Shear Behaviour of Reinforced Concrete Members Without Stirrups and Subjected

Diunggah oleh

monolith80Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Shear Behaviour of Reinforced Concrete Members Without Stirrups and Subjected

Diunggah oleh

monolith80Hak Cipta:

Format Tersedia

Shear behaviour of reinforced concrete members without stirrups and subjected

to fatigue loads

Juan Manuel GALLEGO

Research assistant

Technical University of

Madrid (UPM)

Madrid, Spain

Carlos ZANUY

Assistant Professor

Technical University of

Madrid (UPM)

Madrid, Spain

Luis ALBAJAR

Professor

Technical University of

Madrid (UPM)

Madrid, Spain

jmgallego@caminos.upm.es

czs@caminos.upm.es

lalbajar@caminos.upm.es

Summary

The shear fatigue behaviour of reinforced concrete elements without stirrups is a complex process

that involves a large number of variables. Because of its brittle nature, a better understanding of

shear fatigue is convenient, so that practical recommendations with mechanical basis can be

proposed. Experimental evidence indicates that shear fatigue failure starts with the formation of a

diagonal crack from the inclination of a flexural crack in one of the shear spans. This diagonal crack

then propagates with load cycles, both upwards to the load application point and downwards to the

support. Final shear fatigue failure takes place by the destruction of the compression zone when its

depth is too small to resist the compression force acting on it. In addition, it is also possible an

unstable propagation of the diagonal crack as soon as it forms. A critical point of the process is

therefore the formation of the diagonal crack. In this paper, the capabilities of a predictive model to

estimate the number of cycles to diagonal cracking are explored. A comparison is carried out with

first experimental results on haunched reinforced concrete beams without stirrups, which are typical

of cantilever slabs of bridge decks.

Keywords: Beams; fatigue; reinforced concrete; shear strength; bridge deck slabs.

1.

Introduction

Concrete structures may suffer fatigue when they are subjected to cyclic loads. Despite of the fact

that typical fatigue failure of reinforced concrete elements is due to the brittle fracture of the

longitudinal reinforcement, experimental works have shown that shear fatigue failure is also

possible [1]-[3]. Previous experimental works carried out in reinforced concrete elements without

stirrups have shown that different fatigue failure mode may be developed according to the type,

position and magnitude of applied loads, geometry, reinforcement ratio and material properties of

tested specimens. In general, the shear fatigue failure appears as a consequence of the formation and

progressive development of a diagonal crack from an existing flexural crack. After diagonal

cracking, the crack propagates into the compression zone until failure takes place due to the

destruction of the compression zone when its depth is too small to resist the applied force acting on

it (failure mode referred to as shear-compression failure). The propagation of the diagonal crack

can also be instantaneous, leading to an even more brittle failure mode (referred to as diagonalcracking failure). Accordingly, a critical aspect of the shear fatigue process is the formation of a

diagonal crack. Therefore, the availability of a predictive tool for diagonal cracking seems very

interesting.

A predictive model is proposed in the paper to estimate the number of cycles to diagonal cracking.

The model has been based on the stress state analysis of a flexural crack supposed to be the one that

inclines and propagates during the shear fatigue process. The model has been used to understand the

first fatigue tests carried out in reinforced concrete haunched beams without shear reinforcement.

The specimens of the experimental campaign have been designed to represent the lateral cantilevers

of bridge deck slabs that are usually built without shear reinforcement.

2.

Shear fatigue of RC haunched beams without stirrups

A specific experimental campaign is being developed by the Structural Engineering Group of UPM

to study fatigue behaviour of cantilever slabs of bridge decks. It is noted that this is the first time

that an experimental campaign on haunched specimens is carried out. The results of the first

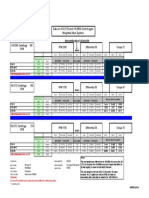

experimental results are presented and analyzed in the full paper. As an example, specimen FT-3a

(with a maximum applied load of 58% of the static strength obtained in a control specimen) showed

shear fatigue failure after 24,152 load cycles. The crack pattern at failure can be observed in

Fig.1(a). In this test, the section from which a diagonal crack formed was at 0.44 m from the

support.

The proposed model can be used to analyze the experimental result of test FT-3a. The results of this

analysis are represented in Fig.1(b), where the abscissa axis represents the distance of each crosssection of one half of the specimen to the support (x = 0.00 m corresponds to the support, while x =

1.20 m represents the midspan). With the proposed model, both the number of cycles to diagonal

cracking and the fatigue strength of the steel reinforcement have been estimated at all sections of

the specimen. The results are represented in the two curves of Fig.1(b).

According to the model, the number of cycles to diagonal cracking is smaller than the number of

cycles to fatigue fracture of the reinforcement. Furthermore, the section with the smallest fatigue

strength corresponds very well with the section from which the diagonal crack forms in the test

(also represented in Fig.1(b)). It is important to note that both the experiment and the model

indicate that the critical shear crack does not appear at midspan, as usual for constant depth

elements. Instead, the critical section shifts to the support.

The experimental and theoretical study presented by the authors has confirmed that shear fatigue

failure can occur in reinforced concrete haunched specimens without stirrups for moderate

maximum load levels, even before the typically reported fatigue failure due to fracture of the steel

reinforcement.

(a)

(b)

Fig.1. Test FT-3a: (a) Crack pattern after shear fatigue failure; (b) Comparison between predicted

and experimental number of cycles to failure.

References

[1]

[2]

[3]

ZANUY C., Anlisis Seccional de Elementos de Hormign Armado sometidos a Fatiga,

Doctoral Thesis, Technical University of Madrid, Madrid, Spain, 2008, 251 p.

CHANG T S., KESLER C E., Static and Fatigue Strength in Shear of Beams with Tensile

Reinforcement, ACI Journal, Vol. 54, No. 6, 1958, pp. 1033-1057.

CHANG T S., KESLER C E., Fatigue Behaviour of Reinforced Concrete Beams, ACI

Journal, Vol. 55, No. 8, 1958, pp. 245-254.

Anda mungkin juga menyukai

- Shear Behavior of Unbonded Post-TensionedDokumen10 halamanShear Behavior of Unbonded Post-TensionedAnonymous eB2AZT3Belum ada peringkat

- Shear Strength by Aurelio MuttoniDokumen10 halamanShear Strength by Aurelio Muttonishak543Belum ada peringkat

- Experimental Investigation of Stress Transients of Blasted - 2020 - EngineeringDokumen11 halamanExperimental Investigation of Stress Transients of Blasted - 2020 - EngineeringAliBelum ada peringkat

- 02 Krasnowski-Concrete-reinforcing Steel Bars Applications and Fatigue TestsDokumen8 halaman02 Krasnowski-Concrete-reinforcing Steel Bars Applications and Fatigue TestsTamiris AlmeidaBelum ada peringkat

- Advances in Bridge Fatigue TestingDokumen11 halamanAdvances in Bridge Fatigue TestingrammirisBelum ada peringkat

- Damage Assessment of RC Flat Slabs Partially Collapsed Due To Punching ShearDokumen13 halamanDamage Assessment of RC Flat Slabs Partially Collapsed Due To Punching ShearEng mohammadBelum ada peringkat

- Column - Beam Connection PDFDokumen16 halamanColumn - Beam Connection PDFTpHoBelum ada peringkat

- Shear Crack Induced Deformation of FRP RC Beams: FrprcsDokumen10 halamanShear Crack Induced Deformation of FRP RC Beams: Frprcsmickey2523Belum ada peringkat

- Shear Strength of Reinforced Concrete Beams Under Uniformly Distributed LoadsDokumen10 halamanShear Strength of Reinforced Concrete Beams Under Uniformly Distributed LoadsMoataz M. M. Rizk100% (1)

- Predicting The Response of Shear-Critical Reinforced Concrete Beams Using Response-2000 and SNI 2847:2013Dokumen9 halamanPredicting The Response of Shear-Critical Reinforced Concrete Beams Using Response-2000 and SNI 2847:2013Rizky Dwi IryandiBelum ada peringkat

- C1. 11NCEE - 001120 - Binder - Zhong - Kwon - ChristopoulosDokumen11 halamanC1. 11NCEE - 001120 - Binder - Zhong - Kwon - ChristopoulosMyron ZhongBelum ada peringkat

- Ultimate punching shear analysis of slab-column connectionsDokumen13 halamanUltimate punching shear analysis of slab-column connectionssamannikBelum ada peringkat

- Load Bearing Bahaviour of Cast in Shear Dowels PDFDokumen7 halamanLoad Bearing Bahaviour of Cast in Shear Dowels PDFToan PhamBelum ada peringkat

- A Parametric Study of R.C. Slab in Beam-Column Connection Under Cyclic LoadingDokumen9 halamanA Parametric Study of R.C. Slab in Beam-Column Connection Under Cyclic Loadingمحمد تانزيم ابراهيمBelum ada peringkat

- 105-s29 Control of Flexural Cracking in Reinforced ConcreteDokumen7 halaman105-s29 Control of Flexural Cracking in Reinforced ConcreteThomas Crowe100% (1)

- New method for stable fracture mechanics tests using wedge splittingDokumen9 halamanNew method for stable fracture mechanics tests using wedge splittingPrayush RajbhandariBelum ada peringkat

- Chapter 2 Literature ReviewDokumen10 halamanChapter 2 Literature ReviewSharan BvpBelum ada peringkat

- Progressive Collapse Resistance of Axially-RestrainedDokumen8 halamanProgressive Collapse Resistance of Axially-RestrainedjeanfatBelum ada peringkat

- Composite Structures 2 PDFDokumen29 halamanComposite Structures 2 PDFsvnBelum ada peringkat

- Continuous Beam Behavior and AnalysisDokumen17 halamanContinuous Beam Behavior and AnalysiseseckinBelum ada peringkat

- Computers and Structures: Adam Wosatko, Jerzy Pamin, Maria Anna PolakDokumen13 halamanComputers and Structures: Adam Wosatko, Jerzy Pamin, Maria Anna Polakno_milk_todayBelum ada peringkat

- Punching of Concrete Slabs Without Shear Reinforcement - GuandaliniDokumen9 halamanPunching of Concrete Slabs Without Shear Reinforcement - GuandaliniAnonymous YAHRBwSYnBelum ada peringkat

- Pernos Hansville PDFDokumen8 halamanPernos Hansville PDFÁlvaro SerranoBelum ada peringkat

- The Wedge Splitting Test, A New Method of Performing Stable Fracture Mechanics TestsDokumen8 halamanThe Wedge Splitting Test, A New Method of Performing Stable Fracture Mechanics TestsPrayush RajbhandariBelum ada peringkat

- Xu2019 Article FatigueBehaviourStudyOfTheShea PDFDokumen11 halamanXu2019 Article FatigueBehaviourStudyOfTheShea PDFLucas EmmanoelBelum ada peringkat

- Deformation capacity of concrete compression zonesDokumen16 halamanDeformation capacity of concrete compression zones01010Belum ada peringkat

- Crack Propagation in A Stiffener To DeckDokumen8 halamanCrack Propagation in A Stiffener To DeckSelim TurkyilmazBelum ada peringkat

- Repair and Strengthening Methods of Flat Slabs For Punching - António M. P. Ramos, Válter J.G. Lúcio, Paul ReganDokumen9 halamanRepair and Strengthening Methods of Flat Slabs For Punching - António M. P. Ramos, Válter J.G. Lúcio, Paul ReganVálter LúcioBelum ada peringkat

- CripplingDokumen10 halamanCripplingaravindkarthiBelum ada peringkat

- JL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous BridgesDokumen18 halamanJL-98-November-December Restraint Moments in Precast Prestressed Concrete Continuous Bridgesjrobert123321Belum ada peringkat

- Punching Shear Strength of Reinforced Concrete Slabs Without Transverse Reinforcement by Aurelio Muttoni PDFDokumen16 halamanPunching Shear Strength of Reinforced Concrete Slabs Without Transverse Reinforcement by Aurelio Muttoni PDFNuttawuit BigGyBelum ada peringkat

- Torsional Strengthening of Reinforced Concrete Box Beams Using Carbon Fiber Reinforced PolymerDokumen7 halamanTorsional Strengthening of Reinforced Concrete Box Beams Using Carbon Fiber Reinforced Polymernvel0006Belum ada peringkat

- Epfl TH4142Dokumen219 halamanEpfl TH4142Anonymous lEBdswQXmxBelum ada peringkat

- Dented BeamDokumen15 halamanDented BeamjeacovjeceBelum ada peringkat

- 01 Tension enDokumen17 halaman01 Tension enKenneth TanBelum ada peringkat

- Civil EngineeringDokumen10 halamanCivil EngineeringMudasir HussainBelum ada peringkat

- Behavior of Steel-Concrete Composite Beams Under Fatigue LoadsDokumen11 halamanBehavior of Steel-Concrete Composite Beams Under Fatigue LoadsSourav ceeBelum ada peringkat

- Size Effect in Pullout Tests: Aci Materials Journal Technical PaperDokumen5 halamanSize Effect in Pullout Tests: Aci Materials Journal Technical Paperfandhiejavanov2009Belum ada peringkat

- Experimental Tests On Tunnel Precast Segmental Lining With Fiber Reinforced ConcreteDokumen8 halamanExperimental Tests On Tunnel Precast Segmental Lining With Fiber Reinforced ConcretemetropodikasBelum ada peringkat

- Experimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenDokumen9 halamanExperimental and Theoretical Investigation of Impact Dynamic Plasticity For CK45 - Hani Aziz AmeenHani Aziz AmeenBelum ada peringkat

- Analysis of Reduced Modulus Action in U Section Steel Sheet PilesDokumen10 halamanAnalysis of Reduced Modulus Action in U Section Steel Sheet PilesArif FauziBelum ada peringkat

- Lateral Stiffness Characteristics of Tall PDFDokumen19 halamanLateral Stiffness Characteristics of Tall PDFLaila Monteiro A MeloBelum ada peringkat

- Shearwall BE Splice 990120Dokumen9 halamanShearwall BE Splice 990120Saeed TariverdiloBelum ada peringkat

- The Mechanical Property of Steel Reinforced Concrete Under Compressive Impact Loading Investigated With The SHPB ExperimentsDokumen6 halamanThe Mechanical Property of Steel Reinforced Concrete Under Compressive Impact Loading Investigated With The SHPB ExperimentsInternational Journal of Science and Engineering InvestigationsBelum ada peringkat

- 1974 Shear Transfer B y Ag InterlockDokumen15 halaman1974 Shear Transfer B y Ag InterlockLuiz Fernando ColussoBelum ada peringkat

- Warner R.F. - Simplified Analysis of Creep in Prestressed Concrete BeamsDokumen9 halamanWarner R.F. - Simplified Analysis of Creep in Prestressed Concrete BeamsCristóbal BerríosBelum ada peringkat

- Behavior of AAC Infill Walls Under Lateral LoadsDokumen7 halamanBehavior of AAC Infill Walls Under Lateral LoadsravirajBelum ada peringkat

- Shear Hinge MechanismDokumen12 halamanShear Hinge MechanismManjula Unnikrishnan N KBelum ada peringkat

- Design of Anchor Plates Based On The Component Method Rybinski & KulhmannDokumen12 halamanDesign of Anchor Plates Based On The Component Method Rybinski & KulhmannvcKampBelum ada peringkat

- Deep BeamDokumen9 halamanDeep BeamDeana WhiteBelum ada peringkat

- Development of Design Criteria For RC Interior Beam-Column JointsDokumen27 halamanDevelopment of Design Criteria For RC Interior Beam-Column JointsM HAFEEZ RAJABelum ada peringkat

- Block Shear Failure PresentationDokumen24 halamanBlock Shear Failure Presentationpraxie83% (12)

- SohamDokumen94 halamanSohamsohamBelum ada peringkat

- Reinforced Concrete Buildings: Behavior and DesignDari EverandReinforced Concrete Buildings: Behavior and DesignPenilaian: 5 dari 5 bintang5/5 (1)

- The Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryDari EverandThe Fatigue Strength of Transverse Fillet Welded Joints: A Study of the Influence of Joint GeometryBelum ada peringkat

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Dari EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Belum ada peringkat

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceDari EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceBelum ada peringkat

- Metropol Parasol, Plaza de La Encarnación - Adventures in EngineeringDokumen2 halamanMetropol Parasol, Plaza de La Encarnación - Adventures in Engineeringmonolith80Belum ada peringkat

- Evaluation of Damage Equivalent Factor For Roadway BridgesDokumen8 halamanEvaluation of Damage Equivalent Factor For Roadway Bridgesmonolith80Belum ada peringkat

- Shrinkage Effect On Beams Strengthened With Additional Concrete LayersDokumen2 halamanShrinkage Effect On Beams Strengthened With Additional Concrete Layersmonolith80Belum ada peringkat

- High-Rise Buildings With Transfer Floors: Drift CalculationsDokumen2 halamanHigh-Rise Buildings With Transfer Floors: Drift Calculationsmonolith80100% (1)

- Prestressed Concrete Girder Bridges Using Large 0.7 Inch StrandsDokumen8 halamanPrestressed Concrete Girder Bridges Using Large 0.7 Inch Strandsmonolith80Belum ada peringkat

- New football stadium roof in Saint-Petersburg analyzed using superelements and incremental launchingDokumen2 halamanNew football stadium roof in Saint-Petersburg analyzed using superelements and incremental launchingmonolith80Belum ada peringkat

- Challenges in Implementing Urban Transport Projects in MumbaiDokumen2 halamanChallenges in Implementing Urban Transport Projects in Mumbaimonolith80Belum ada peringkat

- Rehabilitation and Upgrading of Major Dhyan Chand National StadiumDokumen2 halamanRehabilitation and Upgrading of Major Dhyan Chand National Stadiummonolith80Belum ada peringkat

- Innovation in Long Span Concrete BridgesDokumen2 halamanInnovation in Long Span Concrete Bridgesmonolith80Belum ada peringkat

- Fifty Years of Bridge HistoryDokumen10 halamanFifty Years of Bridge Historymonolith80Belum ada peringkat

- PE Registration Document in Oregon U.SDokumen18 halamanPE Registration Document in Oregon U.Smonolith80Belum ada peringkat

- Suppression of Wind Induced Instabilities of A Long Span Bridge by A Passive Deck Flaps Control System - Part 1 Formulation - 2000Dokumen19 halamanSuppression of Wind Induced Instabilities of A Long Span Bridge by A Passive Deck Flaps Control System - Part 1 Formulation - 2000monolith80Belum ada peringkat

- Poverty Alleviation Through Bridge BuildingDokumen2 halamanPoverty Alleviation Through Bridge Buildingmonolith80Belum ada peringkat

- Long-Term Monitoring of White Rhino, Building With Tensegrity SkeletonsDokumen9 halamanLong-Term Monitoring of White Rhino, Building With Tensegrity Skeletonsmonolith80Belum ada peringkat

- A Fast Incremental-Iterative Procedure For Ultimate Strength Analysis of Composite Cross-Sections With Arbitrary ShapeDokumen8 halamanA Fast Incremental-Iterative Procedure For Ultimate Strength Analysis of Composite Cross-Sections With Arbitrary Shapemonolith80Belum ada peringkat

- SS1 - 1 Chakraborty - LONG PDFDokumen7 halamanSS1 - 1 Chakraborty - LONG PDFmonolith80Belum ada peringkat

- Aerodynamic Problems of S Super-Long Span Cable-Stayed Bridge - IABSE 2005Dokumen8 halamanAerodynamic Problems of S Super-Long Span Cable-Stayed Bridge - IABSE 2005monolith80Belum ada peringkat

- Construction of The La Plata Twinstar DomeDokumen7 halamanConstruction of The La Plata Twinstar Domemonolith80Belum ada peringkat

- Hurricane Wind Power Spectra, Cospectra, and Integral Length ScalesDokumen20 halamanHurricane Wind Power Spectra, Cospectra, and Integral Length Scalesmonolith80Belum ada peringkat

- Nonliner Dynamics of Cable Stays - Part 1 - Sinusoidal Cable Support Excitation - 2005Dokumen28 halamanNonliner Dynamics of Cable Stays - Part 1 - Sinusoidal Cable Support Excitation - 2005monolith80Belum ada peringkat

- An Analysis of Binary Flutter of Bridge Deck SectionDokumen12 halamanAn Analysis of Binary Flutter of Bridge Deck Sectionmonolith80Belum ada peringkat

- Computational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011Dokumen11 halamanComputational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011monolith80Belum ada peringkat

- Computational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011Dokumen11 halamanComputational Study On Aerodynamic Mitigation of Wind-Induced Large-Amplitude Vibrations of Stay Cables With Strakes - 2011monolith80Belum ada peringkat

- Bridge Design Manual M 23-50.06 July 2011Dokumen1.316 halamanBridge Design Manual M 23-50.06 July 2011monolith80Belum ada peringkat

- Regenerative Medicine Manual ISSCA 2020 EnglishDokumen21 halamanRegenerative Medicine Manual ISSCA 2020 EnglishDana MihutBelum ada peringkat

- Design of PID controllersDokumen4 halamanDesign of PID controllersFseha GetahunBelum ada peringkat

- Biology BIOL 1003 CH 1-3 QuizDokumen14 halamanBiology BIOL 1003 CH 1-3 QuizYummyWords100% (1)

- TP5 W9 S9 R0Dokumen2 halamanTP5 W9 S9 R0DickiEffendy0% (1)

- EVOLUTION Class Notes PPT-1-10Dokumen10 halamanEVOLUTION Class Notes PPT-1-10ballb1ritikasharmaBelum ada peringkat

- Ca2Dokumen8 halamanCa2ChandraBelum ada peringkat

- Sundar KandvalmikiDokumen98 halamanSundar Kandvalmikifactree09Belum ada peringkat

- OE Spec MTU16V4000DS2250 3B FC 50Hz 1 18Dokumen6 halamanOE Spec MTU16V4000DS2250 3B FC 50Hz 1 18Rizki Heru HermawanBelum ada peringkat

- Poultry Disease Prevention and ControlDokumen64 halamanPoultry Disease Prevention and Controlsigra100% (3)

- Biomechanics of The Knee During Closed Kinetic Chain and Open KineticDokumen17 halamanBiomechanics of The Knee During Closed Kinetic Chain and Open KineticArmando NetoBelum ada peringkat

- Pembangkit ListrikDokumen2 halamanPembangkit ListrikDede MulyamanBelum ada peringkat

- GMsetDokumen8 halamanGMsetdilo001Belum ada peringkat

- HS-2172 Vs HS-5500 Test ComparisonDokumen1 halamanHS-2172 Vs HS-5500 Test ComparisonRicardo VillarBelum ada peringkat

- G 26 Building Using ETABS 1673077361Dokumen68 halamanG 26 Building Using ETABS 1673077361md hussainBelum ada peringkat

- Cdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFDokumen87 halamanCdd153167-Samsung Un32d6500vf Un32 40 46 55d6400uf 6420uf 6450uf 6500vf 6900wf Chassis U63a SM PDFMilciades MurilloBelum ada peringkat

- Basic Principles of Local GovernmentDokumen72 halamanBasic Principles of Local GovernmentAnne Camille SongBelum ada peringkat

- Chapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Dokumen29 halamanChapter 7 (Additional Notes) Thermodynamics Review (Power Plant Technology by M Wakil)Aries SattiBelum ada peringkat

- UNIT-2 Design of Spur GearDokumen56 halamanUNIT-2 Design of Spur GearMarthandeBelum ada peringkat

- The Grey Nomads Guide To AustraliaDokumen3 halamanThe Grey Nomads Guide To AustraliaFreerangecamping60% (5)

- Project Data Collection & Risk ReportingDokumen2 halamanProject Data Collection & Risk Reportinggambler yeagerBelum ada peringkat

- The Relevance of Vivekananda S Thought IDokumen16 halamanThe Relevance of Vivekananda S Thought IJaiyansh VatsBelum ada peringkat

- Orientation Report PDFDokumen13 halamanOrientation Report PDFRiaz RasoolBelum ada peringkat

- Shaw-Box Hoist - 700 Series Electric Wire Rope 10 To 25 Ton Manual PDFDokumen68 halamanShaw-Box Hoist - 700 Series Electric Wire Rope 10 To 25 Ton Manual PDFMbalekelwa MpembeBelum ada peringkat

- Exercise Stress TestingDokumen54 halamanExercise Stress TestingSaranya R S100% (2)

- Time and Work Assignments PDFDokumen8 halamanTime and Work Assignments PDFpavan0% (1)

- Welcome To International Journal of Engineering Research and Development (IJERD)Dokumen9 halamanWelcome To International Journal of Engineering Research and Development (IJERD)IJERDBelum ada peringkat

- Nakshatra Exaltation DebilitationDokumen3 halamanNakshatra Exaltation DebilitationBhanu Pinnamaneni100% (1)

- Adeptus Evangelion 2.5 - Operations ManualDokumen262 halamanAdeptus Evangelion 2.5 - Operations ManualGhostwheel50% (2)

- L C R Circuit Series and Parallel1Dokumen6 halamanL C R Circuit Series and Parallel1krishcvrBelum ada peringkat

- EM-CABLE Product CatalogDokumen96 halamanEM-CABLE Product Catalogm00h00Belum ada peringkat