Slogan K3

Diunggah oleh

temter0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

345 tayangan5 halamanRisk assessment and management aims to minimize risks to an organization's assets through identifying potential hazards, evaluating risks, and implementing risk control strategies. There are various methods of risk control including avoidance, retention, transfer, and reduction. In occupational health and safety, risk is defined as a measure of the probability and potential severity of an incident. Common hazards include electrical, fire, machinery, and toxic substances. Risk assessment involves identifying hazards, evaluating risks, and implementing controls to reduce or mitigate risks. The findings should be recorded and reviewed periodically or when changes occur.

Deskripsi Asli:

slogan K3 yang inspiratif

Hak Cipta

© © All Rights Reserved

Format Tersedia

DOCX, PDF, TXT atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniRisk assessment and management aims to minimize risks to an organization's assets through identifying potential hazards, evaluating risks, and implementing risk control strategies. There are various methods of risk control including avoidance, retention, transfer, and reduction. In occupational health and safety, risk is defined as a measure of the probability and potential severity of an incident. Common hazards include electrical, fire, machinery, and toxic substances. Risk assessment involves identifying hazards, evaluating risks, and implementing controls to reduce or mitigate risks. The findings should be recorded and reviewed periodically or when changes occur.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

0 penilaian0% menganggap dokumen ini bermanfaat (0 suara)

345 tayangan5 halamanSlogan K3

Diunggah oleh

temterRisk assessment and management aims to minimize risks to an organization's assets through identifying potential hazards, evaluating risks, and implementing risk control strategies. There are various methods of risk control including avoidance, retention, transfer, and reduction. In occupational health and safety, risk is defined as a measure of the probability and potential severity of an incident. Common hazards include electrical, fire, machinery, and toxic substances. Risk assessment involves identifying hazards, evaluating risks, and implementing controls to reduce or mitigate risks. The findings should be recorded and reviewed periodically or when changes occur.

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai DOCX, PDF, TXT atau baca online dari Scribd

Anda di halaman 1dari 5

1.

Risk Assessment in Occupational Health & Safety

Dr.WessamAtif 1 Dr. Wessam Atif

2. Risk Management Risk management is a business

process that aims to minimize or eradicate risks by

maximizing the protection of the assets of the organization

in the most cost effective manner. It covers wider range

than Risk Assessment i.e. risk assessment falls under one of

the risk management strategies which is Risk Reduction.

There are three main aspects to the role of risk

management: 1. Considering the risks inherent in a business

2. Devising strategies to minimize or control these risks 3.

Integrating these risk control strategies into the business

framework of the company. Dr.WessamAtif 2

3. Risk control strategies

n Risk Avoidance. n Risk

Retention. n Risk Transfer. n Risk Reduction.

Dr.WessamAtif 3

4. Risk In the context of HSE, risk is defined as a measure of

the probability for an incident to happen and of the potential

severity of the consequences. [BS OHSAS 18001:2007]

Dr.WessamAtif 4 Severity Probability

5. What is Hazard? Hazard Any object, physical

condition, or physical effect which has the potential to cause

harm. Hazard Categories may include but are not limited

to: Dr.WessamAtif 5 o Land Transport o Air Transport o

Water Transport o Electrical o Fire/Flammable o

Temperature o Explosives o Radiation o Pressure

Potential Energy (stepping, handling.. etc.)

Machinery/Equipment/Hand Tools

Toxic/Corrosive/Hazardous Substances Nuisance/Noise

Vibration Drugs/Alcohol Natural Phenomena Human

(security, crime) Biological Hazard/Illness

6. Incident: Work related event(s) in which an injury

or ill health (regardless of severity) or fatality

occurred, or could have occurred Note 1: An

accident is an incident, which has given rise to injury,

ill health or fatality.

Note 2: An incident where no

injury, ill health, or fatality occurs may also be

referred to as a near-miss, near-hit, close call

or dangerous occurrence. Note 3: An emergency

situaFon is a parFcular type of incident. Dr.WessamAtif

6

7. Dr.WessamAtif 7 5 simple steps for Risk Assessment:

Hierarchy of Control measures for removing or reducing a

hazard: 1. Look for the hazard 2. Decide WHO might be

harmed and how 3. Evaluate / Estimate the RISK and decide

whether existing precautions are adequate or more action

should be done 4. Record your findings 5. Review your

assessment and revise it if necessary

8. Who should do Risk Assessment? Team with experience

and training in hazard identification and risk assessment.

Knowledge of the process or activity. Good communication

and reporting skills. Ability to interpret legislation and

guidance. Attention to detail. Managerial influence to

implement change. Dr.WessamAtif 8

9. How to look for hazards? Task observation. Accident,

ill health or near miss data. Workplace inspections. Job

safety analysis. Legal standards. Guidance; ILO, OSHA,

ISO, HSE ..etc. Consultation. Dr.WessamAtif 9

10. Whom might get harmed? Employees. Maintenance

workers. Cleaners. Contractors. Visitors. Public.

Vulnerable groups (young, inexperienced, pregnant, disabled

.. Etc). Dr.WessamAtif 10

11. Risk evaluation Matrix A] Probability or Likelihood of

Harm Occurring Highly Unlikely1 Reasonably Likely2 Even

Chance3 Highly Likely4 Almost Certain5 Dr. Wessam Atif 11

12. Risk evaluation Matrix B] Consequences or Severity of

Harm Minor Injury: Cuts and abrasions, minor skin or eye

irritations, etc. 1 Injury requiring first aid: Any injury that

requires first aid.2 Injury or industrial disease requiring

medical treatment: Deep wounds, fractures, scalds, burns,

eye injuries, respiratory infections, temporary blindness or

hearing loss, etc. 3 Serious injury or long term medical

effects (industrial disease): Loss of fingers, toes, damage to

eyes, serious medical effects. 4 Major Injury or Fatality: Loss

of limbs, sight, hearing, long term illness or death. 5 12

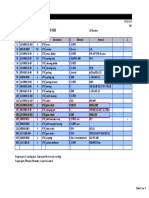

13. Table of Risk Rating 13

14. Dr.WessamAtif 14 Elimination: completely removing

the hazard Substitution: with a less hazardous substance

Engineering controls, design and Isolation Administrative

controls; Job rotation, Instructions and Supervision, safe

system of work, etc. General tidiness and good

housekeeping Supplying personal protective equipment

www.hse.gov.uk Hierarchy of Control measures for removing

or reducing a hazard:

--------------------------------------------------------------------

15. Potential Risk: The original risk with no control

measures in place or with inadequate existing controls.

Dr.WessamAtif 15 Residual Risk: The remaining risk after all

adequate, actual and planned control measures. Prevention

controls: Proactive control measures which help prevent

accidents before happening. Mitigation controls: Control

measures which help in reducing the severity &

consequences of accidents after occurrence.

16. Blank Risk Assessment sheet Dr.WessamAtif 16

17. Why record it? Accident Investigation. Future

reference. Audits and training purposes. Duty of care /

Legal requirements.

-------------------------------------------------------------- Dr.WessamAtif

17 When to review it? n In cases of accidents. n

Periodically. n Change in legal requirements. n After

Audits. n New Activities / equipment / personnel. n New

info available / New technologies.

18. RA has to be Suitable & Sufficient All aspects of

work activity to be reviewed. Routine and Non Routine

operations. Identify significant hazards and risks.

Evaluate the risks. Identify control measures in place and

planned / prevention and mitigation. Take account of risks

to public. Ensure the risk assessment is valid for a

reasonable time. Dr.WessamAtif 18

19. Special cases for a risk assessment! Pregnant / Nursing

mothers Young workers Disabled employees To be

discussed with participants as a group activity

Dr.WessamAtif 19

20. References ILO 2001 ILO-OSH: Guidelines on

Occupational Safety and Health Management Systems. BS

OHSAS 18001:2007 Occupational Health & Safety

Assessment Series. OHSAS 18002 : Guidelines for the

implementation of OHSAS 18001. HSE 2003 HSG 65:

Successful Health & Safety Management. HSE 1994 INDG

163: Five Steps to Risk Assessment. The Egyptian Law of

Labor. www.hse.gov.uk Dr.WessamAtif 20

Top 10 Industrial Safety Slogans Success will always be with

you, as long as you place safety as the first priority.

3. Top 10 Industrial Safety SlogansSafety does not come

instantly, you should implement it consistently.

4. Top 10 Industrial Safety Slogans Say no to carelessness!

5. Top 10 Industrial Safety Slogans A safety message could

safe thousands of life.

6. Top 10 Industrial Safety Slogans Talk less, do your job

safely.

7. Top 10 Industrial Safety Slogans One minute safety talk

can prevent you from injury and death.

8. Top 10 Industrial Safety Slogans Dont neglect an unsafe

condition. It may destroy you a second later.

9. Top 10 Industrial Safety SlogansSafety and productivity

can not be separated. So keep them together.

10. Top 10 Industrial Safety Slogans Safety is endless. Safety

is an ongoing process.

11. Top 10 Industrial Safety Slogans You are a step away

from accident, if you work without safety permit.

Anda mungkin juga menyukai

- HSG65 Managing for Health and Safety: A revised edition of one of HSE's most popular guidesDari EverandHSG65 Managing for Health and Safety: A revised edition of one of HSE's most popular guidesPenilaian: 5 dari 5 bintang5/5 (2)

- Where do I start? 10 Health and Safety Solutions: A Workbook for Busy Managers, Supervisors & Business OwnersDari EverandWhere do I start? 10 Health and Safety Solutions: A Workbook for Busy Managers, Supervisors & Business OwnersBelum ada peringkat

- HWM Question BankDokumen44 halamanHWM Question BankroshanBelum ada peringkat

- Generic Risk Assessment TemplateDokumen16 halamanGeneric Risk Assessment TemplateAjith Nair100% (1)

- Risk Management ModuleDokumen24 halamanRisk Management ModuleMelwin PaulBelum ada peringkat

- Health and Safety Risk Assessments PDFDokumen15 halamanHealth and Safety Risk Assessments PDFAjesh mohan100% (1)

- Risk Assessment ProcedureDokumen8 halamanRisk Assessment ProceduretemterBelum ada peringkat

- OHS Management SystemDokumen33 halamanOHS Management SystemZainorin Ali100% (1)

- Tutorial 4Dokumen40 halamanTutorial 4Isuru chandradasaBelum ada peringkat

- Principles of Prevention and ControlDokumen6 halamanPrinciples of Prevention and ControlArcher ArtilleryBelum ada peringkat

- Module 7Dokumen69 halamanModule 7Annalie Orquesta RosalejosBelum ada peringkat

- Chemical Risk Assessment PDFDokumen8 halamanChemical Risk Assessment PDFS.h. RippendeepBelum ada peringkat

- BSBWHS401 Implement and Monitor WHS Policies, Procedures and Programs To Meet Legislative Requirements (Assessment 1 - 4)Dokumen19 halamanBSBWHS401 Implement and Monitor WHS Policies, Procedures and Programs To Meet Legislative Requirements (Assessment 1 - 4)annwong85Belum ada peringkat

- A General Outline of Department:: Understand The Precautionally Measures Taken During Operation of Different MachineDokumen5 halamanA General Outline of Department:: Understand The Precautionally Measures Taken During Operation of Different MachineTanvi ZakardeBelum ada peringkat

- OHS Management SystemDokumen33 halamanOHS Management Systems_pamungkasBelum ada peringkat

- ISO 45001 Standard - Occupational Health and Safety Management SystemDokumen17 halamanISO 45001 Standard - Occupational Health and Safety Management SystemFahruddin RahmatBelum ada peringkat

- Construction & Maintenance Inspection Checklist - General: 1.1 Principles of A Workplace InspectionDokumen50 halamanConstruction & Maintenance Inspection Checklist - General: 1.1 Principles of A Workplace InspectionSajeewa LakmalBelum ada peringkat

- Principles of Control & PreventionDokumen26 halamanPrinciples of Control & PreventionArcher ArtilleryBelum ada peringkat

- MODULE 2 - Chap 9 Fundamental Principles of RMDokumen35 halamanMODULE 2 - Chap 9 Fundamental Principles of RMngemanonjabulo02Belum ada peringkat

- Managing The Manual Handling RiskDokumen24 halamanManaging The Manual Handling RisksayedmhBelum ada peringkat

- First Aid in WorkplaceDokumen21 halamanFirst Aid in WorkplaceMiroBelum ada peringkat

- Risk AssessmentDokumen82 halamanRisk AssessmentsweetpeaBelum ada peringkat

- Keselamatan & Pengurusan Bengkel SHPE 1033: Introduction To The CourseDokumen15 halamanKeselamatan & Pengurusan Bengkel SHPE 1033: Introduction To The CourseNava Mathi SelvanBelum ada peringkat

- Hazard Identification, Risk Assessment and Control ProcedureDokumen12 halamanHazard Identification, Risk Assessment and Control Procedurevignesh_selvam84Belum ada peringkat

- Hirac 2022Dokumen50 halamanHirac 2022jonnelBelum ada peringkat

- AIS Risk Management and Risk AssessmentDokumen6 halamanAIS Risk Management and Risk AssessmentavsecBelum ada peringkat

- Risk Assessment DocumentDokumen10 halamanRisk Assessment DocumentSukanta BrahmaBelum ada peringkat

- Prelim Cecosh CompileDokumen104 halamanPrelim Cecosh CompilezailajendaleBelum ada peringkat

- Hazard Assessment Program PDFDokumen10 halamanHazard Assessment Program PDFHassan AliBelum ada peringkat

- RICS Surveying Safely Red Cover - HseDokumen16 halamanRICS Surveying Safely Red Cover - HseyohanjBelum ada peringkat

- Overview of Safety ManagementDokumen12 halamanOverview of Safety ManagementLester GarciaBelum ada peringkat

- 559 Bamber StevensDokumen6 halaman559 Bamber StevensWaqas Ahmad KhanBelum ada peringkat

- Risk Management: A Guide To Workplace Safety and Health RegulationsDokumen10 halamanRisk Management: A Guide To Workplace Safety and Health RegulationsGerald100% (2)

- Guideto Risk MGT Regver 20Dokumen10 halamanGuideto Risk MGT Regver 20Bharat MaddulaBelum ada peringkat

- Safety ConceptsDokumen8 halamanSafety ConceptsRishab RajBelum ada peringkat

- Risk Assessment Guidelines - 9cb0Dokumen11 halamanRisk Assessment Guidelines - 9cb0andaminiBelum ada peringkat

- Report 2.safety and HealthDokumen26 halamanReport 2.safety and HealthJoseph Nathan Marquez100% (1)

- Sheet 1Dokumen5 halamanSheet 1moazsrourdBelum ada peringkat

- WHS Presentation - Ivan LisdiyanaDokumen15 halamanWHS Presentation - Ivan LisdiyanaIvan LisdiyanaBelum ada peringkat

- What Is Risk AssessmentDokumen8 halamanWhat Is Risk AssessmenttatonyBelum ada peringkat

- Risk AssessmentDokumen11 halamanRisk AssessmentSanil Kuriakose100% (1)

- Osh Programming: Marnie AlfarDokumen35 halamanOsh Programming: Marnie AlfarAviects Avie JaroBelum ada peringkat

- WS Counter Measures, Control Options andDokumen13 halamanWS Counter Measures, Control Options andJulia AbalosBelum ada peringkat

- Introduction To Occupational Safety and Health ManagementDokumen18 halamanIntroduction To Occupational Safety and Health ManagementJkBelum ada peringkat

- BDA AdvicesheetDokumen16 halamanBDA AdvicesheetMallika RastogiBelum ada peringkat

- Institute of Technology Division of Civil Eng. Safety and Environment Protection Management BDC 323 2 CRHDokumen81 halamanInstitute of Technology Division of Civil Eng. Safety and Environment Protection Management BDC 323 2 CRHKinfe Dufera Gonfa100% (1)

- Controlling OHS Hazards and RisksDokumen22 halamanControlling OHS Hazards and RisksMinnie ALBelum ada peringkat

- Supervision Mandos in HC Discussion GuideDokumen16 halamanSupervision Mandos in HC Discussion Guideflojanas3858Belum ada peringkat

- CH 1Dokumen30 halamanCH 1bawanlavaBelum ada peringkat

- WEEK-1 SafetyDokumen32 halamanWEEK-1 SafetyRegina Jazzmim QuezadaBelum ada peringkat

- What Is Health and Safety?Dokumen37 halamanWhat Is Health and Safety?Bilal MuhammedBelum ada peringkat

- General Risk Assessment Form - NotesDokumen3 halamanGeneral Risk Assessment Form - NotesIbrahim KhleifatBelum ada peringkat

- Lecture 6Dokumen16 halamanLecture 6Shaira Eiram ZayasBelum ada peringkat

- Topic Six: Health Assessment & SurveillanceDokumen29 halamanTopic Six: Health Assessment & Surveillancesrkam100% (1)

- The Hierarchy of Hazard Controls Is A List Which Emphasises Controlling A Hazard at The SourceDokumen25 halamanThe Hierarchy of Hazard Controls Is A List Which Emphasises Controlling A Hazard at The SourceMohinderSingh100% (1)

- CH 12 Promoting Safety and HealthDokumen34 halamanCH 12 Promoting Safety and HealthRifka FitrianaBelum ada peringkat

- The Construction Safety Guide: Injury and Illness Prevention through DesignDari EverandThe Construction Safety Guide: Injury and Illness Prevention through DesignPenilaian: 4 dari 5 bintang4/5 (6)

- Workplace Security Playbook: The New Manager's Guide to Security RiskDari EverandWorkplace Security Playbook: The New Manager's Guide to Security RiskBelum ada peringkat

- CON-kriteria Audit ISO14001Dokumen10 halamanCON-kriteria Audit ISO14001temterBelum ada peringkat

- All Accident Are IncidentDokumen6 halamanAll Accident Are IncidenttemterBelum ada peringkat

- Scaff CheckDokumen4 halamanScaff ChecktemterBelum ada peringkat

- Pere Gang AnDokumen2 halamanPere Gang AntemterBelum ada peringkat

- Game ChartDokumen2 halamanGame CharttemterBelum ada peringkat

- Tabel RulaDokumen4 halamanTabel RulatemterBelum ada peringkat

- SOP Scaffold AustralianDokumen3 halamanSOP Scaffold Australiantemter100% (2)

- Labo SafeDokumen36 halamanLabo SafetemterBelum ada peringkat

- Electric Shock Can Kill YouDokumen6 halamanElectric Shock Can Kill YoutemterBelum ada peringkat

- Kartu Medical Check UpDokumen113 halamanKartu Medical Check UptemterBelum ada peringkat

- Thermal Comfort and The Heat Stress IndicesDokumen11 halamanThermal Comfort and The Heat Stress IndicestemterBelum ada peringkat

- 5S Game: Round One: Circle The Numbers 1Dokumen6 halaman5S Game: Round One: Circle The Numbers 1temterBelum ada peringkat

- Visi Misi DK3NDokumen21 halamanVisi Misi DK3NtemterBelum ada peringkat

- Form IBPRDokumen5 halamanForm IBPRtemterBelum ada peringkat

- R123 PDFDokumen7 halamanR123 PDFtemterBelum ada peringkat

- Noise Reduction Rating (NRR) : Theresa Y. Schulz, PHD, Ltcol, Usaf (Ret.)Dokumen18 halamanNoise Reduction Rating (NRR) : Theresa Y. Schulz, PHD, Ltcol, Usaf (Ret.)temterBelum ada peringkat

- Alat Pelindung DiriDokumen345 halamanAlat Pelindung Diritemter100% (1)

- Msds ABC PowderDokumen5 halamanMsds ABC PowdertemterBelum ada peringkat

- Section III, Chapter 5Dokumen6 halamanSection III, Chapter 5temterBelum ada peringkat

- Job Safety Analysis and Risk Assessment Form: HSE-FF-A.1Dokumen4 halamanJob Safety Analysis and Risk Assessment Form: HSE-FF-A.1temterBelum ada peringkat

- HIRAC Work at Height FedUniDokumen7 halamanHIRAC Work at Height FedUnitemter100% (1)

- HIRAC Work at Height FedUniDokumen7 halamanHIRAC Work at Height FedUnitemter100% (1)

- Hazard Identification at A Major Hazard Facility: Guidance NoteDokumen25 halamanHazard Identification at A Major Hazard Facility: Guidance NotetemterBelum ada peringkat

- Muharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFDokumen154 halamanMuharem Bazdulj - The Second Book (Writings From An Unbound Europe) - Northwestern University Press (2005) PDFjeff tehBelum ada peringkat

- Etl 213-1208.10 enDokumen1 halamanEtl 213-1208.10 enhossamBelum ada peringkat

- Veg Dum Biryani - Hyderabadi Veg Biryani Recipe - Hyderabadi Biryani - Hebbar's KitchenDokumen2 halamanVeg Dum Biryani - Hyderabadi Veg Biryani Recipe - Hyderabadi Biryani - Hebbar's KitchenmusicalcarpetBelum ada peringkat

- 02-09-18 SR - IZ Jee-Adv 2011-P1 PTA-03 Q PDFDokumen31 halaman02-09-18 SR - IZ Jee-Adv 2011-P1 PTA-03 Q PDFswarupBelum ada peringkat

- Types of WinesDokumen91 halamanTypes of Winesrajanrld19880% (1)

- Quality Traits in Cultivated Mushrooms and Consumer AcceptabilityDokumen40 halamanQuality Traits in Cultivated Mushrooms and Consumer AcceptabilityShivendra SinghBelum ada peringkat

- Mathematics 7 LAS Quarter 3Dokumen97 halamanMathematics 7 LAS Quarter 3Villamor Baculi82% (17)

- BMS of Dubai International AirportDokumen4 halamanBMS of Dubai International AirportJomari Carl Rafal MansuetoBelum ada peringkat

- WPCE Wireline Lubricator With Threaded Unions PDFDokumen1 halamanWPCE Wireline Lubricator With Threaded Unions PDFDidik safdaliBelum ada peringkat

- Bomber JacketDokumen3 halamanBomber JacketLaura Carrascosa FusterBelum ada peringkat

- NREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFDokumen35 halamanNREL Novel Electrolyzer Applications Providing More Than Just Hydrogen PDFJosePPMolinaBelum ada peringkat

- Practical Considerations in Modeling: Physical Interactions Taking Place Within A BodyDokumen35 halamanPractical Considerations in Modeling: Physical Interactions Taking Place Within A BodyFábio1 GamaBelum ada peringkat

- Mono 108Dokumen438 halamanMono 108pasaricaBelum ada peringkat

- Presentation 1Dokumen7 halamanPresentation 1Abdillah StrhanBelum ada peringkat

- Temposonics: Absolute, Non-Contact Position SensorsDokumen23 halamanTemposonics: Absolute, Non-Contact Position Sensorssorangel_123Belum ada peringkat

- Practical 3.1 Determining The Specific Heat CapacityDokumen3 halamanPractical 3.1 Determining The Specific Heat CapacityiAlex11Belum ada peringkat

- Nema MG10 PDFDokumen27 halamanNema MG10 PDFManuel Antonio Santos VargasBelum ada peringkat

- Lec22 Mod 5-1 Copper New TechniquesDokumen24 halamanLec22 Mod 5-1 Copper New TechniquesAaila AkhterBelum ada peringkat

- Chapter 01Dokumen16 halamanChapter 01deepak_baidBelum ada peringkat

- List ToolingDokumen10 halamanList Toolingyohanes adi saputroBelum ada peringkat

- Foldable HelmetDokumen16 halamanFoldable Helmetharsha kotewarBelum ada peringkat

- Pantalla Anterior Bienvenido: Cr080vbesDokumen3 halamanPantalla Anterior Bienvenido: Cr080vbesJuan Pablo Virreyra TriguerosBelum ada peringkat

- Exploded View & Parts Listing Air Operated Double Diaphragm PumpDokumen2 halamanExploded View & Parts Listing Air Operated Double Diaphragm PumpCarlos AvalosBelum ada peringkat

- Need For Advanced Suspension SystemsDokumen10 halamanNeed For Advanced Suspension SystemsIQPC GmbHBelum ada peringkat

- Introduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesDokumen65 halamanIntroduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesLance AustriaBelum ada peringkat

- EU - Guidance On GMP For Food Contact Plastic Materials and Articles (60p)Dokumen60 halamanEU - Guidance On GMP For Food Contact Plastic Materials and Articles (60p)Kram NawkBelum ada peringkat

- English 3 Avicenna Graded Test 1Dokumen11 halamanEnglish 3 Avicenna Graded Test 1Mohd FarisBelum ada peringkat

- Logarithmic Functions Week 7Dokumen20 halamanLogarithmic Functions Week 7gadraBelum ada peringkat

- 1.1 Introduction To KennametalDokumen40 halaman1.1 Introduction To KennametalVig PankajBelum ada peringkat

- Manual de Electronica HardbookDokumen970 halamanManual de Electronica HardbookninoferBelum ada peringkat