Pillar and side trim

.

Other measures, such as aligning the

door upward, are not effective. Excess

pressure thereafter will again cause the

door to sag.

For correct alignment adjustment, screws

- 4, 6 and 14 - and guide screws - 2 and

8 - must be loosened.

Door adjusting wrench 3320 with bit

insert 3320/3 must be used for this.

Outer door plate, removing and installing

Removing

Page 12 / 44

Rear door

- Pry off clips - 3 - beginning at bottom

of door - 1 - and remove rear cover - 2 .

- Pry off clips - 5 - beginning at bottom

of door - 1 - and remove rear cover - 4 .

Page 13 / 44

Rear door

Page 14 / 44

- Removing lock cylinder housing:

removing and installing .

- Remove door handle

installing

57-1, Housing,

57-1, Door handle, removing and

- Remove screw - 1 - from bearing bracket - 2 - , located

behind outer door plate.

Rear door

- Remove all screws - 2, 3 and 4 - .

- Carefully remove outer door plate.

Installing

Caution!

Various bolts are used to secure the outer door plate.

Outer door plate is damaged if not allocated correctly.

Page 15 / 44

Rear door

Page 16 / 44

- Carefully set outer door plate in.

- Start all screws - 2, 3, 4 - .

Make sure that the various bolts

are used correctly.

Characteristic for bolt - 2 - : Bolt has point and

thinner washer.

Characteristic for bolt - 3 - : Bolt without point but

with thick washer.

Characteristic for bolt - 4 - : Bolt has point and thick

washer

- Check whether guide pins for retaining

tracks are located in the corresponding

guide holes of inner door part. Then

Rear door

tighten all screws - 2, 3, 4 - .