Concrete Works Inspection & Testing

Diunggah oleh

kbldamDeskripsi Asli:

Judul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Concrete Works Inspection & Testing

Diunggah oleh

kbldamHak Cipta:

Format Tersedia

C.A.T.

GROUP QUALITY ASSURANCE

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

CONTRACT NUMBER 6600032833

BI-10-01282

MASTER GAS SYSTEM (MGS)

56"EGW-2 LOOP-1

FOR

SAUDI ARAMCO

Inspection and Testing for Concrete Works

(QA/P133I.Doc)

0

Rev

QC Manager

Prepared By

QC Manager

Controlled By

20.04.2014

Date

Project Manager

Approved By

C.A.T. GROUP QUALITY ASSURANCE

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

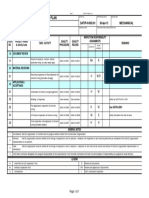

Table of Contents

1.

PROCEDURE NO.

2.

SCOPE AND PURPOSE

3.

APPLICABILITY

4.

RESPONSIBILITY

5.

GENERAL

6.

DEFINITIONS

7.

PROCEDURE

7.1.

Receiving Inspection

7.2.

In-process Inspection and Testing

7.2.1.

7.2.2.

7.2.3.

7.2.4.

7.2.5.

7.2.6.

7.2.7.

7.2.8.

7.3.

Civil and Earth Works

Pre-Pour Inspection

Concrete Placement

Concrete Testing

Form Removal

Concrete Curing and Protection

Finishing

Grouting

Final Inspection and Testing

8.

RECORDS

9.

REFERENCES

10.

ATTACHMENTS

C.A.T. GROUP QUALITY ASSURANCE

1.

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

PROCEDURE NO.

P133I

2.

SCOPE AND PROCEDURE

The scope and purpose of this procedure is to establish a functional Inspection and

Testing system to ensure that the process control of concrete works is adopted and

properly executed in accordance with Client specifications and applicable standards.

3.

APPLICABILITY

All Concrete works.

4.

RESPONSIBILITY

5.

Project Manager

Discipline Engineer

Discipline Foreman

QA Manager

QC Personnel

Material Controller

GENERAL

The responsibility for the Inspection and Testing of the Concrete Works rests primarily

with the QC Inspector, the Discipline Engineer and the Discipline Foreman with audit

by the Senior QA/QC Personnel .

The Discipline Engineer and the Discipline Foreman shall ensure the required work

permits are available and in place on a daily basis. Similarly they shall ensure that

utilized drawings are latest revision

The Project QA & QC Managers shall verify compliance to this procedure by Audit,

and shall perform reviews on all Quality related contractual documentation

The QC Inspector shall be responsible for witnessing tests and inspections and

ensure appropriate documentation in accordance with relevant SATIP.

All forms and records shall be filled out in accordance with the relevant SATIP. Client

SATIP and records are referenced however should the need arise additional forms

shall be developed for specific activities and added as the project progresses

Concrete works shall comply fully with the applicable laws and Client requirements

and specifications.

3

C.A.T. GROUP QUALITY ASSURANCE

6.

DEFINITIONS

SATIP:

SAIC:

SATR:

7.

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

Saudi Aramco Typical Inspection Plan.

Saudi Aramco Inspection Checklist.

Saudi Aramco test Record.

PROCEDURE

7.1.

Receiving Inspection

The cement aggregates and water used shall be in accordance with SAES-Q001. The QC Inspector and Material Supervisor shall control, through the proper

SATIP and procedure that cement, raw materials and concrete reinforcement,

are in compliance.

The Quality Department shall submit to Client Representative, full details of all

materials to be used for the concrete works including, if required, the names of

suppliers or manufacturers and sources of supply, for his review and approval

In accordance with SATIP-Q-001-01.

The Quality Department shall ensure that materials or sources of materials are

not changed. Materials where required, shall be sampled and tested in an

approved laboratory. Results of tests shall be submitted to Client

Representative.

7.2.

In-process Inspection and Testing

7.2.1. Civil and Earth Works (SATIP-A-114-01/ SATIP-S-070-01)

Inspection and Testing of Civil and Earth works shall be done in

accordance with SAES-M-100,SAES-A-114 and Procedure P138I.

7.2.2. Pre-Pour Inspection (SATIP-Q-001-02)

a) Forming

Prior to the placing of concrete, the Discipline Engineer / QC

Inspector must ensure that the forms comply with SAES-Q-001 Sect

8

b) Reinforcement

The reinforcing steel must be in accordance with SAES-Q-001 Sect

5 & 6 and be checked for the following:

4

C.A.T. GROUP QUALITY ASSURANCE

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

The steel is clear of the forms and soil and held firmly in place

by the use of wires, chairs, or spacers.

Mud, oil, concrete and loose scale has been removed.

The steel has been installed in accordance with the foundation

drawings and bending schedule as to size, location and

spacing. The splicing and radius of bends conforms to the

project specifications.

c) Embedded Items (SATIP-Q-001-02)

Embedded items must be checked as follows:

The Discipline Engineer shall check the diameter, length, type,

location, elevation, projection and plumb ness of anchor bolts.

They must be properly secured.

The sleeves for anchor bolts must be checked for correct size

and material, and must be centered on the bolts.

Angles, inserts, plates, sleeves, block-outs and hold-downs shall

be checked for size, thickness, material and location.

Check for installation of conduits and ground wires, when

required.

d) Approval to Pour

Concrete foundations shall not be poured until the QC Inspector or

Client Inspector has completed pre-pour inspection.

Relevant SAIC/SATR shall be used to indicate acceptance to pour.

7.2.3. Concrete Placement (SATIP-Q-001-02)

Previous to, or during the placing of the concrete, the Discipline

Engineer shall check for the following:

a) Concrete surfaces to receive new concrete should have the

loosened particles of aggregate and dirt or mud removed.

b) The ground or existing concrete should be moistened with water.

c) The minimum mixing time should be sufficient to form the uniform

mass and not exceed the time limit for remaining in the mixer.

C.A.T. GROUP QUALITY ASSURANCE

d)

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

When applicable, the slump must be checked to avoid placing

concrete too wet. Water shall not be added to concrete in the field.

e) Equipment made of aluminum or aluminum alloy should not be

used to transport or convey concrete.

f)

All concrete should be thoroughly consolidated by vibrating, but

should not be over-vibrated.

g) Concrete should not be dropped in tall forms without a drop pipe,

moved with a vibrator, nor handled with any other manner, which

could cause separation of materials.

h) In making large pours, an efficient system of placing concrete

should be set up to keep the edges fresh or soft, in order to avoid a

cold joint if there is an unexpected delay.

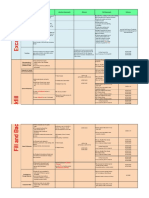

7.2.4. Concrete Testing (SATIP-Q-001-02)

The Saudi Aramco Approved Third Party Technician is responsible for

the testing of concrete as follows and in accordance with SAES-Q-001,

09-SAMSS-97:

When applicable, slump tests for consistency of a concrete batched

mix should be made as per the project specifications. The Saudi

Aramco Approved Third Party Technician should make this test by

taking concrete sample from the truck spout or from the fresh

concrete as it is placed in the forms. A well-proportioned concrete

mix with proper water content will gradually slump but retain its

original cohesive form. A poor mix with excessive water content will

slump quickly, aggregates will separate, and the specimen will

disintegrate. Acceptance criteria of a slump test shall be in

accordance with the specifications.

Cylinder Test shall be done in accordance with 09-SAMSS-97.

Specimens for each set shall be obtained at the same time and from the

same batch of concrete. A standard slump test shall be made each time

compression test cylinders are taken.

Test cylinders shall be dated and numbered consecutively. Each

cylinder of each set shall also be given an identifying letter (A, B etc.)

At least four cylinders shall be made at one time and tested as follows:

1 Cylinder at 3 Days.

1 Cylinder at 7 Days.

2 Cylinders at 28 Days.

6

C.A.T. GROUP QUALITY ASSURANCE

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

Relevant SAIC / SATR shall be used for reporting on cylinder

testing.

A concrete test specimen report must be completed when

specimens are taken for testing. A standard form supplied by the

testing laboratory will be acceptable. The original of this form should

be forwarded to the Site QC Office and one copy must be sent to the

laboratory along with the specimens.

7.2.5. Form Removal (SATIP-Q-001-02)

Determining the time for safe form removal should be based on

the effect on the concrete. There must be no evidence of damage

to the concrete due to stripping operation. The minimum time for

walls or columns, sides of beams, footings, manholes and block

foundations should be 24 hours.

Unless otherwise specified, the shoring under beam bottoms and

supported slabs may be removed after test results indicate that

the concrete has reached 2/3 of the design strength. (in special

cases, such as precast concrete, architectural concrete and long

spans, the Client should be consulted).

Care must be exercised when removing forms to ensure that the

bolts are not disturbed and the concrete is not damaged.

7.2.6. Concrete Curing and Protection (SATIP-Q-001-02)

The concrete should be kept continuously moist for the duration

specified in accordance with SAES-Q-001 Sect 10.

7.2.7. Finishing (SATIP-Q-001-02)

1. All concrete finishing will be in accordance with the approved

project drawings and Client specifications.

2. The finishing of concrete foundations and walls can best be

accomplished immediately after the removal of forms.

3. All concrete shall be inspected to determine that voids, form tie

holes, damaged corners, etc., have been properly repaired.

4. Finished concrete must be protected and cured as specified in

the preceding paragraphs.

C.A.T. GROUP QUALITY ASSURANCE

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

5. Contraction joints in concrete slabs that require sawing will be

cut within the time limit specified in the Client specifications.

6.

Coating for underground portion of foundations shall be done in

accordance with SAES-Q-001, SAES-H-101, APCS 10 and

Coating application shall be recorded on Form P143-2 Paint

Acceptance Report.

7.2.8. Grouting (SATIP-Q-010-01)

7.3.

The Discipline Foreman shall ensure that grouting is mixed and applied

in accordance with SAES-Q-010 and Manufacturers recommendations

and instructions.

Final Inspection and Testing (SATIP-Q-001-02)

The Saudi Aramco Approved Third Party Technician shall prepare, mark, store

and cure test cylinders as per the Client Requirements and specifications.

The results of the tests shall be submitted to client Representative in the period

required in the specifications.

Any defective concrete work shall, at the discretion of the Client

Representative, be demolished completely and rebuilt or cut and made good.

Such rectification shall be re-tested / Inspected in accordance with original

requirements

The Saudi Aramco Approved Third Party Technician shall use the Concrete

Cylinder Record Summary to keep records of the results of testing.

The documents relevant to inspection and testing shall be kept in the QA/QC

Office on Site.

8.

RECORDS

All Forms and records relevant to this procedure shall be kept in the site office by the

QA/QC Supervisor and following the finish of the project repatriated to the area head

office to be archived and kept for a period of Three years.

9.

REFERENCES

SAES-Q-001.

SAES-Q-010.

SAES-M-100.

SAES-H-101.

09-SAMSS-097.

SATIP-A-114-01

8

C.A.T. GROUP QUALITY ASSURANCE

INSPECTION AND TESTING FOR CONCRETE WORKS

REVISION 0 DATED 20.04.2014

SATIP-S-070-01

SATIP-Q-001-02

SATIP-Q-010-01

10.

ATTACHMENTS

None

Anda mungkin juga menyukai

- Saudi Aramco Concrete Coating ProcedureDokumen10 halamanSaudi Aramco Concrete Coating Proceduremoytabura96100% (1)

- Home Interior Exterior - Civil Inspector Interview Question and AnswerDokumen5 halamanHome Interior Exterior - Civil Inspector Interview Question and AnswerZeeshanAliBelum ada peringkat

- SAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionDokumen2 halamanSAIC-A-1002 Fill, Select-Fill and Marl Cap Materials Receiving InspectionhussniosmanBelum ada peringkat

- Nitomortar TC2000Dokumen3 halamanNitomortar TC2000talatzahoorBelum ada peringkat

- QC Inspector Written Test AnswersDokumen40 halamanQC Inspector Written Test Answersmohd khajaBelum ada peringkat

- Nitomortar FCDokumen3 halamanNitomortar FCBalasubramanian AnanthBelum ada peringkat

- Saudi Aramco Oil Company: SECTION 01051 SurveyingDokumen4 halamanSaudi Aramco Oil Company: SECTION 01051 SurveyingphilipyapBelum ada peringkat

- Project Quality RequirementsDokumen8 halamanProject Quality RequirementsSIVABelum ada peringkat

- SAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Dokumen5 halamanSAES-Q-001 (Criteria For The Design & Construction of Concrete Structures)Nino Celso Astillero100% (1)

- 09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsDokumen4 halaman09-SAMSS-106 - Epoxy Coating of Steel Reinforcing BarsFiras AlbaweiBelum ada peringkat

- Saes Q 001 Saes-Q-006Dokumen5 halamanSaes Q 001 Saes-Q-006Abdul Hannan100% (1)

- Civil Test: NameDokumen6 halamanCivil Test: NamePrince JoseBelum ada peringkat

- Saudi Aramco Inspection ChecklistDokumen8 halamanSaudi Aramco Inspection ChecklistAnantha PadmanabhanBelum ada peringkat

- Architectural Painting Works Ins ChecklistDokumen2 halamanArchitectural Painting Works Ins Checklistmunna100% (1)

- Coating Procedure For Bituminous Material Rev 01Dokumen5 halamanCoating Procedure For Bituminous Material Rev 01moytabura96Belum ada peringkat

- Specifications of Painting WorksDokumen7 halamanSpecifications of Painting WorksSiddharth Gamare100% (1)

- Saudi Aramco Typical Inspection PlanDokumen10 halamanSaudi Aramco Typical Inspection PlanMoghal AliBelum ada peringkat

- Corrosion Protection Services GuideDokumen37 halamanCorrosion Protection Services GuideTASNEEM100% (2)

- TDS Nitomortar TC2000 Saudi ArabiaDokumen3 halamanTDS Nitomortar TC2000 Saudi ArabiaHarry BawingBelum ada peringkat

- SAES Q 001 Table ExposureDokumen4 halamanSAES Q 001 Table ExposureKhurram ShehzadBelum ada peringkat

- Saqib Ali Aramco NotesDokumen18 halamanSaqib Ali Aramco NotesAmir Khan0% (1)

- Epoxy Painting Method GuideDokumen3 halamanEpoxy Painting Method GuideKaram MoatasemBelum ada peringkat

- Jotafloor Coating: Technical Data SheetDokumen5 halamanJotafloor Coating: Technical Data SheetBilher SihombingBelum ada peringkat

- MST For Concret CoatingDokumen6 halamanMST For Concret CoatingDelta akathehusky100% (1)

- SATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionDokumen2 halamanSATIP-A-114-01 Earthworks: Site Preparation, Excavation and Backfilling During ConstructionNino Celso AstilleroBelum ada peringkat

- TDS Nitocote EPU Saudi ArabiaDokumen4 halamanTDS Nitocote EPU Saudi ArabiaShaikhRizwan100% (1)

- 02225Dokumen6 halaman02225uddinnadeemBelum ada peringkat

- SAUDI ARAMCO ID/PIEU-30-Nov-2018Dokumen2 halamanSAUDI ARAMCO ID/PIEU-30-Nov-2018Moghal AliBelum ada peringkat

- Nawaz Khan - Civil InspectorDokumen4 halamanNawaz Khan - Civil InspectormlBelum ada peringkat

- Rev. N English 06/ 2020: ProcedureDokumen11 halamanRev. N English 06/ 2020: ProcedureCaio JoppertBelum ada peringkat

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDokumen2 halamanSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyBelum ada peringkat

- Cem Tec White PuDokumen2 halamanCem Tec White Pupravi3434Belum ada peringkat

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDokumen5 halamanTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcBelum ada peringkat

- Saes Q 001Dokumen22 halamanSaes Q 001irfan hussainBelum ada peringkat

- Cement Lining Inspection Plan for PipesDokumen1 halamanCement Lining Inspection Plan for PipesSatheesh Rama SamyBelum ada peringkat

- Saes R 004Dokumen8 halamanSaes R 004Shahzad HussainBelum ada peringkat

- Concrete Placement (Spec)Dokumen18 halamanConcrete Placement (Spec)Vetrivel MuruganBelum ada peringkat

- QC CIVIL VOL 2 SS 7aevfrDokumen26 halamanQC CIVIL VOL 2 SS 7aevfrSudhanBelum ada peringkat

- Sika Grout - 114 SaDokumen3 halamanSika Grout - 114 SaGavriel NgBelum ada peringkat

- Astm e 1745Dokumen2 halamanAstm e 1745Zahoor Ahmed Mohsan100% (1)

- SAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Dokumen2 halamanSAES-Q-006 (Asphalt & Sulfur Extended Asphalt Concrete Paving)Nino Celso Astillero100% (1)

- Medium Curing Cutback Product Data SheetDokumen1 halamanMedium Curing Cutback Product Data SheetRaheelHashmiBelum ada peringkat

- 1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Dokumen7 halaman1st List of Non Inspectable Materials Technical Submittals - VID Comments (OMPPD-GUPD-L-165-17)Mohamed Reda Hussein SengarBelum ada peringkat

- Method Statement For Approval of Layer Thickness - Rev.01Dokumen9 halamanMethod Statement For Approval of Layer Thickness - Rev.01Jox Biol100% (1)

- Qaqc Inspector QuestionaireDokumen4 halamanQaqc Inspector QuestionaireNiño Celso AstilleroBelum ada peringkat

- Qc Manager, Oil and Gas ExperienceDokumen25 halamanQc Manager, Oil and Gas ExperienceniranjanvengadBelum ada peringkat

- Important Points To Remember Practical ThingsDokumen2 halamanImportant Points To Remember Practical ThingsricosanojuanBelum ada peringkat

- Method Statement For Coating Repair of Air Handling Units (Ahu)Dokumen6 halamanMethod Statement For Coating Repair of Air Handling Units (Ahu)moytabura96100% (1)

- Saes H 004Dokumen8 halamanSaes H 004kaleeswaran s100% (1)

- Method Statement Pipe Re-Routing Saudi BinladinDokumen11 halamanMethod Statement Pipe Re-Routing Saudi BinladinShyju MelepurathBelum ada peringkat

- Awais Inspector-PaintingDokumen6 halamanAwais Inspector-PaintingMohammed GaniBelum ada peringkat

- Saes A 114Dokumen2 halamanSaes A 114Nino Celso AstilleroBelum ada peringkat

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDokumen2 halamanSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyBelum ada peringkat

- Rfi FormDokumen2 halamanRfi Formmuhammedemraan0% (1)

- Hempadur Mastic 45880-45881Dokumen3 halamanHempadur Mastic 45880-45881David HoffmanBelum ada peringkat

- P140I Fencing WorksDokumen5 halamanP140I Fencing WorkskbldamBelum ada peringkat

- QA&QC - MS - Concrete WorkDokumen7 halamanQA&QC - MS - Concrete WorkMuhammadZahirKhanBelum ada peringkat

- Nrqs-Mos-008 Concrete WorksDokumen10 halamanNrqs-Mos-008 Concrete Workscivil.godfatherBelum ada peringkat

- METHOD STATEMENT FOR Grout WORKSDokumen6 halamanMETHOD STATEMENT FOR Grout WORKSwajid ZiaBelum ada peringkat

- SECTION 02781 Interlocked Pa Vers: Ministry of Defense, Royal Saudi Air Force King Faisal Air Academy, Majma'ah 02781-1Dokumen11 halamanSECTION 02781 Interlocked Pa Vers: Ministry of Defense, Royal Saudi Air Force King Faisal Air Academy, Majma'ah 02781-1ali mohamedBelum ada peringkat

- Breakout - NCR Writing and ClosureDokumen30 halamanBreakout - NCR Writing and ClosureMichael HicksBelum ada peringkat

- R 17 11 Procurement Management Internal Audit FinalDokumen22 halamanR 17 11 Procurement Management Internal Audit FinalkarthiBelum ada peringkat

- Expediting ProcedureDokumen16 halamanExpediting Procedurekbldam94% (17)

- RT SlideDokumen36 halamanRT SlidekbldamBelum ada peringkat

- Method Statement For PumpDokumen7 halamanMethod Statement For PumpkbldamBelum ada peringkat

- Presentation Induction Quaity NewDokumen31 halamanPresentation Induction Quaity Newkbldam67% (6)

- Welding Super Duplex Stainless Steel Lincoln NorweldSmitweld NITO ConferenceDokumen14 halamanWelding Super Duplex Stainless Steel Lincoln NorweldSmitweld NITO ConferencekbldamBelum ada peringkat

- MS For MV Cable Pulling ProcedureDokumen10 halamanMS For MV Cable Pulling Procedurekbldam100% (2)

- Booster Pump Foundation Excavation ProcedureDokumen9 halamanBooster Pump Foundation Excavation ProcedurekbldamBelum ada peringkat

- Ultrasonic TestingDokumen36 halamanUltrasonic TestingRaj Kumar100% (4)

- Energization Procedure For Switchrack X56-SR-009 June 08 2015Dokumen3 halamanEnergization Procedure For Switchrack X56-SR-009 June 08 2015kbldamBelum ada peringkat

- Splicing and Termination of MV Cables Rev.02 Re-Submitted - 9 Apr-15Dokumen8 halamanSplicing and Termination of MV Cables Rev.02 Re-Submitted - 9 Apr-15kbldamBelum ada peringkat

- BI 10-01429 Kick-Off Meeting Presentation (Quality)Dokumen12 halamanBI 10-01429 Kick-Off Meeting Presentation (Quality)kbldamBelum ada peringkat

- Control and Tracking NDT Result Procedure Rev 04Dokumen9 halamanControl and Tracking NDT Result Procedure Rev 04kbldamBelum ada peringkat

- Manual On Training, Qualification and Certification of Quality Assurance PersonnelDokumen122 halamanManual On Training, Qualification and Certification of Quality Assurance PersonnelkbldamBelum ada peringkat

- Auditing Welds Under ASME IX PDFDokumen21 halamanAuditing Welds Under ASME IX PDFkbldamBelum ada peringkat

- Qa Question - 2Dokumen4 halamanQa Question - 2kbldamBelum ada peringkat

- MANIFA - Quality Initiative.1Dokumen32 halamanMANIFA - Quality Initiative.1kbldamBelum ada peringkat

- QA Rules and ResposibilitiesDokumen24 halamanQA Rules and ResposibilitieskbldamBelum ada peringkat

- Questions For QC ManagerDokumen9 halamanQuestions For QC Managerkbldam100% (3)

- Toolbox Talks - Material ReceivingDokumen6 halamanToolbox Talks - Material ReceivingkbldamBelum ada peringkat

- QA Rules and ResposibilitiesDokumen24 halamanQA Rules and ResposibilitieskbldamBelum ada peringkat

- Tool Box Meeting For NDT ReqDokumen1 halamanTool Box Meeting For NDT ReqkbldamBelum ada peringkat

- BI 10-01429 Kick-Off Meeting Presentation (Quality)Dokumen12 halamanBI 10-01429 Kick-Off Meeting Presentation (Quality)kbldamBelum ada peringkat

- Presentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)Dokumen55 halamanPresentation - QUALITY (SCHEDULE 'Q' REQUIREMENTS)kbldamBelum ada peringkat

- Defensive Driving Manual (English) PDFDokumen105 halamanDefensive Driving Manual (English) PDFkbldam100% (1)

- BI 10-01429 Kick-Off Meeting Presentation (Quality)Dokumen12 halamanBI 10-01429 Kick-Off Meeting Presentation (Quality)kbldamBelum ada peringkat

- Coating Pro APCODokumen27 halamanCoating Pro APCOkbldam100% (1)

- Stop Smoking Before It's Too LateDokumen22 halamanStop Smoking Before It's Too LatekbldamBelum ada peringkat

- Intro To NDTDokumen34 halamanIntro To NDTkbldamBelum ada peringkat

- 1576 2-2016 PDFDokumen61 halaman1576 2-2016 PDFChan NovBelum ada peringkat

- Metals: Vacuum Die Casting Process and Simulation For Manufacturing 0.8 Mm-Thick Aluminum Plate With Four Maze ShapesDokumen14 halamanMetals: Vacuum Die Casting Process and Simulation For Manufacturing 0.8 Mm-Thick Aluminum Plate With Four Maze Shapesrekyts31Belum ada peringkat

- Surface-Mounted Horizontal Tank-Type Soap Dispenser: With All-Purpose ValveDokumen1 halamanSurface-Mounted Horizontal Tank-Type Soap Dispenser: With All-Purpose ValveAndres AguileraBelum ada peringkat

- Bharat PlywoodDokumen25 halamanBharat PlywoodpmyilsamyBelum ada peringkat

- Hebel MC v09.11Dokumen12 halamanHebel MC v09.11Majed NabeelBelum ada peringkat

- Saej 524 V 002Dokumen5 halamanSaej 524 V 002Marcos Verissimo Juca de PaulaBelum ada peringkat

- DS5S2 - (1969) An Evaluation of The Yield, Tensilde, Creep and Rupture Strengths of Wrought 304, 316, 321, and 347 Stainless Steels at Elevated TemperaturesDokumen74 halamanDS5S2 - (1969) An Evaluation of The Yield, Tensilde, Creep and Rupture Strengths of Wrought 304, 316, 321, and 347 Stainless Steels at Elevated TemperaturesJacques StrappeBelum ada peringkat

- Wincap Pricelist 05.11.2020Dokumen6 halamanWincap Pricelist 05.11.2020pavanBelum ada peringkat

- Limit Values For LubricantsDokumen28 halamanLimit Values For LubricantsSindley LimaferBelum ada peringkat

- S235, S275, S355 Structural Steel Grades GuideDokumen5 halamanS235, S275, S355 Structural Steel Grades GuideGopi KrishnanBelum ada peringkat

- Principle Angle Single Point Cutting ToolsDokumen16 halamanPrinciple Angle Single Point Cutting ToolsSoumik DasBelum ada peringkat

- Comparing American and British Piping StandardsDokumen2 halamanComparing American and British Piping Standardsfahimshah1301Belum ada peringkat

- Chapter 2 Alloys - 2012 - Applied Welding EngineeringDokumen5 halamanChapter 2 Alloys - 2012 - Applied Welding EngineeringJames LeonBelum ada peringkat

- Architectural Fasteners & Fittings - Stainless Steel - AnzorDokumen18 halamanArchitectural Fasteners & Fittings - Stainless Steel - AnzorBhaiJan59Belum ada peringkat

- Pengajuan Wps ASMEDokumen1 halamanPengajuan Wps ASMEFerdie OSBelum ada peringkat

- Technical Datasheet: ENGUARD™ BP 75 ARF Multi Purpose Bonding Paste With FibresDokumen2 halamanTechnical Datasheet: ENGUARD™ BP 75 ARF Multi Purpose Bonding Paste With FibresFernando Cesar PérezBelum ada peringkat

- Cable Glands CrossreferenceDokumen8 halamanCable Glands CrossreferenceerstendrainBelum ada peringkat

- Protection of Reinforcement With Corrosion Inhibitors, PhaseDokumen137 halamanProtection of Reinforcement With Corrosion Inhibitors, Phasealwan61Belum ada peringkat

- McMaster - About Plastics Doc 8574KACDokumen3 halamanMcMaster - About Plastics Doc 8574KACkristechnikBelum ada peringkat

- PwpsDokumen2 halamanPwpsTony Tony67% (3)

- Effect of Superplasticizer Type On The PerformanceDokumen14 halamanEffect of Superplasticizer Type On The PerformanceKevin ChumánBelum ada peringkat

- Bill of Quantities of RasuwagadhiDokumen6 halamanBill of Quantities of RasuwagadhiIndra DhakalBelum ada peringkat

- Formolon 622: Homopolymer/Pipe Grade ResinDokumen2 halamanFormolon 622: Homopolymer/Pipe Grade ResinRoshankumar BalasubramanianBelum ada peringkat

- Hardness LectureDokumen14 halamanHardness LectureRyzqyKumaraDhanaBelum ada peringkat

- Catalogue IngeniusDokumen16 halamanCatalogue IngeniusAP Market SolutionsBelum ada peringkat

- Welding Metallurgy for InspectorsDokumen27 halamanWelding Metallurgy for InspectorsAnonymous XzGgqTBelum ada peringkat

- Synaxis Prequalification (2018)Dokumen82 halamanSynaxis Prequalification (2018)Synaxis ReadymixBelum ada peringkat

- ACI 549R-97: Reported by ACI Committee 549Dokumen26 halamanACI 549R-97: Reported by ACI Committee 549curlyjockeyBelum ada peringkat

- Debatosh RoyDokumen26 halamanDebatosh RoyDebatosh RoyBelum ada peringkat

- Corrosion Test by Gravimetric MethodDokumen3 halamanCorrosion Test by Gravimetric MethodShanti Kiran ZBelum ada peringkat