Iroko

Diunggah oleh

xavierlthHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Iroko

Diunggah oleh

xavierlthHak Cipta:

Format Tersedia

ISSN 0794 - 0378

THE NIGERIAN JOURNAl.;

OF

PURE AND APPUED SCIENCES

Nig. 1. Pure & Appl. Sci. Vol.

Printed in Nigeria

22 (2007): 2129 - 2135

07940378

2007 Faculty of Science Unlv, of Ilorin, Nigeria.

A CONTINUOUS COLUMN DESIGN FORMULA AT ULTIMATE STRENGTH FOR

AXIALLY LOADED IROKO (MllicJa exce/sa) TIMBER COLUMN

A. A. Jimoh

Department of Civil Engineering University of Ilorin, llorin, Nigeria.

ABSTRACT: A continuous column design equation for axially loaded Iroko (Botanical name: Milicia excelsai wood

column or strut is presented. The procedure simplifies the usual tedious design method of categorization of columns into short.

intermediate and slender according to the values of slenderness ratio. To derive the design equation, an experimental program was

carried out on direct axial compressive strength test on lroko specimens, to obtain compression stress and strain data. The data

were subsequently analyzed to derive the wood typical stress-strain equation in compression. This equation and the Euler Engesser stress formula were used to obtain values of critical stress and corresponding slenderness ratios. From these values.

analysis was carried out to derive a continuous column design equation to fit the theoretical ultimate loads with the experimental

values.

.

,

INTRODUCTION

1.

The timber material of interest in this report is Iroko, of botanical name Milicia excelsa. The tree is up

to 48 m high and 9 m .in girth, deciduous, with straight and cylindrical bole and grey to dark brown or

blackish bark. lroko is a very common large forest trees with dark green foliage and distinctive leaves

with pale to dark brown wood having a fairly open grain. Iroko is called in local language in Nigeria

as follows, Hausa: loko, Yoruba: iroko, Ibo: oji. It is wide spread in tropical Africa, from the Ivory

Coast to Mozambique. Its main habitats are the rainforest and forest outliers in savanna woodland areas.

It is very durable, resistant to decay, termites, and marine-borer attack, and very stable, with little

shrinkage and movement once seasoned. It is the most sought-after construction timber in West Africa

and used in boat building, laboratory benches, domestic flooring and marine work (Keay et aI., 1964;

NCP2, 1973; Jackson, 1978; Desch, 1991).

However, there has been no established design procedure for Iroko column, which can be used for its

rational application as a column or strut. A related design information on wood where a column is

categorized into short, intermediate and slender is given in a reference (Jozsef and Benjamin, 1982)

where each column category has its own peculiar design formula. However, it has been reported that

division of the slenderness ratio into short, intermediate, and slender categories with subsequent

analysis is quite involved and may not be necessary. Instead of categorization into these ranges, a

continuous column formula is appropriate (Mazur, 1965). At ultimate, when stress is not proportional to

strain, tangential modulus can replace modulus of elasticity in Euler's equation (Borislav, 1975;

William, 1977), giving Euler-Engesser stress formula, This equation and the stress-strain equation in

. compression of the material are used to obtain the critical stress and corresponding slenderness ratio.

These processes are carried out on Iroko material, as already analysed for Ayin (Anogeissus leiocarpus)

column, (Jimoh, 2005), to derive the column design equation.

2. Theory

The intention here is toobtain values of Iroko column compression stress against slenderness ratio.

Euler's critical load for a strut of elastic material is given by

1[2EI

P =-cr.

L2

(I)

From the equation, the critical stress (O'er) is given as:

1[2E

cr

=---

cr

(;

(2~

)2

2129

Nig. J. Pure & Appl. Sci. Vol.

A.A. Jimoh

At ultimate, stress is not proportional to strain .and therefore. Young's modulus E in eqn.(2) is replaced

by tangential modulus E, and becomes

0'

cr

n2E

t

(3)

(~)2

This is the Euler- Engesser critical stress formula.

Eqn.(3) can be written in terms of slenderness ratio as

L=nJE,

r

(4)

O'er

In order to solve eqn.(4), pairs of val~es of E, and O'er are obtained from stress-strain equation so that

after substitution for them in the equation, corresponding values of slenderness ratio (Ur) can be found.

3.

EXPERIMENTAL INVESTIGATION

An experimental program was carried out to obtain stress and strain data and stress- strain equations. A

laboratory test was carried out on direct axial tensile and compression test parallel to grain and flexure

on Iroko wood material. Air-dried Iroko wood obtained from a timber market in IIorin town, Nigeria,

was used for the test. Compression specimen was cut into nominal dimension 20 mm by 20 mm in

section and 80 mm long, flexural specimen dimension was 25 mm by 25 mm in section and 380 111m

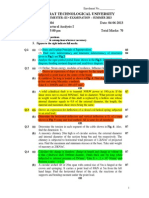

long. Dimension for the irregular shape tension specimen is shown in Figure I, all specimens are

shaped as in ASTM, (1985), but with.reduced dimensions to suit the testing equipment. Fifty specimens

were tested in each case using a Testometric Universal Testing Machine. Strain was monitored using

the downward movement of the compression plate.

10

~cb

~

30

20

/D

25

~~

~~

~

50

20

30

Figure I: Tension specimen nominal dimension (in mm)

At the end of the test, stress and strain data were analyzed, using Microsoft Excel 2003, to obtain the

average strength and strain and stress-strain relationship for each specimen. Polynomial stress-strain

equation of order 3 of the form (ax) + bx2 + ex ) was found appropriate because the least squared error

(R2) was close to I. The average of.each of the coefficients (a, b, and c), in the stress-strain equation was

obtained and used to derive the typical stress-strain equation in compression. The summary of the

result of analysis is' shown in Table I.

2130

Nig. J Pure & App/. Sci. Vol. 22

Column design formula for axially loaded iroko limber column

Table I: Experimental

data of Iroko material

Minimum

34.48

34.85

84.53

Average

51.5

71.38

123.80

Maximum

68.53

114.50

151.53

Strain

Minimum

Tension

Compression

0.019

Average

.0378

0.04636

Maximum

0.066

.0753

Strength

property

Compression

Flexure

Tension

0.0285

Standard deviation

9.9

22.16

22.26

Moisture content of specimens vary between 8.5 to 11.5 with an average of 10.5 %. Typical axial

stress-strain equations in compression and in tension are

.

crc

= -13844953'+

724182 -582

(5)

crt = 1601189 3 -156748 2 + 6492.3

(6)

respectively, where (J and E denote the stress and strain, respectively. The curves representing these

equations are shown in Figures 2a and 2b respectively.

fit = y = 1601189x3

156748x2

frt

= y = -1384495x3 + 72418x2 +

+ 6492.3x

E

.

z

~

II)

II)

~

II)

60

100

50

80

E

E

60

>:

40

III

III

-e

20

-20

40

30

20

10

III

o

~

582.07x

120

..

0.02

0.03

0.04

0.01

-10

strain (x)

--_._-_ .._----_ .._---Figure 2a: Typical tensile stress-strain curve

~

0

0.05

0.02

0.04

0.06

strain (xl

Figure 2b: Typical compression

stress-strain

curve

4. DERIVATION OF CONTINUOUS COLUMNEQUA TION

(a) Values for Stress and Slenderness ratio

The stress and slenderness ratio values were obtained from analysis of the typical stress-strain

5. The analysis was carried out as follow:

The tangential modulus E, is the first derivative of equation 5 and it is given by

= 8cr/8E

That is;

E =-3(1384495)2

t

equation

+2(72418)-582

(7)

2131

A.A. Jimoh

Nig. J. Pure & Appl. Sci. "01. 22

In order to solve equation 4, strain (8) values were substituted in equation 5 and 7 to obtain pairs of

stress (0') and tangential modulus (EJ Both results (0' and E,) are then substituted in equation 4 to

obtain the corresponding slenderness ratios, shown in Table 2. The data show that for increasing critical

stress, the slenderness ratios are decreasing. The limit for optimum critical stress is 50 N / mm2 when

the slenderness ratio value is 10,

Table 2: Stress versus slenderness

Strain

Stress from

Eqn.(5)

Tangential

modulus

Et

ratio results for Iroko

Slenderness

ratio

Llr

Stress

from fit

Eqn.(8)

Ratio

of

Fit col

5

factual

stress

col.2

(I)

(2)

(3)

(4)

0.0078

8.289042249

1459,0928

41.697874

0.0079.8.435350351467.055441.4473095.193029

0.00795

8.50880196

1471.0056

41.323547

0.008

8.58245056

1474.935

41.200ne

0.009

10:09519115

1549.1617

38.93281

(5)

4.990.1691

(6)

0.60

0.62

0.62

0.63

0.76

5.2960262

5.4000055

7.6271894

Limit for good result ( slenderness ratio Llr not greater than 37)

0.01

0.015

0.0151

0.0152

0.0153

0.0154

0.0155

0.0156

0.0157

0.0158

0.02

0.021

0.022

0.023

0.024

0.025

0.025

0.026

0.0265

0.0266

0.0267

0.028

0.03

0.032

0.034

0.036

0.038

0.0385

0.0385

11.678005

1615.0815

36.960474

9.9890984

20.3524293'8

1820.0759

29.720852

21.052784

20.53453674

1822.0575

29.604874

21.250303

20.7168381

1823.956

29.489682

21.446859

20.89932517

1825.7715

29.37526

21.642456

21.08198963

1827.5039

29.261595

21.837102

21.26482318

1829.1532

29.148674

22.0308

21.44781751

1830.7195

29.036482

22.223556

21.63096431

1832.2027

28.925006

22.415377

21.81-125528

1833.6028

28.814234

22.606269

29.53264

1817.396

24.654619

29.875917

31.33799981

179f.9391

23.76570131.424989

33.1/374924

1758.1753

22.900847

32.918957

34.351581341716.1044

22.053893

34.364515

36.543189121665.7266

21.21892

35.768031

38.18026563

1607.0419

20.390072

37:13555

38.18026563

1607.0419

20.390072

37.13555

39.75450388

1540.0501

19.561354

38.472802

40.51546274

1503.4392

19.145079

39.131782

40.66542877

1495.8678

19.061595

39.26289

40.81463352

1488.2133

18.977949

39.393781

42.681237761381.145817.87828741.077811

45.2569:35

1189.0135

16.109255

43.621759

47.41513984

963.65336

14.168587

46.133217

49.08939652

705.06534

11.910925

48.61364

50.21324928

413.24944

9.0161601

50.962129

50.72024236

88.20566

4.144596

52.311126

50.74281852

1.7528587

0.5841317

50.78928

50.742818521.75285870.5841317

50.78928

2132

0.86

1.03

1.03

1.04

1.04

1.04

1.04

1.04

1.04

1.04

1.0 I

1.00

.0.99

0.99

0.98

0.97

0.97

0.97

0.97

0.97

0.97

0.96

0.96

0.97

0.99

.1.01

1.03

1.00

1.00

Column design formula for axially loaded iroko timber column

(a)

Nig. J. Pure & Appl. Sci. Vol. 22

Graph ofStrcss Versus Slcndcrncss Ratio

Graph for stress versus slenderness ratio results of Table 2 were plotted and is shown in Figure 3 as a

design chart. The graph' shows an initial optimum region with a critical stress of 50 N/mm2, This stress

has a slenderness ratio of 10, Beyond this value, the graph has negative gradients,

r--'----.-

60

Equation of fit

stress = 0.0013(Ur)3 - 0,1014(Ur)2

+ o 881(Ur) + 50.309

R2 = 0.9942

50

fit ------------------actual

40

I

I

20

10 .

o .~-------.-------.-------.

o

70

40

60

slenderness ratio (Ur)

---_._--_._._---_._----------------'

Figure 3: Stress versus slenderness

ratio for Iroko column

(b) Equation of Fit for Stress versus Slenderness Ratio

In order to have a handy equation to design Iroko column, statistical regression analysis was carried

out, using Microsoft Excel 2003, on critical stress and slenderness ratio results in Table 2, From the

regression analysis, Equation (8) was obtained,

.

Stress = 0.00 13(Ur)J - 0.10 14(Ur)2 + 0.881 CUr) + 50.309

(8)

The curve of tit for this equation is shown in Figure 3. The least square error for the tit is 0,99. Also

stress results from the experimental stress-strain formula equation (5) and the. stress from the tit

equation (8) are shown respectively in columns (2) and (5) in Table 2, The two column results show a

tit of least square error (R2) of unity,

5.

VERIFICATION OF DESIGN EQUATION

Verification of equation (8) was carried out by comparing the results of experimental compression test

carried out on iroko specimens and the result obtained with design equation (8), These results are

shown in column 5 and column 8 of Table 3. From the table, the ratio of theoretical stress obtained

using equation (8) to experimental stress ranged between 71% to 123% with an average of 100 %.

2133

ig. J. Pure & Appl. Sci. Vol. 2

A.A. Jimoh

SINo

Width

b

(mm)

I

I

2

3

4

5

6

7

8

9

10

17.40

17.20

17.00

,17.20

17.20

17.00

17.00

17.40

17.00

17.00

Table 3: Experimental verification of design eqn.(8) for Iroko column

Exper.

_ Slendernes

theoretic.

height L

Radius.

Exper.

ultimat

ult.stressultimate.

of

s ratioUr

c

strcss

Gyratn r

eqn.(8)

Load

(mm)

(mill)

(kN)

(Nzmm ')

(Nzrnrn ')

(mm)

Depth

d

2

17.10

17.20

17.40

17.00

17.00

17.20

17.20

17.00

17.40

17.00

57.3

57.77

57.85

57.9

58.9

57.75

50.45

59.11

57.12

58.77

13463

16084

15023

1)258

15220

12605

15868

11508

11851

19806

45.25

54.37

50.79

52.18

52.05

43.11

54.27

38.90

40.06

68.53

4.94

4.97

5.02

4.91

4.91

4.97

4.97

4.91

5.02

4.91

7

11.61

11.63

11.52

11.80

12.00

11.63

10.16

12.04

11.37

11.98

Theorl

Exp.

(Co1.8

/coI.S)

8

48.91

48.88

48.99

48.72

48.52

48.88

50.16

48.48

49.13

48.55

average

6.

DISCUSSION

The design equation (8) obtained here is for air-dry Iroko material with moisture content ranging from

8.5% to 11.5 %. Usually for design of wood, the maximum slenderness ratio recommended is 30. this

gives for a Iroko column, a design stress (ae,) of20 N/mm2.

The stress-slenderness ratio curve for Iroko is identical to that of wood given in a reference (Jozsef and

Benjamin, 1982), because for wood the limit of slenderness ratio (Llr) for short column is eleven while

II is also obtained here when the optimum stress is 50 N/mm2 However, the continuous column

equation obtained here has removed the difficulty usually encountered in categorization in the design of

a timber column.

7.

CONCLUSION

From the analysis, it can be concluded that:

(I) The stress-slenderness ratio curve for Iroko is identical to that for other woods and the stress

slenderness ratio relationship for air dry lroko with moisture content not more than 11.5% is

Stress = 0.00 l3(Llr)) - 0.10 14(Lld + 0.881 (Llr) + 50.309

(2) Both the equation (8) and stress-slenderness ratio curve in Figure 3 can be used to design an Iroko

column when the slenderness ratio is not more than 37.

REFERENCES

Annual Book of American Society for Testing and Materials Standard, (ASTM), (1985). Wood,

Volume 04. 09, section 4, Philadelphia, USA pp 55-56.

Borislav, D. Z. (1975). Inelastic behaviour of wood Beam- Columns. Journal of the Structural Division,

ST2. pp. 416-434.

Desch, H. E. (1991). Timber, its structure, properties and utilization, 6tl) Edition, revised by

Dinwoodie ,J. M., Macmillan Education, London

Jackson, N. (1978j. Civil Engineering Materials, English language book society and Macmillan Press

Ltd, London.

2134

9

1.08

0.90

0.96

0.93

0.93

1.13

0.92

1.25

1.23

0.71

1.00

Column design form II la lor axially loaded iroko timber column

Nig. J. Pure & Appl.

sa.

Vol,.22

Jimoh, A.A. (2005). Ultimate Strength Design of Axially Loaded Ayin iAnogeissus leiocorpusy Timber

Columns, Journal of Applied Science and Technology (Ghana), Vol. 10, Nos. I & 2, pp, 2934.

Jozsef, B. and Benjamin. A. J, (1982), Mechanics of Wood and Wood Composites, Van Nosttrand

Reinhold Company, New York.

.

Keay, R. W.J., Onoche, C.F.A. and Stanfield, D.P. (1964). Nigerian Trees, Vol. II, Department of

Forest Research Institute Ibadan, Nigeria. pp 188-189.

Mazur, S. J. (1965). On a rational column formula Symposium on Timber and Timber Structures,

Transactions of the Engineering Institute of Canada, P.aper No. EIC -65 -BR&

STRI3, Bridge and Structural, Vol. 8, No, A-16. pp 11-12.

Nigerian standard code of practice on building and construction part 2 (NCP2) (1973), Federal

department of forest research lbadan , Nigeria, pp 13-24

William, A. N. (1977). Theory and Problem of strength of Materials, Schaums Outline Series, New

York: McGraw Hill Book Company, pp 264-278.

2135

Anda mungkin juga menyukai

- Characteristic Withdrawal Capacity and Stiffness of Threaded RodsDokumen13 halamanCharacteristic Withdrawal Capacity and Stiffness of Threaded RodsAndrej SørensenBelum ada peringkat

- Mechanical Science for Technicians: Volume 1Dari EverandMechanical Science for Technicians: Volume 1Penilaian: 5 dari 5 bintang5/5 (1)

- Strength of Materials - Deformation Due To Axial Load - Hani Aziz AmeenDokumen32 halamanStrength of Materials - Deformation Due To Axial Load - Hani Aziz AmeenHani Aziz Ameen91% (32)

- Pen Rchive Oulouse Rchive Uverte : O A T A O OataoDokumen14 halamanPen Rchive Oulouse Rchive Uverte : O A T A O OataoZundali FirdausBelum ada peringkat

- Structural Analysis-I-Summer-13Dokumen2 halamanStructural Analysis-I-Summer-13harnishtanna21285Belum ada peringkat

- Modeling and Simulation of The Orthogonal Cut by Using The Law of DamageDokumen4 halamanModeling and Simulation of The Orthogonal Cut by Using The Law of DamageHayderyBelum ada peringkat

- Chapter 2Dokumen9 halamanChapter 2Fadhiran YahyaBelum ada peringkat

- MODULE-2 Torsion and Bending StressesDokumen14 halamanMODULE-2 Torsion and Bending Stressesrhea lee enriquezBelum ada peringkat

- App 1975 070190723Dokumen26 halamanApp 1975 070190723ARUN KRISHNA B J am21d400Belum ada peringkat

- Chapter 1Dokumen50 halamanChapter 1AdzmierHassanBelum ada peringkat

- Tutorial SheetDokumen5 halamanTutorial SheetujjalBelum ada peringkat

- Chapter 1 - STRESS AND STRAIN PDFDokumen34 halamanChapter 1 - STRESS AND STRAIN PDFnurul eryn100% (1)

- Effective Length Factor For The Design of X-Bracing Systems PDFDokumen5 halamanEffective Length Factor For The Design of X-Bracing Systems PDFGonzalo AbarcaBelum ada peringkat

- Theory of Elasticity - Structural EngineeringDokumen7 halamanTheory of Elasticity - Structural EngineeringVijay Aravind100% (1)

- Lab ManualDokumen14 halamanLab ManualBenni AmirBelum ada peringkat

- Analytical and Experimental Study of Vibration Behavior of FRP Composite I-BeamsDokumen8 halamanAnalytical and Experimental Study of Vibration Behavior of FRP Composite I-BeamsRaviyashuBelum ada peringkat

- 2 Upsetting Test of Forgeability of MetalDokumen9 halaman2 Upsetting Test of Forgeability of MetalJc Ong100% (1)

- D28MA Civil Engineering Materials: Lecture 3 - Mechanical Properties BDokumen41 halamanD28MA Civil Engineering Materials: Lecture 3 - Mechanical Properties BMahesh GanesanBelum ada peringkat

- Hutchinson Fracture Delamination of Beams Under Transverse Shear and BendingDokumen10 halamanHutchinson Fracture Delamination of Beams Under Transverse Shear and BendingTashi MalhotraBelum ada peringkat

- Stresses in BeamsDokumen9 halamanStresses in BeamsAyad SlabyBelum ada peringkat

- Analysis of Compression of Hollow Circular Elastomeric Bearings 1992Dokumen9 halamanAnalysis of Compression of Hollow Circular Elastomeric Bearings 1992ciscoBelum ada peringkat

- Ce6302 Notes Rejinpaul - 2 PDFDokumen49 halamanCe6302 Notes Rejinpaul - 2 PDFSekar Dinesh50% (2)

- ECS 238 - Chapter 1 (Stress and Strain)Dokumen131 halamanECS 238 - Chapter 1 (Stress and Strain)dixn__Belum ada peringkat

- Som-I: Assignment - I: Columns and Struts (B. Tech. 2 Year: 2019 - 2020)Dokumen1 halamanSom-I: Assignment - I: Columns and Struts (B. Tech. 2 Year: 2019 - 2020)Prince SinghBelum ada peringkat

- Take Home QuizDokumen8 halamanTake Home QuizAshley SimmonsBelum ada peringkat

- MOS II - TUTORIAL SHEET Week 4 PDFDokumen2 halamanMOS II - TUTORIAL SHEET Week 4 PDFShirishaVijayapuramBelum ada peringkat

- Comparison of a steel column design buckling resistance between the South African/Canadian (SANS 10162-1:2005/CAN/CSA-S16- 01:2005), Eurocode 3 (EN 1993-1-1:2005) and Australian /New Zealand (AS4100:1998/NZS3404:1997) standards- Part II: South African Hot-Rolled I- SectionDokumen8 halamanComparison of a steel column design buckling resistance between the South African/Canadian (SANS 10162-1:2005/CAN/CSA-S16- 01:2005), Eurocode 3 (EN 1993-1-1:2005) and Australian /New Zealand (AS4100:1998/NZS3404:1997) standards- Part II: South African Hot-Rolled I- SectionIOSRjournalBelum ada peringkat

- Civ1501 Engineering Statics Semester 2, 2002: Beam BendingDokumen9 halamanCiv1501 Engineering Statics Semester 2, 2002: Beam BendingHundeejireenyaBelum ada peringkat

- Mechancs of SolidsDokumen4 halamanMechancs of SolidsParthipan JayaramBelum ada peringkat

- Oneil StrengthsDokumen22 halamanOneil StrengthsOneil Prettyboyswagg LeitchBelum ada peringkat

- Double Lap Joint ReportDokumen9 halamanDouble Lap Joint Report130IME19Belum ada peringkat

- Unit - I - Stress and Strain SCIA1301: School of Building and Environment Department of Civil EngineeringDokumen124 halamanUnit - I - Stress and Strain SCIA1301: School of Building and Environment Department of Civil EngineeringUllyses SebialBelum ada peringkat

- Materials and ManufacturingDokumen23 halamanMaterials and ManufacturingAnh NguyenBelum ada peringkat

- 1VECF1 - Analysis of Crack-Tip Constraint Due To V - and U - Side Grooves in C (T) SpecimensDokumen11 halaman1VECF1 - Analysis of Crack-Tip Constraint Due To V - and U - Side Grooves in C (T) SpecimensslvjayaprakashBelum ada peringkat

- Chapter 6 Stresses in BeamsDokumen43 halamanChapter 6 Stresses in BeamsccipjayyBelum ada peringkat

- Art:10 1007/BF03187820 PDFDokumen4 halamanArt:10 1007/BF03187820 PDFniky186Belum ada peringkat

- The Science of Winding Paper RollsDokumen31 halamanThe Science of Winding Paper RollsRobin KuoBelum ada peringkat

- Bending and Axial Compression With RestraintsDokumen8 halamanBending and Axial Compression With RestraintsszalaijaBelum ada peringkat

- Effect OF: Axial Loads On Radial Stress in Curved BeamsDokumen13 halamanEffect OF: Axial Loads On Radial Stress in Curved BeamsRenner EgalonBelum ada peringkat

- Wood Research Determination of Fatigue and Static Strength of Scots Pine and Beech WoodDokumen8 halamanWood Research Determination of Fatigue and Static Strength of Scots Pine and Beech WoodBunga AnggrainiBelum ada peringkat

- ISTAM - Stress Concentration Factor Convergence Study of A Thin PlateDokumen7 halamanISTAM - Stress Concentration Factor Convergence Study of A Thin PlateKanak_KalitaBelum ada peringkat

- FEA Question BankDokumen6 halamanFEA Question Bankmenmoli2012Belum ada peringkat

- Stress and StrainDokumen60 halamanStress and StrainMuhammad Shafie100% (1)

- Ib Tutorial 4 (12 13) Sem 2Dokumen5 halamanIb Tutorial 4 (12 13) Sem 2omarnasriBelum ada peringkat

- Geas FormulaDokumen29 halamanGeas Formularoy016Belum ada peringkat

- Assignment 07 AE670Dokumen3 halamanAssignment 07 AE670Audrey BrooksBelum ada peringkat

- Diploma Strength of Materials 5th UnitDokumen30 halamanDiploma Strength of Materials 5th UnitSuresh BalamBelum ada peringkat

- Archive of SID: Stress Concentrations of Symmetrically Laminated Composite Plates Containing Circular HolesDokumen14 halamanArchive of SID: Stress Concentrations of Symmetrically Laminated Composite Plates Containing Circular HolesAugusto Tinoco PadauiBelum ada peringkat

- Stress Loops Effect in Ductile Failure of Mild Steel: O.O. OluwoleDokumen10 halamanStress Loops Effect in Ductile Failure of Mild Steel: O.O. OluwolearunkumarnoolaBelum ada peringkat

- 2002 Int Ansys Conf 57Dokumen7 halaman2002 Int Ansys Conf 57Halyna HafiychukBelum ada peringkat

- Anticlastic Action of Flat Sheets in BendingDokumen5 halamanAnticlastic Action of Flat Sheets in Bendingalfakir fikriBelum ada peringkat

- Theories of FailureDokumen77 halamanTheories of FailureAnonymous 6HADGUEXDBelum ada peringkat

- Effects of Stacking Sequence and Clamping Forceon The Bearing Strength of Mechanically Fastened Joints in Composite LaminatesDokumen9 halamanEffects of Stacking Sequence and Clamping Forceon The Bearing Strength of Mechanically Fastened Joints in Composite Laminateskhudhayer1970Belum ada peringkat

- 1994 - SCHARDT - Generalized Beam Theory - An Adequate Method For Couple Stability ProblemsDokumen20 halaman1994 - SCHARDT - Generalized Beam Theory - An Adequate Method For Couple Stability ProblemsJanaína Souza AlvesBelum ada peringkat

- AS4100 Standard Grades and Sections: Asst. Prof. Hang Thu Vu Hang@civil - Uwa.edu - AuDokumen49 halamanAS4100 Standard Grades and Sections: Asst. Prof. Hang Thu Vu Hang@civil - Uwa.edu - AuKevin BaxterBelum ada peringkat

- 9-2-Specimen For A Novel Concept of Biaxial Tension Test - Design and OptimisationDokumen7 halaman9-2-Specimen For A Novel Concept of Biaxial Tension Test - Design and OptimisationmrbeegzBelum ada peringkat

- Theories and Analyses of Thin and Moderately Thick Laminated Composite Curved BeamsDokumen14 halamanTheories and Analyses of Thin and Moderately Thick Laminated Composite Curved BeamsTejas GotkhindiBelum ada peringkat

- CHAPTER 2 (Partial) : - Notation and TerminologyDokumen16 halamanCHAPTER 2 (Partial) : - Notation and TerminologyxavierlthBelum ada peringkat

- 42 Ermco 2015 Assessment of Concrete Compressive Strength in StructuresDokumen9 halaman42 Ermco 2015 Assessment of Concrete Compressive Strength in StructuresIoan SosaBelum ada peringkat

- Type of Piles Paper by BernandDokumen13 halamanType of Piles Paper by BernandmahakBelum ada peringkat

- Astm A416a416m 06 PDFDokumen5 halamanAstm A416a416m 06 PDFBobby SetiawanBelum ada peringkat

- Inverted T-Beam Update - Next Phase: 2017 Virginia Concrete ConferenceDokumen39 halamanInverted T-Beam Update - Next Phase: 2017 Virginia Concrete ConferencexavierlthBelum ada peringkat

- BS 5400 Part 6 PDFDokumen36 halamanBS 5400 Part 6 PDFxavierlth50% (2)

- (PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Dokumen173 halaman(PPT) Eurocode 2 Design of Concrete Structures EN1992-1-1 (Walraven)Gregory SimmonBelum ada peringkat

- BOF32 - Drewett - en 1504 PresentationDokumen33 halamanBOF32 - Drewett - en 1504 PresentationUygar KöprücüBelum ada peringkat

- Design of Low-Rise Reinforced Concrete BuildingsDokumen384 halamanDesign of Low-Rise Reinforced Concrete BuildingsCamilo Andres Torres100% (2)

- Jurnal Teknologi: Seismic Behaviour of Base Isolation System Using Lead Rubber BearingDokumen10 halamanJurnal Teknologi: Seismic Behaviour of Base Isolation System Using Lead Rubber BearingxavierlthBelum ada peringkat

- Pushover AnalysisDokumen20 halamanPushover AnalysisMarcelo Quisbert100% (2)

- Volume B: Figure 4.2.2-42: The Actual Stucture in 3DDokumen5 halamanVolume B: Figure 4.2.2-42: The Actual Stucture in 3DxavierlthBelum ada peringkat

- Bill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2Dokumen20 halamanBill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2xavierlthBelum ada peringkat

- 3 ReinforcedConcreteChapter3Dokumen28 halaman3 ReinforcedConcreteChapter3xavierlthBelum ada peringkat

- CH2SMDokumen32 halamanCH2SMxavierlthBelum ada peringkat

- SA Ch01Dokumen9 halamanSA Ch01Mohd AsmawiBelum ada peringkat

- Retaining Wall DesignDokumen55 halamanRetaining Wall DesignMohit Kohli100% (1)

- Bill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2Dokumen17 halamanBill Mosley John Bungey & Ray Hulse: Reinforced Concrete Design To EC2xavierlthBelum ada peringkat

- Tata Steel - Blue Book - Advance - Section - Properties - For - Students PDFDokumen20 halamanTata Steel - Blue Book - Advance - Section - Properties - For - Students PDFshugd31085100% (1)

- Section Properties03Dokumen20 halamanSection Properties03xavierlthBelum ada peringkat

- SlopeDesignGuidelines JKRDokumen37 halamanSlopeDesignGuidelines JKRtanchuanngan100% (9)

- Pilecap DesignDokumen70 halamanPilecap DesignxavierlthBelum ada peringkat

- Design of Reinforced Concrete Structure - Volume 3 - DR. Mashhour A. GhoneimDokumen425 halamanDesign of Reinforced Concrete Structure - Volume 3 - DR. Mashhour A. Ghoneimmdkml75% (4)

- Terzaghi's Bearing Capacity EquationsDokumen23 halamanTerzaghi's Bearing Capacity Equationskiddho100% (2)

- Single Pilecap 182Dokumen2 halamanSingle Pilecap 182tanksaumil84% (32)

- Terzaghi's Bearing Capacity EquationsDokumen23 halamanTerzaghi's Bearing Capacity Equationskiddho100% (2)

- Based On Malaysian LawDokumen5 halamanBased On Malaysian LawxavierlthBelum ada peringkat

- Single Pilecap 182Dokumen2 halamanSingle Pilecap 182tanksaumil84% (32)

- Single Pilecap 182Dokumen2 halamanSingle Pilecap 182tanksaumil84% (32)

- Wind Loads Calculation BS6399Dokumen3 halamanWind Loads Calculation BS6399jeddij100% (1)

- LEC# 15. Vapor Compression, Air ConditioningDokumen31 halamanLEC# 15. Vapor Compression, Air ConditioningAhmer KhanBelum ada peringkat

- Guest WiFi With MikroTik RoutersDokumen1 halamanGuest WiFi With MikroTik Routersmahad3vaBelum ada peringkat

- ESPKey Tool Manual v1.0.0Dokumen36 halamanESPKey Tool Manual v1.0.0Jad HaddadBelum ada peringkat

- Database Management Systems: Lecture - 5Dokumen37 halamanDatabase Management Systems: Lecture - 5harisBelum ada peringkat

- Evaluasi Pengelolaan Sampah Di Kawasan Pantai Kabupaten Bantul, D. I. YogyakartaDokumen14 halamanEvaluasi Pengelolaan Sampah Di Kawasan Pantai Kabupaten Bantul, D. I. YogyakartaRavyola AzzahraBelum ada peringkat

- SSC CGL Tier-Ii Grand Test - 9Dokumen5 halamanSSC CGL Tier-Ii Grand Test - 9A SAI PAVANBelum ada peringkat

- 03 VEX SpotDokumen2 halaman03 VEX SpottemamBelum ada peringkat

- Cantors Algebra of SetsDokumen29 halamanCantors Algebra of SetsKevs SebastianBelum ada peringkat

- JAGUAR E-TYPE: Assembly Instructions 1: View of The Engine View of The CockpitDokumen17 halamanJAGUAR E-TYPE: Assembly Instructions 1: View of The Engine View of The Cockpitfranciss87Belum ada peringkat

- Math 138 Functional Analysis Notes PDFDokumen159 halamanMath 138 Functional Analysis Notes PDFAidan HolwerdaBelum ada peringkat

- NEW Handbook UG 160818 PDFDokumen118 halamanNEW Handbook UG 160818 PDFHidayah MutalibBelum ada peringkat

- Corirubber: Cori Engineers Private LimitedDokumen1 halamanCorirubber: Cori Engineers Private LimitedVivace SystmBelum ada peringkat

- Civil Engineering - Development Length Calculation As Per Indian CodeDokumen2 halamanCivil Engineering - Development Length Calculation As Per Indian CodeOsthePrakashBelum ada peringkat

- Imn 903000 E06Dokumen158 halamanImn 903000 E06Paul CasaleBelum ada peringkat

- Biology Paper 6 NotesDokumen5 halamanBiology Paper 6 NotesbBelum ada peringkat

- PHP Question AnswerDokumen20 halamanPHP Question AnswerManish SharmaBelum ada peringkat

- Computer MCQ Test For Nts 4,5,6Dokumen1 halamanComputer MCQ Test For Nts 4,5,6Mohsan NaqiBelum ada peringkat

- Network Fault Conditions - PPT 3 PDFDokumen78 halamanNetwork Fault Conditions - PPT 3 PDFbik_mesiloveBelum ada peringkat

- Visvesvaraya Technological University: "Dijkstra'S Algorithm"Dokumen34 halamanVisvesvaraya Technological University: "Dijkstra'S Algorithm"RASHMIBelum ada peringkat

- PIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) FinalDokumen82 halamanPIA B2 - Module 2 (PHYSICS) SubModule 2.2 (Mechanics) Finalsamarrana1234679Belum ada peringkat

- Quick Start Guide For Driver Compilation and InstallationDokumen6 halamanQuick Start Guide For Driver Compilation and InstallationvijayBelum ada peringkat

- The Network+ Cram Sheet: Networking ConceptsDokumen4 halamanThe Network+ Cram Sheet: Networking ConceptsISTAKHAR UDDIN AHAMED100% (1)

- SO100K Installation InstructionDokumen32 halamanSO100K Installation InstructionAlwin Anno SastraBelum ada peringkat

- Sesam and Bladed - Efficient Coupled Analyses - Webinar Presentation - tcm8-102589 PDFDokumen31 halamanSesam and Bladed - Efficient Coupled Analyses - Webinar Presentation - tcm8-102589 PDFsamiransmitaBelum ada peringkat

- MDM Heiana Nadia Hamzah: Prepared byDokumen50 halamanMDM Heiana Nadia Hamzah: Prepared bySyarfa FurzanneBelum ada peringkat

- ManualDokumen31 halamanManualextremtigerBelum ada peringkat

- 2-Way Doherty Amplifier With BLF888ADokumen27 halaman2-Way Doherty Amplifier With BLF888AerdemsecenBelum ada peringkat

- Bsm2300a SeriesDokumen324 halamanBsm2300a SeriesIBRAHIMBelum ada peringkat

- Wrong Number Series 23 June by Aashish AroraDokumen53 halamanWrong Number Series 23 June by Aashish AroraSaurabh KatiyarBelum ada peringkat

- Silvaco ATHENA Description 1 PDFDokumen18 halamanSilvaco ATHENA Description 1 PDFRahul JaiswalBelum ada peringkat

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisDari EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisPenilaian: 4 dari 5 bintang4/5 (2)

- Quantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsDari EverandQuantum Physics: A Beginners Guide to How Quantum Physics Affects Everything around UsPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- The Laws of Thermodynamics: A Very Short IntroductionDari EverandThe Laws of Thermodynamics: A Very Short IntroductionPenilaian: 4.5 dari 5 bintang4.5/5 (10)

- Aerodynamics for Engineering StudentsDari EverandAerodynamics for Engineering StudentsPenilaian: 5 dari 5 bintang5/5 (5)

- Hyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionDari EverandHyperspace: A Scientific Odyssey Through Parallel Universes, Time Warps, and the 10th DimensionPenilaian: 4.5 dari 5 bintang4.5/5 (3)

- Basic Math & Pre-Algebra Workbook For Dummies with Online PracticeDari EverandBasic Math & Pre-Algebra Workbook For Dummies with Online PracticePenilaian: 4 dari 5 bintang4/5 (2)

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedDari EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedPenilaian: 5 dari 5 bintang5/5 (1)

- Einstein's Fridge: How the Difference Between Hot and Cold Explains the UniverseDari EverandEinstein's Fridge: How the Difference Between Hot and Cold Explains the UniversePenilaian: 4.5 dari 5 bintang4.5/5 (51)

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideDari Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuidePenilaian: 3.5 dari 5 bintang3.5/5 (7)

- Mathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingDari EverandMathematical Mindsets: Unleashing Students' Potential through Creative Math, Inspiring Messages and Innovative TeachingPenilaian: 4.5 dari 5 bintang4.5/5 (21)

- Quantum Mechanics 1: Particles & WavesDari EverandQuantum Mechanics 1: Particles & WavesPenilaian: 4 dari 5 bintang4/5 (11)

- Centrifugal Pumps: Design and ApplicationDari EverandCentrifugal Pumps: Design and ApplicationPenilaian: 2 dari 5 bintang2/5 (7)

- Build a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Dari EverandBuild a Mathematical Mind - Even If You Think You Can't Have One: Become a Pattern Detective. Boost Your Critical and Logical Thinking Skills.Penilaian: 5 dari 5 bintang5/5 (1)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ADari EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ABelum ada peringkat

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsDari EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsBelum ada peringkat

- Handbook of Mechanical and Materials EngineeringDari EverandHandbook of Mechanical and Materials EngineeringPenilaian: 5 dari 5 bintang5/5 (4)

- ParaPro Assessment Preparation 2023-2024: Study Guide with 300 Practice Questions and Answers for the ETS Praxis Test (Paraprofessional Exam Prep)Dari EverandParaPro Assessment Preparation 2023-2024: Study Guide with 300 Practice Questions and Answers for the ETS Praxis Test (Paraprofessional Exam Prep)Belum ada peringkat

- Fuels, Furnaces and Refractories: International Series on Materials Science and TechnologyDari EverandFuels, Furnaces and Refractories: International Series on Materials Science and TechnologyPenilaian: 5 dari 5 bintang5/5 (1)

- Pilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CDari EverandPilot's Handbook of Aeronautical Knowledge (2024): FAA-H-8083-25CBelum ada peringkat