Braithwaite Type Pressed Steel Water Storage Tank

Diunggah oleh

Lawrence CainHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Braithwaite Type Pressed Steel Water Storage Tank

Diunggah oleh

Lawrence CainHak Cipta:

Format Tersedia

Galvanizing in engineering

and the environment

Braithwaite type pressed steel

water storage tank

Johannesburg, South Africa

Close-up of panels and bolts.

Braithwaitetype pressed

steel water storage tank

Johannesburg, South Africa

The Application

Our findings

The concept of liquid storage in

tanks constructed by means of a

series of modular steel panels bolted

together on site was originally

developed and patented in 1901

by Braithwaite in the United

Kingdom, an organisation which has

continued to be active to this day.

The Braithwaite water tank and

stand is situated on the eastern

rampart of the Johannesburg Fort.

The water tank steel panels have

the same pressed steel form that

is used to manufacture present

day Braithwaite tanks. Braithwaite

commenced business in 1901.

Large storage tanks constructed

to this design from pressed steel

sections such as the one in this case

history are generally mounted on

steel towers and used extensively as

in this case by municipal authorities.

Although the coating on the

fasteners has failed and are now

discolouring the remaining hot

dip galvanized coating on the

pressed steel panels, they are still

structurally sound but would shortly

require over coating or replacement.

Environmental conditions

South Africa is known for its many

atmospheric conditions from

relatively benign to extremely

corrosive. Although Johannesburg

has no doubt suffered from

pollution from numerous sources,

one such source being the old

Orlando and Kelvin Power Stations

(see article in magazine No. 26),

where huge amounts of coal were

burnt monthly, the atmosphere is

currently relatively benign. The

area of Johannesburg currently falls

into corrosion category (C1 or C2

in accordance with ISO 9223)and

therefore has a zinc corrosion rate

of less than 1mm per year.

(See Corrosion Category table in

magazine No. 23, page 62).

The coating on the pressed steel

panels ranges from 2.7 mils (68m)

to 3.6 mils (91m), which in terms

of the life of the water tank, is

impressive to say the least.

Should the water tank have been

ordered prior to 1937 the British

specification BS 729 would not have

been in existence as it was first

published in that year.

However, BS 729 requires that

for steel thickness less than 5mm

but greater and equal to 2mm a

coating mass of 460 grams/m2

(coating thickness 64m) and

for steel thickness greater than

5mm a coating mass of 610grams/

m2 (coating thickness 85m), be

deposited on the steel.

View on the roof looking north.

continued over the page

44_

Braithwaitetype pressed

steel water storage tank

Acknowledgement

Hot Dip Galvanizers Association,

Southern Africa

www.hdgasa.org.za

Page 1 of 2

continued over

Braithwaitetype pressed steel water

storage tank Johannesburg, South Africa

As it was difficult to assess the

steel thickness of these panels, we

must assume that they were most

probably 5 to 6mm thick, as per the

local equivalents.

In order to establish when the water

tank and structure was installed,

we discussed the history of the fort

with Mr Herbert Prins a Heritage

Architect,who was kind enough

to share some facts in trying to

establish the age of the water tank.

The following sequence of events

is known:

The Prison within the Rampart was

built in 1893.

The rampart (the embankment on

two sides of the Fort) was built

in 1896.

Boer war commenced in 1899 and

ended in 1902.

Paul Kruger built several forts in

the Johannesburg / Pretoria area

at much the same time as the one

in Johannesburg.

Johannesburg surrendered in May

1900 and the Boer garrison moved

out at the same time the British

garrison moved in.

After the Boer war the British

garrison moved out (some time

between 1902 and 1907 when the

Transvaal received responsible

government).

In 1909 the womens goal was

built.

In 1928 the Awaiting Trial prisoner

block was built.

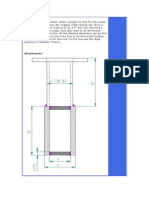

Minimum coating thickness, 2.7mils (68m) onpanel.

Maximum coating thickness, 3.6mils (91m) on panel.

General view of water tanks.

Conclusion

It would seem that there was

a strong possibility that the

Braithwaite water tanks were

ordered from the United Kingdom to

accommodate water for the entire

goal including the Awaiting Trial

prisoner block and that suggests

that the tanks may have been

in existence since about 1930.

Should this be correct, then the

hot dip galvanizing has performed

considerably well over the 76 odd

years. Several coating thickness

readings were taken at between

2.7 to 3.6 mils (about 68 to 91m)

see photos. On one bolt the

coating thickness read as 0.99 mils

(25m), but generally the fasteners

were starting to corrode and are

discolouring the hot dip galvanized

surface of the plates. This makes

sense, as they would have had an

original coating thickness of about

45 to 70m and with a zinc corrosion

rate of less than a micron a year,

would be 70 to 80 years old. No

surface inspection was done on the

inside of the tank. The structure

holding up the water tanks is fairly

corroded but could, if required, be

restored. The components could

be abrasively blasted and hot dip

galvanized and if the tanks were

also re-galvanized, the tank and

tank stand would provide a further

70 odd years of service free life at

the site.

45_

Page 2 of 2

Anda mungkin juga menyukai

- SRIA Concrete Historical ReinforcementDokumen10 halamanSRIA Concrete Historical ReinforcementfatherofgeorgeBelum ada peringkat

- Welded Wire Reinforcement WWM WWR Common SizesDokumen2 halamanWelded Wire Reinforcement WWM WWR Common Sizesgullipalli100% (1)

- Reinforced Concrete Reservoir AssignmentDokumen7 halamanReinforced Concrete Reservoir AssignmentKuza AnasBelum ada peringkat

- Foundation and Skid Design for Large Gas CompressorsDokumen4 halamanFoundation and Skid Design for Large Gas Compressorsdicktracy11100% (1)

- Steel Bridge Design Handbook - Bridge Steels - Mech - Properties - Vol - 01Dokumen59 halamanSteel Bridge Design Handbook - Bridge Steels - Mech - Properties - Vol - 01Cyril VomáčkaBelum ada peringkat

- Transfer Plate Design in Two StagesDokumen2 halamanTransfer Plate Design in Two Stagessitehab100% (1)

- Braithwaite Hot Pressed Steel Tank HistoryDokumen8 halamanBraithwaite Hot Pressed Steel Tank Historysegunoyes0% (1)

- Understanding Design StripsDokumen55 halamanUnderstanding Design Stripsphong00x3100% (1)

- Mix Design and Pumped ConcreteDokumen13 halamanMix Design and Pumped ConcreteLimbu Niwa Lawahang100% (1)

- Vibration TechnologyDokumen18 halamanVibration TechnologySakthimgsBelum ada peringkat

- Steel Tank BrochureDokumen8 halamanSteel Tank BrochureclintBelum ada peringkat

- Compressor FoundationsDokumen11 halamanCompressor FoundationsararratiBelum ada peringkat

- Composite construction - exploiting strengths of steel and concreteDokumen8 halamanComposite construction - exploiting strengths of steel and concreteAngel PestañoBelum ada peringkat

- Mechanicl EngineeringDokumen981 halamanMechanicl EngineeringBobby WaltersBelum ada peringkat

- Ce1305 - Foundation EngineeringDokumen12 halamanCe1305 - Foundation Engineeringsaamy100% (2)

- Machine Foundations in Oil and Gas IndustryDokumen64 halamanMachine Foundations in Oil and Gas IndustryPower PowerBelum ada peringkat

- Partial Fixity BaseDokumen24 halamanPartial Fixity Basekhemindra narain100% (1)

- Geotechnical Report: Technological Institute of The Phillipines 938 Aurora BLVD, Cubao, Quezon CityDokumen4 halamanGeotechnical Report: Technological Institute of The Phillipines 938 Aurora BLVD, Cubao, Quezon CityLara Jane LopegaBelum ada peringkat

- Concrete Silos: Failures, Design Issues and Repair/Strengthening MethodsDokumen26 halamanConcrete Silos: Failures, Design Issues and Repair/Strengthening MethodsMadhav PurohitBelum ada peringkat

- Foundation Design Philosophy For Rotating EquipmentDokumen7 halamanFoundation Design Philosophy For Rotating EquipmentKyaw Kyaw AungBelum ada peringkat

- Cement Kilns - Design Features of Rotary KilnsDokumen15 halamanCement Kilns - Design Features of Rotary KilnsmaiquelernBelum ada peringkat

- Trench DesignDokumen8 halamanTrench DesignZoebairBelum ada peringkat

- Example 1 - Geotechnical Data ReportDokumen63 halamanExample 1 - Geotechnical Data ReportValar MorghulisBelum ada peringkat

- Introduction To Coiled TubingDokumen82 halamanIntroduction To Coiled Tubingaza azaBelum ada peringkat

- Safdeck Specification Sheet - KenyaDokumen3 halamanSafdeck Specification Sheet - KenyagraceBelum ada peringkat

- Pile Cap Design ExamplesDokumen70 halamanPile Cap Design Examplest_solanki200160% (5)

- Chapter 3-2 Revised Wind-Loading Design Procedures For SANS 10160Dokumen14 halamanChapter 3-2 Revised Wind-Loading Design Procedures For SANS 10160Andreas KamwankaBelum ada peringkat

- 100-Year Design Life of Rock Bolts and Shotcrete - 5th Ground Support in Mining Underg ConstDokumen6 halaman100-Year Design Life of Rock Bolts and Shotcrete - 5th Ground Support in Mining Underg Consteep1977Belum ada peringkat

- BLAST FURNACE MAIN RUNNER DESIGN OPTIMIZATIONDokumen11 halamanBLAST FURNACE MAIN RUNNER DESIGN OPTIMIZATIONSaptarshi SenguptaBelum ada peringkat

- Fabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)Dokumen58 halamanFabricators' and Erectors' Guide To Welded Steel Construction - 1999 (Structural Welding)johnknight000Belum ada peringkat

- AASHTO Guide Specifications For Design of Pedestrian Bridges 2009 (Draft)Dokumen17 halamanAASHTO Guide Specifications For Design of Pedestrian Bridges 2009 (Draft)Laurence Arcon Banal0% (1)

- Specification Series 20 Ss Sluice GateDokumen6 halamanSpecification Series 20 Ss Sluice GatepramodtryBelum ada peringkat

- Braithwaite Type Pressed Steel Water Storage TankDokumen2 halamanBraithwaite Type Pressed Steel Water Storage TankLawrence CainBelum ada peringkat

- Ammonia Storage Tank PDFDokumen5 halamanAmmonia Storage Tank PDFAnonymous 1XHScfCI33% (3)

- DNTanks PrestressedConcreteTank PDFDokumen122 halamanDNTanks PrestressedConcreteTank PDFTam AlasadiBelum ada peringkat

- BS8110 Simply Supported Slab DesignDokumen8 halamanBS8110 Simply Supported Slab DesignRavish RavindraBelum ada peringkat

- Reconstruction of Clarin Bridge - Steel Arch Bridge Construction Methodology ALTERNATIVE 1 - 21032018Dokumen33 halamanReconstruction of Clarin Bridge - Steel Arch Bridge Construction Methodology ALTERNATIVE 1 - 21032018galih setyoBelum ada peringkat

- Internship ReportDokumen36 halamanInternship ReportShashwatAnantBelum ada peringkat

- Chapter Three: Construction Equipment ManagementDokumen42 halamanChapter Three: Construction Equipment ManagementbulchaBelum ada peringkat

- Optimum Design of Steel Pipe RacksDokumen17 halamanOptimum Design of Steel Pipe RacksRamesh PrabhakarBelum ada peringkat

- Finite Element Analysis of Castellated Steel - MR WAKCHAURE, A V SAGADEDokumen8 halamanFinite Element Analysis of Castellated Steel - MR WAKCHAURE, A V SAGADEpradz71Belum ada peringkat

- Registered Eng. Consulting Firms Tanzania 2015Dokumen9 halamanRegistered Eng. Consulting Firms Tanzania 2015Adam Maranja100% (1)

- Pipeline StructuresDokumen14 halamanPipeline StructuresaikalessBelum ada peringkat

- QUAY WALLSsemaranggijtDokumen12 halamanQUAY WALLSsemaranggijtM Mirza Abdillah PratamaBelum ada peringkat

- Importance of Controlling Temperature Rise Due To Heat of Hydration in Massive Concrete Elements - Anura Nanayakkara PDFDokumen7 halamanImportance of Controlling Temperature Rise Due To Heat of Hydration in Massive Concrete Elements - Anura Nanayakkara PDFsreesh001Belum ada peringkat

- Building Vertical Steel Tank FoundationsDokumen12 halamanBuilding Vertical Steel Tank Foundationskaushik arunexcelloBelum ada peringkat

- Retaining WallDokumen22 halamanRetaining WallDr-Moamen Abd El Raouf100% (1)

- TRH 22 Pavement Management SystemsDokumen157 halamanTRH 22 Pavement Management Systemsannaselemela100% (1)

- Polystorm Performance AssessmentDokumen4 halamanPolystorm Performance AssessmentHemant ChauhanBelum ada peringkat

- APEGBC Guidelines Professional Structural Engineering Services For Part 3 Building ProjectsDokumen32 halamanAPEGBC Guidelines Professional Structural Engineering Services For Part 3 Building Projectsdovi01100% (1)

- Concreto - Bi - Handbook of Machine FoundationsDokumen249 halamanConcreto - Bi - Handbook of Machine FoundationsRafael GarciaBelum ada peringkat

- Bondeck 600 PDFDokumen9 halamanBondeck 600 PDFcivilBelum ada peringkat

- Foundation and Civil Engineering Site DevelopmentDokumen1.152 halamanFoundation and Civil Engineering Site Developmentbnemgradj030Belum ada peringkat

- General Notes For EarthworkDokumen2 halamanGeneral Notes For EarthworkRalph BantoiBelum ada peringkat

- Pavement Deisgn 2012Dokumen59 halamanPavement Deisgn 2012WillowcrestBelum ada peringkat

- Design of Earth DamDokumen53 halamanDesign of Earth Damlehangh90Belum ada peringkat

- Design and Construction of Hydrostatic M PDFDokumen11 halamanDesign and Construction of Hydrostatic M PDFSatyajeet ParidaBelum ada peringkat

- US468296Dokumen4 halamanUS468296Rohan KulkarniBelum ada peringkat

- LCCA Steel vs. Concrete TankDokumen3 halamanLCCA Steel vs. Concrete TankdwianantoraharjoBelum ada peringkat

- American Steel Foundry PracticeDokumen12 halamanAmerican Steel Foundry PracticeRadhakrishnan BalasubramanianBelum ada peringkat

- Lecture 2 - Steel SectionsDokumen45 halamanLecture 2 - Steel Sectionsayoub aliousalahBelum ada peringkat

- Design Development and Innovation at RG Tanna Coal TerminalDokumen10 halamanDesign Development and Innovation at RG Tanna Coal Terminal김남균Belum ada peringkat

- Fixed Steel DamsDokumen3 halamanFixed Steel DamsN. SasidharBelum ada peringkat

- Cement Kilns - Pautas de DiseñoDokumen23 halamanCement Kilns - Pautas de DiseñoCarlosBelum ada peringkat

- Transactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionDari EverandTransactions of the American Society of Civil Engineers, vol. LXX, Dec. 1910 Reinforced Concrete Pier ConstructionBelum ada peringkat

- Ijetae 0614 121Dokumen7 halamanIjetae 0614 121Lawrence CainBelum ada peringkat

- Hydraulic PDFDokumen19 halamanHydraulic PDFLeslie CooperBelum ada peringkat

- Artikel Fisika Bahasa Inggris Tentang Vibration-1Dokumen10 halamanArtikel Fisika Bahasa Inggris Tentang Vibration-1Xerxes Xanthe XyzaBelum ada peringkat

- LM AN INFO 0106 E Tutorial Vibration Analysis PDFDokumen4 halamanLM AN INFO 0106 E Tutorial Vibration Analysis PDFjeyaselvanmBelum ada peringkat

- Nozzle in Flat PlateDokumen11 halamanNozzle in Flat PlateLawrence CainBelum ada peringkat

- Comparative Study Manufacturing Cost Between EN13445 and ASMEDokumen32 halamanComparative Study Manufacturing Cost Between EN13445 and ASMEDries VandezandeBelum ada peringkat

- Active Force on Retaining Wall Supporting Φ Backfill Considering Curvilinear Rupture SurfaceDokumen10 halamanActive Force on Retaining Wall Supporting Φ Backfill Considering Curvilinear Rupture SurfaceLawrence CainBelum ada peringkat

- Methods For Design of Hoppers, Silo's, Bins & BunkersDokumen10 halamanMethods For Design of Hoppers, Silo's, Bins & BunkersJaco KotzeBelum ada peringkat

- WRC107 297Dokumen4 halamanWRC107 297enjoygurujiBelum ada peringkat

- Application of WRC Bulletins 107, 297, 368Dokumen3 halamanApplication of WRC Bulletins 107, 297, 368shivabtowin3301100% (3)

- Design of Tallbuidings Preliminra DesignDokumen20 halamanDesign of Tallbuidings Preliminra DesignMuhammed SabahBelum ada peringkat