QTEL

Diunggah oleh

Moizuddin KhajaHak Cipta

Format Tersedia

Bagikan dokumen Ini

Apakah menurut Anda dokumen ini bermanfaat?

Apakah konten ini tidak pantas?

Laporkan Dokumen IniHak Cipta:

Format Tersedia

QTEL

Diunggah oleh

Moizuddin KhajaHak Cipta:

Format Tersedia

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

TECHNICAL SPECIFICATIONS

FOR

FRAMES & COVERS OF JOINTING CHAMBERS

SPECIFICATIONS NO.

Qtel MAT 1022

Access Networks Division

Qatar Telecom (Qtel)

P.O. Box 217,

Doha, State of Qatar

Revision No.: 1, June 2006

CONTENTS

Access Network Division

Qatar Telecom (Qtel) Q.S.C

1 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION

1.

TOPIC

PAGE NO.

STATEMENT OF COMPLIANCE WITH TECHNICAL

SPECIFICATIONS

2.

TECHNICAL REQUIREMENTS

12

3.

QUALITY ASSURANCE, INSPECTION AND TESTING

22

4.

ENVIRONMENT, TRANSPORTATION, STORAGE &

29

SAFETY

5.

DOCUMENTATION

34

6.

REFERENCES

37

7.

DRAWINGS

40

Access Network Division

Qatar Telecom (Qtel) Q.S.C

2 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

SECTION 1

STATEMENT OF COMPLIANCE

WITH TECHNICAL SPECIFICATIONS

Access Network Division

Qatar Telecom (Qtel) Q.S.C

3 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

SECTION 1

STATEMENT OF COMPLIANCE WITH TECHNICAL SPECIFICATIONS

CONTENTS

SECTION

TOPIC

PAGE NO.

1.1

INTRODUCTION

1.2

PURPOSE OF SPECIFICATIONS

1.3

INTERPRETATION

1.4

CATEGORIZATION OF TECHNICAL

SPECIFI-

CATION CLAUSES

1.5

STATEMENT OF COMPLIANCE

1.6

REFERENCE MATERIAL

11

Access Network Division

Qatar Telecom (Qtel) Q.S.C

4 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

SECTION 1

STATEMENT OF COMPLIANCE WITH TECHNICAL SPECIFICATIONS

1.1

INTRODUCTION

1.1.1

Qatar Telecom (Qtel) Q.S.C. also referred to as "the Purchaser" in this Specifications,

requires Frames & Covers for various types of jointing chambers compliant with this

Specifications: Qtel MAT 1022.

1.1.2 The quantitative requirement is specified separately by the Purchaser in the

"Commercial Part of the Tender Document" or "Invitation for Quotation".

1.1.3 Qtel Specifications are revised, when necessary, by the issue either of amendment

slips or of revised editions. The users of Qtel Specifications shall ascertain that they

are using the latest amendment or edition.

1.2

PURPOSE OF SPECIFICATIONS

1.2.1

The purpose of this Specifications is to enable the 'Purchaser' to: Procurement of Frames and Covers for various types of jointing

chambers, which shall conform to the Specifications form an integral part

of, and co-exist with, the existing external network of the "Purchaser".

Technical evaluation of the material offered, in order to ensure that the

"Purchaser's" technical requirements stipulated in the Specifications are

fully met.

Evaluate the Tenderer's in-service experience in manufacturing and

supplying such materials and quality assurance system.

Selection of a suitable Tenderer / Supplier / Manufacturer for the

required material based on the detailed technical evaluation.

1.3

INTERPRETATION

The Tenderer should refer to the 'Definition of Terms' contained in the Commercial

part of the Invitation to Tender for the interpretation of some of the terms used in this

Specifications.

Access Network Division

Qatar Telecom (Qtel) Q.S.C

5 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

1.4

CATEGORISATION OF TECHNICAL SPECIFICATIONS CLAUSES

1.4.1

To assist the Tenderer in preparing a response to this Technical Specifications

in paragraph format; the paragraphs are categorized as follows: A.

REQUIREMENTS (R)

(R) Indicates a mandatory requirement of the Purchaser. The Tenderer

must state compliance or otherwise in accordance with Clauses No. 1.5.3

to 1.5.7.

B.

QUESTIONS (Q)

(Q) Indicates a question on a mandatory requirement. All questions must

necessarily be clearly and unambiguously answered by the Tenderer.

The response of the Tenderer shall be:

i) Answered, or

ii) Partially answered, or

iii) Not answered

In case of (i) and (ii) above, the relevant answers shall either be appended

in the Statement of Compliance against the particular Clause, or if

referenced to elsewhere in the offer, the relevant reference must be precise

and accurate.

C.

OPTION (O)

(O) Indicates an optional item. In all such Clauses, Tenderer shall clearly

respond with:

i) Integral part of the offer, or

ii) Optionally offered, or

iii) Not offered.

In case of (i) and (ii) above, the relevant details shall either be appended

in the Statement of Compliance against the particular Clause, or if

referenced to elsewhere in the offer, the relevant reference must be precise

and accurate.

1.4.2

INFORMATION AND INSTRUCTIONS TO TENDERERS

All paragraphs which are not designated either as a Requirement (R) or Question (Q)

or an Option (O) are Information or Instructions (I) to Tenderers. The Tenderer shall

carry out all instructions and shall respond with UNDERSTOOD, ACCEPTED AND

COMPLIED (U.A.C) against all such paragraphs within the statements of compliance

and answers to questions, paragraph by paragraph numbered, as in this Specifications.

Access Network Division

Qatar Telecom (Qtel) Q.S.C

6 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

1.4.3

The Tenderer must provide a statement of compliance, in accordance with Clause No.

1.5 against the requirement and also respond to all the questions and options.

1.4.4

The statements of compliance and answers to the questions must be numbered and

given in the same order as of this Specifications with full and complete answers to the

questions interspersed within the statements of compliance as in the Specifications.

1.4.5

References to general descriptions or appendices to the offer should be minimized in

answering the questions and all such references should be precise and must be

relevant in order to be accepted for evaluation.

1.4.6

General descriptions, the required sample documentation and all supporting

documentation, which is appended to the offer, must be fully indexed in each volume

of the Tender

1.5

STATEMENT OF COMPLIANCE

1.5.1

To enable the Purchaser to evaluate the suitability and price of the material being

offered, the Tenderer's responses must be full and complete with relevant information.

In case any item(s) are proprietary in nature, this shall be clearly indicated with

complete supporting documentation/explanation on the nature of its proprietariness

and degree of compliance with the requirements laid down.

(R)

1.5.2

The Tenderer's responses shall be supported by fully detailed documentation and

information such that the degree of compliance offered can be validated.

The

submitted information shall be furnished in tabular form, to the extent possible, and

lengthy, descriptive explanations shall be avoided.

(R)

1.5.3

In the Statement of Compliance the Tenderer must state if the materials offered: (i)

Meet the requirements (R) of the Specifications in full and respond

with: FULLY COMPLIANT (FC). The Tenderer shall also state in

detail as to how the offered materials meet the requirements of the

Clause.

OR

(ii)

Meet the requirement (R) of the Specifications by an alternative

solution proposed by the Tenderer, and if so, the Tenderer shall

respond with FULLY COMPLIANT ALTERNATIVE (FCA). The

Tenderer shall also give detailed explanation as to how the alternate

solution meets the requirement of the Clause.

Access Network Division

Qatar Telecom (Qtel) Q.S.C

7 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

OR

(iii)

Meet the requirements (R) of the Specifications partially and if so the

Tenderer shall respond with: PARTIALLY COMPLIANT (PC). The

Tenderer shall also state the reason why the offer is partially compliant

and which part of the requirement is not compliant.

OR

(iv)

Can not meet the requirements (R) of the Specifications, and if so the

Tenderer shall respond with the words: NON COMPLIANT (NC).

The Tenderer shall also state the reason why the offer is non compliant.

1.5.4

If any development is necessary to meet the requirements of the Specifications (R),

the

Tenderer shall also respond with the words: ADAPTIVE ENGINEERING

REQUIRED (AER) in the Statement of Compliance against the specified

requirement. The Tenderer shall also necessarily state the intended method of

achieving the specified requirements, the time scales involved and supply technical

information, diagrams and drawings as are necessary to enable evaluation.

1.5.5

A Statement of Compliance with the correct responses shall be given against all the

requirements detailed in this Specifications paragraph by paragraph, these being

numbered in accordance with the Specifications. If the Tenderer puts no remark such

as FC, PC, NC etc., the Purchaser shall interpret the same as Non-Compliant (NC)

irrespective of the comments made by the Tenderer.

1.5.6

Any characteristics or technical properties of the offered material that has not been

specified as requirements in the Specifications and is being offered as a part of the

main offer by the Tenderer, shall be stated separately and included in the tender

response so that the Purchaser can take them into account during evaluation.

(O)

1.5.7

In cases where the Tenderer considers that meeting a particular requirement or

set of requirements would lead to an unnecessary increase in price, this shall

clearly be indicated in the offer and may submit alternative proposals for

consideration. Such other possible proposals shall be accompanied by a full

explanation and a diagram, if necessary.

(R)

1.5.8

All documents including information brochures and related material on features/data

sheets, etc. contained therein and submitted with the complete Tender offer response

would necessarily imply that these are part of the offer and that the features/facilities

characteristics/data sheets/Technical details indicated in such documentation, will be

provided and included in the offered system. Such submitted documentation would

form part of the Contract later, unless otherwise specifically indicated. The exception

indications/report, if any, shall necessarily be enclosed along with each documentation

Access Network Division

Qatar Telecom (Qtel) Q.S.C

8 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

1.5.9

The Tenderer while submitting responses in the format laid down in Clauses No. 1.5.3

to 1.5.6 above shall do so in the following format (sample) covering all the sections of

this Specifications.

(R)

-----------------------------------------------------------------------------------------------------------

Access Network Division

Qatar Telecom (Qtel) Q.S.C

9 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

COMPLIANCE SHEET FORMAT (SAMPLE)

Page ___ of ___

SECTION

NO.

CLAUSE

TOPIC/

RESPONSE

WHETHER

REFERENCE

TENDERER'S

PURCHASER'S

NO.

SUB-

AS PER

SUPPORTIVE

(IF YES TO

REMARKS

COMMENTS

TOPIC

FORMAT

DOCUMENT

PREVIOUS

IF ANY (LIKE

CLAUSE

-ATION

COLUMN)

ADDITIONAL

1.5.3

ATTACHED

VOL. NO./

FEATURES/

TO 1.5.6

(YES/NO)

SECTION

FACILITIES)

AS PER

NO./PAGE

CLAUSE

NO. IN THE

1.5.2

OFFER

Signature___________________________ Company's Seal __________________________

In the Capacity of Name_______________________________________________________

Date ___________________

Access Network Division

Qatar Telecom (Qtel) Q.S.C

10 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 1

1.5.10 With respect to any particular Clause, if there are any activities that are required to be

undertaken by the Purchaser either as a pre-requisite or during any other stage, this

shall be clearly stated against that particular Clause at column No. 7 of the chart

indicated in Clause 1.5.9 above.

1.6

REFERENCE MATERIAL

Wherever the Tenderer makes references to Brochures, Specifications, System

Descriptions etc. in responding to questions, it must include the referenced

document(s), identify the relevant paragraphs within the document(s) and they must

be appropriate and complete to be considered for inclusion in the evaluation of the

offer.

*************************************

Access Network Division

Qatar Telecom (Qtel) Q.S.C

11 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

SECTION 2

TECHNICAL REQUIREMENTS

FOR

FRAME AND COVERS

OF

JOINTING CHAMBERS

Access Network Division

Qatar Telecom (Qtel) Q.S.C

12 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

SECTION 2

TECHNICAL REQUIREMENTS

CONTENTS

SECTION

TOPIC

PAGE NO.

2.1

GENERAL

14

2.2

TYPES OF FRAMES AND COVERS

15

2.3

MATERIALS

15

2.4

DESIGN, SHAPE, SIZE, DIMENSIONS

15

2.5

MANUFACTURE AND WORKMANSHIP

16

2.6

INTERCHANGEABILITY

16

2.7

STRENGTH REQUIREMENTS

17

2.8

QUALITY CONTROL LOAD TEST

17

2.9

MARKING

18

2.10

PROTECTIVE COATING

18

2.11

WEIGHT & SIZE

18

2.12

SAFETY GRIDS

19

Access Network Division

Qatar Telecom (Qtel) Q.S.C

13 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

SECTION 2

TECHNICAL REQUIREMENTS

2.1

GENERAL

2.1.1

This Specifications stipulates the technical requirements for all types of Frames &

Covers for jointing chambers of External Telecommunication Network of Qtel.

2.1.2

Any information or clarification required by the Tenderer in connection with the

Specifications, prior to issue of the contract, shall be obtained from the department

issuing invitation to tender.

2.1.3

The expression, "Quality Assurance Representative" used in this Specifications

refers to the "Quality Assurance Representative" of the Purchaser.

2.1.4

The Purchaser on an agreed quality assurance procedure shall assess compliance

with this Specifications.

2.1.5

The Tenderer shall submit evidence of his in-service experience in the

manufacture and / or supply of such materials.

2.1.6

The Manufacturer will generally be allowed as much freedom as possible in the

choice and amendment of design of material. However, the Purchaser reserves the

right to refuse to accept any material design that does not comply in every respect

with the Specifications and field conditions of use. The Tenderer must obtain

written approval of the Purchaser prior to incorporating any modification or

amendment.

2.1.7

In case of any apparent conflict between the requirements stipulated in this

Specifications, the Tenderer shall seek clarification from the department issuing

invitation to tender.

2.1.8

All instructions, details and dimensions shown on any drawings, diagrams or

Specifications drawn herein shall be taken as forming a part of this Specifications.

2.1.9

Wherever any reference is made to any supplementary specifications such as

British Standards or any other, the latest issue of that Specifications shall be

followed. The properties, qualities and dimensions not defined in this

Specifications, if any, shall generally be equivalent to that of standard material of

the same kind used for similar purpose. The Tenderer shall, however, obtain

written clarification from the Purchaser for any such undefined item prior to

incorporating the same in the offered material.

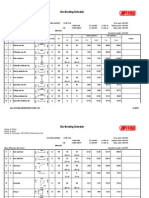

2.2

TYPES OF FRAME & COVERS:

The various standard types of Frames and Covers for jointing chambers of Qtel

External Network are given in Table-1 which also shows the abbreviated code

Access Network Division

Qatar Telecom (Qtel) Q.S.C

14 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

name and Qtel's stock codes are also provided for the Frames and the covers in

order to enable procurement of only Frame or Cover, if necessary.

2.3

MATERIALS:

2.3.1

Frame & Covers Carriageway No. 4 (Type A), Driveway No. 2C (Type A) and

Covers for C/W No. 2 & 3 shall be manufactured from ductile iron.

(R)

2.3.1.1

Frame & Covers Carriageway No. 4 (Type B) and Driveway No. 2C (Type B)

shall be of mild steel to comply with British Standards BS 7613:1994, Grade

S39016Q, with hot dipped galvanized finish (BS 1461:1999); where as the

reinforcing bars shall be of mild steel free from rust.

(R)

2.3.2

The Frames of C/W No. 2 and 3 shall be manufactured from grey cast iron.

(R)

2.3.3

The material to be used:

(R)

(a) Type of material: Spheroidal Graphite iron (ductile iron)

Grade: 500-7 (min tensile strength- elongation) (ISO 1083: 1987)

Class: D 400 (BS EN 124: 1994)

(b) Type of material: Grey Cast iron, Grade to comply with BS 1561:1997

(c) Mild steel: The weldable structural steel material shall comply with BS 7613:

1994, Grade S45016Q.

2.3.4

Safety Grids shall be manufactured from galvanized mild steel in accordance with

BS EN 10137-1/3: 1996.

(R)

2.3.5

TENSILE STRENGTH REQUIREMENT OF DUCTILE IRON / CAST

IRON:

2.3.5.1

When tested in accordance with BS EN124, the minimum tensile strength of the

ductile iron specimen shall be 500 N/mm2 and that of grey cast iron specimen

shall be 180 N/mm2.

(R)

2.3.6

REQUIREMENT OF MATERIALS:

2.3.6.1

The mechanical properties of the ductile iron material used shall be in accordance

with item 5.4, ISO 1083:1987.

(R)

2.3.6.2

The mechanical properties of the grey cast iron material used shall be in

accordance with Item 7.1, BS 1561:1997.

(R)

2.3.6.3

The Manufacturer shall produce the certificate for "Mechanical Properties."

(R)

Access Network Division

Qatar Telecom (Qtel) Q.S.C

15 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

2.3.6.4

Certified manholes Covers and Frames shall have met the requirements given in

Clause 10 of EN 124.

(R)

2.3.6.5

The Supplier shall provide the Purchaser with a test certificate endorsed by the

manufactures of ductile iron / cast iron / steel, stating the process of manufacture

and giving the ductile grade, ladle analysis and the results of each of mechanical

tests applicable to the material.

(R)

2.3.6.6

The steel shall be made by any process except the Bessemer process & rimming

steel shall not be used.

(R)

2.3.6.7

The chemical composition of the steel material used shall be in accordance with

Table 1 & 2 of BS 7613.

(R)

2.3.6.8

The mechanical properties of the steel material used shall be in accordance with

Table 3 of BS 7613.

(R)

2.3.6.9

All steel materials used shall be of weldable quality.

(R)

2.3.6.10

Tolerance on thickness of steel angles / plates shall be in accordance with Class B

of BS EN 10029.

(R)

2.4

DESIGN, SHAPE, SIZE & DIMENSIONS:

2.4.1.

All Frames & Covers shall be manufactured in accordance with the design, shape,

size and dimension specified in the respective Drawings listed in Table 2.

(R)

2.4.2.

The Frames & Covers other than galvanized mild steel type shall have the

product certification BSI-KITE MARK.

(R)

2.4.3.

The covers shall be such that they cannot be displaced by normal traffic.

(R)

2.4.4.

A recess for a prising bar shall be incorporated in ductile iron covers unless other

means of loosening the cover from the Frame are provided. In such cases, the

Manufacturer shall specify the alternative loosening method.

(R)

Access Network Division

Qatar Telecom (Qtel) Q.S.C

16 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

2.5

MANUFACTURE & WORKMANSHIP:

2.5.1

Frame & Covers (Type A) shall be manufactured from ductile iron / cast iron (as

per Clause 2.3.1) of a quality not less than that specified in BS EN 124, 1994, for

class D400 & C250.

(R)

2.5.2

Frames & Covers Carriageway No. 2 shall be self-levelling, non-rocking and nonjamming, comprising of a one-piece Frame and four independent triangular

shaped half covers, in accordance with Drawing No. CN 20001 (Rev. 1) & CN

20004 (Rev. 1).

(R)

2.5.3

Frames & Covers Carriageway No. 3 shall be self-levelling, non-rocking and nonjamming, comprising of a one-piece Frame and six independent triangular shaped

half covers, in accordance with Drawing Nos. CN 20002 (Rev. 1) & CN 20004

(Rev. 1).

(R)

2.5.4

Frames & Covers Carriageway No. 4 (Type A) shall be self-levelling, non-rocking

and non-jamming, comprising of a one-piece Frame and one independent cover, in

accordance with Drawing No. CN 20005 (Rev. 1).

(R)

2.5.5

Frames & Covers Driveway No. 2 (Type A) shall be self-levelling, non-rocking

and non-jamming, comprising of a one-piece Frame and one independent Cover,

in accordance with Drawing No. CN 20006 (Rev. 1).

(R)

2.5.6

Safety Grids shall comprise of one piece, manufactured in accordance with

Drawing No. CN 20007. All sharp edges shall be removed after all working

operations have been completed.

(R)

2.5.7

Number of Safety Grids to be provided with each Frame and Cover shall be as

follows:

(R)

Frame & Cover Carriageway No. 2

- Safety Grids - 2 Nos.

Frame & Cover Carriageway No. 3

- Safety Grids - 3 Nos.

2.5.8

All cast units shall be cleanly cast and shall be free from air holes, sand holes, cold

shuts and chill. They shall be neatly dressed and carefully fettled.

(R)

2.5.9

All castings shall be free from voids, whether due to shrinkage, gas inclusions or

other causes.

(R)

2.5.10

The Covers shall be of a solid top design. They shall be self-draining with a nonskid raised pattern on the upper faces with sharper type.

(R)

Access Network Division

Qatar Telecom (Qtel) Q.S.C

17 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

2.5.11

Frame & Covers (Type B) shall be manufactured from mild steel to comply with

BS Standards BS 7613:1994.

(R)

2.5.12

Frame & Covers Carriageway No. 4 (Type B) & Driveway No. 2C (Type B) shall

be self-levelling, non-rocking and non-jamming, comprising of a one-piece Frame

and one independent Cover, in accordance with Drawing Nos. CN 90005 (Rev. 1)

& CN 90006 (Rev. 1).

(R)

2.6

INTERCHANGEABILITY:

(R)

2.6.1

2.6.2

2.6.3

All Frames and Covers shall be non-rocking, non-jamming and self-levelling.

All covers shall be fully inter-changeable within their Frames.

When Covers are fully installed in the Frame, a clearance of 2mm - 5mm shall

exist all around each cover. Particular care in this respect shall be taken at all

corners.

2.7

STRENGTH REQUIREMENTS:

2.7.1

2.7.1.1

STRENGTH REQUIREMENTS FOR FRAMES & COVERS:

Frames & Covers manufactured to the requirements of this Specifications shall be

capable of supporting and withstanding without any distress or fracture a design

load of 400 KN.

(R)

2.7.1.2

The size of the bearing block for testing shall be of 250 mm dia. and the cover

shall be capable of supporting the specified design load with the bearing block

placed at any position wholly within the perimeter of the Cover.

(R)

2.7.1.3

The manufacture shall verify the design of each type of unit subjecting a sufficient

number of prototypes to the loading tests specified in this Clause and other

relevant Clauses of this Specifications.

(R)

2.8

QUALITY CONTROL LOAD TEST:

(R)

2.8.1

2.8.1.1

2.8.1.2

2.8.1.3

QUALITY CONTROL LOAD TESTS FOR FRAMES & COVERS:

Apart from the initial design proving tests that shall be carried out by the

Manufacturer, routine quality control sampling tests shall also be carried out as

per EN 124, in order to ensure continuing compliance with the requirements of

this Specifications. Records of such quality control tests shall be made available to

the Purchaser or his representative.

A load of 400 KN with a bearing block size of 250 mm dia. shall be applied for

quality control load test.

The product shall be deemed to comply with the quality control loading test

requirements of this Specifications if, when tested in accordance with the

Access Network Division

Qatar Telecom (Qtel) Q.S.C

18 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

procedures described in EN 124, a load of 400 KN is sustained without any

distress or fracture.

2.8.2

PROCEDURE FOR LOADING TEST OF DUCTILE IRON COVERS:

2.8.2.1

APPARATUS: The following apparatus shall be used:

A standard Frame to be used as a supporting Frame.

A bearing block of 250 mm dia., of hardwood faced with hard rubber or other

resilient material, and sufficiently rigid to ensure that the load on the Cover is

evenly distributed over the full area of the block.

(R)

A load applying device, preferably a hydraulic testing machine:

The device shall be capable of applying a load at test 25% greater than the

appropriate test load specified. If a testing machine is used it shall comply with

the accuracy requirements for grade A or grade B testing machines specified in

British Standard BS 1610:1992. If any other load measuring device is used it

shall be accurate to within 2% of the indicated load.

(R)

2.8.2.2

PROCEDURE:

The loading test shall be carried out by applying the appropriate specified load

through the bearing block of specified size placed centrally on the unit or section

(S) being tested.

(R)

The ductile iron Cover shall be supported in the Frame and appropriate load shall

be applied without shock using the testing machine or other measuring device.

The load shall be sustained for a minimum period of thirty (30) seconds.

(R)

2.9

MARKING:

2.9.1

MARKING ON FRAMES & COVERS NOS. 2, 3, 4, & 2C:

(R)

2.9.1.1

2.9.1.2

For Frame & Cover Nos. 2 & 3, the inscription "Qtel" in both English & Arabic

shall be cast in the center of the upper face of each piece of half cover.

For Type A of Frame & Cover No. 4 and 2C, it shall be cast on the diagonally

opposite upper face of Covers, with emblem in the centre.

Type B shall have a loose name plate with the inscription 'Qtel', in both

English & Arabic, one per each unit, for casting into Covers.

For Frame & Cover No. 2 & 3, the Manufacturer's code and the last two figures of

Gregorian year of manufacture shall be legibly marked on the underside of each

half cover and on one flange of the Frame.

For Type A of Frame & Cover No. 4 and 2C, it shall be marked on the

underside of Cover and on one flange of the Frame.

Type B shall have a similar marking on one flange of each Frame & Cover.

Access Network Division

Qatar Telecom (Qtel) Q.S.C

19 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

2.10

PROTECTIVE COATING:

2.10.1

All ductile iron / cast iron units shall be applied with 2 coats of black bitumen

paint, as per BS 4164:2002, over 1 coat of grey color primer.

(R)

The Manufacturer shall specify the type and details of the protective coating

proposed to be applied.

(R)

2.10.2

2.10.3

No coating shall be applied unless the surfaces are clean, dry & free from rust.

(R)

2.10.4

Type B F&C No. 4 and 2C shall be galvanized to comply with BS 1461:1999.

(R)

2.10.5

The galvanizing coating shall be smooth, continuous and free from flux stains.

(R)

2.10.6

The Safety Grids shall be supplied with hot dip galvanized to BS 1461:1999

Standard. All sharp edges to be removed before galvanizing.

(R)

2.11

WEIGHT & SIZE:

The normal weight & size of ductile iron Frame and Covers shall comply with the

following Table.

Type

F&C C/W No. 2

External

Size (mm)

1374x850

Internal

Size (mm)

1220x696

Frame

Weight (kg)

1753

Cover

Weight (kg)

2402

Total

Weight (kg)

415

Height

(mm)

160

F&C C/W No. 3

1984x850

1830x696

2053

3602

565

160

F&C C/W No. 4

(Type A)

F&C D/W No. 2C

(Type A)

F&C C/W No. 4

(Type B)

F&C D/W No. 2C

(Type B)

1115x660

995x540

48

80

128

96

925x455

805x335

33

50

83

96

1015x555

1005x545

18

77

820x345

810x300

13

46

2.12

SAFETY GRIDS:

The Safety Grid shall comprise of one piece manufactured in accordance with BS

EN 10137-1/3: 1996, as per the Drawing No. CN 20007. The material used shall

be mild steel galvanized. All sharp edges shall be removed before galvanizing.

Access Network Division

Qatar Telecom (Qtel) Q.S.C

20 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

TABLE 1

TYPES OF FRAMES & COVERS FOR JOINTING CHAMBERS

Sl. No.

Item

Abbreviated Code Name

Qtel Stock Code

1.

Frame & Cover Driveway No. 2C

(Type A)

F & C D/W No. 2C

(Type A)

040 2163 138

2.

Frame- Driveway No. 2C

(Type A)

F-D/W No.2 C

(Type A)

040 2163 145

3.

Cover- Driveway No. 2C

(Type A)

C-D / W No. 2C

(Type A)

040 2163 143

Frame & Cover Carriageway No. 4

(Type A)

Frame Carriageway No. 4

(Type A)

F & C C/W No.4

(Type A)

F- C/W No. 4

(Type A)

6.

Cover- Carriageway No. 4

(Type A)

C- C/W No. 4

(Type A)

040 2163 043

7.

Frame & Cover Carriageway No.2

F & C C/W No.2

040 2163 020

8.

Frame- Carriageway No. 2

F- C/ W No. 2

040 2163 025

9.

Frame & Cover Carriageway No.3

F & C C/W No.3

040 2163 030

10.

Frame Carriageway No. 3

F-C/W No.3

040 2163 035

11.

Covers Carriageway No. 2 & 3

C-C/W No. 2 & 3

040 2163 033

12.

Frame & Cover C/W No. 2 & 3

Grids Safety

Safety Grids

040 2163 039

13.

Frame & Cover Driveway No. 2C

(Type B)

F & C D/W No. 2C

(Type B)

040 2163 139

14.

Frame- Driveway No. 2C

(Type B)

F-D/W No.2 C

(Type B)

040 2163 146

15.

Cover- Driveway No. 2C

(Type B)

C-D / W No. 2C

(Type B)

040 2163 144

16.

Frame & Cover Carriageway No. 4

(Type B)

F & C C/W No.4

(Type B)

040 2163 041

17.

Frame Carriageway No. 4

(Type B)

F- C/W No. 4

(Type B)

040 2164 146

18.

Cover- Carriageway No. 4

(Type B)

C- C/W No. 4

(Type B)

040 2163 044

4.

5.

Access Network Division

Qatar Telecom (Qtel) Q.S.C

21 of 42

040 2163 040

040 2164 145

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 2

TABLE 2

DRAWINGS OF FRAMES & COVERS FOR JOINTING CHAMBERS

Sl. No.

Frame & Cover Type

Drawing CN Number

1.

Frame Carriageway No. 2

20001 (Rev. 1)

2.

Frame Carriageway No. 3

20002 (Rev. 1)

3.

Pictorial view of Frame & Cover C/W No. 2&3

20003

4.

Cover to fit Frames Carriageway No. 2 & 3

20004 (Rev. 1)

5.

Frames & Covers Carriageway No. 4 (Type A)

20005 (Rev. 1)

6.

Frames & Covers Driveway No. 2C (Type A)

20006 (Rev. 1)

7.

Frames & Covers Carriageway No. 4 (Type B)

9005 (Rev. 1)

8.

Frames & Covers Driveway No. 2C (Type B)

9006 (Rev. 1)

9.

Safety Grid

20007

**************************************************

Access Network Division

Qatar Telecom (Qtel) Q.S.C

22 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 3

SECTION 3

QUALITY ASSURANCE,

INSPECTION

AND

TESTING

Access Network Division

Qatar Telecom (Qtel) Q.S.C

23 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 3

SECTION 3

QUALITY ASSURANCE, INSPECTION AND TESTING

CONTENTS

SECTION

TOPIC

PAGE NO.

3.1

GENERAL

24

3.2

QUALITY ASSURANCE

24

3.3

FACTORY TESTING

26

Access Network Division

Qatar Telecom (Qtel) Q.S.C

24 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 3

SECTION 3

QUALITY ASSURANCE , INSPECTION & TESTING

3.1

GENERAL

3.1.1

The purpose of this Section is to identify the procedures to ensure the proper

Quality Assurance and to establish that the product conforms to specified

technical requirements of this Specifications.

3.1.2

The Manufacturer's quality system shall be based on ISO 9001 or ISO 9002 or

an equivalent recognized international or national standard.

(R)

3.1.3

Tenderer shall provide detailed plans and time schedules for manufacture,

factory tests & delivery of the material. The time schedule shall meet the

Purchaser's requirement specified in the tender document supply order.

(Q)

3.2

QUALITY ASSURANCE

3.2.1

The Contractor shall supply materials that conform to this technical

Specifications and the contract, and shall at no time supply materials that fail

to conform.

(R)

3.2.2

The Contractor shall at all times be responsible for the Quality Assurance of the

supplied materials.

(R)

3.2.3

The Contractor shall maintain an effective and fully documented quality system

capable of ensuring and demonstrating that the materials conform to Qtel

Specifications and the Contract.

(R)

3.2.4

The system of Quality Assurance used shall be in accordance with the Contract,

subject only to any modifications agreed and approved by the Purchaser as a

result of review of the quality system.

(R)

When complying with these Quality Assurance Requirements, the Contractor is

free to choose the means, if not stipulated in this Specifications, by which the

requirements are met; provided that it can be demonstrated to the satisfaction of

the Purchaser that the products conform to the Specifications and Contract, and

that all specific Quality Assurance requirements stipulated in the Specifications

and Contract have been fully complied.

(R)

3.2.5

Access Network Division

Qatar Telecom (Qtel) Q.S.C

25 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 3

3.2.6

3.2.7

3.2.8

3.2.9

3.2.10

The Contractor's quality system should be based on ISO 9001 (Quality Systems)

or any equivalent recognized national or international standard. The standard

system shall be mentioned and complete documentation on the standard system

followed shall be supplied with the tender response for evaluation purposes.

(R)

The Contractor shall document the 'Quality Assurance Program' in the form of

'Quality Manuals and/or Quality Programs' including a 'Quality plan Flowchart

with explanatory notes detailing the quality procedures to be applied for this

contract and submit the same with tender response for evaluation purposes.

(R)

The quality plan shall be specific to the manufacturing process control including

design and shall clearly identify signification milestones in terms of design

reviews, product evaluation and technical audits throughout the design,

manufacturing, testing and packing process.

(R)

The Contractor's 'Quality Check' documentation shall state the criteria for

acceptance and rejection that will be employed to demonstrate that the technical

requirements and values specifies are fully met.

(R)

The Contractor's documentation shall state the criteria for ensuring the specified

quality and reliability of the product taking the following into account:

Design proving

Raw material selection and test

Process control during manufacturing

Product verification

The product verification shall include testing of all products. The test results shall

confirm that all the requirements of this Specifications have been completely met

without any exception.

(R)

3.2.11

RELIABILITY ASSURANCE

3.2.12

The Contractor's Quality Assurance shall include a reliability programme for

ensuring and demonstrating that any reliability requirements specified in the

Contract are met.

(R)

CONTRACTOR'S QUALITY SYSTEM ASSESSMENT

The Purchaser's Quality Assurance Officer shall be given access at all times (on

intimation) to the Contractor's premises in order to conduct assessment of the

quality system.

(R)

Access Network Division

Qatar Telecom (Qtel) Q.S.C

26 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 3

3.2.12.1 As an integral part of an assessment the Purchaser's Quality Assurance Officer may

carry out product and/or process quality audits as necessary to check effectiveness

of the Contractor's Quality Assurance System and obtain evidence to that effect.

3.2.12.2 Notwithstanding the right of the Purchaser to carry out assessments of the

Contractor's quality system, the Purchaser shall be under no obligation to do the

same. Failure to carry out an assessment shall not relieve the Contractor from

complying with the contents of the Specifications.

3.2.13

The Tenderer shall indicate in the submission appropriate cross references between

the quality assurance plan being followed and ISO 9001, if any.

(Q)

3.2.14

To enable the Purchaser to be satisfied from the Quality Assurance "point of view"

and to ensure that the laid down conditions are met, the Tenderer shall:

Indicate in the Tender the Quality Assurance Representative of the Contractor,

responsible for Quality Assurance, for liaising with the Purchaser's Quality

Assurance Representative.

(Q)

Identify the Principal Sub-Contractors intended to be engaged in the contract, if

any, together with the Sub-Contractor's relevant Quality Assurance

documentation.

(Q)

Permit the Purchaser's Quality Assurance Representative to carry out assessments

of all aspects of the system of Quality Assurance, including the design &

manufacture activities regardless of these being in-house or sub-contracted.

(R)

3.2.15

A copy of all documentations referred to in Clause 5.2 of this Specifications shall

be submitted with tender response for evaluation purposes. Copies of all updates

shall be provided by the Tenderer to the Purchaser, within two weeks of issue of

an update.

(Q)

3.3

FACTORY TESTING

3.3.1

GENERAL

3.3.1.1

Testing shall be a continuous process and shall include, testing of raw materials,

testing during production, post manufacture testing, and demonstration testing.

(R)

Access Network Division

Qatar Telecom (Qtel) Q.S.C

27 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 3

3.3.1.2

3.3.1.3

3.3.1.4

All raw materials and component shall conform to appropriate Specifications

before being introduced into production.

(R)

All factory testing results shall be well documented and provided to the Purchaser

as specified in Clause 3.3.2.

(R)

The Tenderer shall briefly state the methods and tests which can be included in the

testing programme to demonstrate that the materials will serve the function as

required in the network when commissioned.

3.3.2

FACTORY RELEASE TESTS

3.3.2.1

The Supplier shall identify and plan the production process and ensure that these

are carried out under controlled conditions. Controlled conditions shall include

the following:

o Documented work instructions defining the manner of production process, use

of suitable production equipment and working environment, compliance with

appropriate Standards and quality plans.

o Monitoring and control of suitable process and product characteristics during

production.

o Criteria for workmanship which shall be stipulated, to the greatest practical

extent, in written standards or by means of representative samples.

3.3.2.2

Copy of all documentation in support of the requirement specified in Clause

shall be submitted with the tender response for evaluation purposes.

3.3.3

FACTORY INSPECTION BY THE PURCHASER'S REPRESENTATIVE

3.3.3.1

The representatives of the Purchaser shall be allowed access to the

Contractor's entire test facilities and test results, anytime during the contract

period.

(Q)

The Contractor shall inform well in advance the date of commencement of all

tests to facilitate the Purchaser's Engineers/ Quality Assurance representative

to be present during testing to verify that all inspection and testing stipulated

in Clause 3.3.4 are actually performed and results recorded properly, complete

the evidence of conformance of the finished product to the specified

requirements. The cost of inspection of two of the Purchaser's Quality

Assurance Representatives for 8 days shall be quoted. The costs for boarding

and lodging of Engineers shall also be included and indicated separately.

3.3.3.2

3.3.3.3

The cost of international travel of Purchaser's Quality Assurance

Representative will be borne by the Purchaser. The total cost of inspection

shall be considered for evaluation.

3.3.3.4

No product shall be packed or dispatched until all activities in the quality plan

or documented procedures have been satisfactorily completed and the

associated data and documentation are made available and authorized.

Access Network Division

Qatar Telecom (Qtel) Q.S.C

28 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 3

3.3.4

MEASURING, INSPECTION & TEST EQUIPMENTS:

The Manufacturer shall control, calibrate and maintain measuring inspection &

test equipments to demonstrate the conformance of the product to the specified

requirements.

3.3.5

INSPECTION, QUALITY TEST RECORDS:

o The Manufacturer shall establish and maintain records which give evidence

that the product has passed inspection and/or test with defined acceptance

criteria and required quality has been achieved.

o All quality records shall be made available for evaluation to the Purchaser and

a copy of all such records shall be submitted along with the supply of

materials.

*************************************

Access Network Division

Qatar Telecom (Qtel) Q.S.C

29 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 4

SECTION 4

ENVIRONMENT,

TRANSPORTATION,

STORAGE & SAFETY

Access Network Division

Qatar Telecom (Qtel) Q.S.C

30 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 4

SECTION 4

ENVIRONMENT, TRANSPORTATION, STORAGE & SAFETY

CONTENTS

SECTION

4.1

TOPIC

PAGE NO.

31

GENERAL

CLIMATIC CONDTIONS

31

4.3

TRANSPORT & STORAGE

32

4.4

VIBRATION & SHOCK

32

4.5

SAFETY OF PERSONNEL

33

4.2

Access Network Division

Qatar Telecom (Qtel) Q.S.C

31 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 4

SECTION 4

ENVIRONMENT, TRANSPORTATION, STORAGE & SAFETY

4.1

GENERAL

4.1.1

This section describes the environmental conditions, which the Frames and

Covers for jointing chambers shall meet and seek information on the range of

conditions within which the offered product are designed to be stored, installed

operated and maintained.

The Supplier shall establish, document & provide written procedures for

handling, transportation & storage.

4.1.2

4.2

CLIMATIC CONDITIONS

4.2.1

The range of climatic conditions and environmental limits for which the

finished material shall be designed for storage, installation, operation and

maintenance are specified below.

External Climatic Conditions

a)

b)

c)

d)

e)

Dry ambient temperature maximum

Dry ambient temperature minimum

Relative humidity

Solar radiation maximum

Rainfall

+60 C

-5 C

100 %

1000 K cals/m square per hour

0 to 350 mm / year

(R)

4.2.2

Manufacturer's Design Specifications

4.2.2.1

The Tenderer shall state the range of climatic conditions/ environmental limits

that the material can endure without even temporarily degrading the

performance capability or sustaining any permanent damage.

The information or range of climatic conditions under which the offered

product will function should include:

a)

b)

The normal climatic (Temperature & humidity) limits.

The short term climatic limits (Temperature & humidity) and duration.

Access Network Division

Qatar Telecom (Qtel) Q.S.C

32 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 4

c)

b)

The number of occasions and duration per year that the short term

limits can be tolerated.

The maximum temperature and relative humidity that can be tolerated

simultaneously and maximum duration of such condition.

(Q)

4.2.2.2

The Tenderer shall identify and state the items, if any, for which a limit

differing from what is specified in Clause 4.1.1 will apply.

4.2.3

Environmentally Sensitive Material

The Tenderer shall identify and state the environmental conditions to which

the product is particularly sensitive and state any special precaution that might

be required during storage, installation, operation and maintenance.

4.3

TRANSPORTATION AND STORAGE

4.3.1

The product shall be protectively packed to withstand any adverse condition

during transportation.

(R)

4.3.2

The product design and packing techniques shall permit the storage in its

original packing in the open space for a minimum period of 15 years.

(R)

4.3.3

The Tenderer shall state the period for which the product can be stored in open

space in its original packing.

(Q)

4.3.4

The Tenderer shall submit the details of mode of transporting and delivering

the material and state any special requirements for transportation, storage,

unpacking and handling that would be required to prevent any damage during

delivery and installation.

(Q)

4.3.5

The Supplier shall arrange for the protection of the quality of the product after final

inspection & test till delivery to destination, i.e. Purchaser's warehouse.

4.4

VIBRATIONS AND SHOCK

4.4.1

The Tenderer shall state the limits of vibration and mechanical shock that each

type of product can withstand under conditions of transport, storage and

installation.

(Q)

4.5

SAFETY OF PERSONNEL

Access Network Division

Qatar Telecom (Qtel) Q.S.C

33 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 4

4.5.1

All safety standards followed by the Tenderer shall be clearly stated.

(Q)

4.5.2

Adequate precautions shall be taken by the Tenderer in designing,

manufacturing, and packing of the product to ensure safety of Purchaser's

personnel during storage, installation and maintenance.

4.5.3

The Tenderer shall take all precautions and also indicate the precautions to be

taken by the Purchaser to avoid injuries to personnel while handling the

material during storage, installation. All safety standards followed by the

Tenderer, and to be followed by the Purchaser, to protect personnel, shall be

clearly indicated.

(Q)

*************************************

Access Network Division

Qatar Telecom (Qtel) Q.S.C

34 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 5

SECTION 5

DOCUMENTATION

Access Network Division

Qatar Telecom (Qtel) Q.S.C

35 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 5

SECTION 5

DOCUMENTATION

SECTION

TOPIC

PAGE NO.

5.1

GENERAL

36

5.2

DOCUMENTATION STRUCTURE &

CONTROL

36

5.3

COPIES OF DOCUMENTATION

36

5.4

DELIVERY OF DOCUMENTATION

36

Access Network Division

Qatar Telecom (Qtel) Q.S.C

36 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 5

SECTION 5

DOCUMENTATION

5.1

GENERAL

The purpose of this section is to identify the documentation required for the

Frames & Covers.

5.1.1

Technical details together with complete supporting documentation for the

offered Frames & Covers for jointing chambers shall be made available &

provided to the Purchaser, with the tender response.

(R)

5.1.2

The Manufacturer's Specifications, (which shall be compliant with the

Purchaser's Specifications) and the actual designed values for all

Specifications parameters of the offered Frames & Covers for jointing

chambers shall be fully furnished by the Tenderer with the Tender

Response.

(Q)

5.2

DOCUMENTATION STRUCTURE AND CONTROL

5.2.1

The documentation shall be in English only, well structured, unambiguous,

and easy to use and control.

(R)

5.2.2

The Tenderer shall indicate the type of documents provided in the standard

documentation package.

(R)

5.3

COPIES OF DOCUMENTATION

5.3.1

The Purchaser shall have the right to reproduce without change, all or any

part of the documents, for its own use.

5.4

DELIVERY OF DOCUMENTATION

5.4.1

All documents pertaining to 'Factory Test Results' shall be supplied at an

appropriate time as specified in the Contract/Purchase Order.

(R)

5.4.2

The Tenderer shall state the standard delivery schedule for the

documentation.

(Q)

*************************************

Access Network Division

Qatar Telecom (Qtel) Q.S.C

37 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 6

SECTION 6

REFERENCES

Access Network Division

Qatar Telecom (Qtel) Q.S.C

38 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 6

SECTION 6

REFERENCES

CONTENTS

SECTION

6.1

TOPIC

PAGE NO.

REFERENCES

Access Network Division

Qatar Telecom (Qtel) Q.S.C

39

39 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 6

SECTION 6

REFERENCES

6.1

REFERENCES:

1)

2)

3)

4)

5)

6)

7)

8)

9)

10)

MAT 1022 (Rev. 1) Qtel Standard Spec. for Frames & Covers

ductile iron.

BS EN 124, 1994 Ductile iron casting, gully tops & manhole tops

for vehicular & pedestrian areas.

BS 7903, 1997 Selection and use of gully tops & manhole covers

for installing within the highway.

ISO 1083, 1987 Spheroidal graphite cast iron classification.

BS 1610, 1992 Materials testing machine and force verification

equipment.

BS 4164, 2002 Protective coating material for F & C of hot coat

based material.

BS 3416 Protective coating material for F & C of cold black

bitumen material.

BS EN 10137- 1/3, 1996 Structural steels in the quenched and

tempered or precipitation hardened conditions. General delivery

conditions.

BS 1461:1999 Hot dipped galvanized coating on iron and steel

articles.

BS 1561:1997 For grey cast iron.

************************************

Access Network Division

Qatar Telecom (Qtel) Q.S.C

40 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 7

SECTION 7

DRAWINGS

CONTENTS

SECTION

7.1

TOPIC

PAGE NO.

DETAILED DRAWINGS

Access Network Division

Qatar Telecom (Qtel) Q.S.C

41

41 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

SPECIFICATIONS FOR FRAMES & COVERS OF JOINTING CHAMBERS

Qtel MAT 1022

SECTION 7

SECTION 7

DRAWINGS

7.1

DETAILED DRAWINGS:

All details shown in the CN Drawing should be adhered during the manufacturing.

7.1.1

LIST OF DRAWINGS

Sl. No.

Frame & Cover Type

Drawing CN Number

1.

Frame Carriageway No. 2

20001 (Rev. 1)

2.

Frame Carriageway No. 3

20002 (Rev. 1)

3.

Pictorial view of Frame & Cover C/W No. 2&3

20003

4.

Cover to fit Frames Carriageway No. 2 & 3

20004 (Rev. 1)

5.

Frames & Covers Carriageway No. 4 (Type A)

20005 (Rev. 1)

6.

Frames & Covers Driveway No. 2C (Type A)

20006 (Rev. 1)

7.

Frames & Covers Carriageway No. 4 (Type B)

9005 (Rev. 1)

8.

Frames & Covers Driveway No. 2C (Type B)

9006 (Rev. 1)

9.

Safety Grid

20007

************************************

END OF SPECIFICATIONS

Access Network Division

Qatar Telecom (Qtel) Q.S.C

42 of 42

Spec. No.: Qtel MAT 1022

Revision No.: 1

Revision Date: June 2006

Anda mungkin juga menyukai

- SaudiAramco ladder designDokumen1 halamanSaudiAramco ladder designDomie Neil Bucag SalasBelum ada peringkat

- Aggregate Sub-Base Course and Base Course: Engr. Juniffen I. Tacadena, Meng-Ce, Pe-1, Me-1Dokumen24 halamanAggregate Sub-Base Course and Base Course: Engr. Juniffen I. Tacadena, Meng-Ce, Pe-1, Me-1T JBelum ada peringkat

- RC2 Series Screw Compressor Maintenance ManualDokumen161 halamanRC2 Series Screw Compressor Maintenance ManualMichele CassiniBelum ada peringkat

- MS BMS Installation Project 1A, 1B & 1CDokumen19 halamanMS BMS Installation Project 1A, 1B & 1Carun kurlanBelum ada peringkat

- 10.section 4.0 - Sewerage WorksDokumen19 halaman10.section 4.0 - Sewerage WorksNarain Muthukrishnan100% (1)

- Sample Problem 3.4Dokumen13 halamanSample Problem 3.4Emerson Ipiales GudiñoBelum ada peringkat

- Kahramaa Appendix 11Dokumen41 halamanKahramaa Appendix 11Lepanto SakyodBelum ada peringkat

- Qatar - Civil Defense Code For VentilationDokumen4 halamanQatar - Civil Defense Code For Ventilationsachinmangrulkar100% (1)

- Qatar - Civil Defense Code For VentilationDokumen4 halamanQatar - Civil Defense Code For Ventilationsachinmangrulkar100% (1)

- Qatar - Civil Defense Code For VentilationDokumen4 halamanQatar - Civil Defense Code For Ventilationsachinmangrulkar100% (1)

- CCTV Surveillance System: Technical Specifications Chapter: A General A.1 Scope of WorkDokumen2 halamanCCTV Surveillance System: Technical Specifications Chapter: A General A.1 Scope of WorkRabin ShresthaBelum ada peringkat

- Method Statement For Flushing of Sprinkler PipingDokumen2 halamanMethod Statement For Flushing of Sprinkler PipingMoizuddin Khaja71% (17)

- SEO-Optimized Title for Muck Disposal Plan ChapterDokumen11 halamanSEO-Optimized Title for Muck Disposal Plan ChaptertchangmaiBelum ada peringkat

- Boq Road+project-NhaiDokumen10 halamanBoq Road+project-NhaidhwaniBelum ada peringkat

- Bid Capacity Civl ContractDokumen2 halamanBid Capacity Civl ContractAnonymous Of0C4dBelum ada peringkat

- An Introduction To Orgone Matrix Material (Jon Logan)Dokumen42 halamanAn Introduction To Orgone Matrix Material (Jon Logan)Jose CiprianiBelum ada peringkat

- Ert BoqDokumen10 halamanErt BoqAbhishek ShatagopachariBelum ada peringkat

- Technical Specification of Solar Street Lighting Systems PDFDokumen3 halamanTechnical Specification of Solar Street Lighting Systems PDFnani yeshuBelum ada peringkat

- Method Stament For Street Pole LightDokumen16 halamanMethod Stament For Street Pole Lightمقاول تكييف كهرباء وصحيBelum ada peringkat

- Lighting Spec for Parks, Public Spaces and ArchitectureDokumen40 halamanLighting Spec for Parks, Public Spaces and ArchitecturezeliteBelum ada peringkat

- AtmDokumen2 halamanAtmJegan RichardBelum ada peringkat

- Hawar HighwayDokumen31 halamanHawar HighwayantogsBelum ada peringkat

- Qatar - Substation DetailsDokumen1 halamanQatar - Substation DetailsakhilBelum ada peringkat

- Expression of Interest (Eoi) : Submitted byDokumen6 halamanExpression of Interest (Eoi) : Submitted byGausMohiuddin0% (1)

- Boq BMSDokumen1 halamanBoq BMSOmar Mhmmad100% (1)

- EP-MS-P4-S3-085 - 11kV Heat Shrinkable Joints - (KM Material Spec)Dokumen8 halamanEP-MS-P4-S3-085 - 11kV Heat Shrinkable Joints - (KM Material Spec)dimaomarBelum ada peringkat

- Hydraulic road blocker designDokumen52 halamanHydraulic road blocker designMohamad Tawfiq100% (1)

- SECTION 15105 Pipes and Tubes Rev 0Dokumen60 halamanSECTION 15105 Pipes and Tubes Rev 0Munir RasheedBelum ada peringkat

- QCDFSS 4.1 - External Access - 4.1 Rev 0307 PDFDokumen16 halamanQCDFSS 4.1 - External Access - 4.1 Rev 0307 PDFRotsapNayrbBelum ada peringkat

- Method Statement: Plumbing & Ug Piping WorksDokumen17 halamanMethod Statement: Plumbing & Ug Piping WorksMuhammad Sami ParvezBelum ada peringkat

- Public Park Survey Report PDFDokumen24 halamanPublic Park Survey Report PDFsomya guptaBelum ada peringkat

- Quotation For CCTV Camera 2017 2019Dokumen3 halamanQuotation For CCTV Camera 2017 2019amithbalu100% (1)

- Subject: Technical and Cost Proposal of CCTV Camera Supply & InstallationDokumen3 halamanSubject: Technical and Cost Proposal of CCTV Camera Supply & InstallationMainuddin Bhuiyan0% (1)

- Residual Life Assessment and Failure of The BoilerDokumen21 halamanResidual Life Assessment and Failure of The BoilernagasureshBelum ada peringkat

- BOQ Light Point WiringDokumen3 halamanBOQ Light Point Wiringdeyanshu7Belum ada peringkat

- Operation and Maintenance Contract for Vacuum Sewer SystemDokumen169 halamanOperation and Maintenance Contract for Vacuum Sewer SystemRiju MathewBelum ada peringkat

- QTA Minimum Building Requirements For New HotelsDokumen11 halamanQTA Minimum Building Requirements For New Hotelsvijaydeep1100% (4)

- Pump Station BOQDokumen43 halamanPump Station BOQMustafa Abdullah100% (1)

- Bhutan Telecom-Request For Proposal For Technical and Functional Specifications For Building A Tier-III Data Center For Bhutan Telecom - V1Dokumen10 halamanBhutan Telecom-Request For Proposal For Technical and Functional Specifications For Building A Tier-III Data Center For Bhutan Telecom - V1jancukjancukBelum ada peringkat

- Street Light Inspection: Cscec-Tata JODokumen1 halamanStreet Light Inspection: Cscec-Tata JOdoly damanik50% (2)

- BOQ For Civil Works (Annexure-I)Dokumen2 halamanBOQ For Civil Works (Annexure-I)dox4useBelum ada peringkat

- HP Authorized Letter TCMDokumen4 halamanHP Authorized Letter TCMNukhairi Mohd SoharBelum ada peringkat

- Customer Guide Lines TSC Ver 4 0Dokumen54 halamanCustomer Guide Lines TSC Ver 4 0Sijo JoyBelum ada peringkat

- BOQ For Bore WellDokumen21 halamanBOQ For Bore Welldassagra100% (2)

- Bbs Culvert MasterDokumen7 halamanBbs Culvert MasterRajendra VenturiBelum ada peringkat

- Specifications-Villa Project Saudi ArabiaDokumen17 halamanSpecifications-Villa Project Saudi ArabiajatinBelum ada peringkat

- Site - PlanDokumen18 halamanSite - PlanHaymanAHMEDBelum ada peringkat

- Smart PoleDokumen11 halamanSmart PoleRhammdas DasariBelum ada peringkat

- SOR Road WorksDokumen95 halamanSOR Road WorksPooja ChauhanBelum ada peringkat

- 18m RTTDokumen31 halaman18m RTTanon_477481779Belum ada peringkat

- SSD Duct Standard Rev 4Dokumen9 halamanSSD Duct Standard Rev 4Haresh PatelBelum ada peringkat

- ECHO M Installation and User ManualDokumen309 halamanECHO M Installation and User ManualJerry RdzBelum ada peringkat

- Hyundai HGMAP Protection RelayDokumen22 halamanHyundai HGMAP Protection RelayminpyitBelum ada peringkat

- 21FB0082 BoqDokumen2 halaman21FB0082 BoqCelsoRapiBelum ada peringkat

- Monthly Progress Report: Frischmannprabhu (India) Pvt. LTDDokumen54 halamanMonthly Progress Report: Frischmannprabhu (India) Pvt. LTDshravan38Belum ada peringkat

- Qcs 2010 Section 13 Part 4 Unit Masonry PDFDokumen12 halamanQcs 2010 Section 13 Part 4 Unit Masonry PDFbryanpastor106100% (1)

- ALOK DMRC Admit CardsDokumen5 halamanALOK DMRC Admit Cardsshilpi10Belum ada peringkat

- Andhra - Pradesh - Govt Rules For Epc ContractsDokumen29 halamanAndhra - Pradesh - Govt Rules For Epc Contractsanon_740216180Belum ada peringkat

- Checklist For Power Transformer FoundationDokumen2 halamanChecklist For Power Transformer FoundationRupesh KhandekarBelum ada peringkat

- Annex A: Technical Application Template: Amanat Afghanistan USAID CONTRACT NUMBER AID-306-H-17-00003Dokumen34 halamanAnnex A: Technical Application Template: Amanat Afghanistan USAID CONTRACT NUMBER AID-306-H-17-00003wafiullah sayedBelum ada peringkat

- Reply To Consultant Comments - Revised - With Letter HeadDokumen3 halamanReply To Consultant Comments - Revised - With Letter HeadghadeerBelum ada peringkat

- EP-MS-P4-S4-015 Issue 3 2011 Specification For 11kV-433V Oil Filled Ground Mounted Distribution TransformersDokumen1 halamanEP-MS-P4-S4-015 Issue 3 2011 Specification For 11kV-433V Oil Filled Ground Mounted Distribution TransformersMahmoud Hassan SelimBelum ada peringkat

- 4 Bed Rooms Villa Al Burj Al Thaki Mep Work QuoteDokumen3 halaman4 Bed Rooms Villa Al Burj Al Thaki Mep Work QuoteAL BURJ AL THAKIBelum ada peringkat

- Schedule Rates For 2009-10Dokumen5 halamanSchedule Rates For 2009-10vinujohnpanicker80% (5)

- M007-CCC-STR-MES-00005 Rev. 2.0Dokumen102 halamanM007-CCC-STR-MES-00005 Rev. 2.0Mikku KattaBelum ada peringkat

- Office of The GrampanchayatDokumen1 halamanOffice of The GrampanchayatAKASH Hota0% (1)

- Administration of Ut of Daman & Diu Electicity Deaprtment,: Technical SpecificationsDokumen102 halamanAdministration of Ut of Daman & Diu Electicity Deaprtment,: Technical Specificationsmanoj semwalBelum ada peringkat

- 2 - Sicet-2aDokumen65 halaman2 - Sicet-2aMuhammed Jasim100% (1)

- Transformer 20mvaDokumen102 halamanTransformer 20mvassvasavaongcBelum ada peringkat

- QCD Sample CommentsDokumen13 halamanQCD Sample CommentsMoizuddin KhajaBelum ada peringkat

- HG Raindance Showersystems Planning InstallationDokumen56 halamanHG Raindance Showersystems Planning InstallationMoizuddin KhajaBelum ada peringkat

- Homeowners Swimming Pool Online Handbook V3a1Dokumen22 halamanHomeowners Swimming Pool Online Handbook V3a1Moizuddin KhajaBelum ada peringkat

- Hydro Static Test Report PipingDokumen8 halamanHydro Static Test Report PipingMoizuddin KhajaBelum ada peringkat

- Regulationsof Internal Water Installationsand ConnectionDokumen66 halamanRegulationsof Internal Water Installationsand ConnectionHenrik Gal de OcampoBelum ada peringkat

- MEP SECOND FIX INSPECTION CHECKLISTDokumen1 halamanMEP SECOND FIX INSPECTION CHECKLISTMoizuddin KhajaBelum ada peringkat

- Checklist For Fire MainsDokumen4 halamanChecklist For Fire MainsMoizuddin KhajaBelum ada peringkat

- Levels As Per GridDokumen1 halamanLevels As Per GridMoizuddin KhajaBelum ada peringkat

- Inspection/Test Request Form (IRF) : General InformationDokumen2 halamanInspection/Test Request Form (IRF) : General InformationMoizuddin KhajaBelum ada peringkat

- Checklist For TrenchingDokumen4 halamanChecklist For TrenchingMoizuddin KhajaBelum ada peringkat

- Rfi FormDokumen1 halamanRfi FormMoizuddin KhajaBelum ada peringkat

- AnsysDokumen18 halamanAnsysmechanical engineering100% (12)

- Checklist of Fcu-AhuDokumen4 halamanChecklist of Fcu-AhuMoizuddin Khaja100% (1)

- Accumulation-Mode Varactor Optimization for 200Q RF ICsDokumen2 halamanAccumulation-Mode Varactor Optimization for 200Q RF ICsmenguemengueBelum ada peringkat

- System 1: Bently NevadaDokumen4 halamanSystem 1: Bently Nevadanabil160874Belum ada peringkat

- HF Acid Processing Valves Technical SpecificationsDokumen4 halamanHF Acid Processing Valves Technical Specificationssemarasik_651536604Belum ada peringkat

- Sangshad BhabanDokumen21 halamanSangshad Bhabanuniqueboy6050% (2)

- As3000 Service Manual PDFDokumen180 halamanAs3000 Service Manual PDFsambadeeBelum ada peringkat

- Phase Shifted Full Bridge Converter for EV Battery ChargingDokumen23 halamanPhase Shifted Full Bridge Converter for EV Battery ChargingArun.G eeea2016Belum ada peringkat

- Nitotile Fix PRO - High performance tile adhesiveDokumen2 halamanNitotile Fix PRO - High performance tile adhesivetalatzahoorBelum ada peringkat

- Michlaski Light Ultraviolet and InfraredDokumen21 halamanMichlaski Light Ultraviolet and Infraredm_bohnBelum ada peringkat

- 9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by LayoutDokumen7 halaman9500-WGEL-S003-ISGP-G00000-MP-4306-00017 - 01A - MTO PFF - by Layoutsuresh100% (1)

- NJAPA-PaveXpress V2 PresentationDokumen75 halamanNJAPA-PaveXpress V2 PresentationLuis MogrovejoBelum ada peringkat

- Balancing Redox ReactionsDokumen2 halamanBalancing Redox ReactionsblobmarleyBelum ada peringkat

- Home water pressure booster pumpDokumen3 halamanHome water pressure booster pumpbadaasaabBelum ada peringkat

- Caterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)Dokumen28 halamanCaterpillar Cat 336E L Excavator (Prefix YEP) Service Repair Manual (YEP00001 and Up)kfsmmeBelum ada peringkat

- GEOtouch®PET NEEDLE-PUNCHED NONWOVEN GEOTEXTILEDokumen1 halamanGEOtouch®PET NEEDLE-PUNCHED NONWOVEN GEOTEXTILEManas Kumar SamalBelum ada peringkat

- HOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsDokumen12 halamanHOMOLOGOUS SERIES ORGANIC CHEMISTRY BASICS-past-paper-questionsJo PatrickBelum ada peringkat

- Aceros PoscoDokumen35 halamanAceros PoscoregistrosegBelum ada peringkat

- Database Normalization Is The Process of Organizing The Fields and Tables of A Relational Database To Minimize RedundancyDokumen2 halamanDatabase Normalization Is The Process of Organizing The Fields and Tables of A Relational Database To Minimize RedundancyStan DitonaBelum ada peringkat

- Unit One: Wind LoadsDokumen67 halamanUnit One: Wind Loadsabdu yimerBelum ada peringkat

- CM700 Users GuideDokumen13 halamanCM700 Users GuidenurazrreenBelum ada peringkat

- Geotech Civ150 CompressDokumen4 halamanGeotech Civ150 CompressismaeelBelum ada peringkat

- DTH Drilling MachineDokumen8 halamanDTH Drilling MachineREL PromoBelum ada peringkat

- INA FAG Water Pump BearingsDokumen31 halamanINA FAG Water Pump Bearings2bjornBelum ada peringkat

- Durability Analysis 101Dokumen4 halamanDurability Analysis 101fkaram1965Belum ada peringkat

- Smart Test Series: 1-Circle The Correct Answer. (12x1 12)Dokumen4 halamanSmart Test Series: 1-Circle The Correct Answer. (12x1 12)Dr. AyshaBelum ada peringkat

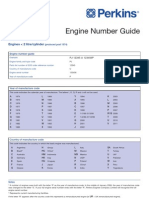

- Perkins Engine Number Guide PP827Dokumen6 halamanPerkins Engine Number Guide PP827Muthu Manikandan100% (1)