Torque Settings For Wheel Nuts

Diunggah oleh

Th NattapongJudul Asli

Hak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

Torque Settings For Wheel Nuts

Diunggah oleh

Th NattapongHak Cipta:

Format Tersedia

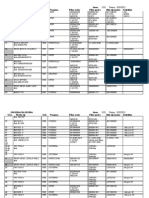

Torque settings for wheel nuts and bolts

on commercial vehicles

Important!

Check torque settings regularly!

Vehicle make

Thread

Torque setting (Nm)

Bolt centering

Hub centering

M201.5

350

450

M221.5

350

600

M221.5

510580

550600

7/8 11 BSF

510580

550600

Trilex

Auwrter

Bedford

To ensure wheel nuts/bolts are correctly tightened on

truck wheels, please note the following:

DAF

M181.5

M201.5

a) Torque value:

It is imperative to adhere to the torque values specified by the

vehicle manufacturers. On steel rims the wheel nuts should

always be tightened crosswise.

b) Torque wrench:

For reasons of operational safety, the use of a torque wrench

is recommended as this ensures the prescribed torque values

are adhered to exactly.

c) Impact wrench:

With serial fittings, electric- or air-powered single or multiple

impact wrenches are frequently used for reasons of efficiency.

Unless these wrenches are designed for a single nut size using

the maximum torque permitted by the machine, adhering to

the correct torque value is usually difficult and depends more

or less on the skill of the fitter. Regular checks using a torque

wrench are recommended under all circumstances.

280350

340400

270300

450520

320350

M221.5

700

Atego

M181.5

400

Atego

M201.5

500

Actros

M221.5

600

Axor

M221.5

600

Daimler

Faun

M181.5

290320

M201.5

370400

M221.5

430460

Iveco

M181.5

335410

M201.5

440540

M221.5

380450

580650

45045

60060

EVO-Bus, Setra

MAN

M181.5

39020

M201.5

47525

M221.5

57525

M221.5

450550

7/8 11 BSF

600

M201.5

450500

M221.5

550600

M181.5

37565

M201.5

52575

M221.5

67030

7/8 14 UNF

67030

RVI

Scania

d) Other:

Hubs and wheels on all vehicles are coated with primer and

usually with a top coating to protect them from rust. These

coatings tend to give after the first few miles. Nuts and bolts

also need time to settle. It is therefore essential that the wheel

nuts are checked after the first 30 miles and tightened where

necessary. Regular checks are also important later, because if

the wheels are loose, the bolt holes wear ovally and damage

the wheel bolts.

Use the prescribed wheel mounting elements.

Exchange nuts and bolts which are rusty or hard to move.

Before fitting, remove rust and dirt from the contact area

around the wheel, axle hub and brake drum.

An alloy wheel is approximately twice the thickness of a steel

one, which means that longer wheel bolts are required.

Steyr-Daimler-Puch

Volvo

VW

Transporter T2, T5

M141.5

180

Transporter T4 to 12/95

M141.5

160

Transporter T4 from 01/96

M141.5

180

LT28, 31

M141.5

200

LT35, 40, 45, 50

M181.5

320

Trailer

M141.5

110120

M181.5

270

320

M201.5

350

450

M221.5

450500

630650

M222

430

*) with spring washer and flat collar nut

10 Nm = 1 Kpm

All details given without guarantee

Status June 2010

www.continental-truck-tires.com

www.continental-corporation.com

Conti_Torque Settings_us_2010.indd

30.06.10

14:11

Anda mungkin juga menyukai

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Dari EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Penilaian: 5 dari 5 bintang5/5 (1)

- Minor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsDokumen46 halamanMinor Sweeping Machines: Technical Operating and Basic Maintenance InstructionsBogdan NgrBelum ada peringkat

- Texa Motor Truck 40.0.0 Latest Version Application List en-GBDokumen251 halamanTexa Motor Truck 40.0.0 Latest Version Application List en-GBkallatisBelum ada peringkat

- Gaz560 Steyr Mo236, 246Dokumen47 halamanGaz560 Steyr Mo236, 246Marinko100% (1)

- MAN TGA Guidelines To Tting Bodies Manual - PDF Seroma Workshop 2020 PDFDokumen167 halamanMAN TGA Guidelines To Tting Bodies Manual - PDF Seroma Workshop 2020 PDFTransport DepartmentBelum ada peringkat

- EN ET Kat SG WebDokumen72 halamanEN ET Kat SG WebVictor HeasBelum ada peringkat

- Filteri Rad MatDokumen19 halamanFilteri Rad MatPaulo Diego AguileraBelum ada peringkat

- VAS PC V19.01.01 English Full VW-SEAT-SKODA-AUDI-BENTLEYDokumen2 halamanVAS PC V19.01.01 English Full VW-SEAT-SKODA-AUDI-BENTLEYricardo-cruz-7385Belum ada peringkat

- Peugeot Diagramas 1Dokumen101 halamanPeugeot Diagramas 1Febe Cespedes100% (1)

- Print Version - 2006-2014 Fiat Ducato Fuse Box DiagramDokumen5 halamanPrint Version - 2006-2014 Fiat Ducato Fuse Box DiagramlogisztikaBelum ada peringkat

- Wabco D Version ECU (Cab) PDFDokumen1 halamanWabco D Version ECU (Cab) PDFاحمد ابو عبداللهBelum ada peringkat

- Leyland Daf 55 AIr SchematicDokumen6 halamanLeyland Daf 55 AIr SchematicEsirpus RekufBelum ada peringkat

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusDari EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusBelum ada peringkat

- DC600 9773-10419Dokumen22 halamanDC600 9773-10419Jaime ArreolaBelum ada peringkat

- Elemax General2014Dokumen8 halamanElemax General2014saran gulBelum ada peringkat

- Elite 1500 Wiring Diagram V3Dokumen2 halamanElite 1500 Wiring Diagram V3johnBelum ada peringkat

- 303 14 PDFDokumen38 halaman303 14 PDFTuan TranBelum ada peringkat

- Convenience Electronics Polo 9N 1,4 TDI PD 2002 55 KW AMFDokumen12 halamanConvenience Electronics Polo 9N 1,4 TDI PD 2002 55 KW AMFflorea tulituBelum ada peringkat

- Manual VW Golf 1 6 Tdi DSG SpecsDokumen3 halamanManual VW Golf 1 6 Tdi DSG SpecsDarko KaracBelum ada peringkat

- WarningDokumen268 halamanWarningElguaro MecánicoBelum ada peringkat

- D3 Suspension DiagnosticsDokumen8 halamanD3 Suspension DiagnosticsPrudencio Serviano IIIBelum ada peringkat

- MLT 731 Turbo Series F-E3 - MT / Mlt-X732 100P S1-E3: PagesDokumen15 halamanMLT 731 Turbo Series F-E3 - MT / Mlt-X732 100P S1-E3: Pagesjuan pablo viazzi100% (1)

- Miller PartsDokumen10 halamanMiller PartsAugusto BellezaBelum ada peringkat

- Gpu 18 Om-2084a Series 500392aDokumen214 halamanGpu 18 Om-2084a Series 500392aCRISTIAN MOLANO100% (1)

- Ix Est42 BlockdiagramDokumen34 halamanIx Est42 BlockdiagramBranko AndricBelum ada peringkat

- s14 Sr20det FSMDokumen816 halamans14 Sr20det FSMnissmo127100% (1)

- Repair Manual JSK 38Dokumen38 halamanRepair Manual JSK 38aiyubi2Belum ada peringkat

- Vito Part1Dokumen97 halamanVito Part1Rezme Mbarek100% (1)

- S04 Rotary Actuator HELAC L10 360° (Turret)Dokumen32 halamanS04 Rotary Actuator HELAC L10 360° (Turret)AndersonBelum ada peringkat

- IVECO Powerstar SpecSheet 7800Dokumen4 halamanIVECO Powerstar SpecSheet 7800Userfabian215100% (1)

- Clutch Hino 5.5Dokumen5 halamanClutch Hino 5.5Yeam_90Belum ada peringkat

- Om612 Remove Install Cylinder HeadDokumen7 halamanOm612 Remove Install Cylinder Headmichalpompa.mpBelum ada peringkat

- DAF Truck en b4511Dokumen119 halamanDAF Truck en b4511Ashraf MostafaBelum ada peringkat

- Code DescriptionDokumen37 halamanCode DescriptionاحمدميدوBelum ada peringkat

- Touran No. 204 / 1: Position of Relays and Fuses Electronics Box Low, From May 2005Dokumen18 halamanTouran No. 204 / 1: Position of Relays and Fuses Electronics Box Low, From May 2005Dariaxa Sos CarsBelum ada peringkat

- 2008 SYSTEM WIRING DIAGRAMS Mercedes-Benz - ML350Dokumen4 halaman2008 SYSTEM WIRING DIAGRAMS Mercedes-Benz - ML350Lukaz Juarez100% (2)

- Eurocargo 2006 Euro4Dokumen230 halamanEurocargo 2006 Euro4Peter KariukiBelum ada peringkat

- Iveco DAILY MCA2014 4x4Dokumen48 halamanIveco DAILY MCA2014 4x4Krum KashavarovBelum ada peringkat

- 14+ +electric Electronic+SystemDokumen450 halaman14+ +electric Electronic+SystemModise Thee Shepherd Mofokeng100% (2)

- Aufbaurichtlienien Atego 1998Dokumen138 halamanAufbaurichtlienien Atego 1998Petar Tanevski100% (1)

- Audi Q7 A005Q720020-Basic Equipment From Model Year 2007Dokumen1.302 halamanAudi Q7 A005Q720020-Basic Equipment From Model Year 2007Fábio MagnoBelum ada peringkat

- GLR SGR eDokumen2 halamanGLR SGR eronald.1978Belum ada peringkat

- 2018 Ford Transit Owners ManualDokumen512 halaman2018 Ford Transit Owners ManualRobert VelascoBelum ada peringkat

- Berlingo Iii 9HF (Dv6dted) 1.6Dokumen11 halamanBerlingo Iii 9HF (Dv6dted) 1.6Fabian Carrasco NaulaBelum ada peringkat

- Complete Program Denoxtronic Diesel Systems: For The Testing and Repair ofDokumen8 halamanComplete Program Denoxtronic Diesel Systems: For The Testing and Repair ofAlessandro SambugaroBelum ada peringkat

- Trailer Brake & Suspension Products Manual PDFDokumen220 halamanTrailer Brake & Suspension Products Manual PDFVincent PriceBelum ada peringkat

- 4206 PtoDokumen3 halaman4206 PtoHaidar Chandu100% (1)

- Ts 45 Fault Codes Booklet MurphyDokumen68 halamanTs 45 Fault Codes Booklet MurphyIvan PerezBelum ada peringkat

- Komatsu ComplexDokumen2 halamanKomatsu ComplexPram BudiBelum ada peringkat

- Trakker Euro 4-5 BBI Part 1Dokumen140 halamanTrakker Euro 4-5 BBI Part 1blablabla578100% (6)

- User Manual Digital Tachograph Release 4.0 - VDODokumen156 halamanUser Manual Digital Tachograph Release 4.0 - VDOW100% (1)

- 042 Man TruckDokumen4 halaman042 Man TruckFilippos100% (1)

- AXOR - Specifications PDFDokumen18 halamanAXOR - Specifications PDFenzo7259Belum ada peringkat

- KTD-00734-J BFlash User ManualDokumen19 halamanKTD-00734-J BFlash User Manualsandeep bagulBelum ada peringkat

- Jimny PDFDokumen237 halamanJimny PDFRustico Guerreiro100% (1)

- ETronic Failuretree Iveco V643Dokumen147 halamanETronic Failuretree Iveco V643Victor Montesdeoca100% (1)

- 16s181 Ahelical TeethaDokumen11 halaman16s181 Ahelical Teethaعبدالغني القباطي100% (1)

- Intarder Fuer 6 S 1600 1700 1900Dokumen2 halamanIntarder Fuer 6 S 1600 1700 1900kujkoja100% (1)

- TEXA Motor Trucks v19.0.0 EngDokumen289 halamanTEXA Motor Trucks v19.0.0 EngBombonica1984100% (1)

- Hydrocarbon Processing August 2018Dokumen149 halamanHydrocarbon Processing August 2018VS2712100% (1)

- CDI-T Item TB2-Berth and Pile (Technical Final V1)Dokumen18 halamanCDI-T Item TB2-Berth and Pile (Technical Final V1)Th NattapongBelum ada peringkat

- Workplace Safety and Health (Risk Management) ReguDokumen3 halamanWorkplace Safety and Health (Risk Management) ReguTh NattapongBelum ada peringkat

- CDI-T Operating Manual Section 4.0 Terminal Inspection ProceduresDokumen6 halamanCDI-T Operating Manual Section 4.0 Terminal Inspection ProceduresTh NattapongBelum ada peringkat

- CDI-T Technical Questionnaire 2007 (Fourth Edition)Dokumen127 halamanCDI-T Technical Questionnaire 2007 (Fourth Edition)Th NattapongBelum ada peringkat

- CDI-T Management Questionnaire 2007 (Fourth Edition)Dokumen107 halamanCDI-T Management Questionnaire 2007 (Fourth Edition)Th Nattapong100% (1)

- BH34196 Advanced Inspection ServicesDokumen24 halamanBH34196 Advanced Inspection ServicesTh NattapongBelum ada peringkat

- Cswip 3.1 New BookDokumen342 halamanCswip 3.1 New BookMohsin Rasul90% (52)

- Elevator Traction Machine 20131018 Elevator Traction MachineDokumen8 halamanElevator Traction Machine 20131018 Elevator Traction MachineTh NattapongBelum ada peringkat

- Electric Wire Rope Hoist 950169USA DC EngDokumen8 halamanElectric Wire Rope Hoist 950169USA DC EngTh NattapongBelum ada peringkat

- TIS1479 Eng-2541 (1998)Dokumen16 halamanTIS1479 Eng-2541 (1998)Th NattapongBelum ada peringkat

- Electric Wire Rope Hoist 950196 Economy Wire Rope Crab EngDokumen6 halamanElectric Wire Rope Hoist 950196 Economy Wire Rope Crab EngTh NattapongBelum ada peringkat

- Manual Chain Hoist 950181 BB Manual Chain Hoist EngDokumen4 halamanManual Chain Hoist 950181 BB Manual Chain Hoist EngTh NattapongBelum ada peringkat

- Electric Chain Hoist 950199 BB Windmill Hoist Series EngDokumen2 halamanElectric Chain Hoist 950199 BB Windmill Hoist Series EngTh NattapongBelum ada peringkat

- Crane-Components 950164-Crane-ComponentsDokumen8 halamanCrane-Components 950164-Crane-ComponentsTh NattapongBelum ada peringkat

- Electric Wire Rope Hoist 950168DC BB EngDokumen8 halamanElectric Wire Rope Hoist 950168DC BB EngTh NattapongBelum ada peringkat

- Electric Chain Hoist 950158 BB BLFD Series EngDokumen2 halamanElectric Chain Hoist 950158 BB BLFD Series EngTh NattapongBelum ada peringkat

- Electric Chain Hoist 950152 BB NHD Series EngDokumen2 halamanElectric Chain Hoist 950152 BB NHD Series EngTh NattapongBelum ada peringkat

- JDN Ultra Low Monorail HoistsDokumen3 halamanJDN Ultra Low Monorail HoistsTh NattapongBelum ada peringkat

- Electric Chain Hoist 950188 BB Low Headroom Series EngDokumen4 halamanElectric Chain Hoist 950188 BB Low Headroom Series EngTh NattapongBelum ada peringkat

- Electric Chain Hoist 950102 BB ECH Series EngDokumen8 halamanElectric Chain Hoist 950102 BB ECH Series EngTh NattapongBelum ada peringkat

- Pfi-Es-3 (2000) PDFDokumen4 halamanPfi-Es-3 (2000) PDFBarnum Pebble Darrel100% (1)

- Crane Components 950192 New Motor EngDokumen6 halamanCrane Components 950192 New Motor EngTh NattapongBelum ada peringkat

- MiniOper ManDokumen48 halamanMiniOper ManTh NattapongBelum ada peringkat

- JDN Ratchet Hoists WittDokumen1 halamanJDN Ratchet Hoists WittTh NattapongBelum ada peringkat

- JDN Monorail Air HoistsDokumen3 halamanJDN Monorail Air HoistsTh NattapongBelum ada peringkat

- JDN ServiceDokumen3 halamanJDN ServiceTh NattapongBelum ada peringkat

- JDN TrolleysDokumen5 halamanJDN TrolleysTh NattapongBelum ada peringkat

- JDN QualityDokumen1 halamanJDN QualityTh NattapongBelum ada peringkat

- JDN Low Headroom TrolleysDokumen3 halamanJDN Low Headroom TrolleysTh NattapongBelum ada peringkat

- Brake System NISSAN B16Dokumen51 halamanBrake System NISSAN B16Alex HernandezBelum ada peringkat

- PM The All-New BMW X3 M and BMW X4 M With M Performance PartsDokumen4 halamanPM The All-New BMW X3 M and BMW X4 M With M Performance PartsDanny StoBelum ada peringkat

- AL SteeringWheelControlBrochure FINAL printAPPGUIDE (Web)Dokumen29 halamanAL SteeringWheelControlBrochure FINAL printAPPGUIDE (Web)Cristian IonBelum ada peringkat

- Crossword PuzzleDokumen1 halamanCrossword PuzzlewniccoleBelum ada peringkat

- WGC 20t FrannaDokumen12 halamanWGC 20t FrannaLance Zhengling YinBelum ada peringkat

- Presentation Ligier MK84Dokumen14 halamanPresentation Ligier MK84Ricardo DivilaBelum ada peringkat

- Nissan Sunny 1.6 S-EnG - Euro 4Dokumen1 halamanNissan Sunny 1.6 S-EnG - Euro 4TI KO TI KOBelum ada peringkat

- Ecu 2.5 DiagramDokumen6 halamanEcu 2.5 Diagramkishan Kumar100% (1)

- Renta Juni Juli August Septembar 2022Dokumen13 halamanRenta Juni Juli August Septembar 2022alic spedBelum ada peringkat

- 2022 Proton Iriz and Persona Facelift ASEAN NCAP Crash Test ReportDokumen4 halaman2022 Proton Iriz and Persona Facelift ASEAN NCAP Crash Test ReportcarbasemyBelum ada peringkat

- R Rear Suspension: R 40K - 46K R 48K - 52KDokumen12 halamanR Rear Suspension: R 40K - 46K R 48K - 52KAbdelkader DraïBelum ada peringkat

- Impala ClassicDokumen652 halamanImpala ClassicCarlos Hernan Donoso FuenzalidaBelum ada peringkat

- Audi 80 1988 PDFDokumen11 halamanAudi 80 1988 PDFZoran TrajkovicBelum ada peringkat

- Brochure TritonDokumen4 halamanBrochure TritonHeadhunters DecendentBelum ada peringkat

- Immobilizer System: Main MenuDokumen7 halamanImmobilizer System: Main Menusontong234Belum ada peringkat

- McLaren Artura Order ZED7LQ6 Summary 2023-04-03Dokumen5 halamanMcLaren Artura Order ZED7LQ6 Summary 2023-04-03Kaus CrimsonBelum ada peringkat

- FSM Datsun Pick Up 1977 PDFDokumen537 halamanFSM Datsun Pick Up 1977 PDFLuis Miguel Condori100% (1)

- Catalogo Master Q1-2017 PDFDokumen142 halamanCatalogo Master Q1-2017 PDFVictor ZhicayBelum ada peringkat

- Vafc SettingDokumen11 halamanVafc SettingMohd KhairulBelum ada peringkat

- AssobravDokumen2 halamanAssobravgnr_ssaBelum ada peringkat

- ChevroletSilverado20042006 - G103 GroundpointDokumen1 halamanChevroletSilverado20042006 - G103 GroundpointPinko PallinoBelum ada peringkat

- Seat - Exploded View, Front: Cushion Side Shield - Manual Seat Track With Manual ReclineDokumen10 halamanSeat - Exploded View, Front: Cushion Side Shield - Manual Seat Track With Manual Reclinetonythetiger0% (1)

- fd60 fd100 enDokumen4 halamanfd60 fd100 enELOY DE LA CRUZ BARJABelum ada peringkat

- 99790-87100-13 - To The Cat Lift Truck OwnerDokumen8 halaman99790-87100-13 - To The Cat Lift Truck OwnerBARRENECHEA DELGADO ISAACBelum ada peringkat

- TD1297-04 Fifth Wheel ENDokumen11 halamanTD1297-04 Fifth Wheel ENSyed Danyal SalamBelum ada peringkat

- Project Report On BulletDokumen27 halamanProject Report On Bulletsanjeev bhagatBelum ada peringkat

- Double Road Engine Shed v2Dokumen13 halamanDouble Road Engine Shed v2ruedanton131100% (1)

- Final Report of MercedesDokumen71 halamanFinal Report of Mercedesnash_world7Belum ada peringkat

- Jaggi Crdi ReadingDokumen5 halamanJaggi Crdi ReadingjassBelum ada peringkat

- B56 BrochureDokumen2 halamanB56 BrochureRizkyy Rachmalya Zainal100% (1)