Approved WPS& PQR For P91

Diunggah oleh

saktheeswaran100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

1K tayangan8 halamanWPS & PQR for SA335P91

Judul Asli

Approved WPS& PQR for P91

Hak Cipta

© © All Rights Reserved

Format Tersedia

PDF atau baca online dari Scribd

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniWPS & PQR for SA335P91

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

100%(2)100% menganggap dokumen ini bermanfaat (2 suara)

1K tayangan8 halamanApproved WPS& PQR For P91

Diunggah oleh

saktheeswaranWPS & PQR for SA335P91

Hak Cipta:

© All Rights Reserved

Format Tersedia

Unduh sebagai PDF atau baca online dari Scribd

Anda di halaman 1dari 8

we

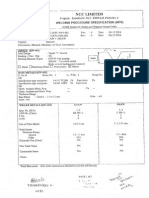

=PETRON | PROCEDURE Quauiricarion recoros (par) _| [NIC OC -

2X660MW NCC POWER PROJECT NCC

Anaothavarm,Varahavipul parehsya, TP Gudur Mandal, SPSR Nellore Distr, AP

Infra

‘GW-483 PROCEDURE QUALIFICATION RECORDS POR)

(See 200.2, Section i, ASME Boller and Pressure Vessel Code)

Record Actual Variables Used to Weld Test Coupon

Company Name:PETRON ENGINEERING CONSTRUCTION LTD,

procedure qualfiation Record No.PECL/NCCL/PCR-AS ate:26.9.18

Ps no:PECYINCCL/WPS-15

cing Processfes):STAvE=sMAW

Hype (Manual, Automat, Semi-Automatic: MANUAL

ows caw-so2) :

: TEES

was 324 mm “60mm

xaos |

6 t 3

t smn

ile

‘ Sab ee

Groove Designo Test Coupon

(For comtnation qualifications, the epost weld metal hikes shal be recorded for ech ler metal an proces used)

ase wa --TREATENT

seri Specs 335 p91 osing / Soaking TemperatreRange.70°C0°C

verre, oc UNS Hamar 335.6983 Holsing / Soaking Time 270 mint

pvo.ase Group Not toPNosst Group Noa. istecrentne 5c

trices frst coupon mm iets oF cooing 75°C

Dimer of Test Coupon 324.

imo Pes Thickness es than 3 mm

oiner wa

nen ras rawa0a a Ta leasiaw.

se spectecon Sas 20 355 Cones [PeemCompostion| =.=

as siento e0s.29 018-39 Mice

ites meal no Gi 7 Gieking [argon | s9.9% | aa

wou ett Analisis No 5 5 rating [na im we

seo iter tata 73mm 35, imd sacking | rgon | Sass aa

ies sea mrodc Form Tou rm Jtherna

venereal Filer Meta a a

erode Fx castetion ws Na chaRacrEnis

xr m7 7 Jearentoc

rade ame m7 a otsrerocens ocer

ves eta hckness a5 8 mp. Refer Table. o2 Vos Refer Table.ot

a a Junasten lectode Sie2AOmm|Giametr and

ower ewth-2 th 2) THO: 3.7%02.21

poston awa ode of Metal Trastr for GMAW FCAW:NA

Peston o Grove: 36 Heat nua

ves Progression (Ui, cownnin Loa thera

otharsa a

rave! Sped mmmin js Raer Table

sin or Weave Sed:both string & weave

osesieariowe2oa)

cheat ermperatr:“220 Minas or ingle Pas (Pe Sie): Mule pss

eras temperature 300% Linsle o Muto eectrdesSnle

ost Heating 20-200 for ous lomerva

Page tof2

Nhe wordy

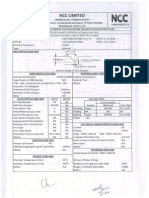

(ave48s (conTINUE)

PR No-PECYNCcL/PaR-44

as, coilfor both ELECTRICAL CHARACTERISTICS (QW.409) and TECHNIQUE (QW-410

Filer Metr Caren

ats |rawsere_ovete. eras, Comment

weld cssteaion [oiomtrer |PE2"4 | AMS | nang) lamin | we Aoi, Tames ees Teh

pits ieee Polaty | range) fae vey

noor_| raw | enoose2 [25 | ocen | soso | iea7 | 50-70 NA

wor pass | swaw | esmis-e9 [25 | ocep | eo-ao | ae22 | 5070 rr

sidpass | sMAW | 901589 | 32 | ocer | soaa0| aoe [5575 3

mPa ET saw | ease | «| acer | 00x50] 222 | sooo Wa

“Tense Test (QW-150)

Spesmen ] width [Thickness | Aree | UlimateTotalLoad | _Uimate Tenile | WeldSwess wm] Elongation over GLa] Type ofFalure and

No. _| damm | diam | damme | “inn stress (in MP3) Mos) Som (in) Location

n [wa [so | ume 782 e826 ss2869 3a polaaaeree

ee 77 ws.m7 , 515.157 36 Meee

Suldesend est (Q-160)

[ez “ype and Specimen res

(SceBenaisax 7 Tube Opening ane

(See Benasa2 Seton

(Sie Benase3 Stacy

(See Benaisar Suan

FAcional wo side Bends 385 8586 were done & ound Satara

Toughness Tests (QW.170

soxcmen | naen | Spsnen J, 78 eed as Crap wee ek

No. | Location | size tue | bors | shear | Mis(in) oun

wa [wane ma

[comnts resus were found satisfactory

‘le. Wald Tet (QW.0).

rose — satisfactory (Yes/No): NA enetion ito Farent Metal Yes/No} NA

sero — Resuts: NA

ordnes Test Satisfactory Conducted at OMEGA INSPECTION 8 ANALYTICAL LABORATORY, Re. Report No-09/279e Date 26Sep 2018)

pepostAnays:na

Jotnenna ;

ise’ Name-SHRIOEVENDERSINGH & SHR CHHOTE AL SINGH Welder No-Pw.t2—a6 stampa.

[ess Concuctesby:PETRON ENGINEERING CONSTRUCTION LTD. _Laboretory NAMIE-OMEGA INSPECTION & ANALYTICAL LABORATORY

Laboratory Report Ne-OIAL/2014/09-279 dated 26/Sep/2024

erty thatthe statements in thi recor are corect and that he test welds were prepare, welded, and tested in accordance withthe

reavirements of Section ofthe ASME Baier and Pressure Vesa ode,

Jorcanisation PETRON ENGINEERING CONSTRUGTION [0. NocEPG, NCCPPL

Signature he X ig s oh Re

Namo Ame Ko- iste)

Dato 26-214

PREPARED ewe BY “APPROVED oY

Page 20f2

Pl UI Tal

“PETRON WELDING PROCEDURE sPEciFICATIONS (wes) | IN CL

£ 2X660MW NCC POWER PROJECT NCC

frotremoruateoemaan rcrrwanaoitnnowisr | A

“QW-482 WELDING PROCEDURE SPECIFICATIONS [WPS]

(ee QW.200 4, Scion ASME Dole and Pressure Vessel Cod)

|conary Name : BETRON ENGINEERING CONSTRUCTION 7,

we'singFrocecureSpecction No:PECLINCCL/C-937/WPS-15 Rev ODate 2659.14

svpporting POR Wo s}PECYNCCYPOR-S Oate26 9.14

eng Procenstes)grawasnaaw Typetel Manus

[Auteravc Mania Mechine, orSemi-Automate)

promis tawsa. Den

AS PER SEETOH "I prove weld"

fico Spacing:3 to ammm i SA335 Gr. POT

Jescking: No For RotyesFor oer pases)

backing Mater Type: Eorather than root ass

eter to both bacing and etna)

rete .

frenetic a

ronan eta o

lotner 5

080m

ssches Production Drawings, Weld Simba of Wien Descriton 1

prouishow te panel arrangement ofthe pars to be welded. Where

poptcabe, the cetais of weld groove maybe spec.

ate ooton ofthe menufcture, sketches may be attached tlstate

foi cesien, wots tyes, and boas sequence eg, for natch toughness

J-ocedures, for multiple proces procedures, te

Faase merats Tawa]

pvo:ase ‘Group Nos, te Po. 156 Group No:

Specincation anétype/erade or uns Number'S-335 GRADE POL

J: Seecication ae tpe/grace or UNS NumbersA-338 GRADE P91

Jone Anaysis and Maen. Prop NA

to chem. anys and Mech rapt

cena Range:

ease Meta (roove'5 mm 0200p ier ALL

Kim Pass hikness 1/2 in [£3 mes

Jornerna

JFCLER METALS TQW-AOHY 7 craw Sa

spect. 58) ASE SASS

Jaws No. (ls) ERO0S-09 3015.09

Fs, i a

vo, 5 5

sic oF ite Metal 5 Nomsnal amar 552, ind

iter etal Product Form SUD MA

Isvolementl Fier Metal NA Wa

fc eta

rricaness ange:

loroove 2mm 20000

er AL AL

eectrode Fux Cass) Na Na

rss Type Na NA

Fux rade Name Na Na

[consumable neee Na NA

former Na Ne

each base meta filer meta combination should ba recorded ain@ualy

wigue

perk

“=PETRON WELDING PROCEDURE SPECIFICATIONS (WPS| NCC

megs 2X660MW NCC POWER PROJECT NCC

Anta, vr puchyet PG Mar SS ere AP Ley

“WPS NO.PECL/NCCL/C-937/WPS-15 Rev. 0 Date :26.9.14 QW-482 (page2 of 2)

JosToNsranaen STEAD EAT TREATMENT LOW

of Groove: LL sing epee ae, 7051

ee ws ae

eres os f17 T<100nm & 6 hs fr exe ston neh (25

Jr ove i. 100 mn) wheres Weis ln Nona

epee ‘ foe oeaing vaca nate fcooleg Max 10°C for Tesomim .7Cfo sos Te

bs usec tore 75am

frenearamoa Joinerna

PretestTenpeature Minimum 20° easiaw am

Joep Termes, Macon: 350% cay PERSERLCOMBOIROD Fate

retest MemtenarceContnenst-720C Min), Se) ieee |

rs: Heating Ater completion of welding ite the wedng area coli to 100s Ves Esa eee aati

Js cep het dy Moin “20-100 ford HourforeS0mm & 2Hour for Toni

bn stan pw neat, hang | a Na wa

sacking | “Ron sae SO

{contnvou or paca esting, where aplbl shuld be ecard) forecua

ccrncacranacTERSTCs a3)

= Filer et Taree ett | een | vous [oven] Gere: emote commerce

wei | rece [ccsncauoe [poner | Weert | Amp | smcl | rove” | VO, [ney] ssa eiqunnecar Toot mg

Past) lcseteaton fo Pec | cones | tov | wary | ee | "ra ‘el

Toor | craw | eames [75] — een — [res 726 | ana

eri shaw | eases [2s] —ocer [sir 1526 | ai

sans [SHAW | eoiea [32 | 9ck [ea irae | ae

wooone| samw | esses | 4 | ocer | asare wa | es

fps nao or gower or eary an, sul be recorded ores erode, paNon, an THCE a

ting curen Hest ng x)

ferstenttecrode ee and ype:240mmDameter an EWTh-2 (WT 20} (THs 1.78022)

(Pure Tunsten, 2% Torts ee)

voce o ert rarer or cma reams

(Srey, Stor resting, te)

fecawaue Tana

[sine or Weare tecoTaWsnge& SMAI sng weave

(Baa ida nto be exe 3 tines late a)”

ostice, norte, Ga Cup Suet TO 16 mms

nt ane ners Cleaning (sting, Grinding, RUSHING GROIN

let ook cous

osctatanna

ere Tue to Work Dancena

ote Sele us (resis) ULTLE

ste or Sole ecradessNGLE

Havel Spee Rang] 42 2 mm/Min

ectode Spang

orvanisation NocePC NGOPPL

Biante =.

|wame Ae

ies ose

baie

L\ a ‘APPROVED BY |

fonawee-yie657S0NT195e

Y

{

Aia7-80-B)

ya Wg \ 1 =aveg|

WW vin HSBUNS’S vane ewer!

Paes z amv

Dorwo Wasson O/vD 33 99N apnea

3

3

Z

3

z

=

Aieef 90/51 €

oF

Teproln| STP] FO | os nce Mres-se6 us| MO | TE IOS, T

Toe

suewoy vty, fovemoune oe, camak | | mau | | ouimer] onnwwvownaurorte | os

oneOEP Sw mTOH Neos

TE GT suvasnanouvsens| D99E “aNBL SNIDOH/ ONDIOS

DINOCH = Tod-€F 0-309T on waaucoar anal AY SE un009 40 31%

bak aaaL mancoONNa| i 29/35E ‘ONILYAN 40 3¥4

“FT -Sam/TODN FIBA" ON Sa 4iee]eo/ pi aol 31-45 ‘ON Lw¥HD|

‘S0-aw/869 (193d "ON 34NGIDON| Sra, "on swoany| TO ‘ON LNA

“i050 1531 INIALVSHL VIM OTIM S08 Pence) a

) »N “dW “AYOTIAN ‘193fOUd BIMOd JON MWIO99XZ

“LT NOILINYLSNOD ONINSANIONA NOWLAd NOYLIdn

VY

YU

40 1 e6ed Led Seevs HOd

osu pg:25:20 PLISLIBO

(fo

e190)

00:20,

L

*hporto/ si ~ Bi es oy) jaw

ex feos roth, HAV

Aol gi cgeh | eozb OE oo9x vee D

YY \ba Seen

Lge | é

00:

7 ae in

‘yloz'0-ALVa 94

we es

ng ac00:» wio7e)8

JZLMd ‘Fd SEES SI eOaMOONTOSa

ee

| |

— fs ig

Wein AA ie

jrow ane > omdbderey rf

yee pao persqent ge

Oo

sete le

HE [Eee ace ig

| | | [~

| 2

2. OL

SOIALA OIL SO1AL $ OAL OIAL # CIAL CIAL CIAL4 OAL OAL OIAL # OIAL IAL IAL CIAL OIAL SOCIAL &

OIAL4 OIAL4 OIAL4 OAL OIAL 4 IAL OIAL 4 OIAL 4 OIAL 4 OIAL @ CIAL @ OAL 4 OIAL 4 OIAL 4 CIAL # CIAL # CIAL 4 OIAL # CIAL 4 CIAL # OAL # OIAL # OIAL

Telefax : 044 « 2250 0127, 2250 0523

San A) & [wok

ES1o. 1989 coef et

OMEGA INSPECTION & ANALYTICAL LABORATORY

TS. No. 57 & 58, GUINDY INDUSTRIAL ESTATE, GUINDY, CHENNAI - 600 032. INDIA.

TSO / TEC: 17025 : 2005 Accredited by NABL, Dept. of Science & Technology, India

‘Our Esteemed Customers : HYUNDAL, FORD, BHEL, BV, IBR, IRS, ELL, NLC , RITES, CPWD, Etc,

Test Report

ese Rega Report: 26/Sep/2014

Customer : TR_No OIAL/2014/09-279

W/S NCC LIMITED Sample petails +

Nellore

Nellore aaq @ 324 x 60 mm Weld Tube

Matl.: SA 355 Gr.P91+P91

Our Ref. TOCR Nos 14-2509 Sample Drawn By Party

i Ref : PECL/PQR-PECL/NCCL/PQR-15

: Mechanical Test

Party's Ref .

Nature of Test

Test Reference

Test Started on 26-Sep-14

sxsoe isc “mx Test Completed On :26-Sep-14

Page 1 of 1

Test Results

PECL/NCCL/PQR=I5(REF.PROPOSED WPS NO : PECL/NCCL/WPS-15)

REF: GTAW+SMAW-PQR N

EQUIPMENT USED

UTM.Make : FIE. Model : UTN 40.SR No.: 11/98 - 2450.

SAMPLE SIZE TENSILE YIELD. ELONGATION FRACTURE,

com) STRENGTH STRESS ) POSITION

(Mpa) (Mpa)

1 59.0x19.4 648.26 - 532.86 38.80 BROKEN OUTSIDE THE WELD

12 59.5x19.1 649.12 - 515.15 38.60 BROKEN OUTSIDE THE WELD

BEND TESTS :- (4t/180")

SIDE BEND - SB1 : OPEN DISCONTINUTY.

- SB2 : NO CRACKS OBSERVED. PASSES THE

- SB3 : NO CRACKS OBSERVED. PASSES THE

= SB4 : NO CRACKS OBSERVED. PASSES THE

- SB5 : NO CRACKS OBSERVED. PASSES THE

86

PASSES THE

ONCLUDED

ir.T.SREEKANTH Sr. Manager (QA&I)<

Mr.P.SRIDHAR OF M/S.NCC=EPC/<.

WITNESSED

ENGINEER

Tested /verified By.

& vi GxLasuaramanzan

IEF EXECUTIVE OFFICER

Authorised Signatory

‘Noto : Ceriied that the test enumerated above have been carried out In conformity ,with standard Testing procedures and ri

specifications. The Cetiicaterefers ONLY tothe particular sample(6)submittedtor Test. *Indicatesnon accredited range.

areas par customer tion. All Complaints about this should be communicated in writing within 15 days

thedate of issue of this report. The report shall not be reproduced except in full, without the written approval of CIAL,

201AL@OIAL4 OIAL4 OIAL 4 CIAL 4 CIAL 4 CIAL OIAL $ OIAL $ OIAL4 OIAL4 OIAL OIAL4 OIAL 4 OIAL 4 CIAL CIAL

Form No, ; QF/S-10-3

FOIALS OIAL4 CIAL OIAL OIAL 4 OIAL # OIAL 4 OIAL $ OIAL$ OIAL OIAL 4 OIAL 4 OIAL 4 OAL OIALS OILS OIAL

q Tolefax : 044 - 2250 0127, 2250 0523,

Mobile : 94442 55041

E-mail : omega_ial@outlook.com

)

ESTD. 1989

OMEGA INSPECTION & ANALYTICAL LABORATOR

T.S. No. 57 & 58, GUINDY INDUSTRIAL ESTATE, GUINDY, CHENNAI - 600 032. INDIA.

ashanti

Hie

ISO/TEC : 17025 : 2005 Accredited by NABL, Dept. of Science ey Technology, India

Our Esteomed Customers: HYUNDAL FORD, BHEL, BY; IBR, IRS, ELL, NLC, BIS, RITES, CPWD, Etc,

Nature of Test: Macro Examination

Test References: ASTM 6340

Equipment Used : Stereo Microscope

Etchant: Aquaregia, Magnification : 10X

Center

‘sestt288sCONCLUDED"*#*"

Test Report

TRNo/Date_ : 09/279 test started on £26 Sep 2014

Our Ref. TOCR No 14/2509 ‘Test Completed on__: 26 Sep 2014

Customer: M/s. M/s. NCC LIMITED.,

Nellore,

AP~ 824344

Sample Details + 324 X 60 Weld Pipe, Material SA 35 Gr. POTIPOI, WPS Nox PECL]NOCL/WPS-15

Partys Ref. : PECL/POR-PECL/NCCL/POR-15.

‘The macro etched sample was seen by visually and followed by stereo microscope under 10 X

‘magnification reveals complete fusion between weld and base metal. No Weld defects were observed.

Hardness in HV10:

[__ location Tocation Tardness in HV 10Kg | Average Values

Top 333_| 235 _| 932 233.33

Weld Center | 292| 293 | 205 233.33,

Bottom | 209 | 235 | 236 234.66

Top 236 | 925 | 924 225.00

Haz Center | 225 | 204 | 207 225.33

Bottom | 224 | 922 | 925 223.66

Top 215 218 216 216.33

Base Metal Center | 213 | 218 | 218 214.98

Bottom [219 217.66

Concluded

ee

(Metaiturgist)

Tested/Verified

pectticat

3

=

z

3

*

z

6

*

3g

8

s

z

5

=

z

5

*

2

5

«

s

z

3

*

z

3

*

z

3

«

z

3

*

z

8

*

z

6

*

z

3

*

3g

3

*

2

3

*

z

3

*

z

3

*

z

3

3

z

3

3

6

2

x

3

“

z

3

Form No, : OF/S-108

Witnessed By: Mr. T.SRIKANTH OF M/S NCCPPL

‘Note = Gerified that the test enumerated above have been carried out in conformity, with standard Testing procs

‘The Carticate refers ONLY totheparticular samplo(s) submited for Te

he

AOE can

Chief Executive Officer.

‘Authorised Signatory

‘indicates non accredited range. The sampladetails

customer description. All Complaints about this should be communicated in writing within 15 day

12da@ of Issue of this report. The Feport shall not be reproduced except in ful, without the witten approval of CIAL.

SOIAL4 CIAL SOILS OIALS OIAL$ OIAL OIAL @ CIAL # OIAL# OIAL @ OIAL 4 CIAL 4 OIAL 4 OIAL 4 O1AL # OIAL 4 OIAL

Anda mungkin juga menyukai

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDari EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RacePenilaian: 4 dari 5 bintang4/5 (895)

- Approved Wps & PQR Ss To CsDokumen6 halamanApproved Wps & PQR Ss To Cssaktheeswaran100% (4)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDari EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifePenilaian: 4 dari 5 bintang4/5 (5794)

- Approved 316-L WPSDokumen12 halamanApproved 316-L WPSsaktheeswaran100% (1)

- Shoe Dog: A Memoir by the Creator of NikeDari EverandShoe Dog: A Memoir by the Creator of NikePenilaian: 4.5 dari 5 bintang4.5/5 (537)

- Approved WPS&PQR q345Dokumen6 halamanApproved WPS&PQR q345saktheeswaranBelum ada peringkat

- Grit: The Power of Passion and PerseveranceDari EverandGrit: The Power of Passion and PerseverancePenilaian: 4 dari 5 bintang4/5 (588)

- Ss DuplexDokumen4 halamanSs Duplexsaktheeswaran100% (3)

- The Yellow House: A Memoir (2019 National Book Award Winner)Dari EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Penilaian: 4 dari 5 bintang4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDari EverandThe Little Book of Hygge: Danish Secrets to Happy LivingPenilaian: 3.5 dari 5 bintang3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDari EverandNever Split the Difference: Negotiating As If Your Life Depended On ItPenilaian: 4.5 dari 5 bintang4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDari EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FuturePenilaian: 4.5 dari 5 bintang4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDari EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryPenilaian: 3.5 dari 5 bintang3.5/5 (231)

- Rise of ISIS: A Threat We Can't IgnoreDari EverandRise of ISIS: A Threat We Can't IgnorePenilaian: 3.5 dari 5 bintang3.5/5 (137)

- The Emperor of All Maladies: A Biography of CancerDari EverandThe Emperor of All Maladies: A Biography of CancerPenilaian: 4.5 dari 5 bintang4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDari EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaPenilaian: 4.5 dari 5 bintang4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDari EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersPenilaian: 4.5 dari 5 bintang4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDari EverandOn Fire: The (Burning) Case for a Green New DealPenilaian: 4 dari 5 bintang4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDari EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyPenilaian: 3.5 dari 5 bintang3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDari EverandTeam of Rivals: The Political Genius of Abraham LincolnPenilaian: 4.5 dari 5 bintang4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDari EverandThe Unwinding: An Inner History of the New AmericaPenilaian: 4 dari 5 bintang4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDari EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You ArePenilaian: 4 dari 5 bintang4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Dari EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Penilaian: 4.5 dari 5 bintang4.5/5 (121)

- Her Body and Other Parties: StoriesDari EverandHer Body and Other Parties: StoriesPenilaian: 4 dari 5 bintang4/5 (821)